Beruflich Dokumente

Kultur Dokumente

Aero Engine Maintenance and Repair

Hochgeladen von

Durai Raj KumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aero Engine Maintenance and Repair

Hochgeladen von

Durai Raj KumarCopyright:

Verfügbare Formate

www.jdrr5.co.

cc

www.theo7.co.cc

General Requirement of Aircraft Engine

An aircraft engine must be:

reliable, as losing power in an airplane is a substantially

greater problem than an automobile engine seizing. Aircraft

engines operate at temperature, pressure, and speed

extremes, and therefore need to operate reliably and safely

under all these conditions.

Durable: It is the amount of engine life obtained while

maintaining the desired reliability

lightweight, as a heavy engine increases the empty weight

of the aircraft & reduces its payload.

powerful, to overcome the weight and drag of the aircraft.

small and easily streamlined; large engines with substantial

surface area, when installed, create too much drag, wasting

fuel and reducing power output.

repairable, to keep the cost of replacement down. Minor

repairs should be relatively inexpensive.

fuel efficient to give the aircraft the range the design

requires.

capable of operating at sufficient altitude for the aircraft

www.jdrr5.co.cc

www.jdrr5.co.cc

www.jdrr5.co.cc

Powerplant Selection

www.jdrr5.co.cc

Types of reciprocating Engine

Inline Engine

This type of engine has cylinders lined

up in one row. It typically has an even

number of cylinders.

The biggest advantage of an inline

engine is that it allows the aircraft to be

designed with a narrow frontal area for

low drag.

The disadvantages of an inline engine

include a poor power-to-weight ratio,

because the crankcase and crankshaft

are long and thus heavy.

An in-line engine may be either air

cooled or liquid cooled, but liquid-cooling

is more common because it is difficult to

get enough air-flow to cool the rear

cylinders directly

Example: Wright Flyer

Inverted inline engine

www.jdrr5.co.cc

Opposed or O-type Engine

An opposed-type engine has

two banks of cylinders on

opposite sides of a centrally

located crankcase. The

engine is either air cooled or

liquid cooled

Due to the cylinder layout,

reciprocating forces tend to

cancel, resulting in a smooth

running engine free from

vibration.

Low weight to power ratio

www.jdrr5.co.cc

V-Type engine

Cylinders in this engine are

arranged in two in-line

banks, tilted 30-60 degrees

apart from each other

The vast majority of V

engines are water-cooled.

The V design provides a

higher power-to-weight ratio

than an inline engine, while

still providing a small frontal

area.

www.jdrr5.co.cc

Rotary Engine

Rotary engines have all the

cylinders in a circle around the

crankcase like a radial engine

(see below), but the difference

is that the crankshaft is bolted

to the airframe, and the

propeller is bolted to the

engine case.

The entire engine rotates with

the propeller, providing plenty

of airflow for cooling

regardless of the aircraft's

forward speed.

Unfortunately, the severe

gyroscopic effects from the

heavy rotating engine made

the aircraft very difficult to fly.

Le Rhone 9C rotary aircraft engine

www.jdrr5.co.cc

Radial Engine

This type of engine has one or more rows

of cylinders arranged in a circle around a

centrally-located crankcase. Each row must

have an odd number of cylinders in order to

produce smooth operation

A radial engine has only one crank throw

per row and a relatively small crankcase,

resulting in a favorable power to weight

ratio.

The lower cylinders, which are under the

crankcase, may collect oil when the engine

has been stopped for an extended period

causing serious damage due to hydrostatic

lock

In military aircraft designs, the large frontal

area of the engine acted as an extra layer

of armor for the pilot. However, the large

frontal area also resulted in an aircraft with

a blunt and aerodynamically inefficient

profile.

The power output varies from 100 to 3800

hp

www.jdrr5.co.cc

Principles of Operation

www.jdrr5.co.cc

Reciprocating Engine Power and Efficiencies

Piston displacement: The

volume displace by the piston is

known as piston displacement

Compression Ratio: In a piston

engine it is the ratio between

the volume of the cylinder and

combustion chamber when the

piston is at the bottom of its

stroke, and the volume of the

combustion chamber when the

piston is at the top of its stroke.

The compression ratio is

defined as (Swept Volume +

Clearance Volume) / Clearance

Volume

www.jdrr5.co.cc

Indicator Horse Power:

Indicated mean effective pressure is an average

pressure value that theoretically must be present

in a cylinder of an engine during the power

stroke to generate the maximum horsepower

possible, given the pressures recorded within

the cylinder during a dynamometer test.

IHP = PLANK/33,000

P - indicated mean effective pressure

L - length of stroke

A - area of piston head in square inches

N - number of power strokes per minute

K - number of cylinders

www.jdrr5.co.cc

Brake Horsepower

The power developed to the propeller for useful

work is called brake horsepower

Prony brake dynamometer

3300

2 rpm length force

bhp

www.jdrr5.co.cc

Friction Horsepower

FRICTION HORSEPOWER is the difference

between indicated horsepower and brake horse-

power

Thrust Horsepower

Propeller efficiency refers to the percentage of

Brake Horsepower (BHP) which gets converted

into useful Thrust Horsepower (THP) by the

propeller. The propeller is never 100% efficient.

Therefore the propeller efficiency is always a

number less than one.

Neta is propeller efficiency.

www.jdrr5.co.cc

Propeller Efficiency

where J is Advance ratio, n is rpm and D is propeller diameter, V is TAS

The most efficient J depends

upon the propeller blade angle.

Course propellers (large blade

angles) will be more efficient at

larger advance ratios. Fine pitch

propellers will be more efficient at

small advance ratios.

When choosing a fixed pitch

propeller an aeronautical

engineer usually chooses

one, which is optimum for

cruise.

www.jdrr5.co.cc

Efficiencies

Thermal Efficiencies:

The ratio of useful work done by an engine to

the energy of the fuel it uses is called thermal

efficiencies

25 to 30% useful power

15 to 20% lost in cooling

5 to 10% lost in overcoming friction

40 to 45% lost through exhaust

Useful power can be increased by increasing the

compression ratio

Indicated thermal efficiencies =

i.h.p 33000

wt of fuel burned/min heat value 778

www.jdrr5.co.cc

Mechanical Efficiencies:

In an engine it is the ratio of brake horsepower to

indicated horsepower.

The factor greatest effect mechanical effect is the friction

within the engine. Mechanical efficiency is high when the

engine is running at the rpm at which max b.h.p is

developed.

Note: Friction remain practically constant for an engine

p h i

p h b

efficiency mechanical

. .

. .

..

www.jdrr5.co.cc

Volumetric Efficiency

It is a comparison of the volume of fuel/air

charge conducted into the cylinders to the

total piston displacement of the engine

Factors decrease volumetric efficiency

Part throttle operation

Long intake pipes of small diameter

Sharpe bend in intake pipe

Carburetor air temperature to high

Cylinder head temperature to high

Incomplete scavenging

Improper valve timing

www.jdrr5.co.cc

Propulsive efficiency

It is the ratio of thrust horsepower to brake

horsepower. Ranges to 80-85%

Loss is due to friction and slippage

Controlling the blade angle is the best

method to maximize propulsive efficiency

During take off less blade angle

During high speed or diving more blade angle

www.jdrr5.co.cc

END

www.jdrr5.co.cc

Das könnte Ihnen auch gefallen

- Unmanned Aircraft SystemsVon EverandUnmanned Aircraft SystemsElla AtkinsNoch keine Bewertungen

- AE8005 Aircraft Engine Maintenance and RepairDokument1 SeiteAE8005 Aircraft Engine Maintenance and Repairaeronautical rajas100% (1)

- Aero Engine Maintenance and Repair Two Marks With AnswerDokument7 SeitenAero Engine Maintenance and Repair Two Marks With AnswerHariharanNoch keine Bewertungen

- Experimental AerodynamicsDokument2 SeitenExperimental AerodynamicsAmal JoyNoch keine Bewertungen

- Agemp Model 2 ANSWER KEYDokument13 SeitenAgemp Model 2 ANSWER KEYAnonymous P0rZmU100% (2)

- Agemp Two MarksDokument8 SeitenAgemp Two MarksKishore CrazeNoch keine Bewertungen

- AE6011-Aero Engine Maintenance and Repair Question Bank Part-ADokument2 SeitenAE6011-Aero Engine Maintenance and Repair Question Bank Part-AanandNoch keine Bewertungen

- Aemr Two MarksDokument11 SeitenAemr Two MarksRajashree VenugopalNoch keine Bewertungen

- Question Bank: 2 Mark Question and AnswersDokument11 SeitenQuestion Bank: 2 Mark Question and Answersraj6062Noch keine Bewertungen

- AE8302-Elements of Aeronautical Engineering: Reg. NoDokument2 SeitenAE8302-Elements of Aeronautical Engineering: Reg. NoViswanath ViswaNoch keine Bewertungen

- WWW - Entrance Exam - Net Sathyabama University Aeronautical Engineering 7th Sem Industrial Aerodynamics Sample Paper 1Dokument2 SeitenWWW - Entrance Exam - Net Sathyabama University Aeronautical Engineering 7th Sem Industrial Aerodynamics Sample Paper 1Natesan MahendranNoch keine Bewertungen

- Industrial AerodynamicsDokument78 SeitenIndustrial AerodynamicsAnuNoch keine Bewertungen

- Ae-2405 Aircraft Systems LaboratoryDokument42 SeitenAe-2405 Aircraft Systems LaboratorycalinshabuNoch keine Bewertungen

- Airframe Maintenance and Repair - QBDokument5 SeitenAirframe Maintenance and Repair - QBandrw1987Noch keine Bewertungen

- AEMR-Unit - II & III, 2 Marks & 16 Marks Questions With Anwers-IV Yr AeroDokument39 SeitenAEMR-Unit - II & III, 2 Marks & 16 Marks Questions With Anwers-IV Yr AeroRAJASUDHAKAR SNoch keine Bewertungen

- AE6002 Aircraft General Engineering and Maintenance PracticesDokument1 SeiteAE6002 Aircraft General Engineering and Maintenance PracticesKarthi Keyan50% (2)

- Data Collection and Preliminary 3 View DesignDokument5 SeitenData Collection and Preliminary 3 View DesignBrijesh PatelNoch keine Bewertungen

- Assesment Exam (Powerplant)Dokument18 SeitenAssesment Exam (Powerplant)Sealtiel1020Noch keine Bewertungen

- Airframe Maintenance and RepairDokument28 SeitenAirframe Maintenance and Repairaerohod100% (1)

- Lecture 01 - Introduction To Aircraft PropulsionDokument28 SeitenLecture 01 - Introduction To Aircraft PropulsionandriaerospaceNoch keine Bewertungen

- Helicopter Theory QuestionsDokument5 SeitenHelicopter Theory QuestionskrishnamurthyVishNoch keine Bewertungen

- Esa 2 Mark Q & Answer PDFDokument11 SeitenEsa 2 Mark Q & Answer PDFChadwickajiNoch keine Bewertungen

- As-Ii 2marksDokument11 SeitenAs-Ii 2marksrobinston jeyasingh0% (1)

- Module 14 Propulsion Notes-3 PDFDokument5 SeitenModule 14 Propulsion Notes-3 PDFastikNoch keine Bewertungen

- Aircraft General Engineering and Maintenance PracticesDokument1 SeiteAircraft General Engineering and Maintenance PracticesKarthi Keyan0% (2)

- Laboratory ManualDokument75 SeitenLaboratory ManualĞńàŇeśhNoch keine Bewertungen

- CIA 2 Part ADokument9 SeitenCIA 2 Part Aradhakrishnan100% (1)

- AE 8504 Propulsion II 2 MarksDokument20 SeitenAE 8504 Propulsion II 2 MarksBairaviPerumalVigneswaran100% (1)

- Propulsion 2 Marks AnswersDokument12 SeitenPropulsion 2 Marks Answersaustin00012100% (3)

- Agemp QuestionDokument2 SeitenAgemp QuestionAero VijinNoch keine Bewertungen

- AS1 FormatDokument97 SeitenAS1 FormatgurusamyNoch keine Bewertungen

- Ae6012 Air Traffic Control and PlanningDokument1 SeiteAe6012 Air Traffic Control and PlanningIndhu ElangoNoch keine Bewertungen

- 2 Mark Q& A, Univ Ques PDFDokument32 Seiten2 Mark Q& A, Univ Ques PDFRamNoch keine Bewertungen

- Avionics 16 MarkDokument2 SeitenAvionics 16 MarkArJun Rinson100% (1)

- NR 322106 Aircraft Design PracticeDokument8 SeitenNR 322106 Aircraft Design PracticeSrinivasa Rao GNoch keine Bewertungen

- Rockets and Missiles Question BankDokument5 SeitenRockets and Missiles Question BankkannanNoch keine Bewertungen

- Radial TurbinesDokument46 SeitenRadial TurbinesarorabbNoch keine Bewertungen

- AE2353 Wind Tunnel Techniques Anna University Question BankDokument3 SeitenAE2353 Wind Tunnel Techniques Anna University Question BankaeroherozNoch keine Bewertungen

- Agem 2 MarksDokument3 SeitenAgem 2 MarksRamaswamy SubbiahNoch keine Bewertungen

- Content: Part-66 Module 11A. Turbine Airplane Aerodynamics, Structures and SystemsDokument5 SeitenContent: Part-66 Module 11A. Turbine Airplane Aerodynamics, Structures and SystemsJaafar Ali MohamadNoch keine Bewertungen

- Aircraft Design QuestionsDokument2 SeitenAircraft Design QuestionsVijay Gorfad100% (2)

- Elements of Aeronautics Unit 1Dokument16 SeitenElements of Aeronautics Unit 1VikasVickyNoch keine Bewertungen

- Propulsion Unit-I 2marksDokument11 SeitenPropulsion Unit-I 2marksmurjass85Noch keine Bewertungen

- AGEMPDokument12 SeitenAGEMPAravind Phoenix67% (3)

- Rr312102 Aircraft PerformanceDokument8 SeitenRr312102 Aircraft PerformanceSrinivasa Rao GNoch keine Bewertungen

- An Autonomous InstituteDokument80 SeitenAn Autonomous InstituteayeshaNoch keine Bewertungen

- Cargo Adp-2Dokument100 SeitenCargo Adp-2Adrian James100% (3)

- Avionics 2 Marks PDFDokument20 SeitenAvionics 2 Marks PDFJessica Carter100% (1)

- Aircraft Structure Question BankDokument1 SeiteAircraft Structure Question BankShiva100% (1)

- AERO Engine Maintenance AND Repair Notes-1 AERO Engine Maintenance AND Repair Notes-1Dokument29 SeitenAERO Engine Maintenance AND Repair Notes-1 AERO Engine Maintenance AND Repair Notes-1uthira100% (1)

- Aerodynamics-II Part B QuestionsDokument7 SeitenAerodynamics-II Part B QuestionsAeronaughtycs Hamdan100% (1)

- Engine Starting ProceduresDokument6 SeitenEngine Starting ProceduresSuresh RajroyceNoch keine Bewertungen

- Classroom Activities in Aerodynamics: © 2000 Dr. Charley Rodriguez, PH.DDokument21 SeitenClassroom Activities in Aerodynamics: © 2000 Dr. Charley Rodriguez, PH.DAerocse EceitmechNoch keine Bewertungen

- Reciprocating Engine Review PDFDokument148 SeitenReciprocating Engine Review PDFKim BautistaNoch keine Bewertungen

- Chapter 2Dokument74 SeitenChapter 2hailemariam markosNoch keine Bewertungen

- Reciprocating Engine ReviewDokument206 SeitenReciprocating Engine ReviewCed Sison100% (1)

- Recip Engine Part 1Dokument148 SeitenRecip Engine Part 1Patrick Trillana100% (1)

- Aircraft Engines: Reciprocating EngineDokument46 SeitenAircraft Engines: Reciprocating EngineBadal Machchhar100% (1)

- 2023 - AMM - Chap12 - Power PerformanceDokument52 Seiten2023 - AMM - Chap12 - Power Performancetrisha.ara31Noch keine Bewertungen

- Lecture 28 ErkDokument26 SeitenLecture 28 ErkDurai Raj KumarNoch keine Bewertungen

- 16AE327 Industrial Aerodynamics LTPC 3 0 0 3 Unit I Atmosphere 9Dokument2 Seiten16AE327 Industrial Aerodynamics LTPC 3 0 0 3 Unit I Atmosphere 9Durai Raj KumarNoch keine Bewertungen

- Ae15301-Aircraft Materials and Manufacturing Technology PDFDokument115 SeitenAe15301-Aircraft Materials and Manufacturing Technology PDFDurai Raj Kumar100% (1)

- Elements of Aircraft Pollution: June 4, 2012Dokument32 SeitenElements of Aircraft Pollution: June 4, 2012Durai Raj KumarNoch keine Bewertungen

- Reciprocating PumpDokument5 SeitenReciprocating PumpDurai Raj KumarNoch keine Bewertungen

- 13 PAX Short Course Sandwich-ConstructionsDokument59 Seiten13 PAX Short Course Sandwich-Constructionssjn11Noch keine Bewertungen

- Power Plants Used in Airplanes: Unit-VDokument28 SeitenPower Plants Used in Airplanes: Unit-VDurai Raj KumarNoch keine Bewertungen

- Aemr Manual PDFDokument61 SeitenAemr Manual PDFDurai Raj KumarNoch keine Bewertungen

- Sns College of Technology, Coimbatore - 35: Unit - Ii Energy MethodsDokument15 SeitenSns College of Technology, Coimbatore - 35: Unit - Ii Energy MethodsDurai Raj KumarNoch keine Bewertungen

- Elective IvDokument7 SeitenElective IvDurai Raj KumarNoch keine Bewertungen

- 13 PAX Short Course Sandwich-Constructions PDFDokument59 Seiten13 PAX Short Course Sandwich-Constructions PDFDurai Raj KumarNoch keine Bewertungen

- L32 PDFDokument14 SeitenL32 PDFDurai Raj KumarNoch keine Bewertungen

- Flued Mechanics MachineryDokument4 SeitenFlued Mechanics MachineryDurai Raj KumarNoch keine Bewertungen

- Ablative Coating MaterialsDokument12 SeitenAblative Coating MaterialsDurai Raj KumarNoch keine Bewertungen

- Akif LabReport CpDistributionOfAerofoil 4Dokument10 SeitenAkif LabReport CpDistributionOfAerofoil 4Durai Raj KumarNoch keine Bewertungen

- Generate Airfoil Coordinate in Excel Spreadsheet With This Format. in This Tutorial I Use NACA4412 As A Root and NACA 2410 As A TipDokument6 SeitenGenerate Airfoil Coordinate in Excel Spreadsheet With This Format. in This Tutorial I Use NACA4412 As A Root and NACA 2410 As A TipDurai Raj KumarNoch keine Bewertungen

- Integrating Aircraft Warning Systems PDFDokument5 SeitenIntegrating Aircraft Warning Systems PDFDurai Raj KumarNoch keine Bewertungen

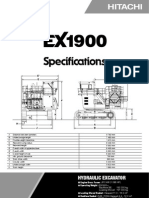

- SAE Net Horsepower: 177 HP (132 KW) Operating Weight: 61,950 Lbs. (28 100 KG) Digging Depth: 47 Ft. 9 In. (14.56 M)Dokument12 SeitenSAE Net Horsepower: 177 HP (132 KW) Operating Weight: 61,950 Lbs. (28 100 KG) Digging Depth: 47 Ft. 9 In. (14.56 M)Bart JohnNoch keine Bewertungen

- DML Sales BrochureDokument4 SeitenDML Sales BrochureGrabiela Hidalgo Medina100% (1)

- Trident OP GEN SET Data SheetDokument2 SeitenTrident OP GEN SET Data SheetAbdulrahman Al HuribyNoch keine Bewertungen

- Specs Retro 580SLDokument4 SeitenSpecs Retro 580SLRojasNoch keine Bewertungen

- StrenghtDokument67 SeitenStrenghtgalati12345Noch keine Bewertungen

- Mr647632en 2019-01Dokument206 SeitenMr647632en 2019-01Dmytro Manzyk100% (3)

- Engine Gross Power: 2 Operating WeightDokument5 SeitenEngine Gross Power: 2 Operating WeightAndi Wardiman AnwarNoch keine Bewertungen

- Fire Pump Installation Systems: 2006 Approval GuideDokument184 SeitenFire Pump Installation Systems: 2006 Approval GuideRAJESHNoch keine Bewertungen

- Tds 11hd FlyerDokument2 SeitenTds 11hd Flyerعلي اثمار ناهي سباهيNoch keine Bewertungen

- VOLVO TAD 1341 GE 300 Kva PDFDokument2 SeitenVOLVO TAD 1341 GE 300 Kva PDFluislunar0% (2)

- Data Sheet-Cummins 6CTA8.3-GM175 Marine Generators EngineDokument4 SeitenData Sheet-Cummins 6CTA8.3-GM175 Marine Generators EngineabdullahaljafarieNoch keine Bewertungen

- D275D6Dokument4 SeitenD275D6WilmerNoch keine Bewertungen

- Heavy Duty Gas Engines: 913 SeriesDokument6 SeitenHeavy Duty Gas Engines: 913 SeriesFodil ZouNoch keine Bewertungen

- Generator and Engine Generador y Motor Gerador e Motor: PCI2200 PCI2800 PCI5000Dokument92 SeitenGenerator and Engine Generador y Motor Gerador e Motor: PCI2200 PCI2800 PCI5000CIVO CivoNoch keine Bewertungen

- 10 VesselsDokument30 Seiten10 VesselsIbrahim ZaidNoch keine Bewertungen

- M8540 M9540 Synchro/Hydraulic: Kubota Diesel TractorDokument4 SeitenM8540 M9540 Synchro/Hydraulic: Kubota Diesel TractorJeya KumarNoch keine Bewertungen

- 70ziv2 BrochureDokument12 Seiten70ziv2 Brochurekiko100% (1)

- Vav 107 PDFDokument16 SeitenVav 107 PDFLeonardo MuñozNoch keine Bewertungen

- KSM8990WH ManualDokument48 SeitenKSM8990WH ManualJuan Andres Rojas SerranoNoch keine Bewertungen

- Conveyor Tension and Trajectory CalculationDokument9 SeitenConveyor Tension and Trajectory CalculationSteve WanNoch keine Bewertungen

- Toyota 1NZ-FE (1.5 L)Dokument9 SeitenToyota 1NZ-FE (1.5 L)Bernard MusonaNoch keine Bewertungen

- BST-860 User Manual 2018-08-17Dokument15 SeitenBST-860 User Manual 2018-08-17ANTAWA PERUNoch keine Bewertungen

- CX75 225SRDokument28 SeitenCX75 225SREng Ahmed ABasNoch keine Bewertungen

- Spec Sheet - EX1900Dokument7 SeitenSpec Sheet - EX1900slatts85Noch keine Bewertungen

- Company Profile Pt. DutaflowDokument62 SeitenCompany Profile Pt. DutaflowRizkiRamadhanNoch keine Bewertungen

- Pressure Pumping Equipment BrochureDokument15 SeitenPressure Pumping Equipment Brochureinyene ekereNoch keine Bewertungen

- Soilmec SM5 - 2016Dokument6 SeitenSoilmec SM5 - 2016gabyorNoch keine Bewertungen

- 9868 0034 01b PowerROC T25 DC Brochure English-WebDokument5 Seiten9868 0034 01b PowerROC T25 DC Brochure English-WebRoni DamanikNoch keine Bewertungen

- Bombas Pvp16Dokument10 SeitenBombas Pvp16Gustavo HuertasNoch keine Bewertungen

- Marathon Electric Nameplate InformationDokument2 SeitenMarathon Electric Nameplate InformationDhrubajyoti BoraNoch keine Bewertungen