Beruflich Dokumente

Kultur Dokumente

01 Sisprod - Pengantar

Hochgeladen von

Eko Adhitya Warman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten10 Seitenpengantar sisprod

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenpengantar sisprod

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten10 Seiten01 Sisprod - Pengantar

Hochgeladen von

Eko Adhitya Warmanpengantar sisprod

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

01 01

PENGANTAR SISTEM PENGANTAR SISTEM

PRODUKSI PRODUKSI

Presentasi Kuliah

TKI-313 Sistem Produksi

Jurusan Teknik Universitas Muhammadiyah

Surakarta

Dosen :MuchDjunaidi

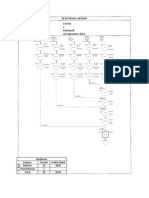

The Role and Importance of The Role and Importance of

Operations Operations

Role of

Operations

Purchasing of Raw

Materials to meet

Production requirements

Managing Stock

Using quality techniques

to ensure maximum

2

Operations

to ensure maximum

quality output is achieved

from minimum inputs

Warehousing and

distribution of

finished products

Ensuring appropriate

methods of

production are used

The Role and Importance of The Role and Importance of

Operations Operations

Operations is important because:

it is one of the CORE activities of any it is one of the CORE activities of any

business

It produces the products and services

which enable the business to make a

profit

OPERATING SYSTEMS OPERATING SYSTEMS

Sistem operasi memiliki 3 tahap berbeda:

Input Proses Output

Raw material Using different The actual goods Raw material

Tenaga kerja

Energi

Using different

stocks in order

to produce a

different

product

The actual goods

INPUT, PROCESS, OUTPUT INPUT, PROCESS, OUTPUT

Production Systems Production Systems

Throughout the operations process decisions have to be made

about the nature of that process.

Planning - What to produce?

Production How to produce it?

Purchasing cost, quantities, quality? Purchasing cost, quantities, quality?

Warehousing and storage (including stock control)

Distribution In-house or outsourced?

Each of these interact with other functional areas of

the Organisation.

PRODUCTION SYSTEMS IN PRODUCTION SYSTEMS IN

MANUFACTURING MANUFACTURING

This is looking at:

the layout of the factory (where each stage of production

takes place)

by which machine or worker,

how many workers/how many machines. how many workers/how many machines.

The splitting up of the production process into small stages

or different jobs is called the division of labour.

A successful system will need a flow of stocks from one job

to another to make sure that there are no delays due to

shortages or bottlenecks

The main factors taken into consideration The main factors taken into consideration

when deciding which production system to when deciding which production system to

use are: use are:

the nature of the product different products made

in different ways

the quantity to be produced mass production

techniques different to customised products

the resources available finance, number and skills

of staff, size and capacity of factory

Stage of development of business small

businesses tend to have limited capacity and lack of

resources as business grows they can extend product

range

The main factors taken into consideration when The main factors taken into consideration when

deciding which production system to use are: deciding which production system to use are:

Labour intensive vs Capital intensive

Labour intensive is where the cost of labour is greater than the cost

of capital. In the developed country (UK, USA, Japan, etc), labour

is expensive and therefore there are very few companies which

are labour intensive. In other parts of the world labour is cheap

and therefore cost-effective. and therefore cost-effective.

Availability of technology

Continuing developments in technology (CAM, CAD, automation) allow

businesses to design, develop and produce products more quickly.

Robots can carry out very complicated tasks very quickly and with a

high degree of accuracy they can do jobs which humans cant and

there is less wastage and more consistent quality.

Labour Intensive Production Labour Intensive Production

This occurs when:

The cost of labour is cheap and readily

available

The product requires craftmanship to produce

The business is small and does not have the

money to purchase expensive equipment money to purchase expensive equipment

Disadvantages of labour intensive production:

Skilled workers are expensive to pay

Production is limited to small scale

Cannot take advantage of economies of scale

Consistent quality is hard to achieve

Capital Intensive Production Capital Intensive Production

This occurs when:

A standard product is being produced with standard

operations

Labour supply is scare or expensive

Consistency of product and quality is required

economies of scale are desirable

Continuous production is required Continuous production is required

Disadvantages of Capital Intensive Production:

Set-up costs are very high

Lost production time during breakdowns or

maintenance is very costly

Individual customer requirement cannot be met

Worker motivation can be low due to repetitive work

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Marantz SR8001 AV Surround Receiver Amplifier User ManualDokument79 SeitenMarantz SR8001 AV Surround Receiver Amplifier User Manualtrevor5409Noch keine Bewertungen

- SRS DOCUMENT (Hospital Management System)Dokument24 SeitenSRS DOCUMENT (Hospital Management System)Aaqib Sultan80% (5)

- As Built ScheduleDokument7 SeitenAs Built ScheduleDayana Romero MonroyNoch keine Bewertungen

- Project Execution Plan: Document NoDokument26 SeitenProject Execution Plan: Document NoLeon PeterNoch keine Bewertungen

- Nitin - Pant Magento - Lead Resume Sep 2022Dokument2 SeitenNitin - Pant Magento - Lead Resume Sep 2022Manisha AswarNoch keine Bewertungen

- Manual Wayne 3G7221P-8JKDokument96 SeitenManual Wayne 3G7221P-8JKAlejandro AdriasolaNoch keine Bewertungen

- Redit ResumeDokument3 SeitenRedit ResumeIvanknezNoch keine Bewertungen

- Symbolic Representation For Process Measurement Control Functions and InstrumentationDokument20 SeitenSymbolic Representation For Process Measurement Control Functions and InstrumentationEngr Subyal Huda100% (1)

- Peta Proses OperasiDokument1 SeitePeta Proses OperasiEko Adhitya Warman100% (2)

- 07 Sisprod - FMSDokument35 Seiten07 Sisprod - FMSKristin MackNoch keine Bewertungen

- Script Ali Goes To UniversityDokument4 SeitenScript Ali Goes To UniversityBend ByfaNoch keine Bewertungen

- 06 Sisprod - Just in TimeDokument25 Seiten06 Sisprod - Just in TimeEko Adhitya WarmanNoch keine Bewertungen

- 05 Sisprod - Computer Numerical ControlDokument29 Seiten05 Sisprod - Computer Numerical ControlEko Adhitya WarmanNoch keine Bewertungen

- 04 Sisprod - Line BalancingDokument53 Seiten04 Sisprod - Line BalancingMuhamad Khairul Mas'udNoch keine Bewertungen

- 03 Sisprod - Layout TypesDokument20 Seiten03 Sisprod - Layout TypesEko Adhitya WarmanNoch keine Bewertungen

- 02 Sisprod - Process SelectionDokument20 Seiten02 Sisprod - Process SelectionEko Adhitya WarmanNoch keine Bewertungen

- Automotive Quality High-Power: Stanley Electric's Latest High-Power IR LEDDokument1 SeiteAutomotive Quality High-Power: Stanley Electric's Latest High-Power IR LEDbobbbNoch keine Bewertungen

- Calculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)Dokument4 SeitenCalculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)erson1981Noch keine Bewertungen

- CS2253 Computer Organization and Architecture QBANK2Dokument4 SeitenCS2253 Computer Organization and Architecture QBANK2John LeonsNoch keine Bewertungen

- GoFood UATDokument3 SeitenGoFood UATArsyadani LuthfiNoch keine Bewertungen

- MMC Clinker CoolerDokument4 SeitenMMC Clinker CoolerAlbar BudimanNoch keine Bewertungen

- Practical Java Machine LearningDokument46 SeitenPractical Java Machine Learningeazpil01Noch keine Bewertungen

- Hannstar Product Specification: Model: Hsd101Pfw2Dokument26 SeitenHannstar Product Specification: Model: Hsd101Pfw2massipoedNoch keine Bewertungen

- (4th Year) Roadmap To Dream PlacementDokument1 Seite(4th Year) Roadmap To Dream PlacementashwinNoch keine Bewertungen

- Primary Connector Kit Compliance and Applications SpecificationsDokument2 SeitenPrimary Connector Kit Compliance and Applications SpecificationsluisNoch keine Bewertungen

- Please Refer To The Product Specifications For Details.: Jul-2017/Rev.01Dokument4 SeitenPlease Refer To The Product Specifications For Details.: Jul-2017/Rev.01HARSHA PNoch keine Bewertungen

- sc1088 PDFDokument7 Seitensc1088 PDFMariuszChreptakNoch keine Bewertungen

- Joby Charging GEACS FinalDokument2 SeitenJoby Charging GEACS Finalhjkim0907Noch keine Bewertungen

- Save The Man.a Mobile Game Application 1 1 2Dokument50 SeitenSave The Man.a Mobile Game Application 1 1 2Gonzales RhoybinsonNoch keine Bewertungen

- Watermaster Rev.wDokument52 SeitenWatermaster Rev.wJack NgNoch keine Bewertungen

- Vadeb Brochure GeneralDokument2 SeitenVadeb Brochure GeneraljmpbarrosNoch keine Bewertungen

- SCR100 User Manual V1.1Dokument35 SeitenSCR100 User Manual V1.1Luis Boch EnriquezNoch keine Bewertungen

- List of Vlsi BooksDokument15 SeitenList of Vlsi BooksMahesh100% (2)

- Security Checkup Harmony Endpoint 2024-03-25T09!02!44 KenpipeSacco-797494aa-Hap2 FinalDokument15 SeitenSecurity Checkup Harmony Endpoint 2024-03-25T09!02!44 KenpipeSacco-797494aa-Hap2 FinalellyineahNoch keine Bewertungen

- Chatgpt Chatbot MiniDokument2 SeitenChatgpt Chatbot MiniJulie BlintNoch keine Bewertungen

- ITD Brochure InfromationDokument5 SeitenITD Brochure InfromationAfrican InstituteNoch keine Bewertungen

- S.O.L.I.D First Five Object-Oriented Design OODDokument2 SeitenS.O.L.I.D First Five Object-Oriented Design OODnacNoch keine Bewertungen

- Dbms Solutions For Past Question PapersDokument31 SeitenDbms Solutions For Past Question PapersAriel PeterNoch keine Bewertungen