Beruflich Dokumente

Kultur Dokumente

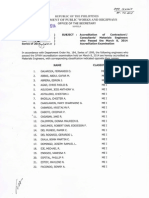

Reviewer - Materials Engineer Accreditation

Hochgeladen von

boodinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reviewer - Materials Engineer Accreditation

Hochgeladen von

boodinCopyright:

Verfügbare Formate

1

2

3

Schedule of Minimum Testing Requirements Governing Items of Work of the

DPWH Specifications for Highways, Bridges and Airports (2004 Edition)

PART C - EARTHWORKS

ITEM 100 CLEARING AND GRUBBING

* This item shall consist of clearing, grubbing, removing and disposing all vegetation

and debris as designated in the contract.

Tests: None

ITEM 101 REMOVAL OF STRUCTURES AND OBSTRUCTIONS

* This item shall consist of the removal wholly or in part, and satisfactory disposal of all

buildings, fences, structures, old pavements abandoned pipelines, and any other

obstruction which are not designated or permitted to remain.

Tests: None

ITEM 102 EXCAVATION

* This item shall consist of roadway, drainage and borrow excavation and the disposal of

materials.

Tests: Same as for Items 103, 104 and 105, whichever is applicable

ITEM 103 STRUCTURE EXCAVATION

* This item shall consist of the necessary excavation for foundation of bridges, culverts,

under-drains, and other structures not otherwise provided in the specifications.

If the excavated materials are washed, the volume involved shall be reported so

that quality control requirements may be adjusted accordingly (submit Project

Engineer Certificate of Waste).

If the excavated materials are incorporated into the work:

Tests:

For every 1,500 m

3

or fraction thereof:

1 G, Grading Test

1 P, Plasticity Test (LL, PL, PI)

1 C, Laboratory Compaction Test

For every 150 mm in uncompacted depth:

1 D, Field Density

ITEM 104 EMBANKMENT

* This item shall consist of the construction of embankment.

Tests:

For every 1,500m

3

or fraction thereof:

4

1 G, Grading Test

1 P, Plasticity Test (LL, PL, PI)

1 C, Laboratory Compaction Test

For each 500m

2

of each layer of compacted fill or fraction thereof:

At least one group of three in situ density test. The layer shall be

placed not exceeding200 mm in loose measurement or based on

the result of compacted trials.

ITEM 105 SUBGRADE PREPARATION

* This item shall consist of the preparation of the sub-grade for the support of overlying

structural layers.

Tests: Same as for Item 104

ITEM 106 COMPACTION EQUIPMENT AND DENSITY CONTROL STRIPS

* This item shall be used in determining the density requirements of selected

embankments, sub-grade, bases and bituminous concrete.

Tests: Same as for Items104, 105, 200, 201, 202, 203, 204, 205, 206 and

300

ITEM 107 OVERHAUL

* This item shall consist of authorized hauling in excess of free-haul distance.

Tests: None

PART D SUB - BASE AND BASE COURSE

ITEM 200 AGGREGATE SUBBASE COURSE

* This item shall consist of furnishing, placing and compaction of aggregate sub-base

course on a prepared sub-grade.

Tests:

For every 300 m

3

or fraction thereof:

1 G, Grading Test

1 P, Plasticity Test (LL, PL, PI)

For every 1,500 m

3

or fraction thereof:

1 C, Laboratory Compaction Test

1 Q, Quality Test (Grading, Plasticity and Abrasion)

For every 2,500m

3

or fraction thereof:

1 CBR, California Bearing Test

For every layer of 150 mm of compacted depth based on the result

of compaction test trials:

At least one group of three in situ density tests for each 500

m

2

or fraction thereof

ITEM 201 AGGREGATE BASE COURSE

5

* This item shall consist of furnishing, placing, and compaction of aggregate base course

on a prepared sub-grade.

Tests:

For every 300 m

3

or fraction thereof:

1 G, Grading Test

1 P, Plasticity Test (LL, PL, PI)

For every 1,500 m

3

or fraction thereof:

1 C, Laboratory Compaction Test

1 Q, Quality Test (Grading, Plasticity and Abrasion)

For every 2,500m

3

or fraction thereof:

1 CBR, California Bearing Test

For every layer of 150 mm of compacted depth based on the result

of compaction test trials:

At least one group of three in situ density tests for each 500

m

2

or fraction thereof

ITEM 202 CRUSHED AGGREGATE BASE COURSE

* This item shall consist of furnishing, placing, and compacting crushed gravel, crushed

stone or crush rock on a prepared sub-grade.

Tests:

Same as for Item 201

For every 1,500m

3

or fraction thereof:

1 F, Fractured face

ITEM 203 LIME STABILIZED ROAD MIX BASE COURSE

* This item shall consist of a foundation for surface course composed of soil aggregate,

lime and water in proper proportions.

Amount of lime to be added:

3 12 mass percent of dry soil aggregates test

Tests:

A. SOIL AGGREGATE

For every 300 m

3

or fraction thereof:

1 G, Grading Test

1 P, Plasticity Test (LL, PL, PI)

For every1,500 m

3

or fraction thereof:

1 Q, Quality Test (Grading, Plasticity and Abrasion)

B. MIX

For every 300 m

3

or fraction thereof:

1 C, Laboratory Compaction Test

1 UC, Unconfined Compaction Test

C. COMPACTED BASE COURSE

For every layer of 150 mm compacted depth:

1 D, Field Density Test for every 150 m or fraction thereof

1 T, Thickness determination for every 150 m or fraction

thereof

6

D. HYDRATED LIME

For every 100T or fraction thereof:

1 Q, Quality Test

ITEM 204 PORTLAND CEMENT STABILIZED ROAD MIX BASE COURSE

* This item shall consist of a foundation for surface course, composed of soil aggregate,

Portland cement and water in proper proportions.

Amount of cement to be added:

6 to 10 mass of dry soil aggregate

Tests:

A. SOIL AGGREGATE

Same as for Item 203

B. CEMENT

1 Q, Quality Test for every 2,000 bags or fraction thereof

C. WATER

1 Q, Quality Test/Project Engineers Certificate

D. MIX

For every 300 m

3

or fraction thereof:

1 C, Laboratory Compaction Test

1 UC, Unconfined Compaction Test

1 CBR, California Bearing Ratio

E. COMPACTED BASE COURSE

For every layer of 150 mm compacted depth:

1 D, Field Density Test for every 150 m or fraction thereof

1 T, Thickness Determination for every 150 m or fraction

thereof

ITEM 205 ASPHALT STABILIZED ROAD MIX BASE COURSE

* This item shall consist of a foundation for surface course, composed of soil aggregate

and asphaltic material in proper proportions.

Amount of asphalt to be added:

4 7 mass of dry soil aggregate

Tests:

A. SOIL AGGREGATE

Same as for Item 203

B. EMULSIFIED ASPHALT

1 Q, Quality Test for every 40T of 200 drums or fraction

thereof

C. MIX

Same as for Item 203

C. COMPACTED BASE COURSE

Same as for Item 203

ITEM 206 PORTLAND CEMENT STABILIZED TREATED PLANT MIX BASE

COURSE

7

* This item shall consist of a foundation for surface course composed of aggregate

Portland cement and water in proper proportion.

Amount of cement to be added:

6 to 10 mass of dry soil aggregate

Tests:

A. SOIL AGGREGATE

Same as for Item 203

B. PORTLAND CEMENT

For every 2,000 bags or fraction thereof:

1 Q, Quality Test

C. MIX

Same as for Item 204

D. WATER

1 Q, Quality Test/Project Engineers Certificate

E. COMPACTED BASE COURSE

For every layer of 150 mm compacted depth:

1 D, Field Density Test for every 150 m or fraction thereof

1 T, Thickness Determination for every 150 m or fraction

thereof

ITEM 207 AGGREGATE STOCKPILE

* This item shall furnishing and placing aggregate in stockpiles at locations.

Tests:

Same as the specified Item No. of the Specification

PART E SURFACE COURSES

ITEM 300 AGGREGATE SURFACE COURSE

* This item shall consist of wearing of top course composed of gravel or crushed

aggregate and other binder material.

Tests:

For every 300 m

3

or fraction thereof:

1 G, Grading Test

1 P, Plasticity Test (LL, PL, PI)

For every 1,500 m

3

or fraction thereof:

1 C, Laboratory Compaction Test

1 Q, Quality Test (Grading, Plasticity and Abrasion)

For every layer of 150 mm of compacted depth based on the result

of compaction test trials:

At least one group of three in situ density tests for each 500

m

2

or fraction thereof

For crushed gravel or crushed stone 1,500 m

3

or fraction thereof:

1 F, Fractured face

8

ITEM 301 BITUMINOUS PRIME COAT

* This item shall consist of preparing and treating an aggregate base course.

Quantity:

1 to 2 L/m

2

Test: 1 Q, Quality Test for every 40T or 200 drums

ITEM 302 BITUMINOUS TACKCOAT

* This item shall consist of preparing and treating an existing bituminous or cement

concrete with bituminous material.

Quantity:

0.2 to 0.7 L/m

2

Test:

1 Q, Quality Test for every 40T or 200 drums

ITEM 303 BITUMINOUS SEAL COAT

* This item shall consist of an application of bituminous material with or w/o an

application of aggregate on an existing bituminous surface course.

A. BITUMINOUS MATERIALS

Quantity:

0.2 to 1.5 L/m

2

Test:

1 Q, Quality Test for every 40T or 200 drums

B. COVER AGGREGATES

Quantity:

5 to 14 kg/m

2

Test:

For every 75 m

3

/200 kg or fraction thereof:

1 G, Grading Test

ITEM 304 BITUMINOUS SURFACE TREATMENT

* This item shall consist of either a single application of bituminous materials followed

by a single spreading of aggregate (single surface treatment) or two applications

bituminous material each followed.

A. AGGREGATES

Quantity:

13.6 to 38 kg/m

2

if using cut back asphalt or asphalt cement

13.6 to 19.04 kg/m

2

if using emulsified asphalt

Tests:

For every 75 m

3

/200 kg or fraction thereof:

1 G, Grading Test

1 P, Plasticity Test (LL, PI)

For every 1,500 m

3

or fraction thereof:

1 Q, Quality Test (Grading, Plasticity and Abrasion)

For every 1,500m

3

or fraction thereof:

1 F, Fractured Face

B. BITUMINOUS MATERIALS

9

Quantity:

1.58 to 2.04 L/m

2

if using cut back asphalt or asphalt cement

1.58 to 2.04 L/m

2

if using emulsified asphalt

ITEM 305 BITUMINOUS PENETRATION MACADAM PAVEMENT

* This item shall consist of furnishing and placing one or more aggregate and one or

more application of bituminous material followed by a seal coat a with cover aggregate

constructed on a prepared base.

A. AGGREGATES

Quantity:

Using Asphalt Cement or Rapid Curing Emulsified Asphalt

Course (crushed) 80 kg/m

2

Key (crushed) 24 kg/m

2

Cover (crushed or screened) 8 kg/m

2

B. BITUMINOUS MATERIALS

Quantity:

7.2 to 11 L/m

2

Test:

Same as for Item 301

ITEM 306 BITUMINOUS ROAD MIX SURFACE COURSE

* This item shall consist of constructing a bituminous road mix surface course on a

prepared base.

A. AGGREGATES

Tests:

Same as for Item 304

B. BITUMINOUS MATERIALS

Quantity:

Using cut back asphalt 4.5 to 7 mass % of total dry aggregate

Using emulsified asphalt 6 to 10 mass % of total dry aggregate

Tests:

Same as for Item 301

C. MIX

Tests:

For every 75 m

3

/130T or fraction thereof:

1 G, Grading Test

1 Ext, Stability Test

1 C, Laboratory Compaction Test

D. HYDRATED LIME

Tests:

For every 100T or fraction thereof:

1 Q, Quality Test

E. COMPACTED PAVEMENT

Tests:

For each full days operation:

10

D & T (Density & Thickness Test), at least one (1) but not more

than three (3) samples shall be taken

ITEM 307 BITUMINOUS PLANT MIX SURFACE COURSE GENERAL

* This item includes general requirements that are applicable to all type of bituminous

surface courses irrespective of gradation of aggregate or kind and amount of bituminous

material.

A. AGGREGATE

Tests:

For every 75 m

3

/200T or fraction thereof:

1 G & P, Grading & Plasticity Tests

For every 1,500m

3

or fraction thereof:

1 Q, Quality Test (Grading, Plasticity and Abrasion, Stripping

and Bulk specific gravity)

1 F, Fractured face

B. BITUMINOUS MATERIALS

Quantity:

5 to 8 mass percent of total dry aggregates

Tests:

1 Q, Quality Test for each 40T or 200 drums or fraction thereof

C. MIX

Tests:

For every 75 m

3

/130T or fraction thereof:

1 G. Grading Test

1 Ext, Stability Test

1 C, Laboratory Compaction Test

D. HYDRATED LIME

Tests:

For every 100T or fraction thereof:

1 Q, Quality Test

E. MINERAL FILLER

Tests:

For every 75 m

3

or fraction thereof:

1 G & P, Grading & Plasticity Tests (LL, PL, PI)

F. COMPACTED PAVEMENT

Tests:

For each full days operation:

D & T (Density & Thickness Test), at least one (1) but not more

than three (3) samples shall be taken

ITEM 308 BITUMINOUS PLANT MIX SURFACE COURSE COLD LAID

* This item shall consist of constructing Bituminous Surface Course (Asphalt Cold Mix)

prepared in central mixing plant, laid cold on a prepared base.

A.AGGREGATE

11

Tests:

Same as for Item 307

B. BITUMINOUS MATERIALS

Quantity:

Using cut back asphalt -- 4.5 to 7 mass % of total dry aggregate

Using emulsified asphalt 6 to 10 mass % of total dry aggregate

Tests:

1 Q, Quality Test for each 40T or 200 drums fraction thereof

C. MIX

Tests:

Same as for Item 307

D. HYDRATED LIME

Tests:

Same as for Item 307

E. MINERAL FILLER

Tests:

For every 75 m

3

or fraction thereof:

1 G & P, Grading & Plasticity Tests (LL, PL, PI)

F. COMPACTED PAVEMENT

Tests:

Same as for Item 307

ITEM 309 BITUMINOUS PLANT MIX (STOCKPILE MAINTENANCE

MIXTURE)

* This item shall consist of a bituminous stockpile maintenance mixture composed of

aggregate, mineral filler, hydrated lime and bituminous material mixed in a central

plant.

A. AGGREGATE

Tests:

Same as for Item 307

B. BITUMINOUS MATERIALS

Quantity:

4 to 10 mass percent of total mix

Tests:

1 Q, Quality Test for each 40T or 200 drums fraction thereof

C. MIX

Tests:

Same as for Item 307

D. HYDRATED LIME

Tests:

Same as for Item 307

E. MINERAL FILLER

Tests:

Same as for Item 307

F. COMPACTED PAVEMENT

Tests:

12

Same as for Item 307

ITEM 310 BITUMINOUS CONCRETE SURFACE COURSE HOT LAID

* This item shall consist of constructing a bituminous concrete surface course composed

of aggregate, mineral filler and bituminous material mixed in a central plant, constructed

and laid hot on prepared base.

A. AGGREGATES

Tests:

Same as for Item 307

B. BITUMINOUS MATERIALS

Quantity:

5 to 8 mass percent of total mix

Tests:

1 Q, Quality Test for each 40T or 200 drums fraction thereof

C. MIX

Tests:

Same as for Item 307

D. HYDRATED LIME

Tests:

Same as for Item 307

E. MINERAL FILLER

Tests:

Same as for Item 307

F. COMPACTED PAVEMENT

Tests:

Same as for Item 307

ITEM 311 PORTLAND CEMENT CONCRETE PAVEMENT

* This item shall consist of pavement of Portland cement concrete, with or without

reinforcement, constructed on the prepared base.

A. CEMENT

Quantity:

9.0 bags/m

3

(40 kg/bag)

Test:

For every 2,000 bags or fraction thereof:

1 Q, Quality Test

B. FINE AGGREGATE

Quantity:

0.50 m

2

/m

3

concrete if using rounded course aggregate

0.54 m

2

/m

3

concrete if using angular or crushed coarse

aggregate

Tests:

13

For every 1,500 m

3

or fraction thereof:

a.) For a source not yet tested or failed in previous quality test:

1 Q, Quality Test (Grading, Elutriation wash, Bulk Specific

Gravity, Absorption, Mortar Strength, Soundness, Organic

Impurities, Unit Weight, % clay lumps and % shale)

b.) For a source previously tested and passed quality test:

1 Q, Quality Test (Grading, Elutriation wash, Bulk Specific

Gravity, Absorption, Mortar Strength)

For every 75 m

3

or fraction thereof:

1 G, Grading Test

C. COURSE AGGREGATE

Quantity:

0.77 m

2

/m

3

concrete if using rounded coarse aggregate

0.68 m

2

/m

3

concrete if using angular or crushed coarse

aggregate

Tests:

For every 1,500 m

3

or fraction thereof:

a.) For a source not yet tested or failed in previous quality test:

1 Q, Quality Test (Grading, Bulk Specific Gravity, Absorption,

Abrasion, Soundness and Unit Weight)

b.) For a source previously tested and passed quality test:

1 Q, Quality Test (Grading, Bulk Specific Gravity, Absorption

and Abrasion)

For every 75 m

3

or fraction thereof:

1 G, Grading Test

D. WATER

Test:

1 Certificate from Project Engineer or 1 Q, Quality Test if

source is questionable

E. JOINT FILLER

1. Poured joint filler

Test:

1 Q, Quality Test on each type of ingredient for each

shipment

2. Pre molded joint filler

Test:

1 Q, Quality Test on each thickness of filler for each

shipment

F. SPECIAL CURING AGENTS

Test:

1 Q, Quality Test for each shipment

G. STEEL BARS

Test:

For every 10,000 kg or fraction thereof for each size:

1 Q, Quality Test (Bending, Tension and Quality Analysis)

14

H. CONCRETE

Test:

Flexural Strength Test on concrete beam samples:

1 Set consisting of 3 beam samples shall represent a 330 m

2

of

pavement, 230 mm depth or fraction thereof placed each day

Volume of concrete not more than 75 m

3

I. COMPLETED PAVEMENT

Test:

Thickness determination by concrete core drilling on a lot basis

Five (5) holes per km per lane or five (5) holes per 500 m when

two (2) lanes are poured concurrently

PART F BRIDGE CONSTRUCTION

ITEM 400 - PILING

* This item shall consist of piling, furnished, driven or placed, cut and spliced.

A. TIMBER PILES

Test:

1 Inspection Report for each size and shipment of timber

B. CONCRETE PILES

a.) Concrete

Test: Same as for Item 405

b.) Reinforcing Steel

Test: Same as for Item 404

C. STRUCTURAL PILES

Tests:

1 IR, inspection Report

1 Q, Quality Test or Mill Test Certificate

ITEM 401 RAILINGS

* This item shall consist of furnishing, fabricating or placing, for bridges and other

structures of the material of combination of materials.

A. CONCRETE

Test:

Same as for Item 405, Class C

B. REINFORCING STEEL

Test:

Same as for Item 404

ITEM 402 TIMBER STRUCTURES

* This item shall consist of construction of timber structures to the dimensions, lines and

grades as shown on the plans.

Tests:

1 Q, Quality Test or Manufacturers Certificate for each type of

material used

15

1 IR, Inspection Report for each type and shipment of timber

ITEM 403 METAL STRUCTURES

* This work shall consist of steel structures portions of composite structures, constructed

in reasonably close conformity with the lines, grades and dimension.

Tests:

1 Q, Quality Test or Manufacturers Certificate for each type of

material used

1 IR, Inspection Report for each type and shipment of metal

ITEM 404 REINFORCING STEEL

* This item shall consist of furnishing, bending, fabricating and placing of steel

reinforcement of the type, size, shape and grade required.

A. BAR REINFORCEMENT FOR CONCRETE

Test:

For every 10,000 kg or fraction thereof for each size:

1 Q, Quality Test (Bending, Tension and Quality Analysis)

B. WIRE AND WIRE MESH

Test:

1 Q, Quality Test

ITEM 405 STRUCTURAL CONCRETE

* This item shall consist of furnishing, bending, and placing and finishing concrete in all

structures except pavements.

A. CEMENT

Quantity: (40 kg/bag)

Class A 9 bags/m

3

of concrete 3,000 psi/20.7 MPa

Class B 8 bags/m

3

of concrete 2,400 psi/16.4 MPa

Class C 9.5 bags/m

3

of concrete 3,000 psi/20.7 MPa

Class P 11 bags/m

3

of concrete 5,000 psi/20.7 MPa

Class Seal 9.5 bags/m

3

of concrete 3,000 psi/20.7 MPa

Test:

For every 2,000 bags or fraction thereof:

1 Q, Quality Test

B. FINE AGGREGATES

Quantity:

ROUNDED ANGULAR/CRUSHED

Class A 0.50 0.54 m

2

/m

3

of concrete

Class B 0.45 0.52 m

2

/m

3

of concrete

Class C 0.53 0.59 m

2

/m

3

of concrete

Class P 0.44 0.47 m

2

/m

3

of concrete

Test:

For every 1,500 m

3

or fraction thereof:

a.) For a source not yet tested or failed in previous quality test:

16

1 Q, Quality Test (Grading, Elutriation wash, Bulk Specific

Gravity, Absorption, Mortar Strength, Soundness, Organic

Impurities, Unit Weight, % clay lumps and % shale)

b.) For a source previously tested and passed quality test:

1 Q, Quality Test (Grading, Elutriation wash, Bulk Specific

Gravity, Absorption, Mortar Strength)

For every 75 m

3

or fraction thereof:

1 G, Grading Test

C. COARSE AGGREGATES

Quantity:

ROUNDED ANGULAR/CRUSHED

Class A 0.77 0.68 m

2

/m

3

of concrete

Class B 0.82 0.73 m

2

/m

3

of concrete

Class C 0.70 0.66 m

2

/m

3

of concrete

Class P 0.56 0.65 m

2

/m

3

of concrete

Test:

For every 1,500 m

3

or fraction thereof:

a.) For a source not yet tested or failed in previous quality test:

1 Q, Quality Test (Grading, Bulk Specific Gravity, Absorption,

Abrasion, Soundness and Unit Weight)

b.) For a source previously tested and passed quality test:

1 Q, Quality Test (Grading, Bulk Specific Gravity, Absorption

and Abrasion)

For every 75 m

3

or fraction thereof:

1 G, Grading Test

D. WATER

Tests:

1 Certificate from Project Engineer or 1 Q, Quality Test if

source is questionable

E. PRE MOLDED FILLER FOR EXPANSION JOINTS

Test:

1 Q, Quality Test on each thickness of filler for each shipment

F. STEEL REINFORCEMENT

Test:

For every 10,000 kg or fraction thereof for each size:

1 Q, Quality Test (Bending, Tension and Quality Analysis)

G. CONCRETE

Tests:

Compressive Strength Test on concrete cylinder samples, one (1)

set consisting three (3) concrete cylinder samples shall be taken

from each days pouring and to represent not more than 75 m

3

of

concrete or fraction thereof

ITEM 406 PRE STRESSED CONCRETE STRUCTURES

17

* This item shall consist of pre-stressed concrete structures and the pre-stressed concrete

portions of composite structures.

A. CONCRETE

Tests:

Same as for Item 405, Class P

B. STEEL REINFORCEMENT

Test:

Same as for Item 404

C. WIRE STRAND

Test:

1 Q, Quality Test for every 20T or fraction thereof

ITEM 407 CONCRETE STRUCTURES

*This item shall consist of the general description of the materials, equipment,

workmanship and construction requirements of concrete structures and the concrete

portions of composite structures.

Tests:

Same as for Items 403, 404 and 411

Elastometric Bearing Pads will be tested to determine its quality

ITEM 408 STEEL BRIDGES

* This item shall consist of construction of steel structure conforming to the lines, grades,

dimension and designs.

Tests:

Same as for Item 403 and 411

Painting:

1 Q, One 20 L can for every 100 cans or fraction thereof

1 Q, One 4 L can for every 100 cans or fraction thereof

ITEM 409 WELDED STRUCTURAL STEEL

* This work shall consist of the joining of structural steel members with welds of the type.

Test:

Same as for 403 and Inspection Report

ITEM 410 TREATED AND UNTREATED TIMBER

* This item shall consist of structural timber of the specie size called on the plans either

treated or untreated as called for in the proposal.

Test:

1 IR, Inspection report

1 Q, Quality Test for preservatives

ITEM 411 PAINT

* This item shall consist of furnishing and applying all paint materials including vehicles,

pigments, pastes, dryers, thinners, and mixed paints for steel and wooden structures.

Test:

1 Q, One 20 L can for every 100 cans or fraction thereof

18

1 Q, One 4 L can for every 100 cans or fraction thereof

ITEM 412 ELASTOMETRIC BEARING PADS

*This item shall consist of the requirement for elastomeric bearing pads whose main

function is to transfer loads or accommodate relative movement between a bridge

superstructure and its supporting structures

ITEM 413 PRE MOLDED JOINT FILLER FOR CONCRETE PAVING AND

STRUCTURAL CONCRETE

* Preformed sponge rubber and rock expansion joint filler for concrete paving and

structural construction

PART G DRAINAGE AND SLOPE PROTECTION STRUCTURES

ITEM 500 PIPE CULVERTS AND STORMDRAINS

* This item shall consist of the construction or reconstruction of pipe culverts and storm

drains.

A. PIPES

Test:

1 Q, Quality Test for one (1) pipe for every 50 pieces (Strength,

Absorption and Dimension)

Alternative Requirements:

1. Compressive Strength for one (1) set consisting of three (3)

concrete cylinder samples for not more than twenty five (25)

pipe cast in the field

2. Inspection Report for each size for not more than twenty five

(25) pipes cast in the field

B. MORTAR AND JOINT FILLER

Cement, fine aggregates and water:

Test:

Same as for Item 405

ITEM 501 UNDERDRAINS

* This item shall consist of constructing under drains, using pipe and granular filter

materials, under drain pipe outlets, and blind drain using granular materials.

A. CONCRETE PIPE (NON REINFORCED)

Test:

Quality Test for 0.5% of the number of pipes for each size but not

less than two (2) for Strength, Absorption and Dimension

Alternative requirements:

1. Compressive Strength for one (1) set consisting of three (3)

concrete cylinder samples for not more than twenty five (25)

pipe cast in the field

2. Inspection Report for each size for not more than twenty five

(25) pipes cast in the field

19

B. CLAY PIPE

Test:

Quality Test for one (1) pipe for every 200 pieces of each size,

with a minimum number of two (2) specimens for Strength,

Absorption and Dimension

ITEM 502 MANHOLES, INLETS AND CATCHBASINS

* This item shall consist of the construction, reconstruction or adjustment of manholes,

inlets, and catch basins.

A. CONCRETE

Test:

Same as for Item 405, Class A

B. LIDS, CAST IRON FRAMES AND GRATING

Test:

Inspection Report

ITEM 503 DRAINAGE STEEL GRATING WITH FRAME

* The steel frame clear openings of drainage grates shall be 15 mm larger than nominal

sizes of industry standard sized pits.

ITEM 504 CLEANING AND RECONDITIONING OF EXISTING DRAINAGE

STRUCTURES

* This item shall consist of cleaning and reconditioning existing pipes and appurtenant

structures.

Test:

Inspection Report

ITEM 505 RIPRAP AND GROUTED RIPRAP

* This item shall consist of the furnishing and placing riprap with or without grout as the

case maybe, with or without filter backing.

Test:

Same as for Item 506

(Cement Aggregate ratio = 1:3)

ITEM 506 STONE MASONRY

* This item shall consist of stone masonry of minor structures, in headwalls for culverts,

in retaining walls at the toes of slopes.

A. CEMENT

Quantity:

2 bags/m

3

of concrete

Test:

For every 2,000 bags or fraction thereof:

1 Q, Quality Test

(Cement Aggregate ratio = 1:2)

B. FINE AGGREGATE

Quantity:

20

0.17 m

2

/m

3

of concrete

Test:

For every 1,500 m

3

or fraction thereof:

1 Q, Quality Test (same as for Item 405)

For every 75 m

3

or fraction thereof:

1 G, Grading Test

C. STONE

Test:

Inspection Report

D. WATER

Test:

1 Certificate from Project Engineer or 1 Q, Quality Test if

source is questionable

ITEM 507 RUBBLE CONCRETE

* This item shall consist of construction of rubble concrete.

ITEM 508 HAND LAID ROCK EMBANKMENT

* This item shall consist of hand-laid rock embankment.

Test:

Inspection Report

ITEM 509 SHEET PILES

* This item shall consist of furnishing, driving cutting off of sheet pile.

A. TIMBER SHEET PILES

Test:

Inspection Report

B. CONCRETE SHEET PILES

Test:

Same as for Item 400

C. STEEL SHEET PILES

Test:

Same as for Item 403

ITEM 510 CONCRETE SLOPE PROTECTION

* This item shall consist of furnishing and placing of concrete slope protection including

all necessary excavation, a bed course and reinforced concrete to the required thickness

and extent to protect slope against erosion.

A. BED COURSE

Test:

Same as for Item 200

B. STEEL REINFORCEMENT

Test:

Same as for Item 404

C. CONCRETE

Test:

Same as for Item 405

21

ITEM 511 GABIONS

* This item shall consist of furnishing, forming wire mesh baskets, and placing rocks

installed at the location designated.

Test:

1 Q, Quality Test for each shipment

PART H MISCELLANEOUS STRUCTURES

ITEM 600 CURB AND GUTTER

* This item shall construction of curb and gutter either pre-cast of cast - in place made of

concrete.

A. CONCRETE

Quantity:

0.078 m

3

/m (curb only)

0.092 m

3

/m (curb and gutter, Type A)

0.145 m

3

/m (curb and gutter, Type B)

0.074 m

3

/m (curb and gutter, Type C)

Test:

Same as for Item 405

B. JOINT FILLER

Test:

Same as for Item 311

ITEM 601 SIDEWALK

* This item shall consist of construction of asphalt of Portland cement concrete sidewalk.

A. CONCRETE

Test:

Same as for Item 405, Class A

B. PRE MOLDED EXPANSION JOINT FILLER

Test:

Same as for Item 311

ITEM 602 MONUMENTS, MARKERS AND GUIDE POSTS

* This item shall consist of right-of-way monuments, maintenance marker posts,

kilometer posts and/ or guideposts.

A. CONCRETE

Test:

Same as for Item 405, Class A

B. REINFORCING STEEL

Test:

22

Same as for Item 404

C. TIMBER

Test:

Same as for Item 410

D. PAINT

Test:

Same as for Item 411

ITEM 603 GUARDRAIL

* This item shall consist of furnishing and constructing posts and guardrails.

A. STEEL POSTS

Test:

Same as for Item 403

B. TIMBER POSTS

Test:

Same as for Item 410

C. CONCRETE

Test:

Same as for Item 405

D. REINFORCING STEEL

Test:

Same as for Item 404

E. RAIL

Test:

Inspection Report

F. PAINT

Test:

Same as for Item 411

ITEM 604 FENCING

* This item shall consist of furnishing and constructing of post and barb wire or chain

link fences.

A. BARB WIRE, CHAIN LINK FABRIC

Test:

1 Q, Quality Test

B. CONCRETE POSTS

Test:

Same as for Item 405

C. STEEL REINFORCEMENT

Test:

Same as for Item 404

ITEM 605 ROAD SIGN

* This item shall consist of furnishing and installing road signs.

Test:

Inspection Report

23

ITEM 606 PAVEMENT MARKINGS

* This item shall consist of placing markings of the finished pavement.

Test:

Same as for Item 411

ITEM 607 REFLECTIVE PAVEMENT STUDS

* This item shall consist of furnishing and installing reflective pavement studs on the

surface of the pavement.

Test:

Inspection Report

ITEM 608 TOPSOIL

* This consists of topsoil furnished, transported and spread, or topsoil removed from

designated areas, haul and spread.

Test:

Inspection Report

ITEM 609 SPRIGGING

* This item consists of planting sprigs of living grass plants.

Test:

Inspection Report

ITEM 610 SODDING

* This item shall consist of furnishing and laying of live sod on the shoulders, slopes,

ditches, or other locations as designated, construction of sod ditch checks or similar

appurtenances.

Test:

Inspection Report

ITEM 611 TREE PLANTING

* This item shall consist of furnishing and planting deciduous shade, flowering trees

evergreen trees less than 150 mm diameter on the areas.

Test:

Inspection Report

ITEM 612 REFLECTIVE THERMOPLASTIC STRIPPING

* This item shall be applied to the road surface in a molten state by mechanical means

with surface application glass beads at a rate not less than 350g/L.

PART I MATERIALS DETAILS

ITEM 700 HYDRATED CEMENT

24

Test:

Same as for Item 405

ITEM 701 CONSTRUCTION LIME (HYDRATED)

Test:

1 Q, Quality Test for every 100T or fraction thereof

ITEM 702 BITUMINOUS MATERIALS

Test:

Same as for Items 301, 302, 303, 306, 307, 308, 309 and 310

ITEM 703 AGGREGATES

Test:

Same as for item of work in the Bill of Quantities

ITEM 703A MINERAL FILLER

* This item shall consist of finely divided material mineral matter such as rock dust, slug

dust, hydrated lime, hydraulic cement, fly ash or other suitable mineral matter.

Test:

Same as for Item 307

ITEM 704 MASONRY UNITS

Test:

1 Q, Quality Test for every 10,000 units or fraction thereof

ITEM 705 JOINT MATERIALS

Test:

Same as for Items 311 and 500

ITEM 706 CONCRETE, CLAY, PLASTIC AND FIBER PIPES

A. CONCRETE

Test:

Same as for Item 500

B. CLAY AND OTHER TYPE OF PIPES

Test:

Refer to applicable requirements of AASHTO Test and Specs

ITEM 707 METAL PIPE

Test:

Same as for Item 400

ITEM 708 CONCRETE CURING MATERIALS AND ADMIXTURE

* This item specifies the classification, sampling, testing, packing and marking of

concrete admixtures.

Test:

1 Q, Quality Test for each shipment

25

ITEM 709 PAINTS

Test:

Same as for Item 411

ITEM 710 REINFORCING STEEL AND WIRE ROPE

A. REINFORCING STEEL

Test:

Same as for Item 404

B.WIRE ROPE

Test:

Same as for Item 406

ITEM 711 FENCE AND GUARDRAIL

A. FENCE

Test:

Same as for Item 604

B. GUARDRAIL

Test:

Same as for Item 603

ITEM 712 STRUCTURAL METAL

Test:

Same as for Items 403 and 406

ITEM 713 TREATED AND UNTREATED TIMBER

Test:

Same as for Item 410

ITEM 714 WATER

Test:

Certificate from Project Engineer or 1 Q, Quality Test, if source

is questionable

ITEM 715 GEOTEXTILES

* This item covers geotextiles fabric for use in subsurface drainage, hydraulic filter,

erosion control, sediment control, pavement superstructures as a water proofing and

stress relieving membrane, and as permeable separator to prevent mixing of dissimilar

materials.

26

27

MINIMUM REQUIREMENTS FOR SUBMISSION OF SAMPLES

MATERIALS MNIMUM TESTING

REQUIREMENTS

MINIMUM

QUANTITY/VOLUME OF

MATERIALS FOR EACH

SAMPLE SUBMITTED

1. Cement 1 sample per 2000 bags 10 kg

2. Asphaltic material

1 sample per 40T or 200

drums

5L

3. Aspahlt mix 1 sample per 130T 20 kg

4. Aggregates

a. coarse aggregate

b. fine aggregate

1 sample per 1,500 m

3

70 kg

50 kg

5. Soil aggregates

a. Classification

b. Routinary tests

c. MDR test and CBR

1 sample per 1,500 m

3

20 kg

50 kg

50 kg

6. Non Reinforced Concrete

Pipes

2 pipes min./0.5% of no.

of pipes

2 pipes

7. Reinforced Concrete Pipes

1 sample per 50 pipes or

2% of # of pipes

1 pipe (1 m length)

8.Steel pipe (galvanized)

1 sample per 500 lengths 2 pcs Of 100 mm long taken

from both ends w/ thread

9. Concrete hollow blocks (CHB)

a. strength

b. moisture content

1 sample per 10,000 units

3 units

3 units

10. Steel bar 1 sample per 10T 1 m

11. Steel sheet (galvanized) 1 sample per 100 sheets 3 pcs 60mm x 60mm

12. Wire strand 1 sample per 20T 2 m

13. Gabion 1m x 2m

28

14. Paints 1 sample per 100 cans 1 - 4L can

15. Joint filler (pre molded) 1 400mm x 400mm

16. Curing compound 1L

17. Concrete cylinder 1 sample per 75 m

3

1 set (3 cylinders)

18. Concrete beam 1 sample per 75 m

3

or 1

day pouring

1 set (3 cylinders)

19. Concrete core 5 holes for every km/lane

20. Asphalt core 1 core for every 100m

21. Water

a. Chemical analysis

b. Sediment load analysis

500 ml

500 ml

22. Structural steel/sheet 1 sample per 50T Reduced section as prescribed

23. Hydrated lime 1 sample per 100T

COMPOSITION AND STRENGTH OF CONCRETE FOR USE IN STRUCTURE

Class of

concrete

Minimum

cement

content per

cu. m

kg (bags)

Maximum

water

cement ratio

kg/kg

Consistency

range in

slump

mm (inch)

Designated

size of

coarse

aggregate

square

opening

std. mm

Minimum

compressive

strength of

150mm x

300mm

concrete

cylinder @

28 days

MN/m

2

(psi)

A 360 (9) 0.53

50 -100 (2

4)

37. 5 4.75

(1 - No. 4)

20.7 (3000)

B 320 (8.5) 0.58

50 -100 (2

4)

50.0 4.75

(2 - No. 4)

16.5 (2400)

C 380 (9.5) 0.55

50 -100 (2

4)

12. 5 4.75

( - No. 4)

20.7 (3000)

P 440 (11) 0.49

100 max ( 4

max)

19.0 4.75

(3/4 - No. 4)

37. 7 (5000)

Seal 380 (9.5) 0.58

100 200 (4

8)

25.0 4.75

(1 - No. 4)

20.7 (3000)

PAYMENT ADJUSTMENT FOR PAVEMENT WITH DEFICIENCY IN

STRENGTH

29

Deficiency in strength of concrete

pavement

Percent (%)

Percent (%) of

contract price

allowed

Less than 5 100

5 to less than 10 80

10 to less than 15 70

15 to less than 20 60

20 to less than 25 50

25 or more 0

PAYMENT ADJUSTMENT FOR PAVEMENT WITH DEFICIENCY IN

THICKNESS

Deficiency in the

average thickness

per lot(mm)

Percent (%) of

contract price

per lot

0 5 100

6 10 95

11 15 85

16 20 70

21 25 50

more than 25 removed and replaced (no payment)

COMMON LABORATORY TESTS

Kind of material Type of test Test duration per sample

(min. # of days)

Cement Physical and chemical 8

Coarse aggregate Grading 3

Specific gravity 3

Absorption 3

Abrasion 1

Unit weight 1

Fine aggregate Grading 3

Specific gravity 3

30

Absorption 3

Unit weight 1

Soil aggregates mixture

(subbase, base and surfaces

courses

Grading 3

Liquid limit 3

Plastic limit 3

Compaction 3

CBR 7

Abrasion 1

Asphalt Physical 4

Paint Physical and chemical 4

Concrete cylinder Compressive 1

Concrete beam Flexural 1

Concrete core Cutting of sample 1

LIMITATIONS/VARIATIONS

ITEM

104

ITEM

105

ITEM

200

1TEM

201

ITEM

202

ITEM

203

ITEM

300

Abrasion loss 50%

max

50%

max

45%

max

45%

max

Plastic index 6%

max

12%

max

6% max

6%

max

4% to

10%

4% to

9%

Liquid limit 30%

max

35%

max

25%

max

25%

max

35%

max

Permitted

variation from

design

THICKNESS

OF LAYER

20mm 10mm

+15mm,

-5mm

Permitted

variation from

design LEVEL

OF SURFACE

+20mm,

-30mm

+10mm,

-20mm

+5mm,

-10mm

+15mm,

-5mm

Permitted

surface

irregularity

30mm 20mm 5mm 5mm

31

measured by 3-

m straight edge

Permitted

variation from

design cross

fall or camber

0.5% 0.3% 0.2% +0.2%

Permitted

variation from

design

longitudinal

grade over 25m

length

0.1% 0.1% 0.1% +0.1%

California

Bearing Ratio

25%

min

80%

min

80%

min

100%

80%

min

DIMESION OF PILES

Length of pile (1m from the butt) Minimum

tip minimum maximum

less than 12m 300mm 450mm 200mm

12m to 18m 320mm 450mm 180mm

more than 18m 350mm 500mm 150mm

REMOVAL OF FORMS

Scope of work Minimum time Minimum % of design

strength

Centering under girders,

beams, frames or arches

14 days 80%

Floors slabs 14 days 70%

Walls 1 day 70%

Columns 2 days 70%

Sides of beams and all other

vertical surfaces

1 day 70%

SIEVE SIZES

NO. 200 0.075mm NO. 20 0.840mm

NO. 100 0.150mm NO. 16 1.180mm

NO. 60 0.300mm NO. 12 1.700mm

NO.50 0.250mm NO. 10 2.000mm

NO. 40 0.425mm NO. 8 2.360mm

32

NO. 30 0.600mm NO. 4 4.750mm

DETAILS OF WELDS

Size of fillet weld Maximum thickness of part

5mm 13mm

6mm 19mm

8mm 32mm

10mm 51mm

13mm 152mm

16mm 152mm and above

MINIMUM LAP FOR SPLICING

GRADE 40 GRADE 60

Tension 24 times bar 36 times bar

Compression 20 times bar 24 times bar

MINERAL FILLER SHALL BE GRADE WITH IN THE FF. LIMITS (703-A)

Sieve size Mass % passing

NO. 30 100

NO. 50 95 100

NO. 200 70 - 100

HYDRATED LIME SHALL CONFORM TO THE FF. REQUIREMENTS (701)

Sieve size Mass % passing

NO. 20 100

NO. 200 85 - 100

MINIMUM WEIGHT OF SAMPLE FOR MOISTURE CONTENT

Sieve No. (passing) Weight

NO. 40 25 grams

NO. 10 50 grams

NO. 4 200 grams

33

300 grams

1 500 grams

2 1000 grams

34

1. What is the sample for compressive strength determination of a structural concrete? Answer: concrete

cylinder sample

2. What is the test to determine the consistency of concrete?

Ans: Slump test

3. What is the length required for RSB sample for quality test?

Ans: 1.0 m/10,000 kg/size/shipment

4. How many samples should be taken for every 75 cu.m fresh concrete?

Ans: 1 set consist of 3-pcs sample

5. What is the required size of test specimen for G.I. sheets?

Ans: 3 pcs-60 mm in 1 sht/100 sheets

6. What kind of paint that has a reflectance or beads?

Ans: Reflectorized Paint

7. What is that construction material that has a property of being a dark brown to black cementitious material in

which the predominating substance is bitumen?

Ans: asphalt

8. For how long or how many hours shall a bituminous prime coat be left undisturbed?

Ans: 24 hours

9. What is the rate of application of bituminous tack coat?

Ans: 0.2 to 0.7 L/sq.m

10. What is the penetration grade of blown asphalt?

Ans: 0 to 30 penetration grade

11. What kind of sample is taken for flexural test?

Ans: Concrete beam sample

12. What are the tests needed for the 2.650 cu.m Item 201 (Aggregate Base Course)?

Ans: CBR, abrasion, GPCD

13. How many grading tests are required for a 3,200 cu.m selected borrow topping (Item 104)?

Ans: 3 grading tests

14. As a materials Engineer, what will you recommend if you find out that the materials to be used as Item 200 if

finer than the required materials?

Ans: blend Item 200 with coarser materials

15. What is the standard specification for LL and PI of Item 201(Aggregate Base Course)?

Ans: maximum of 25% and maximum of 6% respectively

16. What is the CBR requirement for Item 201?

Ans: 80% maximum

17. What asphalt is used for sealing weaken plane joint of concrete pavement?

Ans: Blown Asphalt

18. What is Item 311 of the DPWH Specification (Blue Book)?

Ans: Portland Cement Concrete Pavement

19. What is the machine used for abrasion test?

Ans: Los Angeles Abrasion Machine

20. How to determine the degree of compaction of Items 104, 200, & 201?

Ans: by Field Density Test

21. What is the formula in obtaining the value of PI?

Ans: Liquid Limit minus Plastic Limit

22. What are the other terms for sieve analysis?

Ans: Grading Test, Particle Size Distribution Test, Mechanical Analysis

23. What is the degree of compaction of the soil if the wet density is 2,200 kg/m

3

, with an actual moisture content

of 10.2% and a maximum dry density of 1,960 kg/m

3

?

Ans: 101.23%

24. How many concrete cores shall be taken for one (1) kilometer concrete pavement?

Ans: 5 holes/km/lane

25. What is the moisture content of the soil having an original weight of 162.5 grams and an oven dried weight

of 138.2 grams?

Ans: 17.58%

26. If the group index of a soil is high, what indication does it mean?

Ans: the soil is clayey

27. As a Materials Engineer, how can you determine that the sample placed in the oven is already oven dried?

Ans: if the sample reaches its constant weight

28. In oven drying a sample for test, what temperature shall be maintained?

Ans: 110 5

o

C

29. Why is it that cooling an oven dried sample before weighing is advisable?

Ans: because it can affect its weight

35

30. What is the difference between hygroscopic moisture content from natural moisture content?

Ans: hygroscopic moisture content is the moisture content of an air- dried sample while natural

moisture content is the moisture content of the original sample from the field.

31. For how many bags of cement does a 10 kgs. sample represents?

Ans: 2000 bags

32. For 15, 000 kgs RSB, how many samples shall be submitted for Quality Test?

Ans: 2 pcs 1 m sample

33. An admixture is being introduced to the fresh concrete mixture for heavily reinforced concrete structure using

a pumpcrete to pump out the fresh concrete mix, what admixture should it be?

Ans: Superplasticizer

34. What is the use of blown asphalt?

Ans: as joint filler and water proofing

35. What asphalt is commonly known as hot asphalt or penetration grade asphalt?

Ans: Asphalt Cement

36. How many days does the sample for Immersion Compression Test be soaked in water?

Ans: 4 days @ 50

o

C

37. If ductility test is for asphalt, _____ is for cement? consistency

Ans: Magnesium Oxide, Insoluble Residue, Loss on Ignition

38. Paint is composed of _____

Ans: 35% vehicle, 50% pigment, 15% beads

39. What is the size of tamping rod used in tamping concrete sample?

Ans: 16 mm and 610 mm long with hemispherical tip

40. What is the temperature to be maintained when curing sample after its initial curing?

Ans: 23

o

C 1.7

o

C

41. Concrete cylinders are cured and ready for test. Temperature between 63F to 85F are permitted for a period

not to exceed _____ hours immediately prior to test if free moisture is maintained on the surface of the

specimen at all times.

Ans: three (3)

42. The molds of specimen not to be transported shall be removed after initial curing of _____ hours and should

be cured to the standard curing temperature of 73.4 F 3F

Ans: Twenty-four (24)

43. High plasticity index means _____ of a soil?

Ans: high degree of compressibility

44. Sample to be used for liquid limit and plastic limit tests should pass to what sieve?

Ans: No. 40 (0.425 mm)

45. What compaction rammer shall be used if the specs given for Moisture Density Relation Test (MDR) are

T 180?

Ans: 4.54 kg with 457 mm drop

46. A bean mold measuring 6 x 6 x 20 is to be used for sampling concrete, how many blows/tamps per layer

shall be applied?

Ans: 60 blows/layer

47. If asphalt mix having a weight of 3,020g and an aggregate weighing 2,865.98g, what is the % asphalt by

weight of mix?

Ans: 5.10%

48. What is the material used for Bituminous Prime Coat?

Ans: Cut-back asphalt

49. In Item 303, application of cover aggregates shall be evenly spread over the surface at the rate of

approximately _____?

Ans: 0.004 to 0.007 m

3

/m

2

50. Applying the tolerance of 0.4% for asphalt content to your answer in prob. 47, what is the acceptable range of

asphalt content?

Ans: 4.7% to 5.5%

51. An embankment having a PI of 30%, LL of 40% and GI of 0, what is the degree of compaction for this kind of

soil?

Ans: 95% degree of compaction

52. The minimum cement factor for concrete Class A is 9 bags/cu.m, how about for concrete Class B?

Ans: 8 bags/ cu.m

53. Quality control testing in a DPWH project is the responsibility of the_____?

Ans: Contractor

54. As Materials Engineer, when is the right time to start sampling and testing aggregates?

Ans: Once the source is identified

36

55. The minimum compressive strength for concrete Class P is 5,000 psi, what is the minimum compressive

strength for concrete Class C?

Ans: 3000 psi

56. The volume of concrete mixer per batch shall not exceed the mixers nominal capacity in cu.m as shown on

the manufacturers standard plate on the mixer, except that an overload up to _____ percent above the

mixers nominal capacity may be permitted provided concrete test data for strength, segregation, and uniform

consistency are satisfactory, and provided that no spillage of concrete takes place.

Answer: Ten (10)

57. Where do we take additional cores when the measurement of any core taken from pavement is deficient in

thickness by more than 25 mm?

Answer: at no less than 5 meter intervals parallel to the centerline in each direction from the affected

location

58. Under what climatic condition do we use lower penetration grade or hard asphalt?

Answer: hot climate (cold climate higher penetration grade or soft asphalt)

59. What is the basis for the acceptance or rejection of any construction material?

Answer: Materials test results/reports

60. Penetration test is for asphalt: cement is to _____?

Answer: consistency

61. Slump test is a very important test in fresh concrete to determine _____?

Answer: consistency of concrete

62. How many samples should be taken for an asphalt mix for each full days operation?

Answer: at least one but not to exceed three samples

63. The thickness of asphalt core using a caliper is based on how many measurements?

Answer: four (4)

64. The thickness of concrete core using a caliper is based on how many measurements?

Answer: nine (9)

65. Failed samples do not necessarily mean that the structure it represents is defective, why?

Answer: may be the sampling is incorrect

66. The specification calls for a 1: 2:4 concrete mix. In a one bagger mixer, which of the following amount of

water is most likely required for the mix?

Answer: 20 liters

67. The spot test on asphalt is used to determine ______.

Answer: overheating during the process of manufacture

68. How many samples shall be submitted for test if 315 pails of flat wall enamel paint are to be used in the

project?

Answer: four (4) pails

69. Aggregate Sub base course has a volume of 5, 000 cu.m and to be laid in a 15cm compacted depth. How

many samples shall be submitted for CBR test and for sieve analysis?

Answer: 2 samples for CBR and 17 samples for sieve analysis

70. How many samples shall be submitted for quality test if 60 tons of Bituminous Prime Coat is to be used in the

project?

Answer: Two (2) samples

71. How many compaction tests shall be conducted for Item 201 having a volume of 8,250 cu.m?

Answer: Six (6) compaction tests

72. What composed of Materials Quality Control Monthly Reports?

37

Answer: Summary of field tests and status of test

73. What is the required mixing of mortar for Item 505 (Stone Masonry)?

Answer: 1 part cement and 2 parts sand by volume with sufficient water

74. What is the required mixing of mortar for Item 500 (Pipe Culverts and Storm Drains)?

Answer: 1 part cement and 2 parts sand by volume with sufficient water

75. Before the project starts, the materials Engineer or the technician must have a program on how many samples

for each item of work should be tested based on the minimum testing requirements. What program or report

is this?

Answer: Quality Control Program

76. If sample splitter is not available for use in reducing samples for test, what is the alternative way of reducing

sample for testing size?

Answer: apply quartering method and get two opposite sides as sample

77. The road will not be opened to traffic until test specimens molded and cured have attained the minimum

strength requirements. If such tests are not conducted prior to the specified age the pavement shall not be

operated to traffic until _____ days after the concrete was placed.

Answer: Fourteen (14)

78. As the work progresses, the Materials Engineer should know how many sample has been submitted and tested

and how many samples are to be submitted, in other words the ME must refer to what report so that he/she

may be updated on the balance and on file quality test of the construction materials being used in the project?

Answer: Status of Test

79. It is the minimum moisture content at which the soil can be molded without breaking or crumbling up to 1/8

(3.2 mm).

Answer: Plastic Limit

80. The _____ is expressed as the moisture content corresponding to 25 blows.

Answer: Liquid Limit

81. The concrete has been tested for consistency by the use of a slump cone with base and tamping rod. After the

test, the height of concrete measured is 178 mm. what is the slump of the concrete?

Answer: 127 mm

82. What is the rate of revolution per minute of an abrasion Machine used for testing the mass percent of wear?

Answer: 30 33 rpm

83. If the design of concrete mix has the following corrected batch weights: cement = 40 kgs, fine aggregates = 65

kgs, coarse aggregate = 115 kgs, and water = 15 liters. What is your actual batch weights for 1 cu.m Class

A concrete?

Answer: 360 bags of cement; 585 kgs of fine aggregates; 1035 kgs coarse aggregates; 130 liters water

84. After the soil has been tested in an Abrasion Machine, the mass % of wear computed is equal to 21%. If this

material is for Item 201, does it pass the DPWH specs?

Answer: Yes, because the specs is 50% maximum

85. Quality Control Assurance Report should be submitted every _____?

Answer: week

86. One of the duties of Materials Engineer is to see to it that all the construction materials be tested:

Answer: before it is incorporated into work

87. What is the maximum depth or roadway embankment per horizontal layer in loose measurement?

Answer: 200 mm loose measurement

88. Why is it that 6 samples are needed for quality test of concrete masonry?

Answer: 3 samples for compressive strength and 3 samples for absorption

89. Sample submitted for test should have a tag bearing the name of the project, the quantity represented, kind of

sample, original source, who sampled and who submitted it, the date sampled and date submitted and etc.

What is the common name of that tag for you as Materials Engineer?

Answer: Sample Card

90. If course aggregate like embankment is to be placed in layers, how many layers should a 40 cm thick

Aggregate Base Course is placed?

Answer: Three (3)

91. The ME should always be alert of his schedule with regards to the number of days of a quality test that takes

place. Since not all construction materials can be tested just for a day or even a week so, what is the lead time

should he consider for a quality test of a cement sample?

Answer: One (1) month

92. CBR Sample for test has been compacted but it should be soaked for how many days before testing?

Answer: Four (4)

93. If sieve analysis and plasticity test are used for Soil Classification, what test that its result be used in field

density test?

Answer: Compaction Test or Moisture Density Relation Test

38

94. Heavy rains occur the night before prior to your scheduled field density test, are you going to pursue your

schedule? Why?

Answer: No, because the moisture content is high and can affect the result

95. Checking the gradation of composite aggregates and asphalt content of asphalt mix can be done by what test?

Answer: Extraction Test

96. What is the device used in testing for liquid limit test?

Answer: liquid limit device with grooving tool

97. What apparatus is used in plastic limit test?

Answer: glass plate

98. How long does a vibrator be inserted in a concrete mix?

Answer: not to exceed 15 seconds at 50 60 cm interval

99. Along the slope of high embankment _____ is provided as an erosion control measures and also to improve the

stability of the slope.

Answer: Berm

100. In soil and sub surface explorations for flood control design of foundation condition, a soil sample was

taken for field and laboratory tests. The test required for soil was taken, except

Answer: specific gravity, abrasion, water content, Atterberg Limits, gradation, compaction, relative density

101. Structure crossing above such covered underground drainage conduit shall be laid at least _____ above the

top of the conduit.

Answer: 1.0 m, 0.5 m, 1.5 m, 2.0 m

102. Class of stones for riprap ranging from 30 kgs to a maximum of 70 kgs with at least 50% of the stones

weighing more than 50 kgs.

Answer: Class B

103. Class of stones for riprap ranging from 15 kgs to a maximum of 25 kgs with at least 50% of the stones

weighing more than 20 kgs.

Answer: Class A

104. Class of stones for riprap ranging from 60 kgs to a maximum of 100 kgs with at least 50% of the stones

weighing more than 80 kgs.

Answer: Class C

105. Class of stones for riprap ranging from 100 kgs to a maximum of 200 kgs with at least 50% of the stones

weighing more than 1500 kgs.

Answer: Class D

106. The maximum size of stone for stone masonry.

Answer: 150 mm

107. The maximum size of aggregate for item 300.

Answer: 1 inch

108. Required maximum liquid limit for Item 300.

Answer: 35%

109. Required plasticity index range on Item 300.

Answer: 4% to 9%

110. Range of sand size.

Answer: 2.0 mm to 0.050 mm

111. The ratio of the volume of voids to volume of solids

Answer: void ratio

112. The ratio of the weight of water to the weight of solids

Answer: moisture content

113. Significance of grading test are, except

Answer: Gives particle size distribution, measures permeability, capillarity, measures the potential cohesion

of soil

39

114. Significance of plasticity index are, except

Answer: indicates compressibility, permeability, indicates the clay fraction of a binder material, measures

the shearing resistance of soil

115. Properties of concrete are, except

Answer: workability, strength, durability, cracking

116. In roadway construction test on sub grade, the following will determine the economical thickness, except

Answer: embankment, base, surfacing, sub-base

117. The relative consistency of a cohesive soil in natural state.

Answer: Liquidity Index

118. In Atterberg limit, the following are determined, except

Answer: shrinkage limit, liquid limit, plastic limit, group index

119. Minimum time for removal of forms and false works for centering under girders, beam, frames and arches.

Answer: 14 days (minimum % of design strength 80%)

120. Minimum time for removal of forms and false works for floor slabs.

Answer: 14 days (minimum % of design strength 70%)

121. Minimum time for removal of forms and false works for walls.

Answer: 1 day (minimum % of design strength 70%)

122. Minimum time for removal of forms and false works for columns.

Answer: 2 days (minimum % of design strength 70%)

123. Minimum time for removal of forms and false works for side of beams and all other vertical surfaces.

Answer: 1 day (minimum % of design strength 70%)

124. Amass of solid reinforced concrete cast around the head of a group of piles to ensure that act as a unit to

support the imposed load

Answer: Pile cap

125: An embankment shall be compacted layer by layer.

Answer: 150 mm

126. Class of concrete deposited in water.

Answer: Class Seal

127. Class of concrete used in all superstructures and heavily reinforced substructures. The important parts of the

structure included are slabs, beams, girders, columns, arch ribs, box culverts, reinforced abutments, retaining

walls, and reinforced footings.

Answer: Class A

128. Class of concrete used in footings, pedestal, massive pier shafts, pipe bedding and gravity walls, unreinforced

or w/ only a small amount of reinforcement.

Answer: Class B

129. Class of concrete used in thin reinforced sections, railings, pre-cast piles, cribbing, and for filler in steel grid

floors.

Answer: Class C

130. Class of concrete used in pre stressed concrete structures and members.

Answer: Class P

131. Height of dropping concrete to the point of deposit

Answer: 1.50 m

132. Reflectorized Thermoplastic Pavement Markings

Answer: Item 612

133. Permitted variation from the design thickness of layer for Item 300

Answer: + 15 mm and 5 mm

40

134. Item 310 shall have a mass percent of air voids with range of _____

Answer: 3% to 5 %

135. Dowel bars for PCCP shall be _____

Answer: plain bars

136. Concrete beam sample when tested by Third Point Method shall have a flexural strength of _____ when

tested in 14 days.

Answer: 3.80 MPa

137. When the required thickness of Item 200 is more than 150 mm, the aggregate sub base shall spread and

compacted in ____

` Answer: two or more layers

138. Item 202 shall have a minimum soaked CBR value of _____

Answer: 80%

139. Permitted variation from design thickness of layer for Item 201.

Answer: 10 mm

140. Sieve designation standard (in mm) for 0.425 mm to alternate US standard

Answer: No. 40

141. If slag is used as course aggregate for Item 311, the minimum density is _____

Answer: 1,120 kg/m

3

142. Minimum price allowed of contract for deficiency in strength of concrete specimens for PCCP which 10% to

less than 15%

Answer: 70%

143. This joint is also called cold joint. It is constructed when there is an interruption of more than 30 minutes in

the concreting operation

Answer: Transverse Construction Joint

144. Minimum variation of the surface from the testing edge of the straight edge between contacts with the surface

in Item 310

Answer: 6.0 mm

145. Portland Cement Treated Plant Mix Base Course after the completion of the final rolling, the surface will be

treated with bituminous curing seal, how much is the rate of application?

Answer: 0.5 L/m

2

to 1.0 L/m

2

146. In Item 201, the volume required in the project is 10,000 cu.m. The required number of CBR test is _____

Answer: four (4)

147. Slump test of concrete determines the following, except

Answer: workability, fluidity, consistency, job density

148. The significance of liquid limit are the ff., except

Answer: measures the shearing resistance of soil, measures the potential cohesion of soil, fineness and shape

of grain, Atterberg limits

149. In soil classification, 35% or less passing No. 200 sieve are the ff., except

Answer: A-1, A-2, A-3, A-4

150. To evaluate the performance quality of a soil as a highway subgrade material

Answer: Group Index

151. If the paving of concrete pavement will be done at the rate 200 ln.m, half width per paving day, how many

sets of concrete beam samples shall be required. Given: A = 115,000 sq.m, width = 6.50 m, thickness = 230

mm

Answer: 353 sets

152. The required liquid limit for selected borrow toppings

Answer: 30%

153. The maximum plastic limit for selected borrow toppings

Answer: 6%

154. Soil is considered unsuitable material when the liquid limit and plastic limit exceeds

Answer: 80% and 55% respectively

155. Soil is considered unsuitable when the material density is

Answer: 800 kg/cu.m or lower

156. The plasticity index is determined in accordance with

Answer: AASHTO T 90

157. The liquid limit is determined in accordance with

Answer: AASHTO T 89

158. The required compaction of embankment, layer by layer

Answer: 95%

159. The minimum compaction trial of embankment

Answer: 10 m wide by 50 m long

41

160. At least how many in situ density tests should be carried out for each 500 m

2

of each layer of compacted

fill?

Answer: three (3)

161. Maximum plasticity index for Item 200

Answer: 12%

162. Maximum liquid limit for Item 200

Answer: 35%

163. Maximum size of grading requirement for Item 200

Answer: 2

164. The Los Angeles Abrasion Test for aggregate sub-base course is determined in accordance with

Answer: AASHTO T 96

165. The required abrasion loss for Item 200

Answer: 50%

166. The minimum CBR required for Item 200

Answer: 25%

167. The required soaked CBR for aggregate sub-base course is determined by

Answer: AASHTO T 193

168. Minimum required percent compaction of each layer of aggregate sub-base course

Answer: 100%

169. In place density determination of aggregate sub-base course material shall be made in accordance with

Answer: AASHTO T 191

170. In some areas where the conventional base course materials are scarce or non available, the use _____

allowable percent weathered limestone (anapog) blended with crushed stones or gravel.

Answer: 40% (60% - crushed stones or gravel)

171. Maximum size of aggregate for base course material under grading B

Answer: 1 inch

172. Maximum required percent abrasion loss for Item 202

Answer: 45%

173. Maximum required mass percent shall have at least one (1) fractured face of Item 202

Answer: 50%

174. Minimum required soaked CBR for Item 202

Answer: 80%

175. Maximum size of aggregate for Item 202 under grading A

Answer: 1 inch

176. Maximum size of aggregate for Item 201 under grading A

Answer: 2

177. Maximum size of aggregate for Item 202 under grading B

Answer: 1 inch

178. This item consists of a foundation for surface course composed of soil aggregate, lime, water in proper

proportion, road mixed and constructed on a prepared subgrade/subbase.

Answer: Lime Stabilized Road Mix Base Course (Item 203)

179. The required plasticity index for Item 203

Answer: 4% to 10%

42

180. Maximum required mass percent of wear for the aggregate on Item 203

Answer: 50%

181. Maximum size of aggregate for Item 203 under grading A and B

Answer: 2

182. Item number for water?

Answer: Item 714

183. In Item 203, how much is the required mass percent of lime to be added to the soil aggregate?

Answer: 3% to 12%

184. Minimum soaked CBR for Item 203

Answer: 100%

185. Required percent compaction for Item 203

Answer: 100%

186. Equipment to be used for initial rolling

Answer: Pneumatic tire roller

187. Equipment to be used for final rolling

Answer: 3 wheel tandem type steel wheel roller

188. The test on asphalt cement consisting of heating the asphalt in an open cup and passing a small test flame

Answer: flash point

189. It is a manually operated device for deriving a measurement of roughness from the surface profile which

may be expressed in terms of International Roughness Index.

Answer: Merlin Road Roughness Measuring Device

190. It is used for the rapid in situ measurement of the structural properties of existing pavement with unbound

granular properties.

Answer: Dynamic Cone Penetrometer

191. What is the thinnest cut back asphalt?

Answer: MC 3000

192. In the construction of bridges projects, what is the method used to determine the casting length of the regular

piles?

Answer: Test Pitting

193. It is an equipment which is used to measure differential deflection between joints of a concrete pavement, to

determine the modulus of the existing slabs for use in the design of an overlay, and to determine the

remaining life of existing pavement.

Answer: Falling Weight Deflectometer

194. What is the equipment used to pinpoint rebars, conduits, pipes, nails and other metals embedded in concrete

before cutting or drilling?

Answer: Rebar Locator

195. What is the instrument or equipment used to measure for surface test of concrete and asphalt pavements as

soon as he concrete has hardened sufficiently or as soon as the asphalt mix has been initially compacted?

Answer: 3 meter straight edge

196. What is the latest state of the art equipment consuming radioactive material which is commonly used in the

compaction control of earth and asphalt road construction and in the measurement of moisture content?

Answer: Nuclear Density Gauge

197. It is an instrument used to measure pavement deflections resulting from vehicle wheel loadings. The results

of the elastic deformation tests are used to evaluate the structural condition of roads, and to help in the design

of road strengthening measures and road capacity improvement.

43

Answer: Benkelman Beam and Deflection Logger

198. What is the instrument that is used for examining the quality of rigid materials such as rocks and concrete?

This instrument is a non destructive portable instrument with dimensions of 110 mm x 180 mm x 160 mm

and its main uses includes the determination of concrete strength (either in situ or pre cast),also to

determine the presence of voids, cracks and other imperfections.

Answer: Pundit Ultrasonic Concrete Tester

199. Soil stabilizing agent

Answer: Lime for silty and clayey soil

Cement for sandy soil

200. Water content at which soil passes from plastic to liquid state.

Answer: LIQUID LIMIT

201. Water content at which soil passes from semi solid to plastic state.

Answer: PLASTIC LIMIT

202. Water content at which soil passes from solid to semi solid.

Answer: SHRINKAGE LIMIT

203. Steel bars placed along longitudinal joints to hold the adjoining slabs together are called _____

Answer: tie bars

204. The concrete pavement surface shows high spots of 15 mm in a 3 m straight edge. The concrete in the area

represented by these high spots _____

Answer: shall be removed and replaced (but if high spots being noted exceeds 3 mm but not exceeding

12 mm, it shall be ground down only.

205. The calibration of the Universal testing machine is conducted _____

Answer: Once a year

206. What is the sampling requirement of bituminous mixture?

Answer: 1 sample per 130 tonnes

207. What is the depth of the thermometer inserted in the bituminous mixture?

Answer: 2

208. In the design of bituminous mix, the design criteria for stability under the Marshall Stability Method for

heavy traffic is ____

Answer: 1800 lbs

209. The stability criteria of the Marshall Stability Method is the maximum load resistance that a specimen will

develop at _____

Answer: 60

210. Bituminous mix specimens are compacted at how many blows at each end for a heavy traffic design under

the Marshall Stability Method?

Answer: 75 blows

211. In a penetration test, if the penetration is 9. What is the grade of the asphalt?

Answer: 85 100

212. In case of scarcity or non availability of Type I Portland cement, what type of pozzolan shall be used?

Answer: Portland Pozzolan Cement Type 1P

213. The required flexural strength of concrete beam sample of Item 311 when tested by the midpoint method.

Answer: 4.50 MPa

214. The required forms to be used in concrete pavement are _____

44

Answer: Steel forms of an approved section

215. Sowing of the weakened plane joints shall be done usually at _____

Answer: Within 24 hours

216. Removal of forms of concrete pavement

Answer: 24 hours

217. The required slump of concrete using slip form method of paving is _____

Answer: 1 inches

218. Deficiency in strength of concrete specimen wherein no payment of contract price allowed is _____

Answer: 25% or more

219. What is the length of a lot of pavement when a single traffic lane is poured?

Answer: 1,000 ln.m

220. What is the length of a lot of pavement when two lanes lane are poured concurrently?

Answer: 500 ln. m

221. What is the required size of concrete beam sample?

Answer: 150 mm x 150 mm x 525 mm

222. What is the required number of set of concrete beam specimens to be taken from each 330 sq. m of pavement

of fraction thereof placed each day?

Answer: 1 set

223. What is the required compressive strength that concrete piles be moved?

Answer: 80% of the designed 28 day compressive strength

224. The required circular pin diameter used to bend 10 20 mm reinforcing steel.

Answer: 6d (20 mm 25 mm = 8d: 28 mm and above = 10d)

225. The mixing speed of the transit mixer during batching.

Answer: 4 to 6 rpm

226. What is the slump of concrete Class A deposited in water?

Answer: 10 to 20 cm

227. This item shall consist of preparing and treating an aggregate base course preparatory to the construction of a

bituminous surface course.

Answer: Prime Coat

228. What item no. is Bituminous Surface Treatment?

Answer: Item 304

229. What is the required tolerance for bituminous material in job mix formula for Item 310?

Answer: 0.4%