Beruflich Dokumente

Kultur Dokumente

90.1307 Tuc-6 BW o & M Manual

Hochgeladen von

Rakesh Karan SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

90.1307 Tuc-6 BW o & M Manual

Hochgeladen von

Rakesh Karan SinghCopyright:

Verfügbare Formate

OPERATION & MAINTENANCE MANUAL FOR

BELT WEIGHER

FLSmidth Pfister India Ltd.

OPERATION & MAINTENANCE MANUAL FOR

BELT WEIGHER

TIL JOB NO : 90.1307

CUSTOMER : JINDAL STEEL & POWER LIMITED.

CONSULTANT : JOCABS ENGG

EQPT : BELT WEIGHER (BW)

FLSmidth Pfister India Ltd.

TABLE OF CONTENTS

SR. NO. DESCRIPTION PAGE NO.

1.0

OPERATION & MAINTENANCE MANUAL FOR TUC-6

CONTROLLER

45

2.0

PRE-REQUISTIES FOR INSTALATIONS FOR A BELT WEIGH

SCALE.

01

3.0 MECHANICAL DATA.

3.1 ASSEMBLY & STARTUP INSTRUCTION. 01

3.2 MAINTENANCE INSTRUCTION. 01

3.3 TESTING / ADJUSTING MANUAL. 01

3.4 ERECTION INSTRUCTION MANUAL. 02

3.5 SAFETY & STORAGE MANUAL. 02

4.0 TECHNICAL DATA.

4.1 TACHOMETER TECHNICAL LITERATURE. 04

4.2 LOADCELL SPECIFICATION. 03

4.3 DATA SHEET. 05

5.0 ELCTRICAL DRAWING 60

6.0 MECHANICAL GAD. 05

TUC 6 OPERATION & MAINTENANCE MANUAL

FLSmidth Pfister India Ltd.

TUC 6 OPERATION & MAINTENANCE

MANUAL

OPERATION & MAINTENANCE MANUAL - INDEX

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

Page 1 of 1

Software_version: 2.x (onwards)

2007-06-14

1.0 Technical data............................................05

TUC6-020-EE23.0-R0

2.0 Functional Description.................................... 04

TUC6-020-EE23.1-R0

3.0 Operator's Manual.........................................07

TUC6-020-EE23.2-R0

4.0 Commissioning Instructions.................................. 11

TUC6-020-EE23.3-R0

5.0 Menu Operations...........................................08

TUC6-020-EE23.4-R0

6.0 Parameter Listing..........................................03

TUC6-020-EE23.5-R0

7.0 Appliance Description..................................... 06

TUC6-020-EE23.10-R1

8.0 Front Facia Layout........................................01

TUC6-020-EE25-R0

TECHNICAL DATA

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.0-R0 Page 1 of 5

Software_version: 1.0 (onwards)

2007-05-15

1.0 System

1.1 Microprocessor : 8xC51FA

1.2 Memory : 64K EPROM

8K RAM with integral Battery

Backup.

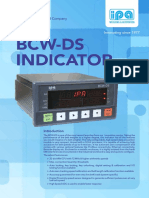

2.0 Construction

2.1 Housing : Aluminium enclosure in DIN

: format

2.2 Colour : Silver anodized

2.3 Dimensions (W*H*D) : 144 * 72 * 245 mm

2.4 Control Panel cutout : 138 * 68 mm

2.5 Control Panel thickness : Min. 1 mm, max. 15 mm

2.6 Mounting space : Approx. 300 mm deep with

connectors

2.7 Wall clearance : Min. 100 mm upwards.

Min. 60 mm on each side with

natural convection

2.8 Weight : Approx. 1.0 Kg

2.9 Mounting : 2 Grub screws at the sides

2.10 Protection type : IP 54 (Front)

3.0 Display

3.1 Display : 2 lines * 16 Characters Vacuum

Fluorescent Display

3.2 Colour : Blue

3.3 Type : VFD, alphanumeric

3.4 Digit height : 5.5 mm legible to approx. 2 m

3.5 Reading angle : Approx. 40 .

3.6 Dimension sign : kg, t (User selectable)

4.0 Control panel

4.1 Type : Membrane foil with pressure

sensitive keyboard.

TECHNICAL DATA

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.0-R0 Page 2 of 5

Software_version: 1.0 (onwards)

2007-05-15

5.0 Environment

5.1 Operating temperature : 0 C to +55 C

5.2 Storage temperature : -20 C to +85 C

5.3 Humidity : Max 85 % relative, without

condensation

6.0 Measurement Input - Loadcell

6.1 Terminal : 9 pole, DB connector

6.2 Measurement input range : 0 to 28 mV

6.3 Supply voltage : Internal 12 V 5 %, Max. 110mA

(e.g. 3 loadcells of 350 ohms in

parallel)

6.4 Measuring cable : 6 core, shielded (min. 80%

optical cover)

Isolation resistance min.120

Mohm/Km

Core cross-section min. 0.34 mm

to 0.5 mm solderable directly to

connector. Cable diameter upto

8mm mountable in connector.

Connect greater cross-sections

with solderable connectors.

6.5 Cable length : l =5.1 * R * A / n

R =Loadcell resistance in ohm

A =Cable cross-section in mm

n =no. of loadcells in parallel

l =Cable length , max. 1000 m

7.0 Measurement Input - Tacho

7.1 Terminal : Screw clamped terminals.

Conductor size 0.14 to 1.5 mm

2

.

7.2 Input signal : Max. 15 V

7.3 Measurement input range : 10 - 2500 Hz, 12 V

7.4 Supply voltage : Internal 12 V 5 %; max. 10 mA

TECHNICAL DATA

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.0-R0 Page 3 of 5

Software_version: 1.0 (onwards)

2007-05-15

7.5 Measuring cable : 3 core, shielded (min. 80%

optical cover)

Isolation resistance min.120

Mohm/Km

Core cross-section min. 0.34 mm

to 1.5 mm

2

.

7.6 Cable length : Max. 1000 m

8.0 Digital Outputs

8.1 Output type : 4 Nos. Relay contacts, 220Vac,

2 Amp contact rating

8.2 Terminal : Screw clamped terminals

Conductor size from 0.5 to 1.5

mm

2

8.3 Functions : RLY1 is used for S1 or S2 O/P.

RLY2 is used for Limit O/P

RLY3 & RLY4 each can be used

for a.] Tacho Fault

b.] Belt Load Error

c.] General Fault

d.] Measurement ON.

9.0 Power supply

9.1 Terminal : Screw clamped terminals

Conductor size 0.14 to 1.5 mm

2

.

9.2 Voltage : 18-36 Vdc

9.3 Power consumption : 12 VA max.

10.0 Analog output

10.1 Function : 0 -20 mA / 4-20 mA isolated o/p

corresponding to Actual feedrate

10.2 Isolation type : Galvanic

10.3 Load : 500 Ohm

10.4 Terminal : Screw clamped terminals

Conductor size 0.14 to 1.5 mm

2

.

10.5 Cable type : 2 core ,shielded.

TECHNICAL DATA

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.0-R0 Page 4 of 5

Software_version: 1.0 (onwards)

2007-05-15

Individual core connectable

directly to connector.

11.0 Impulse output

11.1 Function : 1 relay output corresponding to

either Totaliser1 or Totaliser2.

50 mSec to 500 mSec

programmable ON time pulses

11.2 Terminal : Screw clamped terminals

Conductor size 0.14 to 1.5 mm

2

.

12.0 RS-485 Interface

12.1 Terminal : 5 pole DIN socket

12.2 Transmission : Half duplex, serial bit,

asynchronous mode

12.3 Baud rate : 4800,9600,19200 baud

12.4 Format 8 bits, 1 stop, Np / Ep / Op.

12.5 Cable type : 2 core ,shielded ,max 0.5 mm

2

individual core connectable

directly to connector.

12.6 Function : Used to interface SIO modules to

TUC-6 unit.

13.0 Profibus-DP Interface

13.1 Terminal : 9 pole, DB connector

13.2 Transmission mode : RS 485

13.3 Baud rate : 9600 bps to 12 Mbps max

13.4 Station Address : 01 to 99

TECHNICAL DATA

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.0-R0 Page 5 of 5

Software_version: 1.0 (onwards)

2007-05-15

Optional Interface Modules

14.0 Serial I/O Module

16.1 Interface : RS-485

16.2 Protocol : Modbus RTU

16.3 Terminal : 14-pin screwed terminals

16.4 Transmission : Half duplex, serial bit,

synchronous, adjustable bit mode.

16.5 Baud rate : 4800, 9600, 19200 baud.

16.6 Format : 3 options, user selectable.

16.7 Cable type : 2 core, shielded, max 0.5 mm

individual core connectable

directly to connector.

16.8 Cable length : Max. 1000 m at 19200 baud.

FUNCTIONAL DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.1-R0 Page 1 of 4

Software_version: 1.0 (onwards)

2007-05-15

TABLE OF CONTENTS

1.0 Principle.................................................... 2

1.1 TUC-6 Belt Weigher / SFM system,Overview........... 2

1.2 System Features......................................... ...2

2.0 Functions.................................................. 3

2.1 Zero Setting............................................ 3

2.2 Linearisation of material load...................... 3

2.3 Error Messages.......................................... 3

3.0 Interfaces.................................................. 3

3.1 Computer Interface................................. 3

3.2 Pulse outputs.......................................... 3

3.3 Analog outputs........................................ 3

3.4 Digital I/O............................................ 4

FUNCTIONAL DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.1-R0 Page 2 of 4

Software_version: 1.0 (onwards)

2007-05-15

1.0 Principle

The Conveyor Belt Weigher system consists of a conveyor belt whose load is constantly

weighed with a measuring device. The volume flow is calculated from the product of load

(Load cell value) and belt speed (Tacho frequency or fixed frequency). Integration of the

instantaneous conveyed value results in the amount transported.

The Solid Flow Meter system consists of an Impact plate whose load is constantly

weighed with a measuring device. The volume flow is calculated from the product of load

(Load cell value) and internal speed. Integration of the instantaneous conveyed value

results in the amount transported.

1.1 TUC-6 Belt Weigher / Solid Flow Meter System, Overview:

The TUC-6 calculates the instantaneous value of the material being conveyed and

keeps track of the amount of material conveyed over a period of time.

The measuring unit is operated using the TUC-6 keypad, and the 2 line, 16 digit LCD

display. The display values are called using fixed keys or displayed through pull-down

selection.

The configuration of TUC-6 is determined by the parameter fields. To do this, a selection

is made from the given values in the configuration menus or a parameter is entered

using the front keypad.

1.2 System Features

- Fail safe EEPROM memory for configuration parameters

- Battery buffered RAM for working data

- Date/Time in battery buffered Real Time Clock

- Integrated keyboard and display

- Data memory even with replacement of interface cards

- 1 Impulse output

- Isolated analog signal output interface

- Curve correction

- Zero correction

- Alphanumeric Text displays for Fault diagnosis

FUNCTIONAL DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.1-R0 Page 3 of 4

Software_version: 1.0 (onwards)

2007-05-15

2.0 Functions

2.1 Zero setting

Belt related influences on the belt load can be compensated by means of zero

correction. To do this, the correction process is started with the belt running idle. The

zero correction value, with which the belt load is set off, is calculated automatically after

the zero correction process. The zero correction is initiated from the front keypad.

2.2 Linearisation of material load

If the load on the measuring cell is not linear in the whole range, the load can be

laniaries by entering up to ten correction points.

2.3 Error Messages

Faults/Errors caused by incorrect operations are displayed in clear text in the control

display.

Faults are also made available at the output in the form of potential free contacts.

3.0 Interfaces

3.1 Computer Interface

It is possible to enable remote monitoring and control of the system, by connecting the

unit to a master controller through the serial interface. Modbus RTU and Profibus

protocol options are supported through use of optional modules.

3.2 Pulse Output

One-pulse output (either S1 or S2) is available from the system corresponding to the

quantity being conveyed. The resolution & pulse width of the Totalizer pulses are

configurable.

3.3 Analog output

Isolated Analog output is available for display and/or measurement tasks. Analog current

output corresponds to Actual Feedrate.

FUNCTIONAL DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.1-R0 Page 4 of 4

Software_version: 1.0 (onwards)

2007-05-15

3.4 Digital I/O

One digital input corresponding to external START / STOP command is available. This is

+12V signal I/p to TUC-6.

In case if above input is not used for External Start / Stop command, it can be used for

Tacho input to the TUC-6.

Four Digital outputs are available in the form of potential free relay terminals

corresponding to Pulse Output, Limit Output & Error Outputs.

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 1 of 7

Software_version: 1.0 (onwards)

2007-05-15

TABLE OF CONTENTS

1.0 Keypad and display............................................. 2

1.1 Keypad................................................. 2

1.2 Display................................................. 4

2.0 Functions................................................... 5

2.1 Start.................................................. 5

2.2 Stop.................................................. 5

2.3 Zero setting.......................................... 5

2.4 Error Acknowledgement................................. 6

3.0 Parameter input............................................ 6

4.0 Error Messages............................................ 7

5.0 Abbreviations............................................... 7

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 2 of 7

Software_version: 1.0 (onwards)

2007-05-15

1.0 Keypad and display

1.1 Keypad

TUC-6 has a multi-function keypad, the definition of keys change as per the menu

operations. Some keys have alphabets in the lower left hand corner. These are not used

in this module. The numbers 0 to 9 in the upper right hand corner of some keys are used

for numeric entries.

Characters/Symbols used in the keys have following meaning,

Key not defined

BB - Display Belt Load in %

Key not defined

Display Actual Flowrate

Display Totalizer 1

Key not defined

Display Tacho Frequency

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 3 of 7

Software_version: 1.0 (onwards)

2007-05-15

Display Totalizer 2

Start Zeroing in Manual/Local modes

Key not defined

Cancel (CL)

-In Main Program, S1 value displayed in Line 2 is cleared

-Used to Clear Fault displays

-When used with 'Esc' key, is used to exit from menu.

-Used to accept values modified in the SET menu.

HOR

-Selection of options from list.

-'ENTER' key to accept Password value

Start/Stop

ESC

-Used in combination with 'CL' key to exit from menu.

-Used to discard values modified in the SET menu.

-Display mV value in Calibration menu

UP/DOWN - Scroll Menu/parameter list being displayed.

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 4 of 7

Software_version: 1.0 (onwards)

2007-05-15

1.2 Display

When the TUC-6 is powered on from the mains, the display "Transweigh" is shown for 5

secs.

The system then displays either the Online Menu or the Offline menus, depending on the

status of key pressed during the 5 secs. delay.

-Press 'VER' to bypass 5 sec. delay & jump to Main Program menu.

-Press 'CL' to bypass 5 sec. delay & jump to Offline menus.

If no key is pressed, the system enters Main Program menu at the end of 5 sec. delay.

a) In the Online menu Main Program, the following parameters can be displayed

by selecting keys from the keypad 'X', 'S1', 'S2', 'BB', 'T':

X Actual flowrate value in units selected

S1 Totalizer1 value

S2 Totalizer2 value

BB Belt load value in %

T Weigh Feeder Tacho frequency in Hz.

Other Values are selectable with the '' key. These values are shown below with their

designated names.

BS Belt Speed in m/sec

Date In format yy-mm-dd

Time In format Hour:Minute

b) Error messages

The error messages have the highest priority, i.e. they are not overwritten by any

other display and remain in display until they are acknowledged.

The error messages are listed in section 4.0 "Errors Messages" of this manual.

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 5 of 7

Software_version: 1.0 (onwards)

2007-05-15

2.0 Functions

2.1 Start / Stop

There are two means by which TUC-6 accepts Start/Stop Command.

One is by pressing Start button provided on the Keypad.

Another is by External Start / Stop i/p connected to TUC-6 on X1 connector terminals 10-

11-12.

When in OFF line mode, CONFIGURATION MENU, START -> INT is selected then

TUC accepts command from keypad.

When in OFF line mode, CONFIGURATION MENU, START -> EXT is selected then

TUC accepts command from external input.

When External Start/Stop input is connected to TUC-6, internal FIXED TACHO must be

selected for the system.

START Condition:-

Display - LED above 'START' on.

STOP Condition:-

Display - LED above 'START' off.

2.2 Zero setting

With this key, Zero correction process is initiated.

Conditions

- System in Local/De-Interlock-Volumetric mode

- Belt started

Display - LED over '>0<' flashing.

Note:

Zero setting operation can be canceled by pressing '>0<' key during zeroing process.

With canceling, the old zero setting value is not lost.

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 6 of 7

Software_version: 1.0 (onwards)

2007-05-15

Operation:

The zero setting runs for one belt revolution determined by the belt revolution time set in

configuration. After zero setting operation, the mean value over the zero curve is

calculated and the belt load is re-calculated with the zero correction value. An error

message occurs when the correction limit is exceeded.

2.3 Error Acknowledgment

'CL' key is used to acknowledge errors.

Display

The Error text message is displayed in line 2. All Error texts are characterized with "!" in

the last column

Note:

If an error is already in the display, further errors will not be displayed until this error has

been acknowledged.

3.0 Parameter input

Operating the menus via the TUC keys is described in the Operating Instructions section

of this manual (see Menu Operations, section 2.0)

OPERATORS MANUAL

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.2-R0 Page 7 of 7

Software_version: 1.0 (onwards)

2007-05-15

4.0 Error Messages

Errors are characterized by "!" display in the last position of the display. Error

messages occurring during operation are shown below.

" Message !" = Meaning

> Help

"Tacho Fault !" = Tacho freq. input missing

> Check tacho, tacho cable

"Corr.>set-limit !" = Zero correction error greater than permitted

> Check belt load, repeat zero correction

"Corr. aborted !" = Zero correction cycle aborted.

> Check Tacho input, Drive Interlock input.

"EEProm read !" = Data and checksum in EEProm do not

match

> Enter parameters anew.

"EEProm write !" = Not possible to write to EEProm

> Hardware fault. Replace unit.

" Overload !" = BB > MAX. LOAD value set in Measuring

parameters.

> Check material on belt

" Underload !" = BB < MIN. LOAD value set in Measuring

Parameters.

" SIO Communicat. ! = Communication error with SIO module

> Check connection, interface, and setup

" Master Commun. !" = Communication error between SIO &

Modbus master

> Check connection, interface, and setup

5.0 Abbreviations

'....' key...

=....= Parameter in configuration

BB Belt Load

S1 Totalizer 1

LED Light emitting diode

VFD Vacuum Fluorescent display (16 characters X 2 line)

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 1 of 11

Software_version: 1.0 (onwards)

2007-05-15

TABLE OF CONTENTS

1.0 First start................................................ 2

2.0 Parameters.................................................... 2

3.0 OFFline parameters......................................... 2

3.1 Password................................................ 2

3.2 Measuring Parameters................................... 3

3.3 Configuration Parameters.............................. 4

3.4 Calibration........................................... 7

3.4.1 Calibration using weights.........................7

3.4.2 Calibration without weights...................... 8

3.5 Analog Output......................................... 8

3.6 Calibration correction.................................. 9

3.7 System data............................................ 10

4.0 ONline parameters........................................... 11

4.1 Main program.......................................... 11

4.1.1 Zero Correction................................. 12

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 2 of 11

Software_version: 1.0 (onwards)

2007-05-15

1.0 First start

When starting for the first time the following procedure must be followed:

Steps

1.1 Check jumpers

1.2 Connect peripheral appliances

1.3 Enter parameters

1.4 Calibrate system

1.5 Zero setting

1.6 Calibration correction

2.0 Parameters

See "Menu Operations" (section 2.0) for description about menu parameters and

operations.

3.0 OFFline parameters

3.1 Password

=Password=

When power is turned ON and 'CL' key is pressed during the 5 sec. delay, the

system comes to this option Press '/' keys to scroll through the different menus.

To select any menu,Press '' key with that menu being displayed in the 2nd display line.

=Enter Password=

Enter the 5 digit Password and press '' key.

The OFFline parameter access is disabled if the wrong password is entered. The

same can be accessed only on right password entry. Once enabled, the

parameters can be accessed till the ONline menu is accessed or power to the

system is turned 'Off'.

Display: "Y" - On right password entry

"N" - On wrong password entry

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 3 of 11

Software_version: 1.0 (onwards)

2007-05-15

3.2 Measuring parameters

=M. RANGE= Measuring Range

The voltage rise is defined as the voltage difference which the measuring cell

delivers between a belt loaded with 100% load and an empty belt.The value to

be set is the next lowest setting value to this value.

Select : 1.0 / 3.0 / 6.0 / 12 mV

=Units,X= Units,Capacity

Designation of all capacity displays.

If "t/h" is selected as designation,all other values are automatically defined with

"t".

Select : kg/h, t/h

=D. Pt,X= Decimal point,capacity

Definition of the position of the decimal point within the 4 digit capacity display.

Select : 000000 / 00000,0 / 0000,00 / 000,000

=Nom. Cap.= Nominal capacity

Flow rate with 100% belt load and nominal tacho frequency = 100% capacity.

Input : Numerical value of capacity

=D. Pt,S1=Decimal point, Totalizer 1

Definition of the position of the decimal point within the 6 digits display of

Totaliser 1

Select : 000000 / 00000,0 / 0000,00 / 000,000

=Units,S1= Units ,Totalizer 1

Definition of designation for resettable Totaliser 1

Select : kg / t

=D. Pt,S2= Decimal point, Totalizer 2

Definition of the position of the decimal point within the 6 digits display of

Totaliser 2

Select : 000000 / 00000,0 / 0000,00 / 000,000

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 4 of 11

Software_version: 1.0 (onwards)

2007-05-15

=Units,S2 = Units ,Totaliser 2

Definition of designation for non-resettable Totaliser 2

Select : kg / t

=Fixed Freq. = Frequency input source

Select: Yes - Tacho frequency is simulated internally (0500 Hz)

No - Tacho frequency is read from tacho input connected to TUC-6.

=Tacho Freq= Nominal tacho frequency

Input: 0-9999 Hz (Only used for fixed frequency = "YES")

=Max. Load= Limit maximum load

Maximum limiting value causing error message "Overload!".

Input : Numerical value in %

=Min. Load= Limit minimum load

Minimum limiting value causing error message "Underload!".

Input : Numerical value in %

3.3 Configuration Parameters

=Rev. Time= Belt revolution time

Time for one revolution of the belt with nominal tacho frequency.

Input : Numerical value in 0,1 s steps

=Zero Limit= Zero correction limit

This parameter determines the number of percentage points by which the zero

correction value may differ from the zero value. If the difference is greater, the

error message "CORR.>SET-LIMIT!" is displayed and the zero value calculated

is discarded.

Input : numerical value in %

=Run Time= Tacho supervision time

Time for monitoring the tacho input pulses.

Input : 0-999.9 s in 0.1s steps

(No monitoring with input "0")

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 5 of 11

Software_version: 1.0 (onwards)

2007-05-15

=Impulse time=

The impulse output can be assigned to Totaliser 1, Totaliser 2 or kept Off.

Select : S1 / S2 / Off

=On_Time=

The impulse ON time can be set using this parameter.

Select : 50mS / 100mS / 250mS / 500mS

=Error1= Error 1 output

Selection of one of the following errors at the output

Error No. Error description

1 Tacho Fault

2 Belt load error

3 General fault

4 Measurement ON

Select: 1 / 2 / 3 / 4

=Error2= Error 2 output

As per =Error1= above.

Select: 1 / 2 / 3 / 4

=Limit = Limit value

The potential free output for Belt load value above this value.

Select : Numerical value in %

=L_Delay= Hysteresis time

Time after which the output goes high when Belt load remains above limit values

1 or 2

Input : Numerical value in 0,1 sec steps.

=Clear,S2=

Clear Totaliser2 value

Input : No / YES

=Meas_Filt=

Meas_Filt provides Loadcell input signal filtering. Select 0 to de-select filtering.

Select: 0/ 1 / 2 / 3 / 4 / 5 steps

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 6 of 11

Software_version: 1.0 (onwards)

2007-05-15

=Display_Step=

Digit step provides damping of display and analog output values.

Select : 1 / 2 / 3 / 4 / 5 / 6 steps

=AO_mode=

Selection of analog output range is carried out with this parameter

Select: 0-20 / 4-20 mA

=Output=

Selection of NO or NC configuration for Relay outputs.

Select: NO / NC

=SIO_INT= SIO Interface

Selection of the peripheral device at SIO module

Select: Off / Modbus / Profibus

=SIO_BAUD= SIO baud rate

Setting the baud rate at serial interface

Select: 4800 / 9600 / 19200 baud

=SIO_SETUP= SIO data format

Definition of data format at serial interface

Select: Data Stop Parity

8 1 None

8 1 Even

8 1 Odd

=SIO_ADDR= SIO address

Address of controller when connected to a multi-drop bus on the SIO module

Input: Numerical value from 00-99.

=SIO_MONITOR= SIO monitoring time

Monitoring time for communication.

Input: Numerical value in 1 sec. steps

Note: IF "00" selected, SIO communication monitoring is disabled. In systems, where

"Remote Interlock" mode of operation is used, i.e. Setpoint & Start/Stop through SIO,

this parameter should not be set to "00".

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 7 of 11

Software_version: 1.0 (onwards)

2007-05-15

=Tacho Type=

The Tacho used is selected with this parameter.

Select: 1 - Tacho with 128 serations.

2 - Tacho with 200 serations.

=Start=

Start input source is selected with this parameter. Select "Int" for start through

keypad & "Ext for start through digital input.

Select: Int / Ext

3.4 Calibration

Calibration of the scale can be carried out in 2 ways,

i) Using Calibration weights

ii) Using previous calibration values.

In this mode, previous calibration values, viz

'COUNT_DL' and 'COUNT_BL', are used to calibrate the scale.

=Re-calibrate? ->= Recalibrate?

The 2 modes in calibration menu are initiated by the following procedure,

i) Mode 1 - Calibration using Weights

Press ''. Pressing '' key will exit the menu without recalibration.

ii) Mode 2 - Calibration without weights

Press keys '1','2','3' and '' in sequence. Pressing '' key will exit the menu

without recalibration.

Input : As above

3.4.1 Mode 1 - Calibration using Weights

=Dead load=

The actual value is displayed in terms of "d" in the lower display line.With a

completely empty belt , delete the dead load with the '' key.The actual value

displayed then shows 0000 d; the dead load is compensated.Press '' key to

switch further.

Input : None

TIP : Press 'ESC' key to display the actual value in mV.

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 8 of 11

Software_version: 1.0 (onwards)

2007-05-15

=Calibration load= Calibration load

The actual value is displayed in terms of "d" in the lower display line. Load a

known weight and wait for a steady display.

The display then shows the actual value on the left and is ready to accept the new

value.

CALIBRATION LOAD

1230 => 0000

Enter the calibration load value on the right hand side. A value of 2000

corresponds to 100% Belt load.Scale the input value according to the calibration

load.Conclude the calibration procedure with '' key.The value entered is saved

on exit.

Input : Numerical value of calibration load in terms of "d".

TIP : Press 'ESC' key to display the actual value in mV.

3.4.2 Mode 2 - Calibration without Weights

=Count_DL= Dead Load Count

The Dead Load is displayed in terms of internal calibration counts. The numerical

keys can be used to change this value. Press '' key to switch further.

Input : Numerical value

=Count_BL= Belt Load Count

The Belt Load corresponding to 100% load is displayed in terms of internal

calibration counts. The numerical keys can be used to change this value. Press

'' key to switch further.

Input : Numerical value

3.5 Analog Output

=Re-Calibrate?= Analog output re-calibration

The analog output calibration menu is released on selecting ' for this

parameter. Pressing '' key will not affect the existing values stored in memory.

Selection : /

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 9 of 11

Software_version: 1.0 (onwards)

2007-05-15

=Min_Value= I1 Output Min. value

This is used to adjust the minimum output value at the Analog output I1. The

present analog output count value is displayed in the display 2

nd

line. Press ''

key to increase/decrease the analog output value.

Esc key is used to toggle assignment of '' key as increase or decrease key.

Press to save value and proceed further.

=Max_Value= I1 Output Max. value

This is used to adjust the maximum output value at the Analog output I1. The

present analog output count value is displayed in the display 2

nd

line. Press ''

key to increase/decrease the analog output value.

Esc key is used to toggle assignment of '' key as increase or decrease key.

Press to save value and proceed further.

3.6 Calibration correction

If measurement of the momentary load shows non-linear characteristics, correction in

order to increase the linearity is possible.

For this upto 10 measuring points can be taken and stored from 0....100% capacity.

Between these measuring points, the curve is then linearized.

To start the calibration correction process, calibrate the system. Take a measuring point

e.g at 20% capacity and operate the system at 20% of nominal capacity.

Switch on the capacity display on the unit and note the average indicated capacity.

Bypass a determined quantity (at completed belt revolutions) and reweigh it using a

static weigher. Take the measurement time by a stop watch. From the actual conveyed

capacity and the time taken, calculate the true conveying capacity.

Conveying capacity (t/h) = Reweighed quantity (t) x 3600

Time (sec)

Input the displayed value (S1) and the measured value in the unit. Repeat the

procedure for other calibration points,if necessary.

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 10 of 11

Software_version: 1.0 (onwards)

2007-05-15

N DISP MEASURED

0 0123,00000,0

=Curve_Correction=

=Edit ->= Press '' key to enter the curve correction menu. Press ''

key to exit the menu.

Pressing '' key will display the correction points as shown,

" N" - The correction point number,from 0 to 9

" DISP." - Input for quantity of conveyed material as displayed

Input : Numerical value in units & resolution of S1.

" MEASURED" - Input for measured quantity of material using a static scale.

Input : Numerical value in units & resolution of S1.

Press '" key to increment to the next correction point. After 10 correction points are

displayed, next '" press will display the following in the lower line,

" Exit ->"

Press '' to exit the menu and '' to move to correction point number 0

3.7 System data

=CPU crystal=

CPU crystal frequency is displayed

Input : None

=S/W Ver.= Software version

Display of software version

Input : None

=Date=

The date can be changed through this parameter.

Input : Numerical value in format YY:MM:DD

=Time=

The system time can be changed through this parameter.

Input : Numerical value in format HH:MM:SS

COMMISSIONING INSTRUCTIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.3-R0 Page 11 of 11

Software_version: 1.0 (onwards)

2007-05-15

4.0 ONline parameters

If 'CL' key is not pressed during the 5 sec. power on delay, system goes to the ONline

mode when power is switched ON.

4.1 Main Program

The display in the ONline mode can be switched directly by using keys 'BB','Ta','X',

'S1' and 'S2'. Other parameters are called by pressing '' key.

The following parameters can be displayed in this mode,

X Actual flowrate value in units selected

S1 Totaliser1 value

S2 Totaliser 2

BB Belt load value in %

T Weigh Feeder Tacho frequency in Hz.

BS Belt Speed in m/sec

Date In format yy-mm-dd

Time In format Hour:Minute

4.1.1 Zero correction

Since the belt conveyor scale shows system related oscillation around the zero position,

the zero point is corrected during one belt revolution in order to improve the measuring

precision.

The deviation of the zero point is measured and stored with a plus or minus prefix. This

value is used to correct the momentary load during each measuring cycle.

Zeroing can be started with the system in "Local" or "Manual" mode and in "Start"

condition. Press key to initiate the zero correction cycle.

When zero correction is in progress, deviation of zero point is displayed continuously. At

the end of the zero correction cycle, the average deviation is displayed in percent. If the

deviation is greater than the =Zero_limit= parameter, an error message is displayed and

the value calculated is discarded. Zero correction has to be repeated.

Press key to stop zeroing in progress.

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 1 of 8

Software_version: 1.0 (onwards)

2007-05-15

TABLE OF CONTENTS

1.0 General............................................... 2

1.1 Parameter save...................................... 2

2.0 Parameter menus......................................... 2

2.1 OFFline parameters................................2

2.2 ONline parameters................................. 2

2.3 Parameter label...................................2

2.4 Menu structure.................................... 3

2.5 Keys inside the menu............................. 5

2.6 Calling and operating the menus................... 5

2.7 Menu operation example........................... 7

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 2 of 8

Software_version: 1.0 (onwards)

2007-05-15

1.0 General

The Parameters are entered using the keypad and a 16 digit x 2 line display. The

arrangement of parameters within the menus, options available for each parameters and

writing the parameters are explained in the commissioning instructions.

1.1 Parameter save

The parameters of the system are stored in an EEPROM. On each power ON, the data

in the EEPORM is checked with the contents of the Battery Buffered RAM. If a mismatch

occurs, error message is displayed. Acknowledging the error, reloads the RAM from

EEPROM.

Instantaneous values during system operation are stored in the Battery buffered RAM.

The parameters in a menu are automatically saved when the display is scrolled to

display the next parameter.

When the Online menu "Main_Program" is called, the parameters set in various menus

are checked for logical settings. In case of mismatch, error message is generated. The

corresponding parameter should then be correctly set.

2.0 Parameter Menus

The menu structure is divided into 2 categories,

2.1 OFFline parameters

These parameters can be changed only when the measuring mode is "OFF".

2.2 ONline parameters

These parameters can be changed even when the system is in operation.

2.3 Parameter Label

A differentiation is made between 2 types of parameters:

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 3 of 8

Software_version: 1.0 (onwards)

2007-05-15

Parameter label Display

1. Parameter whose value is entered numerically xxxxxxx

2. Parameter whose value is selected from a list Selection

2.4 Menu structure

The parameters are arranged in different menus. The menus and the parameter listing is

as shown below.

Power ON

Password

Enter Password

Measuring Parameters

Measuring range

Units, Capacity

Decimal point, Capacity

Nominal capacity

Decimal point, S1

Units, S1

Decimal point, S2

Units, S2

Frequency Input

Nominal Tacho frequency

Limit max. load

Limit min. load

Configuration

Belt revolution time

Zero correction limit

Tacho supervision time

Impulse time (S1,S2,OFF)

On_Time for Impulse output

Error1 o/p

Error2 o/p

Limit value

Limit delay time

Clear Totaliser2

Measurement Filter

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 4 of 8

Software_version: 1.0 (onwards)

2007-05-15

Display Filter Step

Analog Output mode

Output type

SIO Interface

SIO Baud

SIO Setup

SIO address

SIO monitor

Tacho Type

Start Input

Analog Output

Re-Calibrate?

Min_Value

Max_Value

Calibration

Recalibrate?

Dead load set ------- Count_DL

Calib. load set ------- Count_BL

Calibration correction

Edit?

N Displayed_value Measured_value

System data

CPU crystal frequency

Software version

Date

Time

Main Program

Display Actual Flowrate,X

Display S1

Display S2

Display Belt Load,BB

Display WF Tacho Frequency,T

Display Belt speed in m/sec,BS

Display Date

Display Time

See Commissioning Instructions" for descriptions of each parameter.

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 5 of 8

Software_version: 1.0 (onwards)

2007-05-15

2.5 Keys inside the Menu

-Entry into a Menu/Sub-menu or

-Selection of various options available for that

parameter

-Saving an entry and/or

-Move further in the menu list

. . . . . -Numerical data input from the keypad

-Exit from menu

+

-Call Online parameters from Main_Program

SET menu

2.6 Calling and operating the menus

1. Power On

a] Possibility 1

The system enters Main_Program menu after 5 Secs., if no key is pressed during this

delay period. If 'VER' is pressed during the 5 sec. delay, the delay is bypassed.

a.1]

TRANSWEIGH

Version_1.0

X = 00,00 t/h

S1 = 00000,0 t

Password

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 6 of 8

Software_version: 1.0 (onwards)

2007-05-15

M. Range 1,0 mV

Press 'Esc' and 'CL' to exit the online menu and enter the offline menus. Exit to Offline

menus is possible in Weigh Feeder 'Stop' condition.

a.2]

Press key to enter the menu.

All Offline menus are Password protected. Entry into the menu is allowed only if the right

password is pressed.

a.3]

..

5 Digit PASSWORD entry using 1 TO 9 keys.

a.4]

If PASSWORD is right, the configuration menus can be accessed

a.5]

The Offline menus can be accessed by pressing '' key. Press 'Esc' and '' key to

scroll the menu backwards.

a.6]

Password

Enter Password

Password

Enter Password

Password

Enter Password:Y

Password

Measuring Param

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 7 of 8

Software_version: 1.0 (onwards)

2007-05-15

Configuration

Password

Password

Press key to enter the menu. The first menu parameter is displayed in the 2nd

display line.

a.7]

Press to change this value.

a.8]

Press 'Esc' and 'CL' to exit the sub-menu and enter the main menu list.

b] Possibility 2

b.1]

The system enters the Offline menu directly, if 'CL' key is pressed during the 5 sec.

delay.

2.7 Menu operation Example

Example : Change the digit step from 1 to 2 in the Measuring parameters menu.

STEP 1 Enter Offline menu as per 2.6 above.

STEP 2

M. Range 3,0 mV

Password

Enter Password

MENU OPERATIONS

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.4-R0 Page 8 of 8

Software_version: 1.0 (onwards)

2007-05-15

M. Range 1,0 mV

M. Range 1,0 mV

UNITS,X kg/h

M. Range 1,0 mV

UNITS,X t/h

UNITS,X t/h

D.Pt. X 0000,00

STEP 3

5digit password, using numerical keys

STEP 4

Only on right password entry.

STEP 5

STEP 6

STEP 7

STEP 8

STEP 9

Step 9 saves the change made in the Units,X in Step 9.

Password

Enter Password

Password

Enter Password:Y

Password

Measuring Param

PARAMETER LISTING

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.5-R0 Page 1 of 3

Software_version: 1.0

2007-05-15

Sr. No. Parameter Value 1 Value 2

1.0 Measuring parameters

1.1 M. Range

1.2 Units, X

1.3 D. Pt, X

1.4 Nom. Cap.

1.5 D. Pt, S1

1.6 Units, S1

1.7 D. Pt, S2

1.8 Units, S2

1.9 Fixed Freq.

1.10 Tacho Freq.

1.11 Max. load

1.12 Min. Load

2.0 Configuration Parameters

2.1 Rev. Time

2.2 Zero Limit

2.3 Run Time

2.4 Impulse Time

2.5 On Time

2.6 Error 1 o/p

2.7 Error 2 o/p

2.8 Limit Value

2.9 L_ Delay

2.10 Clear, S2

2.11 Meas_Filt

PARAMETER LISTING

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.5-R0 Page 2 of 3

Software_version: 1.0

2007-05-15

Sr. No. Parameter Value 1 Value 2

2.12 Disp_step

2.13 AO_Mode

2.14 Output

2.15 SIO_Interface

2.16 SIO_Baud

2.17 SIO_Setup

2.18 SIO_Addr

2.19 SIO_Monitor

2.20 Tacho type

2.21 Start Type

3.0 Analog Output

3.1 Min_Value

3.2 Max_Value

4.0 Calibration

4.1 Count_DL

4.2 Count_BL

5.0 Calibration correction

Displayed Value

5.1

Measured Value

Displayed Value

5.2

Measured Value

Displayed Value

5.3

Measured Value

Displayed Value

5.4

Measured Value

Displayed Value

5.5

Measured Value

PARAMETER LISTING

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.5-R0 Page 3 of 3

Software_version: 1.0

2007-05-15

Sr. No. Parameter Value 1 Value 2

Displayed Value

5.6

Measured Value

Displayed Value

5.7

Measured Value

Displayed Value

5.8

Measured Value

Displayed Value

5.9

Measured Value

Displayed Value

5.10

Measured Value

6.0 System Data

6.1 CPU Crystal 11 MHz 11 MHz

6.2 S/W Version Ver_2.0 Ver_2.0

APPLIANCE DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.10-R1 Page 1 of 6

Software_version: 1.0 (onwards)

2007-05-15

TABLE OF CONTENTS

1.0 General................................................... 2

2.0 System Representation....................................... 2

3.0 Configuration of Jumpers...................................3

3.1 Main Board.............................................. 3

3.2 Measuring Card....................................... 3

4.0 Layout of Main Board...................................... 4

5.0 Main Board External Connectors.............................. 5

6.0 Rear View of TUC6......................................... 6

APPLIANCE DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.10-R1 Page 2 of 6

Software_version: 1.0 (onwards)

2007-05-15

1.0 General

Each member of the TUC-6 family comprises a Basic unit & several I/O modules

connected to the Basic unit on the RS-485 serial Interface. The I/O modules are suited

for external mounting on an assembly plate.

2.0 System Representation

TUC-6

X1

F1 0.5A Mains Connections

24Vdc

+Main Board

X6

Measuring card

X1

X3

Loadcell connection 12V/0.11A for

max. 3 loadcells 350 Ohm

X1

4 Digital outputs

4-20mA Isolated Output

Tacho Pulse Input

X2

X4

X5

Serial interface RS485

Profibus Interface

TUC-6 Display & Keypad

X1 Interface Card

APPLIANCE DESCRIPTION

Belt Weigher/ Solid Flow Meter with TUC-6 Electronics

TUC6-020-EE23.10-R1 Page 3 of 6

Software_version: 1.0 (onwards)

2007-05-15

3.0 Configuration of Jumpers & Dip Switches

3.1 Main Board

Jumper J1 : 1-2 Terminating resistor for X2 Interface

(Connects 120E resistor)

3.2 Measuring Card

Jumper J1 : 1-2 / 9-10 measurement period 4ms

1-2 / 7-8 8ms

3-4 / 9-10 8ms

3-4 / 7-8 16ms

5-6 / 9-10 16ms

5-6 / 7-8 32ms

MAIN BOARD LAYOUT.pcb - Mon Jun 18 10:47:50 2007

PRE-REQUISTIES FOR INSTALLATIONS

FOR A BELT WEIGH SCALE

FLSmidth Pfister India Ltd.

The belt conveyor should wherever possible be provided with a Gravity type take up device.

This is imperative for accuracies of +1 %.

The belt conveyor inclination, if any, should be steady and invariable.

Belt Weigher should be installed on lowest possible belt tension location.

Belt weigher should be installed on such a portion where belt is resting firmly on idlers &

not lifting on the concave portion even under no load conditions The Belt should be

centered at the location of Belt weigher

Belt Weigher should be mounted 3-4 idlers after the convex portion of the Belt.

Belt weigher should not be mounted near the self aligning idlers.

The instantaneous loading of the belt weigher should be within 30-100%.

2 preceding and 2 succeeding idlers of the conveyer should be inline with each other in all

planes.

Material feeding on belt conveyer should be through devices which can give even feed.

The material on the measuring section to be settled & calmed, without relative movement.

It must be assured that upon stopping, the belt does not run back .This is in order to avoid

double weighing.

Protection of the belt weigher measuring arrangement, against weather influence and lateral

wind protection for the weighing section, to be provided.

The belt shall be even and of uniform thickness so that tare weight does not change & the

quality of belting to meet the requirement for weighing purposes i.e. uniform in weight,

smooth and light and as flexible as possible.

The measuring section of the belt conveyor should be supported properly. Sagging and

vibrating of structure should be eliminated.

Three idlers adjacent to the measuring section on both side should turn easily and

concentrically Eccentricity not to exceed 0.2 mm TIR( Total Indicator Runout)

Belt to be provided with proper working scrappers in order to avoid return material.

The belt should be properly vulcanized to maintain the uniform belt thickness & stiffness.

If mounted on the reversible belt conveyer, the belt weigher should be calibrated Separately

in both the directions.

ASSEMBLY & STARTUP INSTRUCTION

FLSmidth Pfister India Ltd.

The Conveyor Belt Weigher System Consists Of three major elements; The belt speed sensor and

the electronic unit.

Each serves a distinct function in the process of accurately weighing Material moving on the belt.

The measuring unit is the primary belt load Sensor, mounting it under the carrying side of belt on

the stringer, it Supports weighing idler and generates an electrical output proportional To the belt

loading with the help of the loadcell. The belt speed sensor Provides stream of pulses each

representing unit of belt travel, the electronic unit processes these two signals to evaluate rate and

weight. The weight is totalised and displayed.

TMA / rd

MAINTENANCE INSTRUCTION MANUAL

FLSmidth Pfister India Ltd.

The belt weighers require very less maintenance especially if idler alignment is carried out

carefully. In new installations, zero and calibration shifts may be expected due to changes in

alignment. Idler etc. In the initial stage it is advisable that zero shifts be monitored every other day

for a few weeks.

1. Is the scale area clean of rocks dust and material build up check if the material is wedged in

scale position preventing force transfer. If noticeable dust buildup is observed, the scale should

be cleaned and measures to avoid the same must be taken.

2. See if the alignment of rollers is disturbed. Ensure that alignment is Proper. Rollers in weigh

zone should rotate freely.

3. See if material buildup is there on the belt. If material build up is Observed the scrapper should

be effectively adjusted.

4. Check if the belt is tracking properly. The belt should run true to the Centre line of idlers in

scale area in loaded and empty condition of The belt.

5. Belt tension must be kept constant. Gravity type pickup is recommended. The gravity pickup

must act Effectively check if the Gravity pickup is acting properly. If not ensure the same.

6. If the skirt boards are provided in weigh zone, ensure that material is not getting entrapped

under the skirt plates or rubber strips.

7. Ensure that speed sensor is running smoothly and there is no material build up on pickup wheel.

Measure the consistency of speed sensor pulses.

8. If the shift observed is abnormal check wiring and the circuits in Electronic unit.

9. Adjust zero (TARE) if everything is proper. However keep the record. Record the shift in

terms of % observed. If the shift is observed quite Often it is advisable to carefully check all

above points and take Appropriate measures. If the problem persists inform with

observations over 10 days to the supplier.

It must be understood that any change in zero results into error in calibration. Calibration of

the system is highly stable unless fault in Component is there. So zero should always be

checked first and all measures external to the belt scale should be taken care of. It is the

Experience of the supplier that most of the times errors in belt scale Are due to zero shift

SAK / rd

TESTING / ADJUSTING MANUAL

FLSmidth Pfister India Ltd.

A. Zero Load Tests

If a belt conveyor scale system has been idle for a period of two hours or more, the system

shall be run for not less than 30 minutes.

The variation between the beginning and ending indication of the master weight totalizer

shall not be more than 1 scale division when the instrument is operated at no load for a

period of time Equivalent to that required to deliver the minimum totalized load of 1000

scale divisions

The zero-load test shall be conducted over a whole number of belt Revolutions, but not less

than three revolutions or 10 minutes operation, whichever is greater

B. Material tests

Use bulk material, preferably that material for which the device is normally used. Either

pass a quantity of pre-weighed material over the belt-conveyor scale in a manner as similar

as feasible to actual Loading conditions, or weigh all material that has passed over the Belt-

conveyor scale. Means for weighing the material test load will depend on the capacity of the

belt-conveyor scale and availability of a suitable scale for the test

SAK / rd

ERECTION INSTRUCTION MANUAL

FLSmidth Pfister India Ltd.

ERECTION QUALITY CONTROL PLAN FOR BELT WEIGHER

SR.

NO.

DESCRIPTION RESPONSIBILITY

1. Supervisory staff should be well trained in enforcing safety

Regulation & be able to distinguish safe unsafe workmanship.

Erection

contractor

2. While engaging men for the job the supervisor should check Up

& make sure that they skilled in the particular job they have to

perform.

3. Package & equipment should be check for damage during

Transit.

4. Quantity should be checked as per packing list to ensure

Completeness of supply.

5. Special care should be taken so as to avoid the damage to the

Load sensing mechanism of supplied equipment.

6. All the points mentioned in the erection instruction manual For

weigh feeders & belt weighers should be complied with

7. Wire ropes, clams, lifting tackles should be inspected for Their

condition before used.

8. The safe working load of the ropes, tackles needed to lift the

Weigh feeder & belt weigher should never be exceeded.

9. When moving the weigh feeder, belt weigher into place the area

should be cordoned off to prevent persons from hitting Against

The erection of the scale in a conveyor belt supplied by others is shown in the General arrangement

drawing. The complete measuring unite can be mounted on the conveyor frame without any modification

of the conveyor structure. Separate foundations are not necessary.

Select the scale location as shown in the general arrangement drawings. A Partial

1. Install the scale system on rigid conveyor

2. The scale should not be located closer than 3 meters from feeder hoppers and skirt boards.

3. The scale must be placed in concave or convex curves

Belt weigher equipment has four mounting plates. The width of these mounting Plates matches the width of

stringers of belt conveyor.

Weighing idler centre line should be matched with the existing carrying idler Centre line. The distance of

the proceeding and succeeding carrying idlers about weighing idler should remain same on either side.

Tacho generator assembly should be mounted on the bracket as indicated in The drawing.

Ensure that the aluminum wheel always touches the conveyor belt at all times

Install the junction box close to the best scale.

Install local federate indicator in the vicinity of the belt scale at a convient Place

ERECTION INSTRUCTION MANUAL

FLSmidth Pfister India Ltd.

LOADCELL MOUNTING PROCEDURE FOR BELT WEIGHER

Belt weigher enclosure cover is to be opened to have an access for changing the loadcell. Weight of

material on the belt is transferred to the loadcell through a mechanical leverage system.

The loadcell is placed horizontally on a machined pad plate and its held with Two bolts from under side.

Towards other end of the loadcell there is a knife edge provided. This knife Edge is connected through a

lever to other knife edge provided on the main Fulcrum lever.

Load transfer takes place through this arrangement. For the replacement of these loadcell initially loosen

the stopper bolt no. 1 and take it down and Remove its not from the place.

Bolt no. 2 holds the base of knife edge towards end of loadcell. Now loosen Bolt no. 2 and take it down

slide the knife edge and take it off.

Remove the loadcell and install new loadcell 3 in its place slide black knife Edge in its place and take bolt

no. 2 up to hold the base of knife edge.

Now raise the stopper bolt no. 1 up and adjust the gap between bolt no. 2 and Stopper bolt no. 1 as 0.2 mm.

SAFETY & STORAGE MANUAL

FLSmidth Pfister India Ltd.

SAFETY & STORAGE MANUAL FOR BELT WEIGHER

Sefety Note

General information

All work related to transport, putting in to storage, setting up/mounting

Connection, start up, trained personnel observing should only perform

Maintenance and repair

The corresponding detailed operating instructions and wiring diagrams,

The warning and safety sign

The specific regulations and requirements for the system and

Normal / regional regulations governing safety and prevention of accidents.

Severe injuries and damage to property may result from

Incorrect use

Incorrect installation or operation

Remove of required protective covers or the housing when this is not permitted.

Designated use These equipments are intended for industrial systems. They correspond to the

applicable Standards and regulations.

The technical data and the information about permitted condition are to be found on

the nameplate and in the documentation.

It is essential that you observe all specified information!

Transportation Inspect the delivery for any damage in transit as soon as you receive The

Delivery. Inform the shipping company immediately. It maybe Necessary To

preclude startup.

Use suitable, sufficiently rated handling equipment if necessary. Remove any

transportation fixture prior startup.

SAFETY & STORAGE MANUAL

FLSmidth Pfister India Ltd.

STORAGE

Comply with the storage conditions specified in the following table for Storage:

Climate zone Packing 1 Storage location Storage time

Temperature

(Europe,

USA,

Canada,

China and

Russia,

excluding

tropical

zones)

Packed in

containers, with

desiccant and

moisture and

moisture indicator

sealed in the

plastic film.

With roof, protected against rain and

snow, no shock loads.

Max .3 year with regular

checks on the packaging

and moisture indictor

(rel. atmospheric humidly

<50%)

Open With roof, enclosed, at constant

temperature and atmospheric

humidity (5c<v>60C, 50% relative

atmospheric humidity) No sudden

temperature fluctuation with filter

(free from dirt and dust.) no

aggressive vapors and shock loads.

2 years or more given

regular inspections. And

mechanical damage as

part of the inspection.

Check the corrosion

protection as intact.

Tropical

(Asia, Africa,

central and

south

America,

Australia ,

new Zealand

excluding

temperate

zone)

Packed in

containers, with

desiccant and

moisture indicator

sealed in the

plastic film.

Protected against

insect damage and

mildew by

chemical

treatment.

With roof, protected against, no

shock loads.

Max. 3 yeasr with regular

checks on the packaging

and moisture

indicator(rel. atmospheric

humidity <50%)

Open

With roof, enclosed, at constant

temperature and atmospheric

humidity (5c<v>60C, 50% relative

atmospheric humidity) No sudden

temperature fluctuation and

controlled ventilation with filter (free

From dirt and dust). No aggressive

vapors and no shock loads.

Protection against insect damage.

2 year or more gave

regular inspections.

Check for cleanliness and

mechanical damage as

part of the inspection.

Check the corrosion

protection is intact.

1) Packing must be performed by an experienced company using the packing materials,

Which have been expressly qualified for the particular application.

TACHOMETER TECHNICAL LITERATURE

FLSmidth Pfister India Ltd.

ROTARY PULSE TRANSDUCER SRS. RPT

1.0 GENERAL

The Transweigh series RPT Rotary Pulse Transducers are low cost incremental encoders to

digitize any rotary motion for display and / or control.

The frequency of their output is proportional to the speed of the input shaft. Depending

upon the type, direction discrimination is also achieved. When combined with Transweighs

other standard and customer-made electronics, these encoders can solve measuring and

control problems relating to speed, position, differentials, frequency time etc.

These tailor-made transducers are designed for specific application by combining a wide

range of standard elements and features. The variables include:

a) The output type

b) Output level and compatibility

c) Type of sensors used

d) Input voltage

e) Casing and packaging

The mechanical drive to the transducers can be affected in a number of ways in accordance

with the requirements. The most satisfactory method is to couple the transducer to a drive

shaft via a flexible coupling, if the drive is by means of a gear change or cogged belt,

appropriate accessories can be provided on request.

All Rotary pulse Transducers are tested and burned in and also Factory Adjusted before

dispatch so that transducers having same type numbers are interchangeable at site . This

greatly simplifies maintains and reduces down time in the unlikely event of a failure.

1.1 OPERATION:

The unit consists of a shaft running in anti-friction bearings. This shaft carries inductive

sensors or optically programmed discs, depending upon the type of sensors used. The

sensors are mounted on the stator body.

With the rotation of the shaft, the coded disc moves relative to the sensor, this picks up the

coded signal.

These signals are then prossed through an electronic circuitry coupled in the RPT and is

available to the user in a from, compatible with any of the standard electrical levels.

TACHOMETER TECHNICAL LITERATURE

FLSmidth Pfister India Ltd.

2.1 NOTE ON OPTICAL TYPES

In the optical units, the optical units the optically programmed disc is mounted on the

central shaft. the disc have LED interrupter straddling them.The aperturing of the interrupter

is an Integral assembly to this. When the shaft is rotated the disc rotates with this ,

producring the Required signals in the interrupter receiver.

The LED chosen is of the new PN Gallium Arsenide type and is hermetically sealed in its

optical casing.

Min RPM =0

Max. Frequency of output =50 KHz

Output Types =Open collector, NPN

3.0 HOUSING

The packaging of the RPT s can be affected a number of standard ways.

3.1 Casing

This is a eugged cast aluminum flange mounted casing which is vermin and splash Proof

and can be offered to IP 54, 55 or 65 specifications. The casing carries a coat of Hard

backed enamel on the outside.

The following standard bearing and seal arrangement are available in this casing type.

i. Bearings for 3000 RPM max. With double lip neoprene seals

ii. Bearings for 3000 RPM max. With metallic labyrinth seals.

iii. Bearings for 6000 RPM max. With double lip neoprene seals

iv. Bearings for 6000 RPM max with metallic labyrinth seals

The termination of the electrical lines can be offered in any of the following versions:

1. 1 meter long flexible lead out ending in crimped terminals

2. 1above in hydraulic hose with termination box to I P 65.

3. Plug connectors.

TACHOMETER TECHNICAL LITERATURE

FLSmidth Pfister India Ltd.

4. Screw terminal.

5. Water proof plug connectors

For application of linear speed measurements of rubber or metallic belts a swivel arrangement and

a friction contact wheel is available . the general arrangement for which is shown in drg . no 000-

M- 0743.

The casing can house a toothed wheel for inductive sensor or an optically coded disc.

The discs size limits the maximum resolution for optical disc can go as high as 500 ppr.

Breakaway Torque with neoprene seals 1.0 kg- M

With metal labyrinths seals 0.9 kg.-M

Shaft inertia 3000 grm.

Cm 40V2 +40Vapprox

Shaft load Axial 50 kg.

Radial 110 kg.

TACHO CARD UNIDIRECTIONAL (F -760)

1.0 DESCRIPTION:

This card forms part of the Rotary pulse Transducer , Series RPT. This Card provides the

necessary interface between an integral light source & detector and the Weighing

Electronics.

An optical disc with alternate transparent and opaque sections is mounted in between the

light source and detector. The optical disc when rotated , causes light stream to be broken

when the opaque section comes in line with the light source and detector . This causes

change in the elector output which is available at the out put point 2.

2.0 USE:

Interface between an optical sensor and the Weighing Electronics.

3.0 INPUTS:

Rotation of optical disc.

TACHOMETER TECHNICAL LITERATURE

FLSmidth Pfister India Ltd.

4.0 OUTPUT:

Pulse output (Open Collector)

5.0 OPERATING VOOLTAGES:

+15 V

6.0 TESTING INSTRUMENTS:

i) Multimeter

ii) Oscillscope

7.0 REPLACEMENT:

None

8.0 SETTINGS:

Mount the optical disc between the light source and detector. Adjust potentiometer P1 to get

11 V at point TP1 .Rotated the optical disc and obscure the pulse output at point 2 .The

output at point 2 should match the rotation of optical disc as the following formula,

Output Freg. (Hz) = Rotation of disc (RPS) * No. of opaque slots on disc

LOADCELL SPECIFICATION

FLSmidth Pfister India Ltd.

LOADCELL SPECIFICATION

FLSmidth Pfister India Ltd.

LOADCELL SPECIFICATION

FLSmidth Pfister India Ltd.

DATA SHEET

FLSmidth Pfister India Ltd.

DATA SHEET

FLSmidth Pfister India Ltd.

DATA SHEET

FLSmidth Pfister India Ltd.

DATA SHEET

FLSmidth Pfister India Ltd.

DATA SHEET

FLSmidth Pfister India Ltd.

ELECTRICAL DRAWING

FLSmidth Pfister India Ltd.

ELECTRICAL DRAWING

CATEGORY OF DRG.

ELECTRICAL DRAWINGS -

DETAIL ELECTRICAL DRAWINGS -

TERMINATION DETAILS -

P.O. NO.

JOB NO

CUSTOMER

PROJECT

124, ABCD, Govt.Indl. Estate, kandivli (West),

Mumbai - 400067, India

Tel.: +91 22 67726000/2868 2311. Fax +91 2267726100

FLSMIDTH PFISTER INDIA Ltd.

:

:

:

:

PP II/JSPL/BRBL/BW-9 DATED. 04-07-2013

REFERENCE

90.1307

JINDAL STEEL & POWER LIMITED

ELECTRICAL DOCUMENTATION FOR

BELT WEIGHER

R1

R1

APPROVAL

R1

AS BUILT

9

0

A

1

3

0

7

CHANGE

1

DATE/NAME

2

CHKD

ENGG

CHKD

DRN

3

08.Jul.2013

08.Jul.2013

08.Jul.2013

08.Jul.2013

DATE

4

NAME

DN

DN

DN

DN

CUSTOMER:

PROJECT:

CONSULTANT:

5

JOCABS ENGG

JINDAL STEEL & POWER LIMITED

6

BELT WEIGHER

7 8 9

TITLE:

TABLE OF CONTENTS

10 11

DRG.NO.:

= A1_TOC

12

90.1307

+

- ----

13 14

SHEET

1

1

9

0

A

1

3

0

7

TABLE OF CONTENTS

PAGE NO. PAGE DESIGNATION DRAWING NO.

APPROVED BY

=A1_FC/1

=A1_TOC/1

=A1_BAS/1

=A1_BAS/2

=A1_BAS/3

=A1_BAS/4

=A1_BAS/5

=A1_BAS/6

=A1/1

=A1/2

=A1/3

=A1/4

=A1/5

=A1/6

=A1_TER/1

=A1_TER/2

=A1_TER/3

=A1_TER/4

=A1_TER/5

=A1_TER/6

=A1_BOM/1

FC

TABLE OF CONTENTS

SYSTEM BLOCK DIAGRAM

SINGLE LINE DIAGRAM

CABLE SCHEDULE

ELECTRICS ENCLOSURE GA

JUNCTION BOX GA

TUC-6 GA.

ELECTRICAL WIRING DIAGRAM

ELECTRICAL WIRING DIAGRAM

VOLTAGE SUPPLY

LOAD CELL

ANALOG INTERFACE

DIGITAL INTERFACE

=A1-X9

=A1-X11

=A1-X13

=A1-JB-X15

=A1-X21

=A1-X22

BILL OF MATERIAL

----

----

021-EE01-R1

021-EE02-R1

021-EE04-R1

021-EE05-R1

021-EE10-R1

021-EE25-R1

021-EE16-R1

021-EE16-R1

021-EE16-R1

021-EE16-R1

021-EE16-R1

021-EE16-R1

021-EE17-R1

021-EE17-R1

021-EE17-R1

021-EE17-R1

021-EE17-R1

021-EE17-R1

021-EE03-R1

1 REVISED 27/8/2013 DN /HS

CHANGE

1

DATE/NAME

2

CHKD

ENGG

CHKD

DRN

3

08.Jul.2013

08.Jul.2013

08.Jul.2013

08.Jul.2013

DATE

4

NAME

DN

DN

DN

DN

CUSTOMER:

PROJECT:

CONSULTANT:

5

JOCABS ENGG

JINDAL STEEL & POWER LIMITED

6

BELT WEIGHER

7 8 9

TITLE:

SYSTEM BLOCK

DIAGRAM

10 11

DRG.NO.:

= A1_BAS

12

90.1307

+

- 021-EE01-R1

13 14

SHEET

1

6

9

0

A

1

3

0

7

OUTPUTS : POTENTIAL FREE

* FLSMIDTHPFISTER SCOPE

INPUTS / OUTPUTS

230 V 10%

50 Hz 5%

MCC

(CUSTOMER)

W

P

0

1

T

O

T

A

L

I

S

E

R

P

U

L

S

E

O

/

P

W

C

0

1

JUNCTION BOX FIELD

W

C

S

0

4

*

W

C

S

0

2

P

A

N

E

L

H

E

A

L

T

H

Y

/

F

A

U

L

T

Y

*

W

C

S

0

1

-

4

*

W

C

S

0

1

-

3

ELECTRICS ENCLOSURE WITH

TUC-6 ELECTRONICS

*

W

C

S

0

1

-

2

W

C

S

0

3

W

C

S

0

5

4

-

2

0

m

A

I

S

O

O

/

P

A

C

T

U

A

L

F

E

E

D

R

A

T

E

*

W

C

S

0

1

-

1

PLC/DCS

(CUSTOMER)

EPT.NO

B55202

B55221

B43058

FILTER CAKE

PRODUCT

SINTER FINES

MATERIAL

CAPACITY

1100 TPH

1000 TPH

40 TPH

QTY

1

1

1

1 REVISED 27/8/2013 DN /HS

CHANGE

1

DATE/NAME

2

CHKD

ENGG

CHKD

DRN

3

08.Jul.2013

08.Jul.2013

08.Jul.2013

08.Jul.2013

DATE

4

NAME

DN

DN

DN

DN

CUSTOMER:

PROJECT:

CONSULTANT:

5

JOCABS ENGG

JINDAL STEEL & POWER LIMITED

6

BELT WEIGHER

7 8 9

TITLE:

SINGLE LINE

DIAGRAM

10 11

DRG.NO.:

= A1_BAS

12

90.1307

+

- 021-EE02-R1

13 14

SHEET

2

6

9

0

A

1

3

0

7

E

L

E

C

T

R

I

C

E

N

C

L

O

S

U

R

E

F

I

E

L

D

M

C

C

(

C

U

S

T

O

M

E

R

)

Fa

U1

U2

I

~

~

TUC-6

-

-

> >

2

230 V 10%

50 Hz 5%

60 VA

230 VAC

FOR ISOLATOR

1 REVISED 27/8/2013 DN /HS

CHANGE

1

DATE/NAME

2

CHKD

ENGG

CHKD

DRN

3

08.Jul.2013

08.Jul.2013

08.Jul.2013

08.Jul.2013

DATE

4

NAME

DN

DN

DN

DN

CUSTOMER:

PROJECT:

CONSULTANT:

5

JOCABS ENGG

JINDAL STEEL & POWER LIMITED

6

BELT WEIGHER

7 8 9

TITLE:

CABLE SCHEDULE

10 11

DRG.NO.:

= A1_BAS

12

90.1307

+

- 021-EE04-R1

13 14

SHEET

3

6

9

0

A

1

3

0

7

SR.

NO.

02

04

06

07

01

03

05

++ - INTEGRATED CABLE FOR LOADCELL AND TACHO

*- POTENTIAL FREE

JB - JUNCTION BOX

YY - UNARMOURED COPPER CABLE

YWY - ARMOURED COPPER CABLE

B55202

B55221

B43058

EQUIP.

NO.

WCS 03

WCS 04

WCS 01

WCS 02

WCS 05

WP O1

WC 01

CABLE.