Beruflich Dokumente

Kultur Dokumente

Report Draft

Hochgeladen von

anon_832740578Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Report Draft

Hochgeladen von

anon_832740578Copyright:

Verfügbare Formate

Observations:

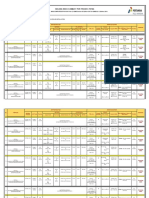

400gm of Cement(OPC)

Consistency 29%

Initial Setting Time 115min

Final Setting Time 170min

10% Sugar; 40gm Sugar+ 360gm Cement(OPC)

Type of Mixing 2 min dry mixing of sugar and

cement followed by 3 min wet

mixing

Sugar ,cement and water mixed

simultaneously for 3 min

Initial Setting Time(min) <10 16.15

Final Setting time(min) <14 20.25

20% Sugar; 80gm Sugar+ 320gm Cement(OPC)

Type of Mixing 2 min dry mixing of sugar and

cement followed by 3 min wet

mixing

Sugar ,cement and water mixed

simultaneously for 3 min

Initial Setting Time(min) 51.3 31.3

Final Setting time(min) 102.3 39.57

5% Sugar; 20gm Sugar+ 380gm Cement(OPC)

Type of Mixing 2 min dry mixing of sugar and

cement followed by 3 min wet

mixing

Sugar ,cement and water mixed

simultaneously for 3 min

Initial Setting Time(min) <12(approx.btw 11 and 12) 11.45

Final Setting time(min) 16 15.3

15% Sugar; 60gm Sugar+ 340gm Cement(OPC)

Type of Mixing 2 min dry mixing of sugar and

cement followed by 3 min wet

mixing

Sugar ,cement and water mixed

simultaneously for 3 min

Initial Setting Time(min) 14.40 16.51

Final Setting time(min) 19.23 21.42

3% Salt + 7% Sugar; 12gm Salt + 28gm Sugar + 360gm Cement(OPC)

(dry mixing followed by wet mixing)

Initial Setting Time(min) 14

Final Setting time(min) 20

*T1: Type 1 mixing: 2 min dry mixing of Sugar and Cement followed by 3 min mixing with water

*T2: Type 2 mixing: Sugar, Cement and water mixed simultaneously for 3 min

y = 0.384x

2

- 7.124x + 38.85

y = 0.8507x

2

- 15.985x + 78.188

0

20

40

60

80

100

120

0 5 10 15 20 25

Effect of Sugar on Setting time of Cement

(T1 mixing*)

Intial setting time

Final setting time

Poly. (Intial setting time)

Poly. (Final setting time)

y = 0.1009x

2

- 1.3243x + 16.488

y = 0.132x

2

- 1.8204x + 22.14

y = 0.384x

2

- 7.124x + 38.85

y = 0.8507x

2

- 15.985x + 78.188

0

20

40

60

80

100

120

0 5 10 15 20 25

Effect of Sugar on Setting time for T1 and T2

Mixing

Initial Setting time (T2)

Final Setting time (T2)

Intial setting time(T1)

Final setting time(T1)

Poly. (Initial Setting time

(T2))

Poly. (Final Setting time (T2))

Poly. (Intial setting time(T1))

Poly. (Final setting time(T1))

10% Jaggery; 40gm Jaggery+ 360gm Cement(OPC)

Initial Setting Time(min) 13-15

Final Setting time(min) 17

20% Jaggery; 80gm Jaggery+ 320gm Cement(OPC)

Initial Setting Time(min) 23

Final Setting time(min) 30

5% Jaggery; 20gm Jaggery+ 380gm Cement(OPC)

Initial Setting Time(min)

Final Setting time(min)

15% Jaggery; 60gm Jaggery+ 340gm Cement(OPC)

Initial Setting Time(min)

Final Setting time(min)

Remarks:

10% Sugar :

Initially, the paste with 10% Sugar is more flowable when compared to OPC

The initial and final setting time occurred within 15 min

High heat of hydration observed when compared to that of normal OPC

Initial and final setting time were not observed sharply

In case of T2 mixing, very little cracks were observed

20% Sugar (T1 mixing*):

Very less amount of heat of hydration

Setting and Hardening occurred almost simultaneously

More number of cracks observed in the hardened specimen

The mix has good binding property (mix has both cohesive and adhesive property)

15 % Sugar:

Good Finishing

More Heat Liberated compared 5% Sugar

* No significant difference in the properties (other than setting time) are observed between T1 and

T2 mixing of sugar

10% Jaggery (T1 mixing*):

Highly Flowable Mix (initially)

High heat of Hydration

The mix is sticky

20% Jaggery (T1 mixing*):

Hard Layer is Formed on the Surface

* The paste is more viscous in case of Jaggery when compared to Sugar

10% Salt (T1 mixing*):

The mix formed is more stiff compared to that of sugar and Jaggery

Liquidity increased upon salt dissolution

Bleed Water is Observed(Water started to come out of the Vicat Mould)

20% Salt (T1 mixing*):

Stiffer mix when compared to 10% Salt

The Hardened Specimen has very high toughness

10% Fenugreek (T1 mixing*):

More amount of water is required to form a paste (about 50ml is added extra i.e. about

225 ml of water is added to form the mix )

No bonding observed (The mix behaved just like sand and water mixture)

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tamiya Colour ChartDokument7 SeitenTamiya Colour Chartmike_hobbs_6100% (3)

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Dokument1 SeiteQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13Noch keine Bewertungen

- Shoroye - 18cf023998 - Che 320 - Term PaperDokument10 SeitenShoroye - 18cf023998 - Che 320 - Term PaperModesola ShoroyeNoch keine Bewertungen

- Paint Method Statement LE 2473 01Dokument5 SeitenPaint Method Statement LE 2473 01eklavyak076757Noch keine Bewertungen

- CMT Braze+: James Evans Segment Manager Robotics Fronius UK LTDDokument11 SeitenCMT Braze+: James Evans Segment Manager Robotics Fronius UK LTDJaviNoch keine Bewertungen

- 43 - Hofmann - Portable Machine Tools Brochure - A4Dokument2 Seiten43 - Hofmann - Portable Machine Tools Brochure - A4Jorge VillalobosNoch keine Bewertungen

- Ydr DMSF SDokument2 SeitenYdr DMSF SFelipeNoch keine Bewertungen

- Physical Vapor DepositionDokument20 SeitenPhysical Vapor DepositionPraveen KumarNoch keine Bewertungen

- IP List - Resin Bonded-Updated-17.09.2021Dokument2 SeitenIP List - Resin Bonded-Updated-17.09.2021sumitNoch keine Bewertungen

- Covalence HTLP80-HP: Product Data SheetDokument2 SeitenCovalence HTLP80-HP: Product Data SheetMahmoud TahaNoch keine Bewertungen

- Asme Ix PT QB Article Xi QB 100 Brazing General RequirementsDokument5 SeitenAsme Ix PT QB Article Xi QB 100 Brazing General RequirementsGabriel Giampietro de AndradeNoch keine Bewertungen

- BME RFI Template - Supplier Profile - 2021Dokument30 SeitenBME RFI Template - Supplier Profile - 2021Amir KaračićNoch keine Bewertungen

- Distillation Worksheet What Is Distillation?Dokument3 SeitenDistillation Worksheet What Is Distillation?Rigen AlamNoch keine Bewertungen

- 6255 - Full-Circle Casing ScraperDokument8 Seiten6255 - Full-Circle Casing Scrapermaulana hapidNoch keine Bewertungen

- Update Stock Material Pemboran (29 Agustus 2017)Dokument230 SeitenUpdate Stock Material Pemboran (29 Agustus 2017)arrelandrawanNoch keine Bewertungen

- Mtech. Design For Manufacturing and AssemblyDokument5 SeitenMtech. Design For Manufacturing and AssemblysimalaraviNoch keine Bewertungen

- Ebikemefa E. Clinton - Presentation On (Srim) ProcessDokument10 SeitenEbikemefa E. Clinton - Presentation On (Srim) ProcessClinton E EbikemefaNoch keine Bewertungen

- Patent of Quench TankDokument9 SeitenPatent of Quench TankAbdulrahman ezzaldeenNoch keine Bewertungen

- Data Sheet P 550: Technical InformationDokument1 SeiteData Sheet P 550: Technical InformationappoosdxbNoch keine Bewertungen

- List Applicable WPS Piping & PipelineDokument6 SeitenList Applicable WPS Piping & PipelineFerdie OSNoch keine Bewertungen

- Abrasive Jet MachiningDokument8 SeitenAbrasive Jet MachiningRanjith KaruturiNoch keine Bewertungen

- CSF-71T Technical Report EN - V2Dokument7 SeitenCSF-71T Technical Report EN - V2Miroslav ThôngNoch keine Bewertungen

- ReactorsDokument814 SeitenReactorsAhmed NasrNoch keine Bewertungen

- Flexi Band: Universal Single-Sided High-Adhesive TapeDokument2 SeitenFlexi Band: Universal Single-Sided High-Adhesive TapeMarina MelentiNoch keine Bewertungen

- Name of Project Facility For Manufacturing of Disposable SyringesDokument1 SeiteName of Project Facility For Manufacturing of Disposable SyringesEyock PierreNoch keine Bewertungen

- 04 ExtrusionDokument57 Seiten04 Extrusion9811923100% (1)

- Test For Spray RateDokument61 SeitenTest For Spray Ratenitish JhaNoch keine Bewertungen

- 1999 - Us5931240 - Drill Bit Concave Steering Channel For Horizontal Directional DrillingDokument7 Seiten1999 - Us5931240 - Drill Bit Concave Steering Channel For Horizontal Directional DrillingCường Nguyễn QuốcNoch keine Bewertungen

- Hydrogen Supplementation in CI EnginesDokument21 SeitenHydrogen Supplementation in CI EnginesHarman Singh NagpalNoch keine Bewertungen

- Microfine Filters - CapsulesDokument1 SeiteMicrofine Filters - CapsulesRashid Khalifa RehmanNoch keine Bewertungen