Beruflich Dokumente

Kultur Dokumente

Comparison of Lumping Approaches To Predict The Product Yield in A Dual Bed VGO Hydrocracker

Hochgeladen von

Sepehr SadighiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Comparison of Lumping Approaches To Predict The Product Yield in A Dual Bed VGO Hydrocracker

Hochgeladen von

Sepehr SadighiCopyright:

Verfügbare Formate

INTERNATIONAL JOURNAL OF CHEMICAL

REACTOR ENGINEERING

Volume 9 2011 Article A4

Comparison of Lumping Approaches to

Predict the Product Yield in a Dual Bed

VGO Hydrocracker

Sepehr Sadighi

Arshad Ahmad

Mansoor Shirvani

Universiti Teknologi Malaysia, sadighi sepehr@yahoo.com

Universiti Teknologi Malaysia, arshad@fkkksa.utm.my

Iran University of Science & Technology, shirvani.m@iust.ac.ir

ISSN 1542-6580

Copyright c 2011 The Berkeley Electronic Press. All rights reserved.

Comparison of Lumping Approaches to Predict the

Product Yield in a Dual Bed VGO Hydrocracker

Sepehr Sadighi, Arshad Ahmad, and Mansoor Shirvani

Abstract

In this research, to predict the product yields of a pilot scale VGO hydroc-

racking reactor charged with mono functional hydrotreating and hydrocracking

catalysts, two different four-lump models are developed. The rst one, called

combined bed model, is a simplex in which there is no boundary between hy-

drotreating and hydrocracking reactions through the reactor. The second one,

called dual bed model, is a rigorous model in which hydrogen consumption and

hydrotreating reactions are included. In this way, the reactor is subdivided into

two different layers, so the effect of hydrotreating reactions on the hydrocrack-

ing section can be considered. Results show that the absolute average deviation

(AAD%) of the yield prediction for the combined bed and the dual bed models are

8.23 percent and 5.87 percent, respectively. The main reason for the lower average

deviation of the dual bed model is its higher accuracy to predict the yield of gas

which is also the major advantage of this approach. However, the simplicity of the

combined bed model can make it more applicable and attractive, especially when

hydrogen consumption as well as sulfur, nitrogen and aromatic specications of

the feed and products are not accessible.

KEYWORDS: hydrotreating, hydrocracking, lump kinetic model, hydrogen con-

sumption, dual bed hydrocracking reactor

1. Introduction

Processing of heavy feedstock into high value products has interested refiners

worldwide due to increasing demand of light oil fractions and decreasing reserves

of low sulfur crude oils. With the consideration of profit margins, hydrocracking

has gained interest because of being an appropriate option for upgrading of heavy

feedstock into various products. Moreover, it is a process in a refinery which

improves the quality and quantity of the refined petroleum products.

Among all the commercially proven technologies for hydrocracking, those

using fixed-bed reactors in series charged with different functionalities are very

favorable. But, the main disadvantage of fixed-bed reactors is the loss of catalyst

activity over time as a result of catalyst deactivation which reduces drastically the

length of run (Alvarez et al., 2008). Typical reactions which occur in

hydrocracking are (i) hydrogenation of polyaromatics, sulfur and nitrogen

containing compounds, and (ii) cracking of higher carbon number (cyclo)-alkanes

to lighter fractions (Balasubramanian & Pushpavanam, 2008). During the

hydrotrating process (HDT) a portion of the hydrogen, dependent to

hydrodesulfurization (HDS) and hydrodenitrogenation (HDN) reactions, is

consumed and most of heavy sulfur and nitrogen compounds are converted to the

light products.

Kinetic modeling of the reactions occurring in a hydrocracker and

estimation of the rate coefficients is a crucial step in its design. An accurate

estimation of the rate coefficients will enable us to optimize and control the

product yield distribution in a hydrocracker. Ideally, the kinetic model should take

into account all elementary reactions which the different components in the

feedstock undergo. However, the complexity of hydrocracking feed makes it

extremely difficult to characterize and describe its kinetic at a molecular level

(Ancheyta et al., 1999).

One way of simplifying the problem is to consider the partition of the

species into a few equivalent classes, the so-called lumps or lumping technique,

and then assume each class is an independent entity (Krambeck, 1991). The major

lumping methods interested in hydrocracking are continuum theory of lumping

and discrete lumping approaches. In the first method, the reactive mixture is

considered to form a continuum mixture with respect to its properties such as

boiling point, molecular weight, carbon number or chemical species (Basak et al.,

2004; Elizalde et al., 2009). But, in the discrete lumping approach, the reaction

network is reduced to the limited number of reactions among the lumped

components. The lumps, based on compound types present in feedstock and

products (e.g., lumps of diesel, kerosene, gasoline, etc.), are often defined by

boiling point ranges. This approach is attractive for kinetic modeling of complex

mixtures because of its simplicity (Ancheyta et al., 2005).

1 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

However, it should be mentioned that lumped kinetics have the following

major disadvantages: (1) they are strongly dependant to feedstock and catalyst;

(2) they are only valid for the range of studied operating conditions, and also (3) if

bench-scale trickle-bed reactors are used for the experimentation, reaction kinetics

will be affected by hydrodynamics and mass transfer processes. If any of those

parameters is to be changed, then the model must be refitted on the basis of a new

experimental program.

To make the lumped models more accurate, it is possible to choose as

many lumps as possible. However, this may lead to a large number of model

parameters (e.g., rate constants). So, less number of species, especially in the case

of limited number of experiments, can make the model more acceptable.

According to discrete lumping approach, there are many researches in

which hydrocracking models with three-lump (Yui & Sanford, 1989; Callejas &

Martinez, 1999; Aoyagi et al., 2003), four-lump (Aboul-Gheit, 1989; Valavarasu

et al., 2005; Sadighi et al., 2010d), five-lump (Ancheyta et al., 1999; Almeida &

Guirardello, 2005; Singh et al., 2005; Sadighi et al., 2010c) and six-lump (Sadighi

et al., 2010a; Sadighi et al., 2010b) partitions have been developed. Moreover, for

the other processes such as catalytic pyrolysis of heavy oil (Meng et al., 2006) and

fluid catalytic cracking (Chen et al., 2007), eight-lump kinetic models were

presented.

In the present study, two kinds of discrete lumping models for a dual bed

pilot scale hydrocracking plant have been compared together. The first approach

is a simplified model which considers only hydrocracking reactions. So, it is

assumed that the catalytic bed operates like a bi-functional catalyst;

hydrocracking reactions can be occurred uniformly through the bed. The second

one is a rigorous approach which needs complementary data from the hydrogen

consumption as well as sulfur, aromatic and nitrogen contents of the feed and

products. This strategy is according to the previous study (Sadighi et al., 2010d).

But its equations are formulated here in detail to make it more applicable for

being used in a mathematical model. To have a more realistic model and closer to

the industrial scenario, the measured yields for estimating the required parameters

are calculated on the basis of mass flow rate of fresh VGO feed.

2. Experimental

The device, catalyst, feed and operating conditions were described completely in

the previous work (Sadighi et al., 2010d). The reactor was composed of four

sections. The first part, having a length of 100 mm, was packed with inert SiC

particles. This section was used to provide a uniform distribution of gas and

liquid. The two following sections with a length of 355mm and 865 mm were

2 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

loaded with 63.5cm

3

hydrotrating and 152 cm

3

hydrocracking catalysts,

respectively. The last section was also contained with 50mm of inert (Figure 1).

Because in the under study process, two mono functional zeolite based

hydrotreating and hydrocracking catalysts were used, the reactor can be called a

dual bed VGO hydrocracker.

Figure 1. Sections of catalytic reactor bed

In this study, two types of commercial hydrotreating and hydrocracking

(zeolite-based) catalysts with the same size of industrial application were applied.

The characteristics of HDT and HDC catalysts are presented in Table 1. Before

charging the feed, both catalysts were heated up to 130

0

C, and also they were held

at this temperature about 6 hr for drying. Then, it is sulfided with an appropriate

agent according to the manual of the catalyst vendor.

3 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Table 1- characteristics of HDT&HDC catalyst

Property HDT HDC

Size & Shape 1/16 & Quadralobe 1/16 & Cylindrical

Color Green Brown

Bulk density (kg/m

3

) 750 850

BET Surface Area (m

2

/g) 186.56 199.46

Langmuir Surface Area(m

2

/g) 259.20 273.71

Average Pore Diam (A

0

) 89.09 69.14

Main Ingredients Mo, Ni, Ti Zr, W, Ni, Si, Al

The hydrocracking feed was prepared by blending of the fresh VGO and

recycle feed (unconverted oil) taken from Isomax unit of a real refinery. The feed

properties are shown in Table 2. Mixing ratio of fresh and recycle feeds were 83.3

vol% and 16.7 vol %, respectively.

Table 2- Properties of fresh VGO and recycle feed

Property Fresh VGO Recycle Feed

SP.GR@15.56C 0.8777 0.8738

Distillation Range (vol%)

ASTM D1160 C C

IBP 329.7 287.8

10% 390.6 390.7

30% 423.2 430.1

50% 445.6 452.9

70% 475.1 478.3

90% 523.7 517.1

End point 567.1 561.3

Nitrogen (ppmwt) 800 200

Sulfur (wt%) 1.4 0.03

Aromatics (wt%) 34 14.5

Asphalt & Resin (wt %) <0.1 <0.1

The pilot scale experiments were carried out under the following process

conditions: (1) H

2

/HC=1357 Nm

3

/Sm

3

; (2) LHSV=0.8, 0.9 and 1.05 hr

-1

; (3)

Temperature=360C, 370C, 380C and 390C, and (4) Pressure =146 bar. The

pressure, the range of LHSV and H

2

/HC were selected according to the

recommendation of the catalyst manufacturer.

4 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

3. Modeling approach for the dual bed hydrocracking reactor

This work considers 4-lump mathematical model, i.e., VGO, distillate, naphtha

and gas to match main products (Table 3). The kerosene and diesel, also light and

heavy naphtha are lumped together as distillate and naphtha cuts, respectively.

Additionally, it is assumed that only VGO (as hydrocracking feed) consumes

hydrogen to be cracked to lighter cuts. So, the total consumed hydrogen in

hydrocracking section can be calculated on the basis of cracked VGO. Therefore,

hydrogen can be included in the mass balance equations without creating high

complexity. Figure 2 illustrates the process pathways associated with the

mentioned strategy. Note that if all pathways of reactions are considered, the

model will include twelve kinetic parameters which should be estimated by using

experimental data.

Table 3. Average properties of hydrocracking product (Sadighi et al, 2010d)

Lump Sp.g @15C IBP-FBP (C)

Gas 0.35 40

-

Naphtha 0.75 40-160

Distillate 0.823 161-370

VGO 0.89 370

+

Figure 2. The complete 4-lump kinetic model

5 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

The following assumptions are considered in the development of the

present models (Mohanty et al., 1991):

1- Hydrocracking is a first order hydrocracking reaction and since hydrogen

is present in excess, the rate of hydrocracking can be taken to be

independent of the hydrogen concentration.

2- The pilot reactor operates under isothermal conditions.

3- A plug flow pattern exists in the trickle bed reactor.

4- Hydrogen feed is pure.

5- The petroleum feed and the products are in the liquid phase in the reactor.

6- The pilot unit is in steady state operation.

7- Catalyst activity does not change with time; therefore simulation is only

valid for start of run conditions.

For each reaction, the kinetic expression is formulated as the function of

mass concentration and kinetic parameters (

0

k , E ). Based on the mentioned

assumptions, rate constants of the proposed models are as follows:

Vacuum gas oil or Feed ( F ): ) exp(

0

RT

E

k k

Fj

Fj Fj

= (1)

Note that j in Eq. 1 represents distillate ( D), naphtha ( N ) and gas ( G )

Distillate ( D): ) exp(

'

' 0 '

RT

E

k k

Dj

Dj Dj

= (2)

' j in Eq. 2 represents naphtha ( N ) and gas ( G ).

Naphtha ( N ): ) exp(

0

RT

E

k k

NG

NG NG

= (3)

In equations 1 to 3, T and R are the bed temperature and ideal gas constant,

respectively.

6 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

From Figure 2, it can be found that for converting VGO to the lighter

products, hydrogen should be consumed for each path. Therefore, the reaction

rates for these products can be described as follows:

Distillate (

D

R ):

=

+ =

G

N j

D Dj F FD D

C k C k R

'

'

) 1 ( o (5)

Naphtha (

N

R ):

NG NG D DN F FN N

C k C k C k R + + = ) 1 ( o (6)

Gas (

G

R ):

N NG D DG F FG G

C k C k C k R + + + = ) 1 ( o (7)

In equations 5 to 7, o shows the consumed unit mass of hydrogen per unit mass

of converted VGO which is added to the molecular structure of products

(distillate, naphtha and gas) during hydrocracking reactions.

3.1. Combined bed model

In this approach, the hydrogen consumption is neglected. It is obvious that during

hydrocracking and hydrotreating reactions, hydrogen molecule is absorbed in the

hydrocarbon structure, but sulfur and nitrogen are removed. According to the

experimental data (Sadighi et al, 2010d), this assumption can create 1% error in

the mass balance which can be considered negligible. So, the o coefficient in

equations 5 to 7 is assumed to be zero.

Additionally, it is assumed that hydrocracking and hydrotreating reactions

are carrying out simultaneously through the reactor bed similar to a bi-functional

hydrocracking catalyst. Therefore, there is no boundary between hydrotrating and

hydrocracking reactions. The scheme of combined bed model is illustrated in

Figure 3(A).

So, the reaction rates (

j

R ) can be formulated as follows:

Vacuum gas oil reaction (

F

R ):

F

G

D j

Fj F

C k R

=

= (4)

7 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Figure 3. Schematic representation of the developed lumping models

(A) Combined bed model (B) Dual bed model

3.2. Dual bed model

In this approach, the reactor is divided into two distinguished layer. In the first

one, after carrying out the hydrotrating reactions (Table 4), the product is entered

to the second layer. Therefore, the second step is only involved of hydrocracking

reactions. The scheme of the dual bed model is illustrated in Figure 3 (B).

Before entering the products of the hydrotrating step into the

hydrocracking one, it is imagined that by using two pseudo streams, H

2

S and NH

3

are extracted from the hydrotrating products. So, they are not involved in the mass

balance equations of hydrocracking section. Because these components are stable

and also their flow rates are negligible, this assumption will not create a

considerable error for the mathematical model. After hydrotrating reactions, to

calculate the mass flow rate of feed, naphtha and distillate, equations 8 to 10 are

formulated. Because the contents of sulfur and nitrogen in the product of the

reactor are less than 50 ppm, they have been neglected.

)) ( 1 (

2

0 0

Af Ap

VGO

H

Nf Sf f fh

X X

Mw

Mw

X X m m = (8)

8 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

) 7 .(

.

3 2

0

0

NH H Nc

N

Nf f

Nh

Mw Mw Mw

Mw

X m

m + = (9)

) 2 .(

.

2 2

0

0

S H H Sc

S

Sf f

Dh

Mw Mw Mw

Mw

X m

m + = (10)

In above equations,

0

f

m is the mass flow rate of the fresh VGO;

0

fh

m ,

0

Nh

m ,

0

Dh

m

are the mass flow rate of the purified VGO, naphtha and distillate leaving the

hydrotreating section, respectively;

Sf

X ,

Nf

X ,

Af

X are the mass fraction of

sulfur, nitrogen and aromatics in the fresh feed, respectively;

S H NH H VGO Sc Nc S N

MW MW MW Mw Mw Mw Mw Mw

2 3 2

, , , , , , , are the molecular weight

of nitrogen, sulfur, nitrogen lumped component (quinoline), sulfur lumped

component (4,6-DMBT), VGO feed (420), hydrogen, ammonia and hydrogen

sulfide, respectively.

Table 4. Major reactions in the hydrotreating of VGO (Sadighi et al., 2010d)

Reaction Lumped component Consumed hydrogen Products

Hydrodesulfurization 4,6-DMBT 2 moles per S atom Distillate & H

2

S

Hydrodenitrogenation Quinoline 7 moles per N atom Naphtha & NH

3

Hydrodearomatization di-aromatics 2 moles per arom. molecule VGO

The reactions in the hydrocracking step are according to equations 5 to 7;

but the o coefficient is calculated by the following quadratic polynomial

equation (Sadighi et al., 2010d).

LHSV T LHSV T LHSV T . . . . .

12

2

22

2

11 2 1 0

| | | | | | o + + + + + = (12)

In this equation, T is the reaction temperature (K); LHSV is liquid hourly space

velocity of the reacting stream through the bed (hr

-1

). Also,

0

| is the intercept

coefficient,

1

| and

2

| are the linear terms,

1 1

| and

22

| are the squared terms and

12

| is the interaction term (Table 5).

Table 5. Coefficient values for the hydrogen consumption

Variable

0

|

1

|

2

|

11

|

22

|

12

|

T.LHSV 3441.319 -10.762 -18.906 0.00854 5.452 -0.00858

9 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

3.3. Model development and parameter estimation

In order to model the reactor, a cell network is applied. All beds from the inlet to

the outlet are divided into a number (N

l

=200) of well-mixed cells which are

grouped along the flow direction. Mixing only occurs within each cell and back

mixing is not accounted for between the adjacent cells. The accuracy of this

approach for the VGO hydrocracking process in trickle bed regime was confirmed

in the previous work (Sadighi et al., 2010d).

To improve the accuracy of the developed model, the volumetric flow rate

in the reactor (v ) is considered variable, and it is calculated according to the

density of output stream of each cell. Therefore, the mass balance equation for

each cell can be written as follows:

) ( ) ( ) ( ) ( '. . ) 1 ( ) 1 ( i i C i V i R i i C

j cat j j

v c q v = (13)

In Eq. 13, j ranges from the fresh feed ( F ) to the gas ( G ), and a negative sign

indicates reactant (fresh feed or VGO).

l

b

cat

N

V

i V = ) ( (14)

) (

) (

0

i

m

i

G

f j

j

v

=

= (15)

) ( ). (

0

i i C m

j j

v = (16)

=

=

=

G

F j

j

G

F j

j

j

m

m

i

.

) (

1

0

0

(17)

0

) ( ). (

f

l l j

j

m

N N C

Y

v

= (18)

In above equations,

j

is density of lumps (Table 3); i is the number of cells

which ranges from 1 to 200; C is the mass concentration of lumps; q is the

effectiveness factor; ' c is the catalyst volume fraction; ) (i V

cat

is the volume of

hydrocracking catalyst in each cell;

b

V is the volume of the bed; N

l

is the number

of cells (200);

0

f

m is the mass flow rate of fresh feed, and

j

Y is the yield of each

lump in the product stream leaving the reactor. The effectiveness factor for

cylindrical catalyst in trickle bed regime and the bed void fraction are 0.7 (Mills

& Dudukovic) and 0.35, respectively.

10 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

For parameter estimation, sum of squared error, SQE , as given below, is

minimized:

2

1

) (

pred

jn

t

N

n

meas

jn

G

F j

Y Y SQE =

=

=

(19)

In Eq.19,

t

N ,

meas

jn

Y and

pred

jn

Y are the number of test runs, the measured and the

predicted yields, respectively.

For the combined bed model, equations 1 to 7 and 13 to 18 should be

solved simultaneously by applying the following boundary conditions:

f

f

m

v

0

) 0 ( = ;

f f

C = ) 0 ( ; 0 ) 0 ( =

D

C ; 0 ) 0 ( =

N

C ; 0 ) 0 ( =

g

C (20)

But, for the dual bed model, equations 1 to 7 and equations 12 to 18

should be solved simultaneously by applying the following boundary conditions:

) 0 (

) 0 (

0

v

=

=

N

f j

jh

m

(21)

=

+ +

=

N

f j

jh N

Nh

N

f j

jh D

Dh

N

f j

jh f

fh

m

m

m

m

m

m

0

0

0

0

0

0

1

) 0 (

(22)

) 0 (

) 0 (

0

v

fh

f

m

C = ;

) 0 (

) 0 (

0

v

Dh

D

m

C = ;

) 0 (

) 0 (

0

v

Nh

N

m

C = ; 0 ) 0 ( =

g

C (23)

To develop the model, Aspen Custom Modeler (ACM) programming

environment (AspenTech, 2004) is used. Then Eq.19 is minimized by sequencing

NL2Sol and Nelder-Mead algorithm which are both existed in Aspen Custom

Modeler software. NL2Sol algorithm is a variation on Newton's method in which

a part of the Hessian matrix is computed exactly and a part of that is

approximated by a secant (quasi-Newton) updating method. To promote

convergence from a poor initial point, a trust-region is used along with a choice of

model Hessian. Hence, the approximate region is found with NL2Sol; then to fine

tune the parameters; Nelder-Mead method is used.

To evaluate the estimated kinetic parameters, absolute average deviation

of predictions ( % AAD ) is calculated by using the following expression.

11 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

100

) (

%

1

2

2

=

=

=

t

t

N

n meas

jn

pred

jn

meas

jn

G

F j

N

Y

Y Y

AAD (24)

Moreover, the goodness of fitting of developed models is checked with

analysis of variance (ANOVA) using Fischer test with 99% probability.

4. Results and discussions

At first for the combined bed model, twelve kinetic parameters, frequency factors

and activation energies were estimated by using the experimental data. After

estimating parameters and predicting yields, the AAD% of the model was 8.28%

in comparison to the measured data.

In Table 6, kinetic constants and the rate order of reactions at the mean

operating temperature (375

0

C) to the highest one (k

DN

or distillate to naphtha) are

presented. It is found that for the combined bed model, the rate orders of

converting VGO to naphtha (k

FN

) and distillate to gas (k

DG

) are significantly

lower than the highest value (k

DN

). It means that these reactions can be ignored.

After eliminating the low-reaction-rate pathways and re-estimating the parameters

(Table 7), the AAD% of the reduced model was found to be 8.23%. It can be

concluded that the model reduction can improve the accuracy of the yield

prediction which is the similar scenario with respect to the previous works

(Sadighi et al., 2010a; Sadighi et al., 2010b; Sadighi et al., 2010c).

From Table 7, it is obvious that apparent activation energies of VGO to

middle distillate and gas are 14.97 kcal/mol and 7.32 kcal/mol, respectively. The

reported ones by Aboul-Ghiet (1989) were about 13-17.5 kcal/mol, and 18-19

kcal/mol, respectively. It is thought that the lower estimated activation energy for

hydrocracking of feed to gas in this work is due to the higher hydrocracking

activity of zeolite type catalyst. Additionally, the estimated activation energy

(Botchwey et al., 2004) for formation of naphtha from middle distillate in the low

severity temperature regime (340 to 370

0

C) was about to 8.8 kcal/mol. Moreover

the reported value for hydrocracking of kerosene to heavy naphtha in an industrial

hydrocracking process charged with amorphous catalyst was 7.43 kcal/mol

(Sadighi et al., 2010 a). It can be concluded that the estimated activation energy of

distillate to naphtha in this work (7.11 kcal/mol) is not far from the others.

The simplified reaction-path network for the four-lump combined bed

model is shown in Figure 4.

12 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

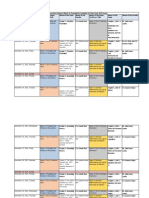

Table 6. Kinetic parameters for complete network of combined bed model

Frequency Factor

(m

3

.hr

-1

.m

3

total cat

-1

)

Activation Energy

(kcal/mol)

Rate order

k

0FD

3.49E+05 E

FD

15.80 k

FD

0.61

k

0FN

2.44E+07 E

FN

69.30 k

FN

3.79E-17

k

0FG

3.34E-01 E

FG

2.10 k

FG

0.024

k

0DN

900.84 E

DN

7.49 k

DN

1

k

0DG

2.48E+07 E

DG

34.07 k

DG

2.98E-05

k

0NG

1.10E+00 E

NG

0 k

NG

0.41

Table 7. Kinetic parameters for reduced network of combined bed model

Frequency Factor

(m

3

.hr

-1

.m

3

total cat

-1

)

Activation Energy

(kcal/mol)

Rate order

k

0FD

1.82E+05 E

FD

14.97 k

FD

0.62

k

0FN

- E

FN

- k

FN

-

k

0FG

2.29E+01 E

FG

7.32 k

FG

0.03

k

0DN

660.20 E

DN

7.11 k

DN

1

k

0DG

- E

DG

- k

DG

-

k

0NG

8.33E-01 E

NG

- k

NG

0.32

Figure 4. The reduced 4-lump kinetic network for the combined bed model

After following again the described strategy for the dual bed model, it was

found that the AAD% of the complete and reduced approaches were 6.77% and

5.87%, respectively. The apparent kinetic constants of those are presented in

Tables 8 and 9, respectively. Also, the reduced kinetic network of this strategy is

depicted in Figure 5.

13 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Table 8. Kinetic parameters for the complete network of the dual bed model

Frequency Factor

(m

3

.hr

-1

.m

3

HCR cat

-1

)

Activation Energy

(kcal/mol)

Rate order

k

0FD

6.72E+07 E

FD

23.37 k

FD

0.57

k

0FN

1.04E+08 E

FN

24.63 k

FN

0.33

k

0FG

0 E

FG

13.08 k

FG

0

k

0DN

0 E

DN

2.14 k

DN

0

k

0DG

6.90E+03 E

DG

28.15 k

DG

1.43E-06

k

0NG

1.55E+00 E

NG

0 k

NG

1

Table 9. Kinetic parameters for the reduced network of the dual bed model

Frequency Factor

(m

3

.hr

-1

.m

3

HCR cat

-1

)

Activation Energy

(kcal/mol)

Rate order

k

0FD

1.32E+07 E

FD

21.25

k

FD

0.59

k

0FN

1.42E+10 E

FN

31.02

k

FN

0.32

k

0FG

- E

FG

- k

FG

-

k

0DN

- E

DN

- k

DN

-

k

0DG

- E

DG

- k

DG

-

k

0NG

1.514 E

NG

- k

NG

1

Figure 5. The reduced 4-lump kinetic network for the dual bed model

It should be noted that the kinetic constants and the kinetic network of the

combined bed model (Table 7 and Figure 4) show the performance of

hydrotreating and hydrocracking sections together. But the related ones for the

14 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

dual bed model (Table 9 and Figure 5) only demonstrate the performance of the

hydrocracking catalyst.

Therefore, it can be understood that in comparison to the combined bed

approach, the dual bed one can predict the yield of hydrocracking reactor with

lower AAD% about 2.36%. The brilliant point in this approach which can be

understood from Table 9 is its requirement to only five kinetic parameters

(frequency factors and activations energies) to predict twelve sets of test runs

(three levels of LHSV and four levels of temperature). But, this approach needs

complete information from hydrogen consumption as well as sulfur, nitrogen and

aromatic contents of the feed and product. In contrast, combined bed model needs

seven parameters to predict the yield of products with AAD % of 8.23. But it is a

simplex in which no hydrotrating or hydrogen consumption data is needed.

In the previous works (Sadighi et al., 2010a), it was reported that the

activation energies for both light and heavy naphtha to gas were about to 9

kcal/mol for a dual-functional amorphous hydrocracking-hydrotreating catalyst.

But, from Tables 7 and 9, it can be concluded that in this range of operating

temperature, the activation energy for hydrocarcking of naptha to gas is

independent to temperature (E

NG

=0). The reason for this phenomenon is supposed

to be higher ability of zeolite type catalysts for hyrocracking (Shimada et al.,

1997). So, gas formation from naphtha may be influenced by the nature of

catalyst, and it is independent to temperature within the operating range.

The AAD percentages for all lumps are presented in Table 10. It can be

concluded that the predictions of the combined and dual bed models are close

together and they are acceptable for all products except to the case of gas for the

combined bed model. Additionally, in the Table 11, the ANOVA of both

strategies has been presented. The positive point in this table is acceptable

difference between the F-critical and the F-test of the proposed models.

Table 10. The AAD% for the different dual bed lumping models

Lump

Combined bed

(Completed)

Combined bed

(Reduced)

Dual bed

(Completed)

Dual bed

(Reduced)

Gas 21.04 20.7 11.00 9.26

Naphtha 4.92 5.34 8.29 7.04

Distillate 5.33 5.11 4.87 4.34

Un.VGO 1.83 1.76 2.90 2.85

Ave. 8.28 8.23 6.77 5.87

15 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Table 11. ANOVA results of the developed models

Combined bed

(complete)

Combined bed

(reduced)

Dual bed

(complete)

Dual bed

(reduced)

DF* of regression 11 6 11 4

DF* of residual 36 41 36 43

R

2

-adjusted (%) 99.944 99.974 99.916 99.976

F-value 1789.69 3865.29 1189.87 4193.26

F-critical (1%) 2.79 3.28 2.79 3.79

*DF is degree of freedom

Figures 6 to 9 show comparisons between the measured yields and the

predicted ones. To evaluate the accuracy of the prediction, the corresponding

deviation plot is also presented. The deviation error reported in these figures was

calculated as follows:

100

Pr

%

=

yield Measured

yield edicted yield Measured

Error (25)

As it was resulted from Table 10, close mappings between the measured

and predicted yields by using both approaches can be understood. Moreover, it

can be found that deviations are acceptably distributed evenly around the zero; but

in the Figure 6, more deviation for the gas lump can be found for the combined

bed model.

Additionally, the deviation plot for the predicted gas by the combined bed

model in the Figure 6 demonstrates that in most of temperatures and LHSVs, the

dual bed model predicts lower yield for the gas lump in comparison to the

measured data. It is supposed that this deviation is because of disregarding the

reactions which can produce gas in the hydrotreating layer. Conversely, for most

of temperatures and LHSVs, the combined bed model predicts higher values for

the yield of gas. It is supposed that the main reason for this deviation is the

consideration of gas producing reactions in all points along the catalytic bed.

Because of lower ability of hydrotreating catalyst to produce gas than that of

hydrocracking one, the model predicts more gas in comparison to the measured

values. Therefore the yield of gas can be laid between the values predicted by the

combined and dual bed models.

16 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

Figure 6. Predicted yields (, &), measured yields (, & ) and

deviation plots for the prediction of gas lump

17 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Figure 7. Predicted yields (, &), measured yields (, & ) and

deviation plots for the prediction of naphtha lump

18 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

Figure 8. Predicted yields (, &), measured yields (, & ) and

deviation plots for the prediction of distillate lump

19 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Figure 9. Predicted yields (, &), measured yields (, & ) and

deviation plots for the prediction of VGO lump

5. Conclusions

It was demonstrated that the product yields of a pilot scale VGO-hydrocracker

could be predicted with the AAD% of 5.87% by using a four-lump rigorous model

approach, called the dual bed model. This model could predict the yield of gas,

naphtha, diesel and residue with the AAD% of 9.26%, 7.04%, 4.34% and 2.85%,

respectively. These deviations for 12 test runs (48 observations) in three levels of

LHSV and four levels of temperature can be satisfying. But to develop such a

20 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

model, the hydrogen consumption of the process was needed. Moreover, sulfur,

nitrogen and aromatic content of the feed and product should be analyzed. In

contrast, there was a simpler four-lump approach, called the combined bed model

which was capable of predicting the yield of products with the AAD% of 8.23%.

This model could predict the yield of gas, naphtha, diesel and residue with the

AAD% of 20.7%, 5.34%, 5.11% and 1.76%, respectively. The enormous deviation

for the gas lump can be the disadvantage of this model. But, the advantage of this

model over the dual bed model was its simplicity because it only required product

yields to tune the model parameters.

6. Nomenclature

6.a Notations

AAD Absolute Average Deviation, %

C

Mass concentration, kg/m

3

D Distillate

E Apparent activation energy, kcal/mol

G

Gas

k

Reaction rate constant, m

3

.hr

-1

.m

3

cat

-1

0

k

Frequency factor, m

3

.hr

-1

.m

3

cat

-1

LHSV

Liquid Hourly Space Velocity, hr

-1

0

m Mass flow rate, kg/hr

Mw

Molecular weight

S

Mw

Molecular weight of sulfur (32)

N

Mw

Molecular weight of nitrogen (14)

N

Naphtha

l

N

Number of cells (200)

t

N

Number of experiments

R

Ideal gas constant, 1.987 kcal.kmol

-1

.K

-1

j

R

Reaction rate of lump j, kg.hr

-1

.m

3

cat

-1

21 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

T Temperature, K or R

b

V

Total Volume of bed, m

3

cat

V

Volume of catalyst per cell, m

3

VGO

Vacuum Gas Oil

X Mass fraction of lumps

Y

Yield of products

6.b Greek letters

o Consumed mass of hydrogen per mass of VGO

12 22 11 2 1 0

, , , , , | | | | | | Coefficient values for the hydrogen consumption

' c Catalyst void fraction

q

Effectiveness factor

v Volume flow rate, m

3

/hr

Density, kg/m

3

6.c Subscripts

Af

Aromatic in feed

Ap

Aromatic in product

' Dj

Distillate to lighter lumps

Dh Diesel in the output stream of hydrotrating bed

fh

VGO feed or residue in the output stream of hydrotrating bed

Fj

Feed to lighter lumps

i Cell number

j

Distillate, naphtha and gas lumps

' j

naphtha and gas lumps

2

H Hydrogen

S H

2

Hydrogen sulfide

n Number of experiments

Nc Nitrogen lumped component

22 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

Nf

Nitrogen in feed

Nh Naphtha in the output stream of hydrotrating bed

3

NH Ammonia

Sc Sulfur lumped component

Sf

Sulfur in feed

References

Aboul-Gheit K., "Hydrocracking of vacuum gas oil (VGO) for fuels production",

Erdol Erdgas Kohle, 1989, 105, 1278.

Almeida R. M. and Guirardello R., "Hydroconversion kinetics of Marlim vacuum

residue", Catalysis Today, 2005, 109, 104.

Alvarez A. and Ancheyta J., "Modeling residue hydroprocessing in a multi-fixed-

bed reactor system", Applied catalysis A: General, 2005, 351, 148.

Ancheyta J., Sanchez S. and Rodriguez M. A., "Kinetic modeling of

hydrocracking of heavy oil fractions: A review", Catalysis Today, 2005,

109, 76-92.

Ancheyta-Juarez J., Lopez-Isunza F. and Aguilar-Rodriguez E., "5-Lump kinetic

model for gas oil catalytic cracking", Applied Catalysis A: General, 1999,

177, 227.

Aoyagi K., McCaffrey W. C. and Gray M. R., "Kinetics of hydrocracking and

hydrotreating of coker and oilsands gas oils", Petroleum Science

Technolology, 2003, 21, 997.

Basak K., Sau M., Manna U. and Verma R.P., "Industrial hydrocracker model

based on novel continuum lumping approach for optimization in

petroleum refinery", Catalysis Today, 2004, 98, 253.

Balasubramanian P. and Pushpavanam S., "Model discrimination in

hydrocracking of vacuum gas oil using discrete lumped kinetics", Fuel,

2008, 87, 1660.

23 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Botchwey C., Dalai A.K. and Adjaye J., "Kinetics of Bitumen Derived Gas Oil

Upgrading Using a Commercial NiMo/Al

2

O

3

Catalyst", The Canadian

Journal of Chemical Engineering, 2004, 82, 478.

Callejas M. A. and Martinez M. T., "Hydrocracking of a Maya residue, kinetics

and product yield distributions", Industrial Engineering Chemical

Research, 1999, 38, 98.

Chen C., Yang B., Yuan J., Wang Z. and Wang L., "Establishment and solution of

eight-lump kinetic model for FCC gasoline secondary reaction using

particle swarm optimization", Fuel, 2007, 86, 2325.

Elizalde I., Rodrguez M.A. and Ancheyta J., "Application of continuous kinetic

lumping modeling to moderate hydrocracking of heavy oil", Applied

Catalysis A: General, 2009, 365, 237.

Krambeck F.J., "Kinetics and thermodynamics lumping of multicomponent

mixtures", Elsevier, 1991, Amsterdam, 111.

.

Meng X., Xu C., Gao J., Li L., "Catalytic pyrolysis of heavy oils: 8-lump kinetic

model", Applied Catalysis A: General, 2006, 301, 32.

Mills P.L., Dudukovic M.P., "A Dual-Series Solution for the Effectiveness Factor

of Partially Wetted Catalysts in Trickle-Bed Reactors", Ind. Eng. Chem.

Fund., 1979, 18, 2.

Mohanty S., Saraf D. N. and Kunzro D., "Modeling of a hydrocracking reactor",

Fuel Processing Technology, 1991, 29, 1-17.

Sadighi S., Arshad A. and Mohaddecy S. R., "6-Lump Kinetic Model for a

Commercial Vacuum Gas Oil Hydrocracker", International Journal of

Chemical Reactor Engineering, 2010a, 8, A1.

Sadighi S., Arshad A. and Irandoukht A., "Modeling a Pilot Fixed-bed

Hydrocracking Reactor via a Kinetic Base and Neuro-Fuzzy Method",

Journal of Chemical Engineering Japan, 2010b, 43 (2), 174.

Sadighi S., Arshad A. and Irandoukht A., "Kinetic Study on a Commercial

Amorphous Hydrocracking Catalyst by Weighted Lumping Strategy",

International Journal of Chemical Reactor Engineering, 2010c, 8, A60.

24 International Journal of Chemical Reactor Engineering Vol. 9 [2011], Article A4

http://www.bepress.com/ijcre/vol9/A4

Sadighi S., Arshad A. and Rashidzadeh M., "4-Lump kinetic model for vacuum

gas oil hydrocracker involving hydrogen consumption", Korean Journal of

Chemical Engineering, 2010d, 27 (4), 1099.

Shimada H., Yoshitomi S., Sato T., Matsubayashi N., Imamura M., Yoshimura Y.

and Nishijima A., "Dual-functional Ni-Mo sulfide catalysts on zeolite-

alumina supports for hydrotreating and hydrocracking of heavy oils",

Studies in Surface Science and Catalysis Hydrotreatment and

Hydrocracking of Oil Fractions, Proceedings of the 1st International

Symposium/6th European Workshop, 1997, 106, 115-128.

Singh J., Kumar M., Saxena A. K. and Kumar S., "Reaction pathways and product

yields in mild thermal cracking of vacuum residues: A multi-lump kinetic

model", 2005, Chemical Engineering Journal, 108, 239.

Valavarasu G., Bhaskar M. and Sairam B., "A Four Lump Kinetic Model for the

Simulation of the Hydrocracking Process", Petroleum Science

Technology, 2005, 23, 1323.

Yui S. M. and Sanford E. C., "Mild hydrocracking of bitumen-derived coker and

hydrocracker heavy gas oils: kinetics, product yields and product

properties, Industrial Chemical Research, 1989, 28, 319.

25 Sadighi et al.: Lumping Model for a Dual Bed VGO Hydrocracker

Published by The Berkeley Electronic Press, 2011

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Cult of KUDokument31 SeitenCult of KUEli GiudiceNoch keine Bewertungen

- American Literature TimelineDokument2 SeitenAmerican Literature TimelineJoanna Dandasan100% (1)

- Douglas Frayne Sargonic and Gutian Periods, 2334-2113 BCDokument182 SeitenDouglas Frayne Sargonic and Gutian Periods, 2334-2113 BClibrary364100% (3)

- ATLAS CYLINDER LUBRICATOR MANUALDokument36 SeitenATLAS CYLINDER LUBRICATOR MANUALKaleb Z king webNoch keine Bewertungen

- On MCH and Maternal Health in BangladeshDokument46 SeitenOn MCH and Maternal Health in BangladeshTanni ChowdhuryNoch keine Bewertungen

- UNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Dokument6 SeitenUNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Bergonsolutions AingelNoch keine Bewertungen

- 2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsDokument15 Seiten2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsSamuel PintoNoch keine Bewertungen

- Nec TutorialDokument5 SeitenNec TutorialbheemasenaNoch keine Bewertungen

- Avance Collection Mixer Grinder SpecsDokument3 SeitenAvance Collection Mixer Grinder SpecsfaNoch keine Bewertungen

- Single-phase half-bridge inverter modes and componentsDokument18 SeitenSingle-phase half-bridge inverter modes and components03 Anton P JacksonNoch keine Bewertungen

- Academic Language Use in Academic WritingDokument15 SeitenAcademic Language Use in Academic WritingDir Kim FelicianoNoch keine Bewertungen

- Yayasan Pendidikan Ramadanthy Milad Anniversary SpeechDokument6 SeitenYayasan Pendidikan Ramadanthy Milad Anniversary SpeechDina Meyraniza SariNoch keine Bewertungen

- Delhi Police ResultDokument26 SeitenDelhi Police ResultExam Aspirant100% (1)

- Encrypt and decrypt a file using AESDokument5 SeitenEncrypt and decrypt a file using AESShaunak bagadeNoch keine Bewertungen

- PPPoE Packet Format - HCNADokument6 SeitenPPPoE Packet Format - HCNARobert Sanchez OchochoqueNoch keine Bewertungen

- RRC Igc1Dokument6 SeitenRRC Igc1kabirNoch keine Bewertungen

- Packetfence Network Devices Configuration Guide: For Version 3.5.0Dokument76 SeitenPacketfence Network Devices Configuration Guide: For Version 3.5.0René FabricioNoch keine Bewertungen

- Iwwusa Final Report IdsDokument216 SeitenIwwusa Final Report IdsRituNoch keine Bewertungen

- Ti 1000 0200 - enDokument2 SeitenTi 1000 0200 - enJamil AhmedNoch keine Bewertungen

- Cambridge IGCSE: 0450/11 Business StudiesDokument12 SeitenCambridge IGCSE: 0450/11 Business StudiesGodfreyFrankMwakalingaNoch keine Bewertungen

- Food 8 - Part 2Dokument7 SeitenFood 8 - Part 2Mónica MaiaNoch keine Bewertungen

- Diwali - An Overview of The Festival of LightsDokument3 SeitenDiwali - An Overview of The Festival of LightsSumeetNoch keine Bewertungen

- Lect 1.2 Principles of Food Process DesignDokument43 SeitenLect 1.2 Principles of Food Process Designmahmoud hassanNoch keine Bewertungen

- Chair Locker Provides Storage and Space SavingsDokument32 SeitenChair Locker Provides Storage and Space SavingsElza S. GapuzNoch keine Bewertungen

- Modul English For Study SkillsDokument9 SeitenModul English For Study SkillsRazan Nuhad Dzulfaqor razannuhad.2020Noch keine Bewertungen

- Participatory Assessment of Ragay Gulf Resources and SocioeconomicsDokument167 SeitenParticipatory Assessment of Ragay Gulf Resources and SocioeconomicsCres Dan Jr. BangoyNoch keine Bewertungen

- Plant Processes: Lesson 3Dokument3 SeitenPlant Processes: Lesson 3Kayla Ta’jaeNoch keine Bewertungen

- Upper Six 2013 STPM Physics 2 Trial ExamDokument11 SeitenUpper Six 2013 STPM Physics 2 Trial ExamOw Yu Zen100% (2)

- Mobile-Friendly Cooperative WebDokument7 SeitenMobile-Friendly Cooperative WebWahyu PNoch keine Bewertungen

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDokument10 SeitenChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINoch keine Bewertungen