Beruflich Dokumente

Kultur Dokumente

Advanced Vibration Analysis On Gear Box Train

Hochgeladen von

oded98100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

205 Ansichten25 SeitenGearbox train condition monitoring and vibration analysis

Originaltitel

Advanced Vibration Analysis on Gear Box Train

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenGearbox train condition monitoring and vibration analysis

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

205 Ansichten25 SeitenAdvanced Vibration Analysis On Gear Box Train

Hochgeladen von

oded98Gearbox train condition monitoring and vibration analysis

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 25

Advanced Vibration Analysis on

Gear Box Train and vibration

elimination

by

Udayashankar P. Eng., MBA,CMRP

Suncor Energy

359

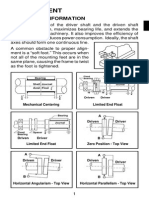

Machine Train configuration

Brief History

Problem description

Analysis

Rectification

Conclusions

360

Machine Train Configuration

Compressor

Gearbox Turbine

361

Machine Train Configuration GA Drawing

Compressor

Gear Box

Turbine

362

_ ,. --

..... .. .... _.-;- ..... ,._---... .... . .... -- . -. . - - -- -: ...

!.

I

i

..... /0. ;.(

G"I HA."'Dl 0 "",..C -"""'UI"T'tll..OC

Ui!J"r our. Lr r.r.- u a

.,-rzl:h :.:v.;r A- -'. U l '$

D#''4Jiir' ..rr..:_..,,.,r ,..-.,-:Nt r-h"'

.r-.1>#'- - - S'I"'UU.O J4DD .or...-....

Ni-Cr .-.rc$'1._1!. -

1":;1,14

. . _ c q .. r01C'i!' J aAI'W r <efYrcnOC'l

;..fL.;_

o-o -...r

=-l:J.:=

I /

J-:.t:. 1J C

! . .--

'

I

'

llot..t"r

I

I

.

- ... 1-J ... t'

6- "-4

"""' .D1:7VLN

:=;. ,.,-

.. .. .....

Unit Details

Service: Gas oil Recycle Gas

Driver: Steam Turbine

Compressor: Centrifugal Compressor

Gear Box: Double Helical Gear ( 109 teeth), Pinion ( 50 teeth)

Ratio: 2.18:1

RPM: Low Speed Shaft:5609 & High Speed Shaft :12228

Suction Pressure (Psig): 1250

Discharge Pressure (Psig): 1450-1500

Temperature Suction (

0

F ) 188; Discharge (

0

F ) 190-220

Discharge Flow (MSCFH): 4500 TO 5000 SCFM

Monitoring system for Gear Box: Casing mounted accelerometers one each for

Low Speed and High speed. Online monitoring system is provided for analysis,

trending, etc

363

Brief History-7K-20 Gear box

Gear Box was overhauled in1999, 2003,2005, 2006, 2008.

The gears were not changed from 1999 onwards as per the records available.

In general contact pattern of the gears was good; Dimensional, run out & clearance

checks within specs

Bearings on the high-speed shaft were in poor condition. Some damage and

overheating of the Babbitt was evident in the top halves. Low speed shaft bearings did

not have any major damage.

2005 Inspection did reveal some deposit and discoloration due to overheating on the

GB Bearings. However the Bearings were replaced.

GB vibration acceleration was trending high from the start up on April 15 th 2005

though the vibration velocity did not trend that high. Vibration alarms occurred on this

gear box & alarm levels were re-adjusted up to an overall level of 18 gs on low speed

shaft.

April 2006 Specialised Machinery Consultant deployed to conduct a vibration &

operating deflecting shape analysis (ODS).

Dominant frequency at 15 times the running speed of the pinion. There was no

abnormal gear mesh vibration.

364

Brief History ( Continued)

Engineering evaluation at that time in 2003-2005 recommended that:

Frequency of 5 years between major inspections for the gearbox is

considered too long*

Evidence of overheating at the bearing as indicated by:

1) melting of white metal

2) by the evidence of varnish deposition on the bearing top half.

The overheating is considered to be caused by the effect of the following:

Use of higher viscosity oil. (ISO 46 grade instead of the original ISO 32)

Increase in speed ratio and higher output speed for the pinion shaft.

Increase the alarm limits from 10g-12g-14g-18g-22g. No real effort done to

address root cause....... The high vibes resulted in frequent failure of

Compressor also.

We were trusting the Experts.........

365

Problem Description

High Vibration acceleration of Low and High Speed shafts

Both the speed and the compressor flow rate have a significant

effect on the gear box vibration.

Vibration levels are at the worst in the speed range of 5420 to

5620 rpm of the low speed shaft i.e. 11,815 to 12,252 rpm of the

high speed shaft. If we do not operate in this range catalyst life

will be affected. Catalysts change: $5M

Spectrum showed high vibration at a single frequency that is 15X

Compressor speed.

366

Observations

The vibration amplitude (units in g peak) with stud mounted accelerometers at

3.056 KHz frequency i.e. 15 times run speed frequency of the high speed shaft at

12,224 rpm:

Gear Box Front Right Side Gear Box Left Side

G measured before correction were in the range of 40 g

H=4

A=29

V=10

H=15

V=16

H=40

H=27

V=27

H=3.4

V=25.5

V=4

H=25

V=16

H=7

V=18

H=28

A=3.6

A=47

H=13

A=2

H=10

A=8

367

Analysis

The casing vibration velocities on the GB were comparable to sister

compressors 7K-10 and &7K-01.

The acceleration trend was increasing slowly on both the LS and HS side of

the gears.

Had there been a defect in the gears the GB would not have sustained that

long service in spite of indications of High Vibes.

The predominant frequency was 15 times the high speed shaft frequency

which again did not seem to correlate to any mechanical components of the

assembly train.

It was suspected that this is also due to possible excitations. Can only be

confirmed if a natural frequency test of the gears or a hammer test is done.

New instrumentation specific for capturing high frequency vibration data-

the 2

nd

and 3

rd

harmonic associated with this 15X fundamental frequency

was captured.

368

Analysis

As per API guidelines the acceleration is a parameter for

assessing the condition only but not for Machinery Protection.

From the machinery protection point of view, velocity is the

more appropriate value to be monitored which is already being

done using portable data collectors.

Further from Vibration perspective it is the TREND that counts

most rather than the absolute values.

For the gearbox in question the casing vibration velocities have

not changed significantly in spite of an increase in the

acceleration.

369

Analysis

Following types of Vibration data were collected :

Time waveforms from the Online system and field data using stud

mounted accelerometers.

Frequency averaging from Bently panel and field data using stud

mounted accelerometers.

Peak hold vibration data from Bently panel and field data using stud

mounted accelerometers.

Operating deflecting shape data of the gear box, its pedestal, grout and

foundation.

370

Analysis

GB Pedestal is made of two metal plates & two C-Channels welded together

No anchor bolts used to anchor these plates to the concrete

Anchor bolts can also get loose with time

Unit is running over 30 years and Oil spills observed all over the area including

foundation, base plate & pedestal

Chances of weak bond between pedestal & concrete, base plate and grout are

high

Vibrations at all the test points had a dominant peak at 3.056 KHz. i.e. 15 times

running speed of high speed shaft at 12 224 rpm. The gear mesh frequency at

12224 rpm of high speed shaft was 10.187 KHz.

Compressor impeller has 18 vanes and diffuser has 14 vanes.

371

Rectification- Action Plan

GB Inspected in 2005

Continuously Monitored

Correlation between Vibes & Process identified. Marginal reduction

in RPM to keep vibe levels recommended

ODS done using External Expertise.

Based on this it was decided to rectify the foundation & fill up the

voids during an Opportunity

GB vendor (OEM) was consulted

Vibes alarm levels adjusted safely (twice)

Circuits checked for integrity of the readings.

372

Efforts Made

Stiffen the steel pedestal and attempt to repair the

bond to the concrete.

Ensure that the gear box is properly anchored to the

pedestal

If we do nothing, the vibration levels will likely worsen.

As the vibrations increase the Gear Box deflections will

increase to the point the failure will occur

373

CH - 7K-20 Gas/Oi l Recycl e Comp

7K-20 -1

Anal yze Spectr um

24-Jan-06 16:00:38

PK = 19.42

LOAD = 100.0

RPM = 60. (1.00 Hz)

0 100 200 300 400 500 600

0

4

8

12

16

20

24

Fr equency i n kCPM

P

K

A

c

c

e

l

e

r

a

t

i

o

n

i

n

G

-

s

Fr eq:

Or dr :

Spec:

177.51

2958.5

17.41

Spectrum on gearbox with high frequency

accelerometer showing 2

nd

& 3rd harmonic of the

fundamental frequency- Aug 2005

Figure - Spectrum from Data Manager - Spectrum does

not show 2nd or 3rd harmonic of frequency- August

2005

Before rectification- Vibration Spectra

374

Animation- ODS of the Gear Box

375

Rectification Plan

Gear box was removed & sent to a specialized Gear Box facility

Adhesive anchors were installed

Pressure grouting was done to fill the voids

Additional reinforcement plates installed

Old grouting was removed & refilled with fresh grout

In situ machining of the base done to level the base

All base bolts replaced

The Machinery train realigned and running ever since.

Compressor overhaul extended to at least 2 to 4 years.

376

Installed Adhesive anchor

bolts at approx. 4 apart

Installed 3/4 Adhesive anchor bolts

at approx. 12 apart on the base

plate

Rectification Plan- Adhesive anchors

377

Top

7K-20 Turbine

Gearbox

Mount

7K-20 Compressor

Void Locations

Top view

Side View

7K-20 Voids In the Gear Box Foundation

378

Rectification Plan-Reinforcement

379

.--

.

-

I

I

!__l

-

-.._

-

'

..

I

I

I

i I

I

I I.

I :

I 1 I

0. ___b

4XISTr'- /.PDcSTAL

<

-

-

'

-

"-

.._

.._

-

'

_/ STiFF..

IE i j/

N O SCALE

'

I

'

.---

.__

STI FF

Fe II'

S V- OOi_

/ 2-!3- 9 4

/ E .- 'f...-1 A L

/ I

SliFF i12. \ ''

- -- ,

I

-- I

p--,r--:r--<;. g:f? G >/ !

- . - : I

10"--1 A

CH - 7K-20P Bentl y Panel

TREND DISPLAY OF Overall Val ue

0 100 200 300 400 500 600 700 800

0

3

6

9

12

Days: 18-Jan-06 To 13-Feb-08

R

M

S

A

c

c

e

l

e

r

a

t

i

o

n

i

n

G

-

s

=7K-20P -B1P

=7K-20P -B2P

2

3

-

J

u

l

-

0

6

Date:

Ti me:

Amp1:

13-Feb-08

13:17:55

1.005

Vibration Trend- Pre and Post Correction cases

Reduction in

Vibration

380

Figure - Spectrum from Data Manager - Spectrum does not show 2nd or 3rd

harmonic of frequency- August 2005

Post Rectification- Spectrum

381

Gear Box Vibration Before/ After correction

Before: 18g to 22g for 20 years approximately

Predominant: 15 times RPM

RPM restricted to Max 5000

After: 3 to 3.5g

Predominant: 1 x RPM

RPM: 5650

Result: Catalyst life increase due to increased

run time & higher pressure

Estimated Annual Benefit: at least $1 million &

one extra outage avoided

382

Conclusions

Highest amplitude vibrations on the gearbox are not frequencies that

would be normally associated with a gearbox mechanical issue.

It was challenging to absolutely identify the source without doing a speed

sweep and mechanical impact tests (with the machine shutdown).

The increased levels were well above any industry guidelines for long-term

reliability.

The ODS showed significant motion of the gearbox pedestal at those

frequencies.

The pedestal is concrete filled and the bond between the steel pedestal

and the concrete must have failed. ODS showed that at, at least on one

anchor bolt foot, the gearbox is not well attached to the pedestal.

The pedestal and concrete were contaminated with oil. Oil and ANY

relative motion at micro-cracks in the concrete or between the concrete

and bonded steel will cause the cracks to grow or the bond to fail.

383

Das könnte Ihnen auch gefallen

- GM Motors &DELPHI Vibration STD PDFDokument66 SeitenGM Motors &DELPHI Vibration STD PDFMachineryeng0% (1)

- Case Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerVon EverandCase Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Signature AnalysisDokument49 SeitenSignature AnalysisVirgilio100% (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Condition Monitoring For ElectricalDokument28 SeitenCondition Monitoring For ElectricalArindam SamantaNoch keine Bewertungen

- Vibration Reference GuideDokument2 SeitenVibration Reference GuideErez Matana100% (1)

- Mechanical Natural Frequency and Bump Testing PDFDokument22 SeitenMechanical Natural Frequency and Bump Testing PDFalvaroinc04100% (2)

- Random Vibrations: Analysis of Structural and Mechanical SystemsVon EverandRandom Vibrations: Analysis of Structural and Mechanical SystemsNoch keine Bewertungen

- THK Ball Screw En16Dokument382 SeitenTHK Ball Screw En16Bonell Antonio Martinez Vegas100% (1)

- Vibration Analysis of Centrifugal FansDokument18 SeitenVibration Analysis of Centrifugal FansMohd Asiren Mohd Sharif100% (4)

- High Vibration at Main Gear Box of Gas TurbineDokument9 SeitenHigh Vibration at Main Gear Box of Gas TurbineJJNoch keine Bewertungen

- Summative Test in Grade 10 ScienceDokument2 SeitenSummative Test in Grade 10 ScienceErwin Bucasas80% (25)

- Bump TestDokument123 SeitenBump Testtylerdurdane100% (1)

- A I RS: David G. Dorrell, William ThomsonDokument11 SeitenA I RS: David G. Dorrell, William ThomsonEng Bagaragaza RomualdNoch keine Bewertungen

- Advanced Vibration Analysis On Gear Box TrainDokument25 SeitenAdvanced Vibration Analysis On Gear Box TrainmitrachintuNoch keine Bewertungen

- Bearing Vibration Analysis in Labview PDFDokument11 SeitenBearing Vibration Analysis in Labview PDFAli ShanNoch keine Bewertungen

- Diagnostic Reference ChartDokument4 SeitenDiagnostic Reference ChartRao ShahbazNoch keine Bewertungen

- Fluid Film Bearing Diagnostics Using Envelope SpectraDokument14 SeitenFluid Film Bearing Diagnostics Using Envelope SpectraJose Luis RattiaNoch keine Bewertungen

- Vibration Analysis of Gear Box.5-MilosprokoDokument3 SeitenVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Tensile TestDokument27 SeitenTensile TestMuhd Fauzan IbrahimNoch keine Bewertungen

- Methodical Phase AnalysisDokument31 SeitenMethodical Phase Analysisturboconch100% (1)

- Vibration Measurements On Slow Speed MachineryDokument9 SeitenVibration Measurements On Slow Speed MachineryMohd Asiren Mohd SharifNoch keine Bewertungen

- ORBIT AnalysisDokument4 SeitenORBIT AnalysisManoj PaneriNoch keine Bewertungen

- Order Analysis ToolkitDokument16 SeitenOrder Analysis ToolkitManuel Enrique Salas FernándezNoch keine Bewertungen

- Turbo ExpanderDokument105 SeitenTurbo Expandermartinandrei100% (11)

- Transient Vibration Analysis Dec07 HandoutDokument24 SeitenTransient Vibration Analysis Dec07 HandoutsandragoncNoch keine Bewertungen

- Centrifugal Fans Using Vibration Analysis To Detect ProblemsDokument3 SeitenCentrifugal Fans Using Vibration Analysis To Detect ProblemsGivon Da Anneista100% (1)

- MH pgs0700Dokument15 SeitenMH pgs0700Hamza Nouman100% (1)

- AMPLITUDE MODULATION Versus BEATSDokument5 SeitenAMPLITUDE MODULATION Versus BEATSHaitham YoussefNoch keine Bewertungen

- Bend Shaft Vibration SpectrumDokument6 SeitenBend Shaft Vibration SpectrumAvnish DubeyNoch keine Bewertungen

- Advanced Vibration Analysis TechniquesDokument324 SeitenAdvanced Vibration Analysis Techniquesharikrishnanpd3327Noch keine Bewertungen

- A Review of Enveloping and Demodulation TechniquesDokument6 SeitenA Review of Enveloping and Demodulation TechniquesMohamed WahidNoch keine Bewertungen

- Basics of VibrationDokument6 SeitenBasics of VibrationChetan PrajapatiNoch keine Bewertungen

- Dynamic Signal Analysis BasicsDokument18 SeitenDynamic Signal Analysis BasicsDina ArzinaNoch keine Bewertungen

- Journal Bearing VibrationDokument6 SeitenJournal Bearing VibrationEmanuel Bruno Santos100% (1)

- Recent Advances in Vibrations AnalysisDokument248 SeitenRecent Advances in Vibrations AnalysisJosé RamírezNoch keine Bewertungen

- Bently Book Chapter 4 Timebase Plots1Dokument18 SeitenBently Book Chapter 4 Timebase Plots1Manuel L LombarderoNoch keine Bewertungen

- Transient Speed Vibration Analysis: Insights Into Machinery BehaviorDokument47 SeitenTransient Speed Vibration Analysis: Insights Into Machinery Behaviorpeach5Noch keine Bewertungen

- Monitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005Dokument60 SeitenMonitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005eko bagus sunaryo100% (2)

- Rolling Element Bearing Fault Detection With A Single Point Defect On PDFDokument8 SeitenRolling Element Bearing Fault Detection With A Single Point Defect On PDFsunil481Noch keine Bewertungen

- Gear VIbDokument355 SeitenGear VIbAnderson V. Viana100% (1)

- Edexcel GCSE (9-1) Physics SP4 Waves Test With Mark Scheme 16 - 17Dokument16 SeitenEdexcel GCSE (9-1) Physics SP4 Waves Test With Mark Scheme 16 - 17Paul Burgess93% (30)

- Phase MeasurementDokument5 SeitenPhase Measurementuak107080Noch keine Bewertungen

- Vibration Analysis of Rolling BearingsDokument99 SeitenVibration Analysis of Rolling BearingsDaniel_Ali_bNoch keine Bewertungen

- Manual K5 e K5-ADokument194 SeitenManual K5 e K5-AGlauber Tenorio de OliveiraNoch keine Bewertungen

- Detect Machinery Faults by Using Peak VueDokument13 SeitenDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- Orbit ReferenceDokument25 SeitenOrbit ReferenceIlku100% (1)

- Fluid Flow Lectures DR SalahDokument161 SeitenFluid Flow Lectures DR SalahAhmad Ammar Al-dabubi100% (18)

- Structural Health MonitoringVon EverandStructural Health MonitoringDaniel BalageasNoch keine Bewertungen

- Rotating Machinery Reliability for Technicians and EngineersVon EverandRotating Machinery Reliability for Technicians and EngineersNoch keine Bewertungen

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionVon EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNoch keine Bewertungen

- VibMatters Current IssueDokument19 SeitenVibMatters Current IssueUsman JabbarNoch keine Bewertungen

- Woodward Governor Test Stand PDFDokument74 SeitenWoodward Governor Test Stand PDFfjafarvand100% (5)

- Envelope BearingDokument14 SeitenEnvelope BearingHussein Razaq100% (1)

- Analyzing Fluid Film Bearings and Rotordynamics With ANSYS - PresentationDokument34 SeitenAnalyzing Fluid Film Bearings and Rotordynamics With ANSYS - PresentationARKA technocorpNoch keine Bewertungen

- Gantry CraneDokument31 SeitenGantry CraneWaheed Ahmad100% (1)

- Vibration Analysis Gt6 Generator LibyaDokument6 SeitenVibration Analysis Gt6 Generator LibyaRohit GunerkarNoch keine Bewertungen

- Subsynchronous Resonance Analysis: Types OF SSR InteractionDokument4 SeitenSubsynchronous Resonance Analysis: Types OF SSR InteractionBhavik PrajapatiNoch keine Bewertungen

- ISO Category II (Analysis I)Dokument5 SeitenISO Category II (Analysis I)nspcl o&eNoch keine Bewertungen

- Vibration AnalysisDokument10 SeitenVibration AnalysisYasser BayoumyNoch keine Bewertungen

- Mode Shapes of Centrifugal Pump Impeller PDFDokument4 SeitenMode Shapes of Centrifugal Pump Impeller PDFhachanNoch keine Bewertungen

- Condition Monitoring of Centrifugal Blower Using Vibration AnalysisDokument10 SeitenCondition Monitoring of Centrifugal Blower Using Vibration AnalysismustafaNoch keine Bewertungen

- Phase Analysis: Making Vibration Analysis Easier: SearchDokument4 SeitenPhase Analysis: Making Vibration Analysis Easier: Searchdillipsh123Noch keine Bewertungen

- Monitoring and Analysis of Machine VibrationDokument6 SeitenMonitoring and Analysis of Machine VibrationAvinashNoch keine Bewertungen

- Identification of Bearing Defects by Spectral AnalysisDokument6 SeitenIdentification of Bearing Defects by Spectral AnalysisShashankSharmaNoch keine Bewertungen

- Advanced Vibration Analysis On Gear Box TrainDokument25 SeitenAdvanced Vibration Analysis On Gear Box TrainIfeduba KayceeNoch keine Bewertungen

- Unit 4Dokument60 SeitenUnit 4sughashiniNoch keine Bewertungen

- GB Noise PDFDokument30 SeitenGB Noise PDFoded98Noch keine Bewertungen

- 55 R ModDokument1 Seite55 R ModschneidieNoch keine Bewertungen

- Reliabilty For OperatorDokument62 SeitenReliabilty For Operatoroded98Noch keine Bewertungen

- Workenergyandpowerppt 131208202046 Phpapp02Dokument26 SeitenWorkenergyandpowerppt 131208202046 Phpapp02joyNoch keine Bewertungen

- Lecture 2 Tension MembersDokument55 SeitenLecture 2 Tension Memberssamiullah034050100% (1)

- Pressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeDokument13 SeitenPressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeKaushika Rajapaksha PereraNoch keine Bewertungen

- مذكرة شرح Physics - فيزياء لغات للصف الاول الثانوى لمدارس اللغات-الامتحان التعليمىDokument20 Seitenمذكرة شرح Physics - فيزياء لغات للصف الاول الثانوى لمدارس اللغات-الامتحان التعليمىRania Gamal Fouad100% (1)

- Mapping of Magnetic Field Due To Bar Magnet and To Determine Its Magnetic MomentDokument3 SeitenMapping of Magnetic Field Due To Bar Magnet and To Determine Its Magnetic MomentpriyaNoch keine Bewertungen

- CBSE Class 12 Physics Assignment - ElectrostatDokument2 SeitenCBSE Class 12 Physics Assignment - ElectrostatRahul KumarNoch keine Bewertungen

- Response of Single Pile Under Lateral Loads in Cohesionless SoilDokument19 SeitenResponse of Single Pile Under Lateral Loads in Cohesionless SoilIgor BarcelosNoch keine Bewertungen

- Kubo Fluctuation-Dissipation TheoremDokument30 SeitenKubo Fluctuation-Dissipation Theoremmbiswas51Noch keine Bewertungen

- Kinematics of MachineryDokument8 SeitenKinematics of MachineryILAYAPERUMAL KNoch keine Bewertungen

- Processes of Ideal GasesDokument5 SeitenProcesses of Ideal GasesMLNDG boysNoch keine Bewertungen

- TM 200 ManualDokument50 SeitenTM 200 ManualJhuno Silva PaulaNoch keine Bewertungen

- Atomic Rydberg UnitsDokument2 SeitenAtomic Rydberg UnitsQiushi ZhuNoch keine Bewertungen

- Tute Sheet 5 - Tosion in ShaftsDokument1 SeiteTute Sheet 5 - Tosion in ShaftsSimranjeet SinghNoch keine Bewertungen

- ThermalDokument9 SeitenThermalMuhammadNoch keine Bewertungen

- 12ugk403 - Applied Hydraulic EngineeringDokument2 Seiten12ugk403 - Applied Hydraulic EngineeringShan CvNoch keine Bewertungen

- Sample ProblemsDokument36 SeitenSample ProblemsLovely Joy GumbaNoch keine Bewertungen

- Adv Work Energy Practice ProblemsDokument11 SeitenAdv Work Energy Practice ProblemsZanduarNoch keine Bewertungen

- Determination of Gas-Diffusion and Inter PDFDokument9 SeitenDetermination of Gas-Diffusion and Inter PDFfarzadsadeghzadNoch keine Bewertungen

- HHM HandoutDokument16 SeitenHHM HandoutArun ChaitanyaNoch keine Bewertungen

- Transverse Wave On A StringDokument7 SeitenTransverse Wave On A StringYotin MaimanNoch keine Bewertungen

- Pace Final Lap 2 PhysicsDokument219 SeitenPace Final Lap 2 PhysicsBhavesh KriplaniNoch keine Bewertungen

- Problem Set 2.projectile MotionDokument9 SeitenProblem Set 2.projectile MotionCriZhae OconNoch keine Bewertungen