Beruflich Dokumente

Kultur Dokumente

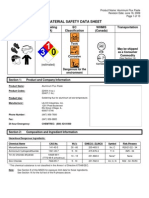

Anti Seize MIL PRF 907E

Hochgeladen von

Mark Evan Salutin0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

102 Ansichten2 SeitenMSDS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenMSDS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

102 Ansichten2 SeitenAnti Seize MIL PRF 907E

Hochgeladen von

Mark Evan SalutinMSDS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Technical Data Sheet

LOCTITE

C5-A

Copper

Based Anti-Seize

October-2008

PRODUCT DESCRIPTION

LOCTTE

C5-A

Copper Based Anti-Seize provides the

following product characteristics:

TechnoIogy Anti-Seize

Appearance Smooth copper colored paste

LMS

Cure Non-curing

AppIication Lubrication

LOCTTE

C5-A

Copper Based Anti-Seize provides a shield

against high temperature seizing and galling. All mated parts,

studs, bolts, flanges and gaskets, remove more easily and in

cleaner and better condition. This product can be used on

copper, brass, cast iron, steel, all alloys including stainless

steel, all plastics and all non-metallic gasketing materials.

Typical applications include original equipment and

maintenance, and equipment associated with petroleum

chemicals, steel mills, power plants, marine and foundries.

This product is typically used in applications with an

operating range of -29 C to +982 C.

MIL-PRF-907

LOCTTE

C5-A

Copper Based Anti-Seize was qualified to

Military Specification ML-PRF-907E.

TYPICAL PROPERTIES

Specific Gravity @ 25 C 1.2 to 1.4

LMS

Density @ 25 C, g/ml 1.27

Flash Point - See MSDS

Solids/Non-Volatile Content, % 40

Penetration, SO 2137, 1/10mm 320 to 380

LMS

TYPICAL PERFORMANCE

An anti-seize lubricant used on a bolt helps to develop greater

clamp load for the same torque compared to an unlubricated

bolt. An additional benefit is greater uniformity in clamp load

among a series of bolts. The relationship between torque and

clamp load is expressed in the following equation:

T = K x F x D

T = Torque (Nm, lb.in, lb.ft)

K = Torque coefficient or nut factor, determine experimentally

F = Clamp load (N, lb.)

D = Nominal diameter of bolt (mm, in.)

Torque coefficient, k:

12.7 mm steel bolts (grade 8) and

nuts (grade 5)

0.16

12.7 mm steel bolts (grade 8) and

nuts (grade 5), solvent cleaned, not lubricated

0.27

(n critical applications, it is necessary to determine the K

values independently. Henkel corporation makes no warranty

of specific performance on any individual fastener)

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and shouId not be seIected as

a Iubricant for chIorine or other strong oxidizing materiaIs.

For safe handIing information on this product, consuIt the

MateriaI Safety Data Sheet (MSDS).

Directions for use:

1. For best performance the mating surface should be clean

and free of grease.

2. Note: When grinding or wire brushing, use a dust

mask. Dust from cleaning threads may contain metal

compounds. nhalation may cause lung injury or other

harm.

3. Apply thin coating to threads and flats of nuts and bolts,

assemble.

Loctite MateriaI Specification

LMS

LMS dated November-29, 1999. Test reports for each batch

are available for the indicated properties. LMS test reports

include selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

Storage

Store product in the unopened container in a dry location.

Storage information may be indicated on the product container

labeling.

OptimaI Storage: 8 C to 21 C. Storage beIow 8 C or

greater than 28 C can adverseIy affect product properties.

Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Corporation cannot assume responsibility for product which

has been contaminated or stored under conditions other than

those previously indicated. f additional information is required,

please contact your local Technical Service Center or

Customer Service Representative.

Conversions

(C x 1.8) + 32 = F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

m / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm x 145 = psi

MPa x 145 = psi

Nm x 8.851 = lbin

Nm x 0.738 = lbft

Nmm x 0.142 = ozin

mPas = cP

TDS LOCTTE

C5-A

Copper Based Anti-Seize, October-2008

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. t is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. n light of the foregoing, HenkeI Corporation

specificaIIy discIaims aII warranties expressed or impIied,

incIuding warranties of merchantabiIity or fitness for a

particuIar purpose, arising from saIe or use of HenkeI

Corporation's products. HenkeI Corporation specificaIIy

discIaims any IiabiIity for consequentiaI or incidentaI

damages of any kind, incIuding Iost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere.

denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 1.2

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to IocaI saIes and technicaI support visit: www.henkeI.com/industriaI

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Ignition System - Inspection Check PDFDokument4 SeitenIgnition System - Inspection Check PDFMark Evan SalutinNoch keine Bewertungen

- Ignition Cables and Igniter Installation PDFDokument6 SeitenIgnition Cables and Igniter Installation PDFMark Evan SalutinNoch keine Bewertungen

- Ignition System - Inspection Check PDFDokument4 SeitenIgnition System - Inspection Check PDFMark Evan SalutinNoch keine Bewertungen

- Poly Fiber Reducer R65-75Dokument2 SeitenPoly Fiber Reducer R65-75Mark Evan SalutinNoch keine Bewertungen

- High Low Tension Ignition Comparison PDFDokument4 SeitenHigh Low Tension Ignition Comparison PDFMark Evan SalutinNoch keine Bewertungen

- Material Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationDokument5 SeitenMaterial Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationShemi KannurNoch keine Bewertungen

- Agard 406351 Ground Effect MachinesDokument169 SeitenAgard 406351 Ground Effect MachinesMark Evan SalutinNoch keine Bewertungen

- Poly Fiber Poly-SprayDokument2 SeitenPoly Fiber Poly-SprayMark Evan SalutinNoch keine Bewertungen

- Poly Fiber Poly-SprayDokument2 SeitenPoly Fiber Poly-SprayMark Evan SalutinNoch keine Bewertungen

- Poly FIber BR-8600 Blush RetarderDokument2 SeitenPoly FIber BR-8600 Blush RetarderMark Evan SalutinNoch keine Bewertungen

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDokument10 SeitenSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingMark Evan SalutinNoch keine Bewertungen

- Power CleanDokument2 SeitenPower CleanMark Evan SalutinNoch keine Bewertungen

- Msds For KeroseneDokument6 SeitenMsds For KeroseneMahadeva PrasadNoch keine Bewertungen

- Soldering Flux PasteDokument9 SeitenSoldering Flux PasteMark Evan SalutinNoch keine Bewertungen

- Sting-X II, Aerosol Certified LabsDokument4 SeitenSting-X II, Aerosol Certified LabsMark Evan SalutinNoch keine Bewertungen

- Sonnen Honing OilDokument5 SeitenSonnen Honing OilMark Evan SalutinNoch keine Bewertungen

- Spotcheck Reg Cleaner Remover SKC-HFDokument3 SeitenSpotcheck Reg Cleaner Remover SKC-HFMark Evan SalutinNoch keine Bewertungen

- Blue Chalk-Standard MsdsDokument4 SeitenBlue Chalk-Standard MsdsMark Evan SalutinNoch keine Bewertungen

- Aluminum Flux PasteDokument10 SeitenAluminum Flux PasteMark Evan SalutinNoch keine Bewertungen

- Silver Brazing FluxDokument9 SeitenSilver Brazing FluxMark Evan SalutinNoch keine Bewertungen

- 1201 Alodine, AKA DX 503Dokument7 Seiten1201 Alodine, AKA DX 503Mark Evan SalutinNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- User Instructions - Original Instruction-: ISC2 SeriesDokument14 SeitenUser Instructions - Original Instruction-: ISC2 SeriesAnonymous r3MoX2ZMTNoch keine Bewertungen

- WDX Assembly PowerpointDokument71 SeitenWDX Assembly PowerpointAngel Garcia100% (1)

- Doka Automatic Climbing FormworkDokument32 SeitenDoka Automatic Climbing FormworkNunyaNoch keine Bewertungen

- 6.4L Torque ChartsDokument22 Seiten6.4L Torque ChartsWilson Bueno80% (5)

- Global Engineering Method GEM 0003: RT62 Build ProcedureDokument15 SeitenGlobal Engineering Method GEM 0003: RT62 Build ProcedureCUENCARSNoch keine Bewertungen

- SCANIA Suspension BT300 Work DescDokument44 SeitenSCANIA Suspension BT300 Work DescHeri SuryoNoch keine Bewertungen

- Travers o V47Dokument32 SeitenTravers o V47Jorge Espinoza100% (1)

- Bolted Connexion SheetDokument48 SeitenBolted Connexion SheethalackNoch keine Bewertungen

- MV. Sea Topaz - Preliminary Report of Cargo Tally & Discharging Supervision DateDokument30 SeitenMV. Sea Topaz - Preliminary Report of Cargo Tally & Discharging Supervision DateEggy Alva Reza33% (3)

- 5HP500-590 4139 - 751 - 627dDokument273 Seiten5HP500-590 4139 - 751 - 627ddejanflojd100% (24)

- Cleveland Nose Wheel 199-126 KitDokument31 SeitenCleveland Nose Wheel 199-126 KitMichael MitchellNoch keine Bewertungen

- Towers Presentation 2014Dokument8 SeitenTowers Presentation 2014Jorge Lobos ZapataNoch keine Bewertungen

- As 1214-1983 Hot-Dip Galvanized Coatings On Threaded Fasteners (ISO Metric Coarse Thread Series)Dokument7 SeitenAs 1214-1983 Hot-Dip Galvanized Coatings On Threaded Fasteners (ISO Metric Coarse Thread Series)SAI Global - APAC100% (1)

- Super Clawbot Build InstructionsDokument32 SeitenSuper Clawbot Build InstructionsAlvaro FloresNoch keine Bewertungen

- Alpha One Generation Ii Stern Drive: IndexDokument37 SeitenAlpha One Generation Ii Stern Drive: IndexNicholas Ribic100% (1)

- Chorus Trio: Service MenuDokument151 SeitenChorus Trio: Service MenuАлексей ЖижченкоNoch keine Bewertungen

- IOM Manual 3QEDD3Dokument58 SeitenIOM Manual 3QEDD3JuanFuentesBecerraNoch keine Bewertungen

- Instruction Manual Deadline: Made in CanadaDokument24 SeitenInstruction Manual Deadline: Made in CanadaM PovedaNoch keine Bewertungen

- MK1600 Electric Concrete Floor Saw PartsDokument32 SeitenMK1600 Electric Concrete Floor Saw Partsjmarrero488307Noch keine Bewertungen

- WRCPDokument14 SeitenWRCPagmarketing1959Noch keine Bewertungen

- Hot Bolting Procedure PDFDokument2 SeitenHot Bolting Procedure PDFmasmarkun4444100% (3)

- JPL Bolt TorqueDokument24 SeitenJPL Bolt TorquegotstogoNoch keine Bewertungen

- BA LIFTKET 2011 04a EnglischDokument36 SeitenBA LIFTKET 2011 04a EnglischReymart ManablugNoch keine Bewertungen

- Order Information:: Airfilm Camera SystemsDokument2 SeitenOrder Information:: Airfilm Camera SystemsTom BurmanNoch keine Bewertungen

- Sachs Madass 125 Owners ManualDokument84 SeitenSachs Madass 125 Owners ManualAnna RyanNoch keine Bewertungen

- Scania DC 16 Workshop Manual PDFDokument131 SeitenScania DC 16 Workshop Manual PDFJavier Ruben Chaparro Ramos100% (3)

- Eccentric Connecting Rod Blackbook 2022 SagarDokument91 SeitenEccentric Connecting Rod Blackbook 2022 SagarSuyash KhadeNoch keine Bewertungen

- Adjustment: - Electronic Modulated Air SuspensionDokument2 SeitenAdjustment: - Electronic Modulated Air SuspensionThar KyiNoch keine Bewertungen

- Scanned Indian Standards List PDFDokument30 SeitenScanned Indian Standards List PDFJignesh Trivedi50% (2)

- Desarmar Corona NISSAN 350ZDokument60 SeitenDesarmar Corona NISSAN 350ZEndriago Omar PaucaraNoch keine Bewertungen