Beruflich Dokumente

Kultur Dokumente

Health & Safety Inspection Report No.18. Reply

Hochgeladen von

loveson709Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Health & Safety Inspection Report No.18. Reply

Hochgeladen von

loveson709Copyright:

Verfügbare Formate

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Location:Al Kheesa (All Areas)

Ref. No.18

Inspection Team: Aheer Abdul (Hyder) Antonio Resus (Hyder),

Report Issued by: Aheer Abdul Date: 18-August-2014

Site Safety Review / Inspection Report

Serial

no

Description Item

Serial

no

Description Item

1 Site Access / Egress 1 16 Barricading/Cones/Warning Tapes 1

2 House-keeping 1 17 Signage 1

3 PPE Usage 2 18 Earthmoving machines 2

4 Scaffolds 2 19 Illumination 2

5 Work at heights 1 20 Environment Protection 1

6 Electrical Installations 2 21 Confined Spaces 4

7 Electric Tools 3 22 Chemical Handling N/A

8 Lifting gears 4 23 Gas cutting / Welding operations N/A

9 Excavations 1 24 Contractor's Weekly Inspections 2

10 Permit to Work 4 25 Speed Control - Vehicles 1

11 Fire Protection 2 26 Relevant Toolbox Talks 2

12 Welfare Facilities 2 27 First - Aid Procedures 2

13 Lifting Operations 3 28 Emergency Procedures 2

14 Ladders 2 29 Traffic Plan 3

15 Edge Protection 1 30 Storage Procedures 2

Item Score:1 = Immediate Action Required; 2 = Action Required; 3 = Observation; 4 = No Problems Found;5 = Favorable Observation; 6= Good; X = Not Inspected; NA = Not Applicable

Prepared by: Aheer Abdul Date: 18-August-2014 Signature................ Hyder Representative: RE.

---------------------------------------------------------------------------------------------------------------------

Actions Confirmed by Project Manager: Date: ............... Signature: ...................

Confirmation by SRE: .. Date: ................. Signature: ....................

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Date

Closed

(GOOD PRACTICE)

Recommendations / Actions to Improve:

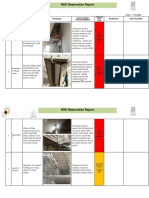

Item No:1

Housekeeping around the Shaft No: 21 appreciably improved.

Keep going such a good practices.

Action Taken by Contractor:

25

L Immediate

Recommendations / Actions to Improve:

Item No:2

Most of the vehicles are over speeding at site. The drivers and

operators are not following site specific speed limit.

Always follow site speed limit to avoid collision.

Provide defensive driving training to all drivers and

operators.

Proper monitoring/supervision required.

Implement penalty system for violators.

Always follow QCS 2010 standards.

Action Taken by Contractor:

Install site speed limit boards and issue internal memo for all

staff and employees. See attached picture and memo.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Date

Closed

15,16,19

L Immediate

Recommendations / Actions to Improve:

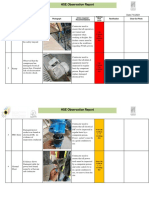

Item No:3

Excavation without Edge protection Road No: 23. Deep

excavation extended to outside fence without Public protection.

Install hard barriers, flash lights & sign boards.

Regular inspection and monitoring.

Implement penalty system for violators.

Action Taken by Contractor:

Install plastic barriers and blinking light to protect that extended

excavation

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

25,26

L Immediate

Recommendations / Actions to Improve:

Item No:4

Most of the vehicles are not following defensive driving system.

Operators and drivers are not turned on warning devices while

at work (Amber beacon lights).

Provide Training and Toolbox talk.

Proper monitoring/supervision required.

Implement penalty system for violators.

Always follow QCS 2010 standards.

Action Taken by Contractor:

Tool box talk conducted regarding defensive driving system.

See attached tool box talk.

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Date

Closed

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

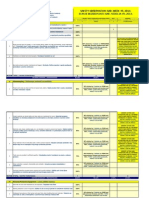

3,26

L Immediate

Recommendations / Actions to Improve:

Item No:5

Working without personnel Safety - Most of the contractors

employees working without minimum PPE (No jacket, No

helmet, No coverall)

Never permit to work without Proper PPE.

Never allowed to work national/cultural dress (i.e. loose

clothing).

TBT must be given frequently.

Regular inspection and monitoring required.

Implement penalty system for violators.

Action Taken by Contractor:

PPE awareness workshop /TBT conducted. See attached tool

box talk.

2,20,30

L Immediate

Item No:6

Lack of Housekeeping- Most of the site areas found unsafe due

to lack of housekeeping(wooden wastes, steel wastes, tyre

wastes, damaged cables, food wastes, damaged plastic

barriers and other Plastic wastes were scattered.

All wastes must be segregated and disposed properly.

Regular inspection and monitoring required.

Action Taken by Contractor:

Housekeeping team start working under supervision of CGC

environmental officer. They are doing full time housekeeping

activities in site. And 4 big skips placed in different areas in site

dumping waste materials.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Date

Closed

25,26

L Immediate

Recommendations / Actions to Improve:

Item No:7

Unsafe practices- Most of the heavy equipments are working

with fully/partially covered drivers cabin. The artificially

covered cabin will obstruct operators visibility and leads to

collision.

Never allowed to work with such artificially covered

cabins.

TBT must be given frequently.

Regular inspection and monitoring required.

Implement penalty system for violators.

Action Taken by Contractor:

Given verbal information to all of the operators regarding this

topic and issue a internal memo for subcontractor and CGC jv

Sacyr staffs, operatives.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

14,4,5

L Immediate

Recommendations / Actions to Improve:

Item No:8

Unsafe working platform-Labourers working on Manhole steel

structures without fall protection. No scaffolding, safety

harness and proper ladders for access/egress.

All works should be carried out as per QCS 2010 standards

Never allowed to work unsafe working platform.

Proved certified Ladders/Scaffold for Working at Height.

All critical works must be managed and supervised by

competent person

Action Taken by Contractor:

Work suspended immediately and scaffolding training on-going

after training certified scaffolder will erect proper working

platform for work at height.

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Serial No.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

2,15,16,17,

19

L Immediate

Recommendations / Actions to Improve:

Item No:8

Site access towards deep excavation without protection in

Road No: 41. (No barrication, hazard warning signs and

warning lights Public protection/accident prevention not

addressed. Also plastic barriers placed as protection without

water.

Provide Hard barriers(Concrete barriers/Cable fence)

Install signboards, flash lights and informatory signs

and illuminated stickers to warn public.

Regular inspection and monitoring required.

All the plastic barriers should be water filled.

Implement penalty system for violators.

Action Taken by Contractor:

Install public protection with green mesh, plastic barriers and

blinking light and sign boards.

18

L Immediate

Recommendations / Actions to Improve:

Item No:09

Unsafe transportation Labourers travelling on heavy

equipment (Equipment No: 28260 JCB and 28789 Grader).

Provide proper and safe transportation.

Never permitted to travel on equipment other than the

operator.

Regular inspection and monitoring required.

Implement penalty system for violators.

Action Taken by Contractor:

Issue warning letter for above mentioned equipment operators.

Issue internal memo regarding safe transportation of

operatives to increase awareness. See attached memo.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Serial No.

28,27

L Immediate

Item No:10

Emergency contact information and arrangements No

emergency arrangement and informatory signboard at site.

Install emergency informatory signboard in each

location. (Contact Number of Police, Ambulance, Civil

Defence, First Aider, Fire warden/fighter and Safety

officers for the area).

Action Taken by Contractor:

Emergency informatory signboard placed in different areas of

site.

12

L Immediate

Recommendations / Actions to Improve:

Item No:11

Lack of welfare arrangements Labourers are used to rest

under the wooden pieces, inside the pipes. Labourers urinating

at site. No proper arrangements for drinking water, labourers

complaining about welfare facilities.

Provide safe and standard shelter for resting.

Arrange toilet units for basic needs.

Distribute chilled water frequently at site.

Action Taken by Contractor:

Install 6 shaded rest areas in site and clean and supply water

inside toilets (total 6 toilets in site). To solve cold water issue

CGC buy 2 new deep freezer machine in additional to two ice

maker machine. Additional one water supplying half lorry start

supplying water in site.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Serial

No.

Observations

(Photograph (7.0x9.3) & Description)

Risk

(H M L)

Time for

Close out

Observations / Actions

Serial No.

24

L Immediate

Item No:12

Lack of monitoring and supervision During the three hours of

site visit, we didnt met any safety professional at site.

Appoint sufficient number of safety professionals at

site.

All the critical activities must be monitored by

competent persons/HS officers.

Rectify all unsafe acts/conditions immediately

Action Taken by Contractor:

3 full time safety officers, 3 safety foreman, one full time safety

officer (sub-contractor) are available full time in site. For

monitoring them 2 senior safety officers and one environmental

officer and one HSE manager is available. Please find

attached organization chart.

Safety Inspection Report

H&S/FM/09/SAF INSP

July 2012

Das könnte Ihnen auch gefallen

- Epoxy COSHHDokument3 SeitenEpoxy COSHHloveson709Noch keine Bewertungen

- HSE Violation & PenaltiesDokument5 SeitenHSE Violation & PenaltiesVladimir Radovanovic100% (1)

- (Bibiyana - III) HSE Observation Report March 12 2018Dokument24 Seiten(Bibiyana - III) HSE Observation Report March 12 2018Reaz Uddin100% (2)

- Safety ObservationDokument76 SeitenSafety Observationsrinibas mohapatra0% (1)

- Consultant Safety Observation 06-09-2020Dokument7 SeitenConsultant Safety Observation 06-09-2020Farhat Sethar100% (2)

- HSE Observation Card LogDokument1 SeiteHSE Observation Card Logramod100% (1)

- Safety Observation Report: Critical FavorableDokument2 SeitenSafety Observation Report: Critical Favorablewendypost73Noch keine Bewertungen

- Near Miss: Bureau of Workers' Compensation PA Training For Health & Safety (Paths)Dokument28 SeitenNear Miss: Bureau of Workers' Compensation PA Training For Health & Safety (Paths)Wahyu ArdaniNoch keine Bewertungen

- Observation Note HSEDokument2 SeitenObservation Note HSESuman Koley100% (2)

- App-16.2 - Risk Assessment For Vermeer Axis WorksDokument13 SeitenApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709Noch keine Bewertungen

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDokument15 SeitenApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709Noch keine Bewertungen

- Recuperadora Terex Rs425c Operacion y MantenimientoDokument199 SeitenRecuperadora Terex Rs425c Operacion y Mantenimientosergio100% (10)

- Strategies To Prevent Fatalites and Severe Loss EventsDokument35 SeitenStrategies To Prevent Fatalites and Severe Loss EventsSreekumarNoch keine Bewertungen

- SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift ProcedureDokument10 SeitenSCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedureloveson709100% (1)

- Rig - 1 - Safety Observation Report#75Dokument1 SeiteRig - 1 - Safety Observation Report#75Jennifer WangNoch keine Bewertungen

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDokument3 Seiten2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNoch keine Bewertungen

- HSE Committee Meeting Rev1Dokument25 SeitenHSE Committee Meeting Rev1Khaled Ismail100% (1)

- Safety ObservationDokument48 SeitenSafety Observationpooloo70100% (1)

- App-16.2 - Risk Assessment For Traffic Signal SystemDokument13 SeitenApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- Safe Use of Power Tools Rev0Dokument92 SeitenSafe Use of Power Tools Rev0mohapatrarajNoch keine Bewertungen

- Safety ReportDokument6 SeitenSafety ReportMuhammad Zarif Amir100% (6)

- Safety Induction TrainingDokument62 SeitenSafety Induction TrainingIGede Sumantra100% (2)

- JSA Template 2017-05-30 Powder Actuated ToolsDokument19 SeitenJSA Template 2017-05-30 Powder Actuated ToolsJayvee Baradas Valdez100% (2)

- Air Law Complete PDFDokument344 SeitenAir Law Complete PDFPilot0% (1)

- Projects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SDokument5 SeitenProjects Transmission Department HSE Inspection Report: # 3091800062 & 63 132/11kV Makhazen S/SAnonymous kWfNFb100% (1)

- Fire Drill Mock Drill (Al-Uqair A)Dokument8 SeitenFire Drill Mock Drill (Al-Uqair A)EsamKhalilAlQadiNoch keine Bewertungen

- Health & Safety Inspection ReportDokument3 SeitenHealth & Safety Inspection ReportLeonardoViannaNoch keine Bewertungen

- Behavior-based safety A Clear and Concise ReferenceVon EverandBehavior-based safety A Clear and Concise ReferenceNoch keine Bewertungen

- Safety Induction For Visitor (English)Dokument66 SeitenSafety Induction For Visitor (English)IGede Sumantra75% (12)

- Safety Joint Inspection Report 9-ReplyDokument12 SeitenSafety Joint Inspection Report 9-Replyloveson709100% (1)

- Near Miss Report: Complete This Form and Email It ToDokument1 SeiteNear Miss Report: Complete This Form and Email It Toloveson709Noch keine Bewertungen

- Hse Close Out Report PresentationDokument31 SeitenHse Close Out Report PresentationLuqman Osman100% (10)

- Safety Alert: Incident SummaryDokument1 SeiteSafety Alert: Incident SummaryAnonymous 3eHGEDbx100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDokument1 SeiteJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNoch keine Bewertungen

- App-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.Dokument15 SeitenApp-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.loveson709100% (1)

- Site ObservationDokument8 SeitenSite ObservationAzhari KlewanNoch keine Bewertungen

- Daily Report 14, AUG 15Dokument10 SeitenDaily Report 14, AUG 15jacklin2012Noch keine Bewertungen

- ZFP Sor 2022-12-1Dokument6 SeitenZFP Sor 2022-12-1irfan shafiqueNoch keine Bewertungen

- Date Observation Action Location Company Due Date StatusDokument3 SeitenDate Observation Action Location Company Due Date Statusnsy2204100% (1)

- Emergency Rescue Plan For Operatives Working at HeightDokument9 SeitenEmergency Rescue Plan For Operatives Working at Heightloveson709Noch keine Bewertungen

- Emergency Rescue Plan For Operatives Working at HeightDokument9 SeitenEmergency Rescue Plan For Operatives Working at Heightloveson709Noch keine Bewertungen

- Observation Report 3b 2Dokument4 SeitenObservation Report 3b 2Amobi EvidenceNoch keine Bewertungen

- Safety AlertDokument2 SeitenSafety Alertjo123nNoch keine Bewertungen

- EI General Safety InspectionDokument8 SeitenEI General Safety InspectionKrishna Jasha100% (2)

- 2020.09.15 FINAL 737 MAX Report For Public ReleaseDokument245 Seiten2020.09.15 FINAL 737 MAX Report For Public ReleaseZerohedge100% (6)

- 2013 Mom Hse 033 PDFDokument18 Seiten2013 Mom Hse 033 PDFebsmsartNoch keine Bewertungen

- HSE Monthly ReportDokument11 SeitenHSE Monthly ReportAlfredo Medina Cano100% (7)

- SAFETY Statistics AprDokument1 SeiteSAFETY Statistics AprSantos RexNoch keine Bewertungen

- 02, Jan, 2022 Azmeel TCF-3 HSE Daily Observation ReportDokument2 Seiten02, Jan, 2022 Azmeel TCF-3 HSE Daily Observation ReportSheri DiĺlNoch keine Bewertungen

- Safety Alert - EnglishDokument1 SeiteSafety Alert - Englishjamilhse7759100% (1)

- Month Wise Checklist For Submission of Various ReturnsDokument3 SeitenMonth Wise Checklist For Submission of Various Returnsadith24Noch keine Bewertungen

- Hse Enforcement Report - May 24, 2014Dokument4 SeitenHse Enforcement Report - May 24, 2014yelsa otrebla100% (1)

- HSE Requirements For Subcontractors-13!8!2013 - EnglishDokument14 SeitenHSE Requirements For Subcontractors-13!8!2013 - EnglishRonald CorralesNoch keine Bewertungen

- ConstructionDokument13 SeitenConstructionmilan shrestha73% (11)

- QDC No ObjectionDokument1 SeiteQDC No Objectionloveson70950% (2)

- Incident Checklist: Other ActionsDokument1 SeiteIncident Checklist: Other Actionsloveson709Noch keine Bewertungen

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDokument3 Seiten2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNoch keine Bewertungen

- ZFP Sor 2021-6-7Dokument5 SeitenZFP Sor 2021-6-7Muhammad JamshidNoch keine Bewertungen

- Contractors Safety ObservationsDokument3 SeitenContractors Safety ObservationsFarrukh JavedNoch keine Bewertungen

- Safety AlertDokument1 SeiteSafety Alertindrak1978Noch keine Bewertungen

- Eye Protection Safety CampaignDokument11 SeitenEye Protection Safety CampaignLamtua Purba100% (2)

- Igc 3 Practical NeboshDokument20 SeitenIgc 3 Practical NeboshAdnan50% (14)

- 306756-000 2002 - February PDFDokument614 Seiten306756-000 2002 - February PDFduongpn50% (4)

- Hse Daily Report 25 Jan 23Dokument5 SeitenHse Daily Report 25 Jan 23FdrianRidhoNoch keine Bewertungen

- ZFP Sor 2021-6-14Dokument5 SeitenZFP Sor 2021-6-14Muhammad JamshidNoch keine Bewertungen

- Loveson Resume HSE ManagerDokument7 SeitenLoveson Resume HSE Managerloveson709Noch keine Bewertungen

- Safety Observation Report: PROJECT: Science MuseumDokument4 SeitenSafety Observation Report: PROJECT: Science Museumfaisal nadeemNoch keine Bewertungen

- Intro Piper AlphaDokument7 SeitenIntro Piper AlphaUmmiey SyahirahNoch keine Bewertungen

- RB - HSE Daily Observation Report Dated 01.07.2021.Dokument4 SeitenRB - HSE Daily Observation Report Dated 01.07.2021.Idris Adeniran100% (1)

- The Result of Poor Cockpit DisciplineDokument16 SeitenThe Result of Poor Cockpit Disciplinevikash_kumar_thakur100% (1)

- Army Aviation Digest - Jul 1977Dokument52 SeitenArmy Aviation Digest - Jul 1977Aviation/Space History LibraryNoch keine Bewertungen

- NEB HSE Observations For LOR On Dated 16-Dec-2014Dokument2 SeitenNEB HSE Observations For LOR On Dated 16-Dec-2014writemeyouNoch keine Bewertungen

- GC 3 Oberservation SheetDokument4 SeitenGC 3 Oberservation SheetIrshad Ali Solangi33% (3)

- Management Walkthrough Observation 22 August 2019Dokument6 SeitenManagement Walkthrough Observation 22 August 2019rodman82350% (2)

- FDNY Report On Fatal Fire, September 13, 1991Dokument11 SeitenFDNY Report On Fatal Fire, September 13, 1991City Limits (New York)100% (1)

- Kabit System CasesDokument4 SeitenKabit System CasesKevin AmanteNoch keine Bewertungen

- Henry Extensile ExposureDokument136 SeitenHenry Extensile ExposureSSNoch keine Bewertungen

- NEBOSH GC3 Observations Sheet SampleDokument12 SeitenNEBOSH GC3 Observations Sheet SampleShezi Bhatti100% (3)

- Hazard Checklists LinksDokument2 SeitenHazard Checklists LinksLuis Enrique100% (1)

- Safety PORR SAR - Week 49-2013Dokument11 SeitenSafety PORR SAR - Week 49-2013Darjan VeličkovNoch keine Bewertungen

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Dokument24 Seiten3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- INV Inv Ass Form TemplateDokument4 SeitenINV Inv Ass Form Templateloveson70950% (2)

- Assmt 1 Incident PhotosDokument3 SeitenAssmt 1 Incident Photosloveson709Noch keine Bewertungen

- INV Action Plan TemplateDokument2 SeitenINV Action Plan Templateloveson709Noch keine Bewertungen

- Maintenance Log - TemplateDokument2 SeitenMaintenance Log - Templateloveson709Noch keine Bewertungen

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Dokument24 Seiten3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- Yam Bahadur Budha CV PDFDokument2 SeitenYam Bahadur Budha CV PDFloveson709Noch keine Bewertungen

- RA082-C Grinding - ThornliebankDokument2 SeitenRA082-C Grinding - Thornliebankloveson709Noch keine Bewertungen

- Scaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557Dokument2 SeitenScaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557loveson709Noch keine Bewertungen

- Scaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557Dokument2 SeitenScaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557loveson709Noch keine Bewertungen

- 005 Ohs-Cop-Starrt & JhaDokument10 Seiten005 Ohs-Cop-Starrt & Jhaloveson709Noch keine Bewertungen

- PMC-FM-HSS-024 Near Miss ReportDokument1 SeitePMC-FM-HSS-024 Near Miss Reportloveson709Noch keine Bewertungen

- N.Selvam:, BE (Mechanical)Dokument2 SeitenN.Selvam:, BE (Mechanical)loveson709Noch keine Bewertungen

- HSE Department Demobilization List: Trade May 2016Dokument1 SeiteHSE Department Demobilization List: Trade May 2016loveson709Noch keine Bewertungen

- Loveson Glariyans: (Address, City, ST ZIP Code)Dokument2 SeitenLoveson Glariyans: (Address, City, ST ZIP Code)loveson709Noch keine Bewertungen

- Board Reqd From AlkheesaDokument1 SeiteBoard Reqd From Alkheesaloveson709Noch keine Bewertungen

- Po Ak-00076 - MR 534Dokument1 SeitePo Ak-00076 - MR 534loveson709Noch keine Bewertungen

- HSE Department Demobilization List: Trade May 2016Dokument1 SeiteHSE Department Demobilization List: Trade May 2016loveson709Noch keine Bewertungen

- CG-6505 Final Investigation Results (1!29!10)Dokument3 SeitenCG-6505 Final Investigation Results (1!29!10)cgreportNoch keine Bewertungen

- Marcus Soos Accident April 19Dokument3 SeitenMarcus Soos Accident April 19api-310805543Noch keine Bewertungen

- Crashing Activity ExamplesDokument12 SeitenCrashing Activity ExamplesQaisar KhanNoch keine Bewertungen

- BG-LifeSavers Booklet v2010Dokument24 SeitenBG-LifeSavers Booklet v2010Achraf BoudayaNoch keine Bewertungen

- Byrd ComplaintDokument21 SeitenByrd ComplaintWSETNoch keine Bewertungen

- High Bird Operations Manual: MARCH 2012Dokument26 SeitenHigh Bird Operations Manual: MARCH 2012Dennis CarrNoch keine Bewertungen

- The Five Orange Pips: Arthur Conan DoyleDokument11 SeitenThe Five Orange Pips: Arthur Conan Doylereza khoshbakhtNoch keine Bewertungen

- English Radio Play - HelenDokument11 SeitenEnglish Radio Play - HelenHelen KemprecosNoch keine Bewertungen

- Taffic Management Plan - 1Dokument26 SeitenTaffic Management Plan - 1SudarshanShanNoch keine Bewertungen

- Fire Accident at JaipurDokument19 SeitenFire Accident at JaipurShaji HakeemNoch keine Bewertungen

- Phases of FlightDokument4 SeitenPhases of FlightJorgeNoch keine Bewertungen

- Sabk Maahad Islahiah Addiniah: Prepared by Noor Azlina BT Said English Panel HeadDokument9 SeitenSabk Maahad Islahiah Addiniah: Prepared by Noor Azlina BT Said English Panel HeadNoor Azlina SaidNoch keine Bewertungen

- Toledo CatalogueDokument26 SeitenToledo CatalogueStevoIlicNoch keine Bewertungen

- Chemicals Zetag MSDS Beads Zetag 7565 - 0710Dokument6 SeitenChemicals Zetag MSDS Beads Zetag 7565 - 0710PromagEnviro.comNoch keine Bewertungen

- Nedlloyd Vespucci and WahkunaDokument58 SeitenNedlloyd Vespucci and WahkunaLyubomir IvanovNoch keine Bewertungen

- Final Report On Accident Involving Diamond Da-42 Aircraft VT-NFM Operated by National Flying Training Institute ON 26/04/2017 AT GONDIADokument49 SeitenFinal Report On Accident Involving Diamond Da-42 Aircraft VT-NFM Operated by National Flying Training Institute ON 26/04/2017 AT GONDIAKumar ManurajNoch keine Bewertungen

- Reading Comprehension: SubjectDokument3 SeitenReading Comprehension: SubjectMiguel OsorioNoch keine Bewertungen

- Cracks in Propeller HubDokument2 SeitenCracks in Propeller Hublitos_92Noch keine Bewertungen