Beruflich Dokumente

Kultur Dokumente

The Effects of Material Properties On Rebound Characteristics of Deris in Automobile Crash

Hochgeladen von

Kuldeep SinghOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Effects of Material Properties On Rebound Characteristics of Deris in Automobile Crash

Hochgeladen von

Kuldeep SinghCopyright:

Verfügbare Formate

Communications in Information Science and Management Engineering DOI No.: 10.

5963/CISME0110005

CISME Vol.1 No.10 2011 PP.22-26 www.jcisme.org C 2011 World Academic Publishing

- 22 -

The Effects of Material Properties on Rebound

Characteristics of Deris in Automobile Crash

Zhan-yu Wang

1

, Xue-jing Du

1

, Hong-guo Xu

2

1

College of Traffic, Northeast Forestry University, China

2

College of Transportation, J iLin University, China

1

zywang77@yahoo.com.cn; duxuejing@yahoo.com.cn;

2

xhgsl@public.cc.jl.cn

Abstract-In order to study the effects of material

properties on rebound characteristics of debris in different

thrown condition, and promote the dynamic behavior

model of debris further in automobile crash, the dynamic

rule of elastic and elastic-plastics rebound parameters

vary with thrown condition are obtained by kinetic

simulation analysis. The rebound parameters indexes are

vertical rebound coefficient, horizontal rebound

coefficient, angle lost coefficient. The effects of rebound

characteristics on dynamic behavior after collision are

discovered. The trend curves of different material nature

varying with rebound parameters are given by combing

qualitative analysis with quantitative calculation. The

abnormal phenomena of debriss motion just like breaking

rebound, is expounded. The results of simulation tests

show that the rebound parameters of elastic-plastic debris

vary with thrown velocity and thrown angle in non-linear,

but in linear with thrown height. Sometimes the rebound

parameters of elastic-plastic debris are higher than 1.

Then, the rebound parameters of elastic debris vary with

thrown height in non-linear, and the change trends is

closed. The vertical rebound coefficient, the horizontal

rebound coefficient, and the rebound coefficient of elastic

debris vary with thrown angle upward with small change

ranges, but big change ranges in downward.

Keywords-automobile crash; thrown debris; rebound

character; dynamic simulation

I. INTRODUCTION

Debris in automobile crash implies much information

about traffic accident. The rebound parameters indexes are

vertical rebound coefficient

n

e , horizontal rebound

coefficient

t

e , angle lost coefficient

a

f that can not only

connection collision velocity with collision deformation,

impact force, and energy loss but also reflect the internal

relation among factors in the process of traffic accident. As

well as Rebound parameters are convenient to solve collision

parameters and are often used as the criterion of controlling

and verifying for accident reconstruction [1]. The classical

collision theory of Newton has laid foundation for collision

velocitys solving [2]. With the constantly rising of traffic

accident rate and the improvement of technology requirement

for accident reconstruction, impact test of real car is taken as

method to study rebound characteristics of automobile in

crash [3]. However, experiment data obtained from real car

collision is limited by experiments quantity. At present, some

mathematical models of collision are used to describe the

relationship between rebound parameters, the value and

direction of relative velocity, as well as collision angle [4,5].

But the effect of thrown condition on rebound characteristics

of debris in crash has no reported. Based on this status, the

relationship between rebound characteristics and thrown

condition is studied through the test performed by dynamic

simulation model built with Ansys/Ls-Dyna. Based on the

results of test, rebound parameters in different thrown

condition are calculated, trend curves of rebound parameters

varying with thrown condition are obtained by discovering the

rule of rebound characteristics of elastic-plastic debris, which

is significant for the better accuracy dynamic behavior model

of debris in automobile crashs establishing, and traffic

accidents reconstructing.

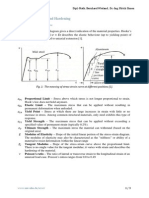

II. SIMULATION MODEL

A. Kinetic Simulation Model

At the moment of collision, debris dropped from vehicle

has independent motion each other. Based on this status,

taking single independent elastic, elastic-plastic, plastic debris

as study object, which diameter is from 1.0 centimeter to 2.5

centimeter. The kinetic simulation model is established by the

method of transient dynamic analysis with Ansys/Ls-Dyna,

which includes two parts. One is elastic-plastic debris left in

automobile crash made up of exhibition 3D Solid 164 in

DYNA. The other is target surface, with which debris contact

non-line is rigid pavement. Figure 1 is kinetic simulation

model of debris in automobile crash.

Figure 1. Kinetic Simulation Model of Debris

B. Model Reliability

The reliability of Ansys/Ls-Dyna models has been verified

by real engineering cases before [6]. However,

Ansys/Ls-Dyna model applied on analyzing dynamic

behavior has never been reported. Take massive consolidation

clay given in the essay [7] as study object to verify the

effectiveness of kinetic simulation model of debris in

Communications in Information Science and Management Engineering DOI No.: 10.5963/CISME0110005

CISME Vol.1 No.10 2011 PP.22-26 www.jcisme.org C 2011 World Academic Publishing

- 23 -

automobile crash by simulating test, whose parameters of test

reference the value given by Lin Qingfeng. Then, Static and

dynamic friction coefficient of asphalt pavement is 0.2,

Youngs modulus of massive consolidation clay is 46Mpa,

Damping coefficient is 1, Density is 2200kgm

-3

, and

Poisson's ratio is 0.3. In a certain condition just as thrown

velocity is 19.4kmh

-1

, thrown height is 0.7m, thrown angle is

zero degree, simulation value of thrown distance obtained by

Ansys/Ls-Dyna is 2.52m, which is consistent with the test

value of average thrown distance 2.45m obtained by

simulating crash device over 10 times. Varying the

corresponding speed, the thrown distance error value between

simulation test and real collision is less than 9.07%. It can be

seen that the kinetic simulation model of debris built by

Ansys/Ls-Dyna is reliable.

III. INFLUENCE OF THROWN CONDITION ON REBOUND

PARAMETERS

A. Rebound Parameters

The rebound parameters indexes are vertical rebound

coefficient

n

e , horizontal rebound coefficient

t

e , angle lost

coefficient

a

f of debris impacting on ground.

Not sticking on the ground debris will be bounce after

impact on the ground. Figure 2 illustrates the relationship

between collision velocity

i

V , rebound velocity

r

V , incident

angle , and rebound angle .

i

V

r

V

nr

V

ni

V

tr

V ti

V

Figure 2. Relationship between Collision Velocity and Rebound Velocity

There,

ni

V is vertical incident velocity,

ti

V is horizontal

incident velocity,

nr

V is vertical rebound velocity,

tr

V is

horizontal rebound velocity.

According to relationship between collision velocity and

rebound velocity showed in Figure 2, rebound parameters

calculating formulas from (1) to (4) were obtained.

ni

nr

n

V

V

e = 1

There,

n

e is vertical rebound coefficient,

nr

V is vertical

rebound velocity,

ni

V is vertical incident velocity.

ti

tr

t

V

V

e = 2

There,

t

e is horizontal rebound coefficient,

tr

V is

horizontal rebound velocity,

ti

V is horizontal incident

velocity.

i

r

V

V

e = 3

There, e is rebound coefficient,

r

V is rebound velocity,

i

V

is incident velocity.

= f 4

There,

a

f is angle lost coefficient, is incident angle,

is rebound angle.

B. Simulation Test

With air drag taking single sphere elastic-plastic debris as

study object to perform simulation test. According to the real

friction coefficient of pave, the static and dynamic friction

coefficient in kinetic simulation model is defined as 0.2. The

rule of rebound parameters varying with thrown velocity,

thrown height, thrown angle in three types of test are

discussed. Firstly, thrown velocity varies from 32.1 km.h

-1

to

41.5 km.h

-1

with a certain thrown height and thrown angel.

Secondly, thrown height varies from 0.8 m to 2.0m with a

certain thrown velocity and thrown angle. Thirdly, thrown

angle varies from -70 to 70 with a certain thrown height and

thrown velocity.

Table 1, 2, 3 are tables of rebound parameters varying with

thrown condition, which obtained by simulation test.

TABLE 1. REBOUND PARAMETERS VARYING WITH THROWN

VELOCITY OF ELASTIC AND ELASTIC-PLASTIC DEBRIS

v /

(ms

-1

)

material

n

e

t

e e

i

V /

(ms

-1

)

r

V /

(ms

-1

)

/() /()

f

8.92

elastic 0.256 0.894 0.835 6.671 5.572 21.934 6.574 0.3

elastic-

plastic

0.170 0.873 0.773 6.798 5.254 28.38 5.98 0.211

9.64

elastic 0.247 0.903 0.851 7.142 6.076 20.357 5.802 0.285

elastic-

plastic

0.047 0.895 0.799 7.244 5.789 26.49 1.49 0.056

9.67.

elastic 0.246 0.903 0.851 7.161 6.097 20.300 5.756 0.284

elastic-

plastic

0.036 0.896 0.803 7.245 5.816 26.42 1.13 0.043

10.30

elastic 0.452 0.909 0.877 10.803 9.477 17.618 8.977 0.509

elastic-

plastic

0.068 0.899 0.815 7.626 6.220 25.01 2.02 0.081

10.80

elastic 0.191 0.921 0.879 7.854 6.907 17.64 3.766 0.214

elastic-

plastic

0.043 0.906 0.828 7.934 6.572 23.970 1.200 0.050

11.50

elastic 0.360 0.917 0.887 8.286 7.353 15.988 6.421 0.402

elastic-

plastic

0.164 0.902 0.835 8.364 6.981 22.680 4.340 0.191

TABLE 2. REBOUND PARAMETERS VARYING WITH THROWN

HEIGHT OF ELASTIC AND ELASTIC-PLASTIC DEBRIS

h /(m) material

n

e

t

e e

i

V /

(ms

-1

)

r

V /

(ms

-1

)

/() /()

f

0.80

elastic 0.530 0.942 0.931 3.179 2.960 10.327 5.857 0.567

elastic-

plastic

0.427 0.729 0.597 4.897 2.923 44.290 29.930 0.676

Communications in Information Science and Management Engineering DOI No.: 10.5963/CISME0110005

CISME Vol.1 No.10 2011 PP.22-26 www.jcisme.org C 2011 World Academic Publishing

- 24 -

0.89

elastic 0.191 0.842 0.628 4.870 3.060 43.130 12.011 0.279

elastic-

plastic

0.424 0.704 0.575 4.948 2.845 46.320 32.210 0.695

0.10

elastic 0.435 0.873 0.809 3.344 2.706 25.740 13.492 0.524

elastic-

plastic

0.308 0.685 0.508 5.016 2.549 48.590 27.010 0.556

0.11

elastic 0.497 0.930 0.913 2.640 2.412 13.006 7.028 0.540

elastic-

plastic

1.875 0.834 0.977 2.700 2.638 17.660 35.590 2.015

0.15

elastic 0.107 0.785 0.544 3.939 2.142 46.682 8.241 0.177

elastic-

plastic

0.359 0.603 0.447 5.335 2.386 56.580 42.090 0.744

0.20

elastic 0.486 0.492 0.487 5.658 2.757 62.251 61.946 0.995

elastic-

plastic

0.220 0.577 0.333 5.647 1.879 62.130 35.820 0.577

TABLE 3. REBOUND PARAMETERS VARYING WITH THROWN

ANGLE OF ELASTIC AND ELASTIC-PLASTIC DEBRIS

/() material

n

e

t

e e

i

V /

(ms

-1

)

r

V /

(ms

-1

)

/() /()

f

70

elastic 6.679 1.001 6.621 4.758 31.505 82.388 88.853 1.079

elastic-

plastic

0.459 1.770 0.509 4.786 2.435 82.650 63.570 0.769

60

elastic 0.886 0.338 0.829 0.711 0.590 67.568 81.045 1.200

elastic-

plastic

0.151 0.658 0.197 4.812 0.948 78.650 48.920 0.622

45

elastic 0.068 0.514 0.203 3.755 0.760 67.990 18.100 0.266

elastic-

plastic

1.070 0.544 0.927 1.795 1.665 54.600 70.140 1.285

30

elastic 0.536 0.653 0.586 3.027 1.773 50.509 44.872 0.888

elastic-

plastic

1.043 0.633 0.838 2.276 1.906 41.460 55.490 1.338

15

elastic 2.053 0.910 0.947 2.347 2.223 8.265 18.157 2.197

elastic-

plastic

0.391 0.632 0.493 4.676 2.303 52.890 39.320 0.743

0

elastic 0.274 0.858 0.654 4.869 3.184 43.082 16.652 0.387

elastic-

plastic

0.424 0.704 0.575 4.948 2.845 46.320 32.210 0.695

-15

elastic 0.085 0.979 0.971 3.246 3.150 7.636 0.669 0.088

elastic-

plastic

0.440 0.710 0.589 5.308 3.124 45.520 32.250 0.709

-30

elastic 0.088 0.807 0.560 5.387 3.016 46.432 6.518 0.140

elastic-

plastic

0.922 0.725 0.791 3.972 3.142 33.870 40.480 1.195

-45

elastic 0.133 0.737 0.491 4.472 2.197 49.252 11.811 0.240

elastic-

plastic

0.395 0.582 0.456 5.807 2.647 57.740 47.050 0.815

-60

elastic 0.080 0.699 0.423 2.952 1.248 53.277 8.656 0.163

elastic-

plastic

0.459 0.368 0.447 5.933 2.650 67.540 71.650 1.061

-70

elastic 0.105 0.378 0.144 5.891 0.850 74.194 44.564 0.601

elastic-

plastic

0.431 0.139 0.575 5.979 2.497 74.840 85.010 1.136

C. Results Analysis

From figure 3 to figure 14 are curves of rebound

parameters varying with thrown condition.

Figure 3. Vertical rebound coefficient vary with

thrown velocity

0

0.1

0.2

0.3

0.4

0.5

8.92 9.64 9.67 10.3 10.8 11.5

Velocity/(ms-1)

V

e

r

t

i

c

a

l

r

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

elastic-plastic

elastic

Figure 4. Horizontal rebound coefficient vary with

thrown velocity

0.84

0.85

0.86

0.87

0.88

0.89

0.9

0.91

0.92

0.93

8.92 9.64 9.67 10.3 10.8 11.5

Velocity/(ms-1)

H

o

r

i

z

o

n

t

a

l

r

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 5. Rebound coefficient vary with thrown

velocity

0.7

0.75

0.8

0.85

0.9

8.92 9.64 9.67 10.3 10.8 11.5

Velocity/(ms-1)

R

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 6. Angle lost coefficient vary with thrown

velocity

0

0.05

0.1

0.15

0.2

0.25

8.92 9.64 9.67 10.3 10.8 11.5

Velocity/(ms-1)

A

n

g

l

e

l

o

s

t

c

o

e

f

f

i

c

i

e

n

t

0

0.1

0.2

0.3

0.4

0.5

0.6

elastic-plastic

elastic

Communications in Information Science and Management Engineering DOI No.: 10.5963/CISME0110005

CISME Vol.1 No.10 2011 PP.22-26 www.jcisme.org C 2011 World Academic Publishing

- 25 -

Figure 7. Vertical rebound coefficient vary with

thrown height

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0.8 0.89 1 1.1 1.5 2

Height/(m)

V

e

r

t

i

c

a

l

r

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 8. Horizontal rebound coefficient vary with

thrown height

0.4

0.5

0.6

0.7

0.8

0.9

1

0.8 0.89 1 1.1 1.5 2

Height/(m)

H

o

r

i

z

o

n

t

a

l

r

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 9. Rebound coefficient vary with thrown

height

0

0.2

0.4

0.6

0.8

1

1.2

0.8 0.89 1 1.1 1.5 2

Height/(m)

R

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 10. Angle lost coefficient vary with thrown

height

0

0.5

1

1.5

2

2.5

0.8 0.89 1 1.1 1.5 2

Height/(m)

A

n

g

l

e

l

o

s

t

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 11. Vertical rebound coefficient vary with

thrown angle

0

1

2

3

4

5

6

7

70 60 45 30 15 0 -15 -30 -45 -60 -70

Angle/()

V

e

r

t

i

c

a

l

r

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 12. Horizontal rebound coefficient vary with

thrown angle

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

70 60 45 30 15 0 -15 -30 -45 -60 -70

Angle/()

H

o

r

i

z

o

n

t

a

l

r

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 13. Rebound coefficient vary with thrown

angle

0

1

2

3

4

5

6

7

70 60 45 30 15 0 -15 -30 -45 -60 -70

Angle/()

R

e

b

o

u

n

d

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Figure 14. Angle lost coefficient vary with thrown

angle

0

0.5

1

1.5

2

2.5

70 60 45 30 15 0 -15 -30 -45 -60 -70

Angle/()

A

n

g

l

e

l

o

s

t

c

o

e

f

f

i

c

i

e

n

t

elastic

elastic-plastic

Communications in Information Science and Management Engineering DOI No.: 10.5963/CISME0110005

CISME Vol.1 No.10 2011 PP.22-26 www.jcisme.org C 2011 World Academic Publishing

- 26 -

From figure 3 to figure 6 are curves of rebound parameters

varying with thrown velocity. It can be seen that the rebound

parameters of elastic-plastic debris vary with thrown velocity

in non-linear, the trend curve and the value of vertical rebound

coefficient and angle lost coefficient are proximity about 0.2,

the trend curve of horizontal rebound coefficient and rebound

coefficient is close, which illustrates that horizontal rebound

coefficient is the key factors affecting rebound coefficient.

However, the rebound parameters of elastic debris vary with

velocity in linear slowly. The vertical rebound coefficient is

low in the scope of [0.1, 0.5]. The horizontal rebound

coefficient and the rebound coefficient change around 0.9.

From figure 7 to figure 10 are curves of rebound

parameters varying with thrown height. It can be seen that the

rebound parameters of elastic-plastic debris are decreased

with thrown height rising, angle lost coefficient trends to be

stable range from 0.56 to 0.75. Dynamic behavior value is in

status of instability accompany breaking rebound. Then, the

rebound parameters of elastic debris vary with thrown height

in non-linear, and the change trends is closed. When thrown

height is 1.5m, the rebound parameters are in the lowest

value.

From figure 11 to figure 14 are curves of rebound

parameters varying with thrown angle. It can be seen that the

rebound parameters of the elastic-plastic debris vary with

thrown angle in non-linear. The change of vertical rebound

coefficient is the key factors affecting rebound parameters and

angle lost coefficient. Sometimes angle lost coefficient is

higher than 1. The vertical rebound coefficient, the horizontal

rebound coefficient, and the rebound coefficient of elastic

debris vary with thrown angle upward with small change

ranges from o.1 to 1.0, but big change ranges in downward.

The rebound parameters of elastic appear variation value,

when thrown angle is 15or 70.

IV. CONCLUSION

The rebound parameters of elastic and elastic-plastic

debris in automotive crash varying with thrown condition are

analyzed as followed:

(1) The rebound parameters of elastic-plastic debris vary

with thrown velocity in non-linear, but in linear slowly of

elastic.

(2) The rebound parameters of the elastic-plastic debris

decrease linearly with the increasing of thrown height.

Sometimes the vertical rebound coefficient e

n

and the angle

lost coefficient f

a

are higher than 1. Then, the rebound

parameters of elastic debris vary with thrown height in

non-linear, and the change trends is closed.

(3) The rebound parameters of elastic-plastic debris vary

with thrown angle in non-linear. Sometimes angle lost

coefficient f

a

is higher than 1. The rebound velocity is

constant about 3.0 ms

-1

. The vertical rebound coefficient, the

horizontal rebound coefficient, and the rebound coefficient of

elastic debris vary with thrown angle upward with small

change ranges, but big change ranges in downward.

ACKNOWLEDGEMENT

This paper is supported by Natural Science Foundation of

Heilongjiang (Grant No. E200943) and National Natural

Science Foundation of China (Grant No. 51108068) and the

S&T Plan Projects of Heilongjiang Provincial Education

Department (Grant No. 11553025).

REFERENCES

[1] Xu Hong-guo. Automobile Accident Project. BeiJing: China

Communication Press, 2004.

[2] Goldsmith W. The Theory and Physical Behaviour of Colliding Solids.

London: Edward Arnold, 1960.

[3] Vincent W. Antone. Estimating the Coefficient of Restitution of Vehicle

to Vehicle Bumper Impacts, SAE1998-01-0553, 1998.

[4] Peter M. Burkhard. V, BEV and Coefficient of Restitution

Relationships as Applied to the Interpretation. SAE2001-01-0499, 2001.

[5] J oel W. Cannon. Dependence of a Coefficient of Restitution on

Geometry for High Speed Vehicle Collisions. SAE2001-01-0892, 2001.

[6] Lei Zheng-bao, Zhong Zhi-hua, Li Guang-yao, et al. Finite element

method for the evaluation of dynamic effects of thin-walled structure in

impacting processes. Chinese J ournal of Applied Mechanics. vol. 32, pp.

70-77, January. 2000.

[7] Lin Qing-feng. Dynamics simulations and experimental study of debris

in automotive crashes. Changchun: College of Automotive Engineering,

J ilin University, 2006.

Das könnte Ihnen auch gefallen

- HyperMesh 11.0 LS-DYNA TutorialsDokument106 SeitenHyperMesh 11.0 LS-DYNA TutorialsKuldeep Singh50% (2)

- Friction Brake TheoryDokument12 SeitenFriction Brake TheoryamolkoushikNoch keine Bewertungen

- Wind Pro ManualDokument45 SeitenWind Pro ManualAziz Khalili0% (1)

- Forces on Fuel Drops in Diesel EngineDokument9 SeitenForces on Fuel Drops in Diesel EngineArman Hamidi50% (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Cyclic Pushover Analysis Estimates Seismic Demands for BuildingsDokument14 SeitenCyclic Pushover Analysis Estimates Seismic Demands for BuildingsАвирмэдийн ГэрэлболдNoch keine Bewertungen

- ML FinalDokument28 SeitenML FinalShreya100% (1)

- FUNDAMENTALS OF FLUID MECHANICS, Cengel Cimbala Solutions Chap01 PDFDokument11 SeitenFUNDAMENTALS OF FLUID MECHANICS, Cengel Cimbala Solutions Chap01 PDFLuis Varela50% (2)

- Wheel Rail WearDokument11 SeitenWheel Rail WearREHAZ100% (1)

- Chapters 1 10 TB Answer KeyDokument427 SeitenChapters 1 10 TB Answer KeyElleana DNoch keine Bewertungen

- Measuring Tread Block Slip in Tire Contact PatchesDokument12 SeitenMeasuring Tread Block Slip in Tire Contact PatchessiritapeNoch keine Bewertungen

- Machine Learning Models and Bankruptcy Prediction Paper FileDokument13 SeitenMachine Learning Models and Bankruptcy Prediction Paper Filepriya psNoch keine Bewertungen

- Is 3074 2005Dokument16 SeitenIs 3074 2005Kuldeep SinghNoch keine Bewertungen

- Is 3074 2005Dokument16 SeitenIs 3074 2005Kuldeep SinghNoch keine Bewertungen

- Planning and Scheduling With Simio:: An Introduction To Simio Enterprise EditionDokument24 SeitenPlanning and Scheduling With Simio:: An Introduction To Simio Enterprise Editioneritros1717Noch keine Bewertungen

- Machine LearningDokument11 SeitenMachine LearningAbhayakrishna V VNoch keine Bewertungen

- Tire Road Surface Conditions and 2D Curve Analysis Based Development of Surrogate Safety MeasuresDokument8 SeitenTire Road Surface Conditions and 2D Curve Analysis Based Development of Surrogate Safety MeasuresbijejournalNoch keine Bewertungen

- 2001 IEEE Intelligent Transportation Systems Conference Proceedings - Oakland (CA),USA - August 25-29, 2001Dynamic Tire Model for Vehicle Control and SimulationDokument6 Seiten2001 IEEE Intelligent Transportation Systems Conference Proceedings - Oakland (CA),USA - August 25-29, 2001Dynamic Tire Model for Vehicle Control and SimulationPunPuan Ronnapee ChaichaowaratNoch keine Bewertungen

- Rotor-Stator Rubbing Contact in An Overhung Rotordynamic SystemDokument3 SeitenRotor-Stator Rubbing Contact in An Overhung Rotordynamic Systemtanha56313955Noch keine Bewertungen

- Lu GRE Model Other Parameters 2Dokument6 SeitenLu GRE Model Other Parameters 2Тимур РеджеповNoch keine Bewertungen

- 5 - Measurement of FrictionDokument5 Seiten5 - Measurement of FrictionAbdulla CamalNoch keine Bewertungen

- 2011 Springback Reduction Method For Sheet MetalDokument4 Seiten2011 Springback Reduction Method For Sheet MetalProf. Jignesh SohaliyaNoch keine Bewertungen

- Nonlinear Stability and Response of Car-Trailer CombinationsDokument14 SeitenNonlinear Stability and Response of Car-Trailer CombinationssmackdooriNoch keine Bewertungen

- Review PaperDokument24 SeitenReview Papergamas141200Noch keine Bewertungen

- 0279 Icnsc177Dokument6 Seiten0279 Icnsc177josa12Noch keine Bewertungen

- Raad - On The Influence of Anti-Roll Stiffness On VehicleDokument8 SeitenRaad - On The Influence of Anti-Roll Stiffness On VehicleCillian ByrneNoch keine Bewertungen

- Concrete Damage Assessment For Blast Load Using Pressure-Impulse DiagramsDokument10 SeitenConcrete Damage Assessment For Blast Load Using Pressure-Impulse DiagramsaomareltayebNoch keine Bewertungen

- Numerical Investigation of Ratchetting Behaviour in Rail Steel Under Cyclic Rolling-Sliding ContactDokument8 SeitenNumerical Investigation of Ratchetting Behaviour in Rail Steel Under Cyclic Rolling-Sliding ContactJay SrivastavaNoch keine Bewertungen

- 13 - 1351 Development of Fragility and Reliability CurvesDokument11 Seiten13 - 1351 Development of Fragility and Reliability CurveshamadaniNoch keine Bewertungen

- Seismic Damage and Damage-Control Design For RC Frames 1990Dokument20 SeitenSeismic Damage and Damage-Control Design For RC Frames 1990Tinh T. LeNoch keine Bewertungen

- Research ArticleDokument21 SeitenResearch Articleranim najibNoch keine Bewertungen

- Lu GRE Model Traction ControlDokument6 SeitenLu GRE Model Traction ControlТимур РеджеповNoch keine Bewertungen

- Friction JDSMCDokument8 SeitenFriction JDSMCVijay KumarNoch keine Bewertungen

- Displacement 5Dokument10 SeitenDisplacement 5Kali DossNoch keine Bewertungen

- Reconstruction Model of Vehicle Impact Speed in PedestrianDokument6 SeitenReconstruction Model of Vehicle Impact Speed in PedestrianCordos NicolaeNoch keine Bewertungen

- Characterization of A Structural Adhesive by Digital Image CorrelationDokument9 SeitenCharacterization of A Structural Adhesive by Digital Image Correlationsebas cortesNoch keine Bewertungen

- Tire Treadwear A Comprehensive EvaluatioDokument28 SeitenTire Treadwear A Comprehensive EvaluatiokonstantinNoch keine Bewertungen

- Mass Proportional Damping in Nonlinear Time-History AnalysisDokument5 SeitenMass Proportional Damping in Nonlinear Time-History AnalysisEvgeny ShavelzonNoch keine Bewertungen

- Keynote Speaker - Prof. S. Talukdar - Vehicle Induced Dynamic Response of A Bridge and Moving Load EstimationDokument6 SeitenKeynote Speaker - Prof. S. Talukdar - Vehicle Induced Dynamic Response of A Bridge and Moving Load Estimationdigvijay singhNoch keine Bewertungen

- A Review On The Application of Friction Models in Wheel-Rail Adhesion CalculationDokument11 SeitenA Review On The Application of Friction Models in Wheel-Rail Adhesion CalculationYan SunNoch keine Bewertungen

- lateral stability telehandlerDokument7 Seitenlateral stability telehandlerReginald D'SouzaNoch keine Bewertungen

- IJREI - Fabrication and Analysis of Spring Testing MachineDokument6 SeitenIJREI - Fabrication and Analysis of Spring Testing MachineIjrei JournalNoch keine Bewertungen

- Sensitivity of The Flow Number To Mix FaDokument12 SeitenSensitivity of The Flow Number To Mix FaMohamed ElgendyNoch keine Bewertungen

- Dense Sand P-Y CurvesDokument8 SeitenDense Sand P-Y CurvesBilal Adeel WithraNoch keine Bewertungen

- Aerodynamic Instability of A Bridge DeckDokument27 SeitenAerodynamic Instability of A Bridge DeckTam CaptainNoch keine Bewertungen

- RobotDokument11 SeitenRobotreast21Noch keine Bewertungen

- Unscented Kalman Filter For Real-Time Vehicle Lateral Tire Forces and Sideslip Angle EstimationDokument6 SeitenUnscented Kalman Filter For Real-Time Vehicle Lateral Tire Forces and Sideslip Angle Estimationneel1237Noch keine Bewertungen

- Effect of Vehicle Speed and Road Surface Roughness On The Impact Factor of Simply Supported Bridges Due To IRC Class A and B LoadingDokument24 SeitenEffect of Vehicle Speed and Road Surface Roughness On The Impact Factor of Simply Supported Bridges Due To IRC Class A and B Loadingrdey36886Noch keine Bewertungen

- Rolling Resistance SimDokument22 SeitenRolling Resistance SimsiritapeNoch keine Bewertungen

- 08 GVorotovicDokument6 Seiten08 GVorotovicMiguel Angel Alvarez BoreaNoch keine Bewertungen

- Vehicle-Bridge Interaction Dynamics and Potential ApplicationsDokument22 SeitenVehicle-Bridge Interaction Dynamics and Potential ApplicationsAli Berkcan BoyluNoch keine Bewertungen

- Grinding Damage Prediction For Ceramics Via CDM Model: Bi ZhangDokument8 SeitenGrinding Damage Prediction For Ceramics Via CDM Model: Bi ZhangDakhlaouiNoch keine Bewertungen

- Suspension System Vibration Analysis With Regard T PDFDokument8 SeitenSuspension System Vibration Analysis With Regard T PDFWai YanNoch keine Bewertungen

- p311 PDFDokument6 Seitenp311 PDFusjothiNoch keine Bewertungen

- An Investigation of The Effect of Shot Peening On The Properties of Lm25 Aluminium Alloy and Statistical ModellingDokument11 SeitenAn Investigation of The Effect of Shot Peening On The Properties of Lm25 Aluminium Alloy and Statistical ModellingInternational Journal of computational Engineering research (IJCER)Noch keine Bewertungen

- Gear Defect Modeling of A MultipleDokument12 SeitenGear Defect Modeling of A MultipleJose Luis RattiaNoch keine Bewertungen

- Dynamic Tire TestingDokument20 SeitenDynamic Tire TestingsiritapeNoch keine Bewertungen

- Finite Element Analysis of Cylinder Piston Impact Based On ANSYS/LS-DYNADokument4 SeitenFinite Element Analysis of Cylinder Piston Impact Based On ANSYS/LS-DYNAAshutosh KumarNoch keine Bewertungen

- Aspects of Side Impact With Vertical Cylindrical Obstacles: SciencedirectDokument7 SeitenAspects of Side Impact With Vertical Cylindrical Obstacles: SciencedirectĐặng Tiến LâmNoch keine Bewertungen

- Elmukashfi-Cocks2021 Article ATheoreticalAndComputationalInDokument35 SeitenElmukashfi-Cocks2021 Article ATheoreticalAndComputationalInAws EmamNoch keine Bewertungen

- Cleary-2001-International Journal For Numerical and Analytical Methods in GeomechanicsDokument23 SeitenCleary-2001-International Journal For Numerical and Analytical Methods in GeomechanicsAlfredo IbañezNoch keine Bewertungen

- Publications 2001-01-3347 Monte Carlo MomentumDokument17 SeitenPublications 2001-01-3347 Monte Carlo MomentumKuldeep SinghNoch keine Bewertungen

- Energies 11 02687Dokument17 SeitenEnergies 11 02687Lucas ErburuNoch keine Bewertungen

- Similitude Requirements and Scaling Relationships Applied TestingDokument65 SeitenSimilitude Requirements and Scaling Relationships Applied Testingmsmh.durrantNoch keine Bewertungen

- Vehicle Dynamics Under Longitudinal ForcesDokument10 SeitenVehicle Dynamics Under Longitudinal ForcesNeerajNoch keine Bewertungen

- A Numerical 2D Simulation of Part Motion in Vibratory Bowl Feeders by Discrete Element MethodDokument12 SeitenA Numerical 2D Simulation of Part Motion in Vibratory Bowl Feeders by Discrete Element Methodbuithang31122001Noch keine Bewertungen

- Numerical and Experimental Study of Concrete I-Beam Subjected To Bending Test With Cyclic LoadDokument20 SeitenNumerical and Experimental Study of Concrete I-Beam Subjected To Bending Test With Cyclic LoadTAMANA SHAMSINoch keine Bewertungen

- Comparison of Spherical Joint Models in The Dynamic Analysis of Rigid Mechanical Systems - Ideal, Dry, Hydrodynamic and Bushing ApproachesDokument46 SeitenComparison of Spherical Joint Models in The Dynamic Analysis of Rigid Mechanical Systems - Ideal, Dry, Hydrodynamic and Bushing ApproachesThaiHuynhNgocNoch keine Bewertungen

- Damage and Plasticity For Concrete BehaviorDokument16 SeitenDamage and Plasticity For Concrete BehaviorJosé Antonio Cornetero UrpequeNoch keine Bewertungen

- Speed enDokument2 SeitenSpeed enKuldeep SinghNoch keine Bewertungen

- Preview Only - Not For DistributionDokument2 SeitenPreview Only - Not For DistributionKuldeep SinghNoch keine Bewertungen

- Full Range Stress Strain CurvesDokument45 SeitenFull Range Stress Strain CurvesLoffegutt100% (1)

- Mmsm1 Handout PlasticityDokument3 SeitenMmsm1 Handout PlasticityKuldeep SinghNoch keine Bewertungen

- Chemical Composition, Mechanical, Physical and Environmental Properties of SAE 1536, Steel Grades, Carbon SteelDokument1 SeiteChemical Composition, Mechanical, Physical and Environmental Properties of SAE 1536, Steel Grades, Carbon SteelKuldeep SinghNoch keine Bewertungen

- 23esv 000489Dokument9 Seiten23esv 000489Kuldeep SinghNoch keine Bewertungen

- Rebar Testing and Design VTT ReportDokument8 SeitenRebar Testing and Design VTT ReportKuldeep SinghNoch keine Bewertungen

- Implast 2016 BrochureDokument1 SeiteImplast 2016 BrochureKuldeep SinghNoch keine Bewertungen

- 356 Aluminum Sand Casting - A356 Aluminum Castings - Leitelt Brothers, IncDokument2 Seiten356 Aluminum Sand Casting - A356 Aluminum Castings - Leitelt Brothers, IncKuldeep SinghNoch keine Bewertungen

- Rebar Testing and Design VTT ReportDokument8 SeitenRebar Testing and Design VTT ReportKuldeep SinghNoch keine Bewertungen

- Harmati Varlaki 10Dokument10 SeitenHarmati Varlaki 10Kuldeep SinghNoch keine Bewertungen

- NOTICE OF VEHICLE OWNERSHIP TRANSFERDokument1 SeiteNOTICE OF VEHICLE OWNERSHIP TRANSFERKrishna MahatoNoch keine Bewertungen

- Graphing With Excel - Superimposing GraphsDokument5 SeitenGraphing With Excel - Superimposing GraphsKuldeep SinghNoch keine Bewertungen

- Q J Mechanics Appl Math 1960 PUGSLEY 1 9Dokument9 SeitenQ J Mechanics Appl Math 1960 PUGSLEY 1 9Kuldeep SinghNoch keine Bewertungen

- 2000 IcrashDokument7 Seiten2000 IcrashKuldeep SinghNoch keine Bewertungen

- 4907 2Dokument28 Seiten4907 2Kuldeep SinghNoch keine Bewertungen

- Intersections: 1310.01 GeneralDokument44 SeitenIntersections: 1310.01 GeneralKuldeep SinghNoch keine Bewertungen

- 2000 IcrashDokument7 Seiten2000 IcrashKuldeep SinghNoch keine Bewertungen

- Fatigue and FractureDokument8 SeitenFatigue and FractureImranKabirNoch keine Bewertungen

- 1999 01 0439 PhotogrammetryDokument16 Seiten1999 01 0439 PhotogrammetryKuldeep SinghNoch keine Bewertungen

- Analysis of Fatal Motorcycle Crashes: Crash Typing: (Accepted 5 April 1995)Dokument7 SeitenAnalysis of Fatal Motorcycle Crashes: Crash Typing: (Accepted 5 April 1995)Kuldeep SinghNoch keine Bewertungen

- Perception-Reaction Time PAGE 49Dokument11 SeitenPerception-Reaction Time PAGE 49Kuldeep SinghNoch keine Bewertungen

- DYNA3DDokument37 SeitenDYNA3DtoopchiNoch keine Bewertungen

- Development of Alertness-level-Dependent Headway Distance Warning SystemDokument6 SeitenDevelopment of Alertness-level-Dependent Headway Distance Warning SystemKuldeep SinghNoch keine Bewertungen

- E 2005 M C D R Mcmis C F: Valuation of Issouri Rash ATA Eported To Rash ILEDokument35 SeitenE 2005 M C D R Mcmis C F: Valuation of Issouri Rash ATA Eported To Rash ILEKuldeep SinghNoch keine Bewertungen

- Modelling Twin Rotor MIMO System Using Genetic AlgorithmDokument7 SeitenModelling Twin Rotor MIMO System Using Genetic AlgorithmVarisa RahmawatiNoch keine Bewertungen

- Application of Negative Binomial DistributionDokument11 SeitenApplication of Negative Binomial DistributionAishaizlNoch keine Bewertungen

- Modelling of The District Heating System's Operation: Girts Vigants, Dagnija BlumbergaDokument6 SeitenModelling of The District Heating System's Operation: Girts Vigants, Dagnija BlumbergaTere NuñezNoch keine Bewertungen

- (Course Booklet For PG Section) Handbook of Informationv6Dokument70 Seiten(Course Booklet For PG Section) Handbook of Informationv6Pitambar KunduNoch keine Bewertungen

- How Math Affect NatureDokument2 SeitenHow Math Affect NatureLaizel Rodulfo100% (1)

- Farahani AlaviDokument274 SeitenFarahani AlaviDUe REnsukeNoch keine Bewertungen

- International Journal of Applied Sciences (IJAS) Volume (2) IssueDokument21 SeitenInternational Journal of Applied Sciences (IJAS) Volume (2) IssueAI Coordinator - CSC JournalsNoch keine Bewertungen

- Chapter 10Dokument40 SeitenChapter 10ermaNoch keine Bewertungen

- Pyo Moon Line DocsDokument113 SeitenPyo Moon Line DocsTebaterrorNoch keine Bewertungen

- Adams Christopher J 201208 Mast CargaExternaDokument135 SeitenAdams Christopher J 201208 Mast CargaExternawdgsNoch keine Bewertungen

- 4-Green Supply Chain Design - A Mathematical Modeling Approach Based On A Multi-Objective Optimization ModelDokument12 Seiten4-Green Supply Chain Design - A Mathematical Modeling Approach Based On A Multi-Objective Optimization ModelSteve DemirelNoch keine Bewertungen

- Presentation Lecture 1 INDU 6111Dokument36 SeitenPresentation Lecture 1 INDU 6111Vinoth RamaiahNoch keine Bewertungen

- LCS Lab 3Dokument11 SeitenLCS Lab 3Waleed RazzaqNoch keine Bewertungen

- Identification of Industrial Robots: Robot Modeling and ControlDokument8 SeitenIdentification of Industrial Robots: Robot Modeling and ControlJuan Felipe Ramirez GonzalezNoch keine Bewertungen

- Portfolio Selection Markowitz ModelDokument15 SeitenPortfolio Selection Markowitz Modelgaurav112011Noch keine Bewertungen

- Majkut 2017Dokument9 SeitenMajkut 2017CristiGheorgheNoch keine Bewertungen

- OpenSAP Ds1 Week 1 TranscriptDokument17 SeitenOpenSAP Ds1 Week 1 Transcriptqwerty_qwerty_2009Noch keine Bewertungen

- Egede Project Final CorrectionDokument119 SeitenEgede Project Final CorrectionAkinbode Sunday OluwagbengaNoch keine Bewertungen

- Unit 1, 2 Control - Systems - NotesDokument97 SeitenUnit 1, 2 Control - Systems - NoteskingsukumarNoch keine Bewertungen

- Wastewater Treatment Process - A Modified Model For Oxidation Pond - IrDokument18 SeitenWastewater Treatment Process - A Modified Model For Oxidation Pond - IrKarthika MohananNoch keine Bewertungen

- Lecture 1 (Notes)Dokument30 SeitenLecture 1 (Notes)Chung Gyeum Lee100% (2)

- Control of Strip Tension in A Rolling Mill Based On Loopers and Impedance ControlDokument6 SeitenControl of Strip Tension in A Rolling Mill Based On Loopers and Impedance Controlyona akatsukiNoch keine Bewertungen

- The Use of Modern Technology in Smart Waste Management and Recycling - Artificial Intelligence and Machine LearningDokument17 SeitenThe Use of Modern Technology in Smart Waste Management and Recycling - Artificial Intelligence and Machine LearningKashaf BakaliNoch keine Bewertungen