Beruflich Dokumente

Kultur Dokumente

Sand and Metal Casting Processes and Techniques

Hochgeladen von

natrix0290 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

10 Ansichten2 SeitenSand and Metal Casting Processes and Techniques

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSand and Metal Casting Processes and Techniques

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

10 Ansichten2 SeitenSand and Metal Casting Processes and Techniques

Hochgeladen von

natrix029Sand and Metal Casting Processes and Techniques

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Precision Machined Component

Sand and Metal Casting Processes and Techniques

There are various casting processes being implemented now days.

Sand Casting: Sand casting mold involves forming a mixture of sand and casting

pouring liquid more li!ely a molten metal into the mold. The metal is then allowed

to solidify and mold removal is carried out. Sand molding consists of two types:

green sand method and the method of air assembly. The "rst consists in mixing the

clay moisture silica and many other additives. The second consists of a mixture of

dry sand and other clay materials not moist. They are mixed with the aid of a fast

curing adhesive. The collective use of these materials is called #air assembly #.

Sometimes there are temporary plug positioned to pour the liquid to be molded. $ir

%set molds often form molds consisting of two parts: the bottom and the top. The

sand mixture is compressed down after its addition. &ot generate any product. $fter

solidi"cation and cooling of the metal the mold is usually destroyed. This is

because removal involves a lot of last minute and crac!s. Casting accuracy depends

largely on the sand and the molding process used. Castings greensand compounds

result in the formation of rough texture on the surface conversion and this feature

ma!es them easily recogni'able. $ir %set molds smoother castings.

(ftentimes the results of the smelting process in the loss of the components of the

sand mixture. )t is possible to reuse green sand by ad*usting the composition as

additives for moisture lost and replenished. $ll the same pattern is eligible to be

reused to produce new sand molds. The reuse method can be continued for an

inde"nite period. )n +,-. the casting process got partially automates. They have

had a great demand for the development of production lines since.

Tour /ith: Spin Casting 0oundry is best !nown as centrifugal rubber mold 1C2MC3. )t

involves the use of centrifugal force to produce castings rubber mold. $s usual

practice a mold having the shape of a dis! was rotated through its 4 bac!bone 4 to a

pre% determined speed. The material used for casting is usually thermosetting

plastic in liquid or molten metal. 5ets poured into the mold through the aperture in

its center. Corresponding to the solidi"cation of metal or thermosetting plastic

ad*usting the yarn "lled mold is conducted.

Typically organic or silicone rubber vulcani'ed is used as a substrate of casting

molds in turn. The vulcani'ation is conducted in the middle of mold manufacturing

process. $fter successful completion of the vulcani'ation process ventilation and

gate must be brought by the mold. This involves the si'e of the channels to ensure

proper material 6ow and air during the course of casting. $ scalpel or a !nife is used

to carry out the two previous processes. The complexity of the mold is directly

proportional to the time required to implement ventilation and door.

7i*ay )ndustries is leading are Manufacturer exporters and suppliers for C&C Turned

Component and Cnc Machine Parts Sand casting Component )nvestment Casting

Component Pressure 8 5ravity 9ie Cast Component Sub $ssembly.

Das könnte Ihnen auch gefallen

- Ae15301-Aircraft Materials and Manufacturing Technology PDFDokument115 SeitenAe15301-Aircraft Materials and Manufacturing Technology PDFDurai Raj Kumar100% (1)

- Material HandlingDokument8 SeitenMaterial HandlingSuman MukherjeeNoch keine Bewertungen

- Metal Casting and Welding 15Me35ADokument29 SeitenMetal Casting and Welding 15Me35A01061975Noch keine Bewertungen

- Dry Sand Molding & Shell Molding ProcessDokument3 SeitenDry Sand Molding & Shell Molding Processরিপন মন্ডলNoch keine Bewertungen

- Ceramic Materials Unit 5,6Dokument32 SeitenCeramic Materials Unit 5,6Akhil BaaNoch keine Bewertungen

- Department of Industrial & Production Engineering BUET, Dhaka-1000Dokument25 SeitenDepartment of Industrial & Production Engineering BUET, Dhaka-1000Anshul ShuklaNoch keine Bewertungen

- Introduction To Casting Processes: BackgroundDokument5 SeitenIntroduction To Casting Processes: BackgroundSubhasis BiswalNoch keine Bewertungen

- Manufacturing ProcessDokument5 SeitenManufacturing ProcessRk RanaNoch keine Bewertungen

- Chapter Four 4.special Casting Processes: Introduction Contents To Be IncludedDokument76 SeitenChapter Four 4.special Casting Processes: Introduction Contents To Be IncludedberhaneNoch keine Bewertungen

- EVAPORATIVE PATTERN CASTING PROCESSDokument13 SeitenEVAPORATIVE PATTERN CASTING PROCESSMajid RazaqNoch keine Bewertungen

- Carbon-Dioxide Gas MoldingDokument3 SeitenCarbon-Dioxide Gas MoldingdhineshNoch keine Bewertungen

- Part - CDokument27 SeitenPart - CAnonymous 9HNJxBNoch keine Bewertungen

- WPT CastingDokument70 SeitenWPT CastingHuzaifaNoch keine Bewertungen

- Moulding ProcessesDokument10 SeitenMoulding ProcessesChinmay Das67% (3)

- 4castingprocesses 120526012606 Phpapp01Dokument28 Seiten4castingprocesses 120526012606 Phpapp01Chennai TuitionsNoch keine Bewertungen

- 7 Dry Sand MoldingDokument3 Seiten7 Dry Sand MoldingFahri RamadhanNoch keine Bewertungen

- Casting LabDokument11 SeitenCasting Labfawad naeemNoch keine Bewertungen

- ME1107 Casting AllDokument129 SeitenME1107 Casting AllMahmud HridoyNoch keine Bewertungen

- Classification Foundries Acc Moulding ProcessesDokument20 SeitenClassification Foundries Acc Moulding ProcessesIngDiaz730% (1)

- BENG (HONS) MECHANICAL ENGINEERING MANUFACTURING PROCESS MACHINING TOPICDokument16 SeitenBENG (HONS) MECHANICAL ENGINEERING MANUFACTURING PROCESS MACHINING TOPICNaeem DeenNoch keine Bewertungen

- Modern Casting Production MethodsDokument14 SeitenModern Casting Production MethodsrabikmNoch keine Bewertungen

- Unit 3Dokument42 SeitenUnit 3Anup M UpadhyayaNoch keine Bewertungen

- CastingDokument9 SeitenCastingapi-3810665Noch keine Bewertungen

- Assignment 2 - EPP201 (149616)Dokument6 SeitenAssignment 2 - EPP201 (149616)shahanmhd51Noch keine Bewertungen

- Recent Advances in Sand CastingDokument6 SeitenRecent Advances in Sand Casting9591007896Noch keine Bewertungen

- BMP - PPT 3Dokument13 SeitenBMP - PPT 32058SOMYAJIT RAYNoch keine Bewertungen

- Casting Manufacturing Lab ReportDokument16 SeitenCasting Manufacturing Lab ReportNiko KoNoch keine Bewertungen

- Ssignment Topic: Casting Process, Material & Technique Course Title: Moulding and Casting Course No. F-ART-S 3204Dokument16 SeitenSsignment Topic: Casting Process, Material & Technique Course Title: Moulding and Casting Course No. F-ART-S 3204muntasir id1Noch keine Bewertungen

- Slip Casting: An Overview of Ceramic Forming MethodDokument5 SeitenSlip Casting: An Overview of Ceramic Forming MethodFaizan MalikNoch keine Bewertungen

- Cassting 1Dokument10 SeitenCassting 1steve ogagaNoch keine Bewertungen

- Foundry Processes: "Why Whittle When You Can Cast?"Dokument21 SeitenFoundry Processes: "Why Whittle When You Can Cast?"lucasNoch keine Bewertungen

- Full Mould Casting: Pradeep Kumar.T.PDokument26 SeitenFull Mould Casting: Pradeep Kumar.T.PVetrivel SezhianNoch keine Bewertungen

- Microsoft Word - Molding Processes - 2Dokument7 SeitenMicrosoft Word - Molding Processes - 2Prashant ParshivnikarNoch keine Bewertungen

- Innovative Casting TechniquesDokument20 SeitenInnovative Casting TechniquesSubhash SharmaNoch keine Bewertungen

- Introduction To Casting ProcessesDokument11 SeitenIntroduction To Casting Processesuvsing100% (2)

- Casting and Welding GuideDokument27 SeitenCasting and Welding GuidePavaniNoch keine Bewertungen

- Sand CastingDokument19 SeitenSand CastingAtul KaushikNoch keine Bewertungen

- Sand Casting A4 LowDokument2 SeitenSand Casting A4 LowNaqi ShaukatNoch keine Bewertungen

- General Manufacturing StepsDokument9 SeitenGeneral Manufacturing StepsPatricia de LeonNoch keine Bewertungen

- CO2 Molding Process GuideDokument5 SeitenCO2 Molding Process GuideKaushik SreenivasNoch keine Bewertungen

- Advanced Metal Casting ProcessesDokument8 SeitenAdvanced Metal Casting Processesrenjithaero100% (1)

- Unit I Sand CastingDokument36 SeitenUnit I Sand CastingSrinivas Gowda100% (1)

- Seminar ReportDokument12 SeitenSeminar ReportShubhali SinghNoch keine Bewertungen

- MP1 M2 Short NotesDokument16 SeitenMP1 M2 Short NotesRadhika GandhiNoch keine Bewertungen

- Is The Lost Foam Process The Future of Metal CastingDokument7 SeitenIs The Lost Foam Process The Future of Metal Castingjmtindia100% (2)

- FKM Lab - Metal Casting Process Lab ReportDokument20 SeitenFKM Lab - Metal Casting Process Lab Reportzazaeureka0% (1)

- Fundamentals of CastingDokument45 SeitenFundamentals of Castingmdrijuahmed742Noch keine Bewertungen

- Seminar On Case Study of Investment Casting by Manish PujaraDokument39 SeitenSeminar On Case Study of Investment Casting by Manish PujaraNikunj PatelNoch keine Bewertungen

- Ae15301 AMMTDokument98 SeitenAe15301 AMMTDurai Raj KumarNoch keine Bewertungen

- Chapter 2Dokument38 SeitenChapter 2Umesh ChandraNoch keine Bewertungen

- Manufacturin G Assignment: Plaster and Ceramic MoldingDokument13 SeitenManufacturin G Assignment: Plaster and Ceramic MoldingbernabasNoch keine Bewertungen

- Casting Series 6Dokument47 SeitenCasting Series 6Janmayjoy Halder SwagataNoch keine Bewertungen

- Name:Rohan Elahi Roll No 2020-ME-161 (Experiment 1) : (Solid Pattern) ObjectiveDokument10 SeitenName:Rohan Elahi Roll No 2020-ME-161 (Experiment 1) : (Solid Pattern) ObjectiveRohan ElahiNoch keine Bewertungen

- Casting Proceses and Defects_UADDokument23 SeitenCasting Proceses and Defects_UADrushabhkhotNoch keine Bewertungen

- Lost Foam CastingDokument31 SeitenLost Foam CastingokicirdarNoch keine Bewertungen

- Casting PDFDokument96 SeitenCasting PDFYerriboina Vishnu VardhanNoch keine Bewertungen

- ME 2201 - Manufacturing Technology-IDokument147 SeitenME 2201 - Manufacturing Technology-IMahendra Babu MekalaNoch keine Bewertungen

- The Fabrication of Materials: Materials TechnologyVon EverandThe Fabrication of Materials: Materials TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Organizational Behavior: MotivationDokument11 SeitenOrganizational Behavior: Motivationnatrix029Noch keine Bewertungen

- Basic Quality ToolsDokument15 SeitenBasic Quality Toolsnatrix029Noch keine Bewertungen

- Total Productive MaintenanceDokument14 SeitenTotal Productive Maintenancenatrix029Noch keine Bewertungen

- How To Build Valid and Credible Simulation ModelsDokument10 SeitenHow To Build Valid and Credible Simulation Modelsraju_robotNoch keine Bewertungen

- Organizational StructuresDokument13 SeitenOrganizational Structuresnatrix029Noch keine Bewertungen

- Selection of Shaft Sinking Method For Underground Mining in Khalashpir Coal Field, Khalashpir, Rangpur, BangladeshDokument6 SeitenSelection of Shaft Sinking Method For Underground Mining in Khalashpir Coal Field, Khalashpir, Rangpur, Bangladeshnatrix029Noch keine Bewertungen

- Normal Versus T DistributionDokument1 SeiteNormal Versus T DistributionAlexandra SolanoNoch keine Bewertungen

- 5S Definition and BenefitsDokument16 Seiten5S Definition and Benefitsnatrix029Noch keine Bewertungen

- Ferrous AlloyDokument15 SeitenFerrous Alloynatrix029Noch keine Bewertungen

- Theory of ConstraintsDokument12 SeitenTheory of Constraintsnatrix029100% (1)

- Value Chain ManagementDokument36 SeitenValue Chain Managementnatrix029Noch keine Bewertungen

- What Is The Importance of Statistics in The Field of EngineeringDokument1 SeiteWhat Is The Importance of Statistics in The Field of Engineeringnatrix029Noch keine Bewertungen

- Benefits of Time StudyDokument2 SeitenBenefits of Time Studynatrix029Noch keine Bewertungen

- Operations Management ConceptsDokument26 SeitenOperations Management Conceptsnatrix029Noch keine Bewertungen

- Quality ConceptDokument34 SeitenQuality Conceptnatrix029Noch keine Bewertungen

- Supply Chain Management Homework - 2Dokument6 SeitenSupply Chain Management Homework - 2natrix029Noch keine Bewertungen

- Achieving Strategic Fit and Scope 1224677889881473 9Dokument42 SeitenAchieving Strategic Fit and Scope 1224677889881473 9natrix029100% (1)

- Lecture - 1 Introduction To Project ManagementDokument46 SeitenLecture - 1 Introduction To Project Managementnatrix029Noch keine Bewertungen

- Statistical Qulaity ControlDokument44 SeitenStatistical Qulaity Controlnatrix029Noch keine Bewertungen

- Method StudyDokument24 SeitenMethod StudyParas ThakurNoch keine Bewertungen

- 05.1. Inventory Management - 10-11Dokument12 Seiten05.1. Inventory Management - 10-11natrix029Noch keine Bewertungen

- Complementary EventDokument3 SeitenComplementary Eventnatrix029Noch keine Bewertungen

- Lecturer-2 Project InitiationDokument46 SeitenLecturer-2 Project Initiationnatrix029Noch keine Bewertungen

- Monte Carlo Methods for Dimensionality and Variance ReductionDokument19 SeitenMonte Carlo Methods for Dimensionality and Variance ReductionRopan EfendiNoch keine Bewertungen

- Probability TheoryDokument6 SeitenProbability Theorynatrix029Noch keine Bewertungen

- 7 - Agile Supply ChainDokument23 Seiten7 - Agile Supply Chainnatrix029Noch keine Bewertungen

- Facility Location Selection For Global ManufacturingDokument97 SeitenFacility Location Selection For Global Manufacturingnatrix029Noch keine Bewertungen

- Supply Chain Management Homework - 2Dokument6 SeitenSupply Chain Management Homework - 2natrix029Noch keine Bewertungen

- L 5 TransportationDokument23 SeitenL 5 Transportationnatrix029Noch keine Bewertungen

- Neuro Fuzzy MethodsDokument77 SeitenNeuro Fuzzy MethodsSelva AymNoch keine Bewertungen

- SIX A Filthy Christmas Miracl JamesDokument55 SeitenSIX A Filthy Christmas Miracl JamescarinaNoch keine Bewertungen

- Schlumber: Kevin: 16010072 Moch Rizky Setiawan: 16010068Dokument12 SeitenSchlumber: Kevin: 16010072 Moch Rizky Setiawan: 16010068KevinNoch keine Bewertungen

- GMP TD Ar FPL 11033Dokument1 SeiteGMP TD Ar FPL 11033Sammy NguyenNoch keine Bewertungen

- The Role of Technology in AgricultureDokument35 SeitenThe Role of Technology in AgricultureDivyesh ThumarNoch keine Bewertungen

- A4 RelationshipgridDokument32 SeitenA4 RelationshipgridjamesNoch keine Bewertungen

- STC Bec Wir Plu D 0209 01 PDFDokument10 SeitenSTC Bec Wir Plu D 0209 01 PDFAdel MorsyNoch keine Bewertungen

- 6-Step Guide to Crushing Imposter SyndromeDokument10 Seiten6-Step Guide to Crushing Imposter SyndromeMark KestNoch keine Bewertungen

- Celecoxib Identification MethodsDokument5 SeitenCelecoxib Identification Methodsabc1679Noch keine Bewertungen

- 2002 - Comparison of The Absorption of Micronized (Daflon 500 MG) and Nonmicronized 14c-Diosmin TabletsDokument9 Seiten2002 - Comparison of The Absorption of Micronized (Daflon 500 MG) and Nonmicronized 14c-Diosmin TabletsMai HuynhNoch keine Bewertungen

- Compabloc Heat Exchangers Cut Downtime at Nynäs RefineryDokument2 SeitenCompabloc Heat Exchangers Cut Downtime at Nynäs RefinerylaythNoch keine Bewertungen

- Edwards Auto 306 CharacteristicsDokument4 SeitenEdwards Auto 306 CharacteristicsJuan Antonio Rubio-LaraNoch keine Bewertungen

- 01 Well Head ComponentsDokument46 Seiten01 Well Head ComponentsKhanh Pham Minh100% (7)

- Queuing System Optimization for Mercury Drug StoreDokument17 SeitenQueuing System Optimization for Mercury Drug StoreAllen Agno llNoch keine Bewertungen

- Will The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityDokument2 SeitenWill The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityKyoko TakayanagiNoch keine Bewertungen

- Pharmaceutical Microbiology - B.pharmDokument383 SeitenPharmaceutical Microbiology - B.pharmkeyurNoch keine Bewertungen

- Torc 4 Abscohort1 - CompressDokument13 SeitenTorc 4 Abscohort1 - CompressFaye MartinezNoch keine Bewertungen

- S# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusDokument25 SeitenS# Isin CFI Code (As Per New ISO) Security Name Security Symbol Sector Name Security Type StatusahmedalishNoch keine Bewertungen

- Miller Toyota-Conversion-Kit Letter ENG WEBDokument4 SeitenMiller Toyota-Conversion-Kit Letter ENG WEBskyduckNoch keine Bewertungen

- PARTNER Contact Closure Adjunct: Installation InstructionsDokument6 SeitenPARTNER Contact Closure Adjunct: Installation InstructionslaurahotNoch keine Bewertungen

- Smoke Stratification - Understanding the DynamicsDokument3 SeitenSmoke Stratification - Understanding the DynamicsGagan UpadhyayNoch keine Bewertungen

- English Sds Turalik 52Dokument13 SeitenEnglish Sds Turalik 52Muhammad ArifudinNoch keine Bewertungen

- Hyundai forklift specification dimensionsDokument6 SeitenHyundai forklift specification dimensionsАлександр ОлейникNoch keine Bewertungen

- Track A Beast ManualDokument21 SeitenTrack A Beast ManualboltojamNoch keine Bewertungen

- Pengaruh Ukuran Potongan Kopra Dalam Proses Pengeringan: Effect of The Copra Cut Size in The Drying ProcessDokument5 SeitenPengaruh Ukuran Potongan Kopra Dalam Proses Pengeringan: Effect of The Copra Cut Size in The Drying ProcessAlexia Desi Ratnasari Loi 1841100210Noch keine Bewertungen

- BiostastisticDokument2 SeitenBiostastisticاحمد ماجد زبنNoch keine Bewertungen

- Ic M423GDokument2 SeitenIc M423GSerikhi AliNoch keine Bewertungen

- Research PresentationDokument13 SeitenResearch Presentationapi-252252011Noch keine Bewertungen

- RV Failure: Pathophysiology, Diagnosis and TreatmentDokument16 SeitenRV Failure: Pathophysiology, Diagnosis and TreatmentRizky Regia TriseynesyaNoch keine Bewertungen

- SP-200 Advanced PumpDokument4 SeitenSP-200 Advanced PumpOsvaldo BravoNoch keine Bewertungen

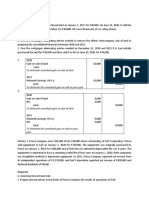

- Let's Check: To Eliminate Unrealized Gain On Sale of LandDokument4 SeitenLet's Check: To Eliminate Unrealized Gain On Sale of Landalmira garciaNoch keine Bewertungen