Beruflich Dokumente

Kultur Dokumente

Direct Duty Cycle Control For MPPT Digital Implementation

Hochgeladen von

Phạm Văn TưởngOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Direct Duty Cycle Control For MPPT Digital Implementation

Hochgeladen von

Phạm Văn TưởngCopyright:

Verfügbare Formate

Direct Duty Cycle Control For MPPT Digital Implementation

An algorithm called Maximum Power Point Tracking (MPPT) helps extract the maximum

available power from PV module depending on environmental conditions.

Aug 25, 2014Arpita Agarwal, Senior Application Engineer, Ankur Kala, Senior Application Engineer, and

Mohammad Kamil, Lead Application Engineer, Freescale | Power Electronics

Maximum Power Point Tracking (MPPT) extracts the maximum available power from photovoltaic (PV) module

depending on solar radiation, ambient temperature and solar cell temperature. MPPT based solar charge

controller implements an algorithm that maximizes the amount of PV module current applied to the battery.

What is in this article?:

Direct Duty Cycle Control For MPPT Digital Implementation

Solar photovoltaic (SPV) systems are employed in applications ranging from simple battery

charging to complex grid-connected solar inverters. Maximum Power Point Tracking

(MPPT) is an algorithm used in solar applications for extracting the maximum available

power from PV module depending on environmental conditions. Maximum power varies

with solar radiation, ambient temperature and solar cell temperature. The voltage at which

PV module can produce maximum power is called 'maximum power point' (or peak power

voltage). A solar charge controller embedded with the MPPT algorithm maximizes the

amount of current going into the battery from the PV module. A low cost 8-bit

microcontroller (MCU) can be used to implement a digital MPPT charge controller. Fig.

1 shows a block diagram of an SPV battery charging with MPPT.

Fig. 1 Battery charging system utilizing maximum power point control

Related Articles

North Carolina State Improves Lithium-Ion Batteries and Stacked Solar Cells

Solar-Powered Unmanned Aircraft Taking Off

Proper Application and Evaluation of the Surge Test for PV Panels

PV Technology Roadmap Efforts Receive Enthusiastic Support

Renewable Energy Sparks Component Development

The most common topology used to implement MPPT algorithm is Perturb & Observe

(P&O). In this method the system perturbs in a certain direction, measures voltage and

current, calculates Power and compares it with the last measured value. If the Power

increases, the system continues to perturb in the same direction or else it perturbs in the

reverse direction. The amount of perturb or disturbance introduced can be controlled by

implementing a closed loop control. It is also referred to as the hill climbing method,

because it depends on the rise and fall of the curve of Power against voltage across the MPP.

This is the simplest MPPT algorithm to implement. Fig. 2 shows an SPV characteristic

curve. The MPP voltage at any instant can be higher or lower from that given (by the SPV

manufacturer). Therefore, control output that decides the operating point should be a

signed number so that it can move forward or backward from the operating point.

Fig. 2 Solar photovoltaic system characteristics showing the maximum power point

Challenges Of Implementing MPPT

The challenges with the MPPT charge controller are to operate the converter steadily,

regardless of SPV conditions, load changes, and noise in system. A buck or boost converter

is used to implement digital MPPT charge controller. SPV voltage and current as well as

battery voltage and current are monitored using an analog-to-digital converter (ADC) to

implement the MPPT and to follow the batterys charging profile. The sense feedback

signals are then processed by an MCU core to calculate next PWM switching tON time. The

PWM module generates the required PWM pattern for a given converter. ADC resolution,

PWM resolution and core data calculation resolution play an important role in its steadiness

of operation.

Operating an 8-bit MCU at 8 MHz reduces MCU power consumption, however, limiting the

PWM input clock to a maximum of 8 MHz. Therefore, for 30 kHz operation the maximum

digital number of PWM would be ~266, or 9 bits. A general ADC may support 8-bit, 10-bit,

or 12-bit resolution. With 9-bit PWM resolution, maximum 10-bit ADC resolution can be

selected, as higher resolution may not be any advantage. Choosing a high resolution ADC

will increase conversion time. The control loop output should be a signed number so the

control loop calculation should be in a signed mode. To keep the number resolution intact, it

should be in an 8-bit fraction mode. The 8-bit fraction mode calculation allows maximum

control loop output to be a digital number swing of -128 to +127. The modulus of maximum

control loop output represents the maximum duty cycle, so it should be either equal to or

more than PWM period value to get maximum resolution for the number of calculations in

the control loop. A Proportional-Integration (PI) control loop compensation block would

also have its own math resolution, and for any given hardware and control loop

performance, it is very tough to find a PI coefficient that can produce zero or one error at

the input of compensation block. Because of all of the above mentioned limitations, the

minimum duty step variation can go up to 2-3% duty cycle, thus the output would always be

unstable across a given reference point with conventional digital PI swing controller

implementation.

Direct Drive

Fig. 3 Direct duty cycle control of the switching MOSFET controls the charging current

Direct duty cycle control is the simplest and most effective way to implement the MPPT

algorithm in an 8-bit MCU where even 1-2 bits LSB error in math calculation can impact the

system. Direct duty cycle control controls the duty cycle from the error produced by

reference and actual value sensed by the controller. The output battery charging current is

sensed by the ADC and is compared with reference current generated by maximum power

point algorithm. Photovoltaic voltage and current are sensed to implement the MPPT

algorithm, so the output of the MPPT algorithm represents a current reference for control of

the charging current. The error (reference - measured) determines the duty cycle of the

switching MOSFET to control the charging current, as shown in Fig. 3. Based on the error

sign, the duty cycle either increases or decreases. As duty cycle directly controls the system,

no multiplications or divisions are required, and the duty cycle can be controlled in the

order of single LSB, without any error. This allows control of PWM duty cycle with

maximum possible resolution, which produces stable operation even with dynamic load.

Consider a scenario where the inverter is running from battery and drawing highly non-

linear current. In this case, rapid changes in the charging current are observed and thus

MPP keeps on oscillating.

With this MPPT mechanism, you can obtain stable operation around MPP, resulting in

higher efficiency of MPPT in the system. Thus, this algorithm enables a tight control over

rapidly changing system conditions.

Das könnte Ihnen auch gefallen

- Lab 07 UpdatedDokument13 SeitenLab 07 Updatedasifa rafiqNoch keine Bewertungen

- Solar MPPTDokument16 SeitenSolar MPPTKiran ZoroNoch keine Bewertungen

- Maximum Power Point Tracking - National InstrumentsDokument7 SeitenMaximum Power Point Tracking - National Instrumentsrosy01710Noch keine Bewertungen

- MPPT of PV Module by Conventional Methods 5.1 Perturb and Observe MethodDokument21 SeitenMPPT of PV Module by Conventional Methods 5.1 Perturb and Observe MethodGavril GiurgiNoch keine Bewertungen

- Paper 04Dokument6 SeitenPaper 04Md ShafiullahNoch keine Bewertungen

- NI Tutorial 8106 enDokument4 SeitenNI Tutorial 8106 enDadang AntonNoch keine Bewertungen

- Practical Guide MPPTDokument16 SeitenPractical Guide MPPTgubiliNoch keine Bewertungen

- Designing of Solar PV Systems and Demonstration of Maximum Power Point Tracking (MPPT) Using MatlabDokument17 SeitenDesigning of Solar PV Systems and Demonstration of Maximum Power Point Tracking (MPPT) Using MatlabRasapalli DivyaNoch keine Bewertungen

- Fuzzy Logic Based MPPT For Grid Connected PV SystemsDokument3 SeitenFuzzy Logic Based MPPT For Grid Connected PV SystemshellohellokkNoch keine Bewertungen

- 10 - New MPPT Algorithm Based On PIC Microcontroller - 2016Dokument15 Seiten10 - New MPPT Algorithm Based On PIC Microcontroller - 2016Ammar Al-KindyNoch keine Bewertungen

- Group 9 (PSE) Simulation - Assignment On ECE509Dokument9 SeitenGroup 9 (PSE) Simulation - Assignment On ECE509GodwinNoch keine Bewertungen

- Design and Implementation of Maximum Power Point Tracking (MPPT) Algorithm For A Standalone PV SystemDokument1 SeiteDesign and Implementation of Maximum Power Point Tracking (MPPT) Algorithm For A Standalone PV SystemShashi ShekharNoch keine Bewertungen

- A New Controller Scheme For Photovoltaics PowerDokument10 SeitenA New Controller Scheme For Photovoltaics PowerHakan PolatkanNoch keine Bewertungen

- Maximum Power Tracking Based Open Circuit Voltage Method For PV SystemDokument12 SeitenMaximum Power Tracking Based Open Circuit Voltage Method For PV SystemSiva ForeviewNoch keine Bewertungen

- Single Sensor Based Photovoltaic Maximum Power Point Tracking Technique For Solar Water Pumping SystemDokument5 SeitenSingle Sensor Based Photovoltaic Maximum Power Point Tracking Technique For Solar Water Pumping SystemPogisho LekgethoNoch keine Bewertungen

- Improved MPPT Converter With Current Compensation Method For Small Scaled PV-ApplicationsDokument6 SeitenImproved MPPT Converter With Current Compensation Method For Small Scaled PV-ApplicationsAnonymous PzbYdcEzNoch keine Bewertungen

- Isscc 2012 / Session 5 / Audio and Power Converters / 5.6Dokument3 SeitenIsscc 2012 / Session 5 / Audio and Power Converters / 5.6Soha SherifNoch keine Bewertungen

- AN296110 Current Sensing For Renewable EnergyDokument4 SeitenAN296110 Current Sensing For Renewable EnergyPhạm Văn TưởngNoch keine Bewertungen

- A Single-Stage Three-Phase Grid-Connected Photovoltaic System With Modified MPPT Method and Reactive Power CompensationDokument6 SeitenA Single-Stage Three-Phase Grid-Connected Photovoltaic System With Modified MPPT Method and Reactive Power Compensationsandeepbabu28Noch keine Bewertungen

- Maximum Power Point Tracking of DC To DC Boost Converter Using Sliding Mode ControlDokument6 SeitenMaximum Power Point Tracking of DC To DC Boost Converter Using Sliding Mode ControlInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- The Modified Control Method For The Single-Stage Three-Phase Grid-Connected Photovoltaic SystemDokument14 SeitenThe Modified Control Method For The Single-Stage Three-Phase Grid-Connected Photovoltaic SystemNguyễn Tiến DũngNoch keine Bewertungen

- Analog Control Algorithm For Maximum Power Trackers Employed in Photovoltaic ApplicationsDokument6 SeitenAnalog Control Algorithm For Maximum Power Trackers Employed in Photovoltaic Applicationstinhmaixatoi2006Noch keine Bewertungen

- Chapter 3Dokument9 SeitenChapter 3jahanviNoch keine Bewertungen

- MPPTPSODokument19 SeitenMPPTPSOKambli MadhusudhanNoch keine Bewertungen

- Novel Control SchemeDokument9 SeitenNovel Control SchemesagarscorpionNoch keine Bewertungen

- Mani Final Review - PPTMDokument50 SeitenMani Final Review - PPTMEEE TechNoch keine Bewertungen

- Design and Implementation of Photo Voltaic System With Soft Switched Boost Converter Using Analog Fuzzy Based MPPTDokument7 SeitenDesign and Implementation of Photo Voltaic System With Soft Switched Boost Converter Using Analog Fuzzy Based MPPTskrtamilNoch keine Bewertungen

- Nadiathul Raihana BT IsmailDokument24 SeitenNadiathul Raihana BT IsmailBinu SbNoch keine Bewertungen

- MPPT New EditDokument27 SeitenMPPT New EditFarhan AkramNoch keine Bewertungen

- Investigation of Three-Phase Grid-Connected Inverter For Photovoltaic ApplicationDokument6 SeitenInvestigation of Three-Phase Grid-Connected Inverter For Photovoltaic ApplicationAmran MaulanaNoch keine Bewertungen

- Ijdacr: Simulation and Digital Implementation of Fuzzy Logic Controller For Solar Maximum Power Tracker ApplicationDokument7 SeitenIjdacr: Simulation and Digital Implementation of Fuzzy Logic Controller For Solar Maximum Power Tracker ApplicationDodik YuniarNoch keine Bewertungen

- WSE U6 AnswersDokument3 SeitenWSE U6 AnswersOMKAR PATILNoch keine Bewertungen

- MPPT SoftDokument42 SeitenMPPT Softsonalika.geetasureshNoch keine Bewertungen

- V/F Speed Control of SVPWM Based Solar Fed Induction MotorDokument7 SeitenV/F Speed Control of SVPWM Based Solar Fed Induction MotorInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- A Presentation ON: "Solar Charge Controller"Dokument19 SeitenA Presentation ON: "Solar Charge Controller"Dipak KhadkaNoch keine Bewertungen

- Ex 4Dokument3 SeitenEx 420EUEE034 JEEVA.SNoch keine Bewertungen

- MSP Buck Regulator Closed LoopDokument4 SeitenMSP Buck Regulator Closed LoopMarkoMarkovicNoch keine Bewertungen

- Literature Review On Solar MPPT SystemDokument12 SeitenLiterature Review On Solar MPPT SystemSifatSharminNoch keine Bewertungen

- A Novel Approach On MPPT Algorithm For Solar Panel Using Buck Boost ConverterDokument5 SeitenA Novel Approach On MPPT Algorithm For Solar Panel Using Buck Boost Converterayoub reseauNoch keine Bewertungen

- Content ServerDokument17 SeitenContent Serverayoub reseauNoch keine Bewertungen

- Point Method The Photovoltaic System: Novel Maximum Power Tracking ForDokument5 SeitenPoint Method The Photovoltaic System: Novel Maximum Power Tracking Forramalakshmi_apsNoch keine Bewertungen

- Design of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerDokument9 SeitenDesign of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerL CHNoch keine Bewertungen

- Optimization of MPPT Step Si in Stand-Alone Solar Pumping SystemsDokument6 SeitenOptimization of MPPT Step Si in Stand-Alone Solar Pumping SystemssunitharajababuNoch keine Bewertungen

- Adjustable Matched Virtual: Photovoltaic PointDokument5 SeitenAdjustable Matched Virtual: Photovoltaic PointChenchu TnvNoch keine Bewertungen

- Acfrogcddbh2pyhmzqmp Yjjctapcmrtv5yxh8dnpvv65k5frczpbvhxfwi80lumx7agophonu2kxvijsdejujp0iq1gmq4dwmy3lfdrbbf7nh 4zkbipdmbh Nzx6uxh7lmc8iqnz2nhr6 x6z1Dokument14 SeitenAcfrogcddbh2pyhmzqmp Yjjctapcmrtv5yxh8dnpvv65k5frczpbvhxfwi80lumx7agophonu2kxvijsdejujp0iq1gmq4dwmy3lfdrbbf7nh 4zkbipdmbh Nzx6uxh7lmc8iqnz2nhr6 x6z1neta123abcNoch keine Bewertungen

- Enhanced Solar PV MPPT System For 12V Battery ChargerDokument8 SeitenEnhanced Solar PV MPPT System For 12V Battery ChargerAliXmetecNoch keine Bewertungen

- Maximum Power Point Tracking AlgorithmsDokument8 SeitenMaximum Power Point Tracking AlgorithmsVICTOR UCHENoch keine Bewertungen

- Application of PI and MPPT Controller To DC-DC ConDokument9 SeitenApplication of PI and MPPT Controller To DC-DC ConwafaNoch keine Bewertungen

- Tracer An Sms El v1.0Dokument44 SeitenTracer An Sms El v1.0Jason KettleNoch keine Bewertungen

- Boost Control: MPPT Continued: - A Simple Method: Perturb and Observe (P&O)Dokument7 SeitenBoost Control: MPPT Continued: - A Simple Method: Perturb and Observe (P&O)Usman FarooqNoch keine Bewertungen

- 2 Hill ClimbingDokument6 Seiten2 Hill ClimbingBillel MadridiNoch keine Bewertungen

- Development of A Microcontroller-Based, Photovoltaic Maximum Power Point Tracking Control SystemDokument9 SeitenDevelopment of A Microcontroller-Based, Photovoltaic Maximum Power Point Tracking Control SystemPal PandianNoch keine Bewertungen

- Pi Control System Based Speed Control of DC Motor Using MicrocontrollerDokument13 SeitenPi Control System Based Speed Control of DC Motor Using MicrocontrollerAnkit BhardwajNoch keine Bewertungen

- Design and Implementation of PhotovoltaicDokument8 SeitenDesign and Implementation of Photovoltaicrostamedastan65Noch keine Bewertungen

- Boost Converter Simulation Using PSIMDokument5 SeitenBoost Converter Simulation Using PSIMnawzatNoch keine Bewertungen

- MPPT - Maximum Power Point TrackingDokument9 SeitenMPPT - Maximum Power Point TrackingSanjeev ReddyNoch keine Bewertungen

- Thesis On Maximum Power Point TrackingDokument5 SeitenThesis On Maximum Power Point Trackingoaehviiig100% (2)

- Comparative Analysis of MPPT Techniques ForDokument6 SeitenComparative Analysis of MPPT Techniques ForPIT_Noch keine Bewertungen

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorVon EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNoch keine Bewertungen

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetVon EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetBewertung: 2 von 5 Sternen2/5 (1)

- Control Intelligence Improves Renewable Energy EfficiencyDokument7 SeitenControl Intelligence Improves Renewable Energy EfficiencyPhạm Văn TưởngNoch keine Bewertungen

- Ethernet IP Texas InstrumentsDokument6 SeitenEthernet IP Texas InstrumentsFranzKafkaNoch keine Bewertungen

- Calculation of Short-Circuit CurrentsDokument35 SeitenCalculation of Short-Circuit CurrentsdaodoquangNoch keine Bewertungen

- Ect129 Uninterruptible Static Power Supplies and The Protection of PersonsDokument44 SeitenEct129 Uninterruptible Static Power Supplies and The Protection of PersonsMarko VujicaNoch keine Bewertungen

- All About HarmonicsDokument240 SeitenAll About HarmonicsKhushal KharadeNoch keine Bewertungen

- Uhc AwatersDokument60 SeitenUhc Awaterskammu9713Noch keine Bewertungen

- Disturbance Observers For Rigid Mechanical Systems - Equivalence, Stability, and DesignDokument10 SeitenDisturbance Observers For Rigid Mechanical Systems - Equivalence, Stability, and DesignPhạm Văn TưởngNoch keine Bewertungen

- C Programming For Embedded System Applications PDFDokument54 SeitenC Programming For Embedded System Applications PDFWendo David PesaNoch keine Bewertungen

- 309 An 09 Solar Panel PowerDokument3 Seiten309 An 09 Solar Panel PowerJoel Medina GuttiNoch keine Bewertungen

- AN296110 Current Sensing For Renewable EnergyDokument4 SeitenAN296110 Current Sensing For Renewable EnergyPhạm Văn TưởngNoch keine Bewertungen

- Tutorial Digital Control Loop DesignDokument17 SeitenTutorial Digital Control Loop DesignPhạm Văn TưởngNoch keine Bewertungen

- Study of A Non-Isolated Bidirectional DC - DC Converter: C.-C. Lin, L.-S. Yang, G.W. WuDokument8 SeitenStudy of A Non-Isolated Bidirectional DC - DC Converter: C.-C. Lin, L.-S. Yang, G.W. WuPhạm Văn Tưởng100% (1)

- Evaluation and DSP Based Implementation of PWM Approaches For SinDokument90 SeitenEvaluation and DSP Based Implementation of PWM Approaches For SinPhạm Văn TưởngNoch keine Bewertungen

- The Adventures of Huckleberry Finn by Mark TwainDokument289 SeitenThe Adventures of Huckleberry Finn by Mark TwainBooks100% (5)

- Uninterruptible Power Supply Multiloop Control Employing Digital Predictive Voltage and Current RegulatorsDokument9 SeitenUninterruptible Power Supply Multiloop Control Employing Digital Predictive Voltage and Current RegulatorsPhạm Văn TưởngNoch keine Bewertungen

- Current-Transformer Phase-Shift Compensation and CalibrationDokument7 SeitenCurrent-Transformer Phase-Shift Compensation and CalibrationrsrtnjNoch keine Bewertungen

- Slaa 075Dokument19 SeitenSlaa 075Manidhar ParvatamNoch keine Bewertungen

- 1.A New Battery Model For Use With Battery Energy Storage Systems and Electric Vehicles Power SystemsDokument6 Seiten1.A New Battery Model For Use With Battery Energy Storage Systems and Electric Vehicles Power SystemschethanNoch keine Bewertungen

- An Improved PV Battery Charger For Low Cost Low PowerDokument4 SeitenAn Improved PV Battery Charger For Low Cost Low PowerPhạm Văn TưởngNoch keine Bewertungen

- IEEE Transactions On Power Systems Volume 10 Issue 2 1995 (Doi 10.1109/59.387938) Larsen, E.V. Sanchez-Gasca, J.J. Chow, J.H. - Concepts For Design of FACTS Controllers To Damp Power SwingsDokument9 SeitenIEEE Transactions On Power Systems Volume 10 Issue 2 1995 (Doi 10.1109/59.387938) Larsen, E.V. Sanchez-Gasca, J.J. Chow, J.H. - Concepts For Design of FACTS Controllers To Damp Power SwingsPhạm Văn TưởngNoch keine Bewertungen

- (Matsui) Sensorless PM Brushless DC Motor DrivesDokument9 Seiten(Matsui) Sensorless PM Brushless DC Motor DrivesPhạm Văn TưởngNoch keine Bewertungen

- Informatics in Control Automation and RoboticsDokument5 SeitenInformatics in Control Automation and RoboticsPhạm Văn TưởngNoch keine Bewertungen

- A Novel Dynamic Var CompensatorDokument4 SeitenA Novel Dynamic Var CompensatorPhạm Văn TưởngNoch keine Bewertungen

- IEEE Transactions On Reliability Volume 43 Issue 1 1994 (Doi 10.1109/24.285133) Sallam, A.A. Desouky, M. Desouky, H. - Shunt Capacitor Effect On Electrical Distribution System ReliabilityDokument7 SeitenIEEE Transactions On Reliability Volume 43 Issue 1 1994 (Doi 10.1109/24.285133) Sallam, A.A. Desouky, M. Desouky, H. - Shunt Capacitor Effect On Electrical Distribution System ReliabilityPhạm Văn TưởngNoch keine Bewertungen

- Inverters For Single-Phase Grid Connected Photovoltaic Systems - An OverviewDokument6 SeitenInverters For Single-Phase Grid Connected Photovoltaic Systems - An OverviewPhạm Văn TưởngNoch keine Bewertungen

- TW Exams Ielts How To Prepare Ielts TipsDokument2 SeitenTW Exams Ielts How To Prepare Ielts TipsHoda ElhadaryNoch keine Bewertungen

- NHSPE ReadingDokument5 SeitenNHSPE ReadingMohamed HanafiNoch keine Bewertungen

- Space Vector Modulation An IntroductionDokument10 SeitenSpace Vector Modulation An IntroductionJohan LinderNoch keine Bewertungen

- Phan Tich 1 Bai Task 2 by Ngoc BachDokument4 SeitenPhan Tich 1 Bai Task 2 by Ngoc BachPhạm Văn Tưởng100% (1)

- MPPT-10 Juta Solar Charge Controller 12V10A-1Dokument2 SeitenMPPT-10 Juta Solar Charge Controller 12V10A-1IkhsanFuadiNoch keine Bewertungen

- ENG NKEA Electrical EletronicsDokument18 SeitenENG NKEA Electrical EletronicsMu'izz KaharNoch keine Bewertungen

- How To Make Your Own Electricity (With Pictures) - WikiHowDokument1 SeiteHow To Make Your Own Electricity (With Pictures) - WikiHowMohamed ShaganNoch keine Bewertungen

- Installation Operation Manual: Growatt 7000UEDokument45 SeitenInstallation Operation Manual: Growatt 7000UEsoti9Noch keine Bewertungen

- Go Power GPR25 ManualDokument15 SeitenGo Power GPR25 ManualursindNoch keine Bewertungen

- Survey On Automatic Solar Tracking SystemDokument3 SeitenSurvey On Automatic Solar Tracking SystemInternational Journal of Innovations in Engineering and ScienceNoch keine Bewertungen

- Weiß 2022 Prog. Energy 4 042009Dokument25 SeitenWeiß 2022 Prog. Energy 4 042009Efstathios MaliakisNoch keine Bewertungen

- 4.3 - Q - CELLS - Data - Sheet - Q.PEAK - DUO - XL-G11.3-BFG - 570-585 - 2021-05 - Rev01 - NADokument2 Seiten4.3 - Q - CELLS - Data - Sheet - Q.PEAK - DUO - XL-G11.3-BFG - 570-585 - 2021-05 - Rev01 - NAJose DiazNoch keine Bewertungen

- Design and Implementation of Solar Tracking SystemDokument5 SeitenDesign and Implementation of Solar Tracking SystemerpublicationNoch keine Bewertungen

- Basics of Solar PV SystemDokument14 SeitenBasics of Solar PV SystemCloue Contad DeriadaNoch keine Bewertungen

- 14SOLB 1229 Sample PDFDokument12 Seiten14SOLB 1229 Sample PDFIrving Guatemala100% (1)

- Manual de Inversores GrowattDokument30 SeitenManual de Inversores GrowattJeudy AsencioNoch keine Bewertungen

- Non - Conventional Sources of EnergyDokument277 SeitenNon - Conventional Sources of Energyadytza1260% (5)

- Smart Sunflower BrochureDokument26 SeitenSmart Sunflower BrochureRox BerserkerNoch keine Bewertungen

- Solar101 Residential June 19Dokument14 SeitenSolar101 Residential June 19Imtiyaz AhmadNoch keine Bewertungen

- Solar Panels For Your Home - Complete 2022 GuideDokument43 SeitenSolar Panels For Your Home - Complete 2022 Guideecto8toto100% (1)

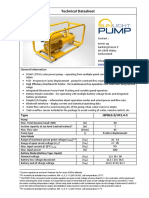

- Technical Datasheet: General InformationDokument2 SeitenTechnical Datasheet: General Information2guntanNoch keine Bewertungen

- Bergamasco SE D 10 00487R1Dokument19 SeitenBergamasco SE D 10 00487R1Cukaj AgostinNoch keine Bewertungen

- Solar Tracking SystemDokument29 SeitenSolar Tracking SystemAnkit Patel100% (5)

- Solar Panel Installtion TechnicianDokument216 SeitenSolar Panel Installtion TechnicianAnkur KUMAR AGGARWAL100% (2)

- PS-M 440W Datasheet - TallmaxM - DE17M - EN - 2019 - B - WebDokument2 SeitenPS-M 440W Datasheet - TallmaxM - DE17M - EN - 2019 - B - Webm_asifNoch keine Bewertungen

- CFD Analysis of Wind Pressure Over Solar Panels at Different Orientations of PlacementDokument8 SeitenCFD Analysis of Wind Pressure Over Solar Panels at Different Orientations of PlacementbabriNoch keine Bewertungen

- FA Solaris ADM 0081610144 02 0912 Web GBDokument40 SeitenFA Solaris ADM 0081610144 02 0912 Web GBLCCesarNoch keine Bewertungen

- How Many Watt Solar Panel To Charge Deep Cycle Battery - EditedDokument5 SeitenHow Many Watt Solar Panel To Charge Deep Cycle Battery - EditedalexNoch keine Bewertungen

- Ghost Control Manual PDFDokument64 SeitenGhost Control Manual PDFNora HernandezNoch keine Bewertungen

- Solar Tracking SystemDokument20 SeitenSolar Tracking SystemDebashishParidaNoch keine Bewertungen

- Solar PV Case StudiesDokument51 SeitenSolar PV Case Studiesrocco1Noch keine Bewertungen

- QS1A Datasheet EN MXDokument2 SeitenQS1A Datasheet EN MXkurtkaukinenNoch keine Bewertungen

- Feasibility of A Mushroom Farm in The Bunkers in El Buey: Sarah Muse, Serena Soltero, Matthew SuarezDokument28 SeitenFeasibility of A Mushroom Farm in The Bunkers in El Buey: Sarah Muse, Serena Soltero, Matthew SuarezRahul SharmaNoch keine Bewertungen

- Integrating BF Systems With Organic Plant Production and Renewable Energy at KSU High Tunnel Complex PDFDokument12 SeitenIntegrating BF Systems With Organic Plant Production and Renewable Energy at KSU High Tunnel Complex PDFtushar patelNoch keine Bewertungen