Beruflich Dokumente

Kultur Dokumente

18 Testing... (pp.83-87)

Hochgeladen von

Asriandy RamadhanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

18 Testing... (pp.83-87)

Hochgeladen von

Asriandy RamadhanCopyright:

Verfügbare Formate

83

ISSN 13921320 MATERIALS SCIENCE (MEDIAGOTYRA). Vol. 13, No. 1. 2007

Sorption Studies of Methylene Blue Dye in Aqueous Solution by Optimised

Carbon Prepared from Guava Seeds (Psidium guajava L.)

Collin G. JOSEPH

1

, Awang BONO

2

, Duduku KRISHNAIAH

2

, Kok Onn SOON

1

1

School of Science and Technology, Universiti Malaysia Sabah, Berkunci 2073, 88999 Kota Kinabalu, Sabah, Malaysia

2

School of Engineering and Information Technology, Universiti Malaysia Sabah,

Berkunci 2073, 88999 Kota Kinabalu, Sabah, Malaysia

Received 20 November 2006; accepted 01 March 2007

The aim of this investigation was to determine the adsorption behavior and kinetics of methylene blue in aqueous

solution on activated carbons prepared from guava seeds by way of the two stage activation method in self-generated

atmosphere using a muffle furnace. The yield and ash contents of the activated carbons obtained decreased with the

increase of activation temperature and time. FT-IR spectra indicated high surface functional groups present in the

carbons. The optimised activated carbon, AK6, had a sorption kinetics that complied with the pseudo-second order

kinetics and was fitted well to Langmuir isotherm model. The highest adsorption capacity was obtained when the

samples (AK6) were subjected to activation temperature of 500

C for 45 minutes giving iodine number of 198.12 mg

g

1

and the percentage of methylene blue removal efficiency of 84.75 %.

Keywords: adsorption kinetic, methylene blue, activated carbons, guava seeds, Langmuir adsorption isotherm.

INTRODUCTION

Activated carbons can be prepared from a large

number of sources, such as palm shells [1 2], wood

[3 4], coconut shells, coals, carbon fibers and pitch.

Activated carbon adsorbs molecules from both liquid and

gaseous phases were found to depend on the specific

surface area, pore size distribution, surface functional

groups (also denoted as surface complexes). Applications

of activated carbons include drinking water purification,

waste-water treatment, sweetener discolouration, food and

chemical processing, solvent recovery, gasoline emission

control, cigarette filters and industrial emission gas

treatment.

Activated carbon is generally considered non-toxic

and will not have any detrimental chemical interactions

with any other chemicals. Activated carbon is a mild

reducing agent and a catalyst [4 6], but will not react

strongly with any organically allowed substances. Thus, it

is used medically to adsorb a wide variety of toxins. If

trace quantities of the activated carbon is left behind, it is

basically nothing but carbon, and ash (metallic elements).

Heavy metals content of activated carbon may be of

interest when it comes in direct contact with food. Large

doses of activated carbon are routinely given in human

poisoning cases. The human dose for poisoning is 1g

activated carbon per kg. body weight [7 8]. In Malaysia,

the state of Perak particularly Bidor, is the largest area for

guava Psidium guajava L plantation. Guava is an important

tropical fruit in Malaysia and claims superiority over other

fruits by virtue of its commercial and nutritional values.

In the last decade, guava in Malaysia has grown in

importance from a neglected fruit to one grown largely for

processing. In the processing line, the fruit is either canned

or converted into juice or puree, or used for producing jam

Corresponding author. Tel.: +6-088-320000 ext 2117; fax.: +6-088-

435324. E-mail address: collin@ums.edu.my (G. J. Collin)

and guava paste. Guava seeds are agricultural by-products

that are currently of no economic value. The seeds are

considered waste product during guava juice processing

(seeds represent about 5 % of the fresh fruit) [9]. The seeds

have high amount of lignocellulosic materials which make

it suitable for the preparation of activated carbons [10].

The aim of this investigation was to determine the

adsorption behavior and kinetics of methylene blue in

aqueous solution on activated carbons prepared from guava

seeds by way of the two stage activation method in self-

generated atmosphere using a muffle furnace.

EXPERIMENTAL

The seeds (from the species Psidium guajava L.) were

collected from a wet market in Sabah (Malaysia). The

seeds were washed and dried in an oven at 110 C for 24

hours. Carbonization by pyrolysis was carried out in a

muffle furnace (Carbolite, RHF 1500). The sample was

placed on a pyrex petri dish, and placed in the hot zone of

the furnace. The samples were heated at 200 C for 15

minutes. The carbonized samples were taken out of the

furnace and stored in a desiccator until the furnace reached

the set activation temperature (400 C 600 C) before

being put back in for activation. After activation at the

required temperature, the activated samples were

repetitively washed with 0.1 M phosphorus acid to reduce

the ash and mineral content of the samples. The washing

was carried out in a water bath shaker at 70 C for 4 hours.

Finally, the carbon was neutralized with 0.1 M sodium

hydroxide. The end product was characterized for

percentage of yield, moisture and ash content, pH value,

iodine number and methylene blue adsorption capacity

from aqueous solution. The yield is defined as the ratio of

the mass of activated carbon obtained to the initial mass of

the guava seed, both based on dry weight [11]. The ash and

moisture contents, pH value, iodine number and methylene

blue adsorption capacity were evaluated by using SIRIM

84

standard method [12]. Iodine number is commonly used in

the industry, as a rough estimate of the surface area of the

activated carbon [11]. The removal efficiency of

methylene blue by the activated carbons at specific time

and concentration was calculated according to equation (1)

[13]. In order to study the adsorption kinetics and

adsorption isotherm for the optimized sample prepared,

different mixing times with a specific initial concentration

of methylene blue were used as parameters. The adsorption

behaviour of the samples was studied by evaluating the

removal efficiency, R

E

, of methylene blue, calculated as

( )

100

0

0

=

C

C C

R

E

, (1)

where C

0

is the initial concentration of aqueous solution of

methylene blue placed in a flask and shaken at 70 C for

4 hours with a 0.2 g samples, and C is the solution

concentration after adsorption, R

E

is expressed in term of

percentage. The surface functional group of prepared

activated carbon was determined by using Fourier

Transform Infrared Spectrometer (FT-IR) [14 15].

RESULTS AND DISCUSSION

The effect of activation conditions on the percentage

of yield, pH value, moisture and ash contents are shown in

Table 1. The results show that the yield decreases with

increasing temperature. The carbon yield also decreases as

the pyrolysis time was increased. The pyrolysed samples at

about 400 C and above consisted of black carbonaceous

material which is carbon [9]. Low activation temperature

cause incomplete burn off and resulting higher yield are

obtained. The activated carbon prepared from guava seed

is basic due to the final washing with NaOH. Overall, the

samples prepared had a pH range of 8.00 to 8.30. The

average moisture content of the activated samples was in

the range of 2 % 3 %. The moisture content detected was

from the contact with the moisture in the atmosphere after

activation. The ash content decreased with increasing

pyrolysis time and temperature up to 600 C. The ash

content of the activated carbons was less than 3 %.

Therefore, the pyrolyzed guava seeds were favorable for

the preparation of activated carbons. The adsorptive

capacities of the samples were analyzed by liquid

adsorption techniques known as iodine number and

methylene blue removal efficiency as shown in Figure 1.

We found that the removal efficiency trend of the

methylene blue coincided with the iodine number,

indicating that pore enlargement occurred and gave rise to

higher adsorption capacity. The adsorptions increased as

the activation time was increased until 60 minutes and

decreased afterwards. Whilst there was an increased in

adsorption as the activation temperature increased from

400 C to 500 C, adsorption decreased as the activation

temperature was increased above 500 C. The results

indicated that the control of activation temperature and

time is very important to produce optimized activated

carbon. Activation at 500 C for 45 minutes, produced

carbons with the highest iodine number and the highest

methylene blue removal efficiency that is 198.12 mg

g

1

and 84.75 % respectively. The iodine number is

comparable with the physically activated carbons prepared

from milo grain (about 190 mg

g

1

) [16].

Due to the high removal efficiency of sample AK6,

adsorption studies such as adsorption isotherms and

kinetics were done using sample AK6 in methylene blue

aqueous solution.

Figure 2 shows the removal efficiency of sample AK6

versus shaking time. The adsorption pattern of methylene

blue by sample AK6 can be described into two regions.

The first corresponds to a fast removal rate, followed by

the second slow removal until equilibrium was achieved.

The equilibrium time for the adsorption of methylene blue

on the activated sample AK6 is 40 minutes. The kinetics

and dynamics of adsorption of methylene blue on activated

carbon can be studied by applying the Lagergren first order

and pseudo-second order rate equations that have been

most widely used for the adsorption of an adsorbate from

an aqueous solution, which are expressed by the equations

( )

303 . 2

log log

ad

e t e

k

q q q = , (2)

t

q

q k

q

t

e

e ad

t

1 1

2

+ = , (3)

where q

e

and q

t

are the amount of dye adsorbed per unit

mass of the adsorbent (in mg

g

1

) at equilibrium time and

time t

, respectively, and k

ad

is the rate constant [17].

Table 1. The effect of activation time and temperature on the percentage of yield, pH value, moisture and ash content of the activated

carbons

Activation condition

Sample

Temperature, C Time, min

pH Yield, % Moisture content, % Ash content, %

AK1 400 30 8.27 51.80 2.90 4.70

AK2 400 45 8.20 40.63 2.77 3.28

AK3 400 60 8.21 23.27 2.56 1.76

AK4 400 90 8.02 16.05 2.71 0.86

AK5 500 30 8.18 39.50 2.70 2.85

AK6 500 45 8.10 30.99 2.87 1.50

AK7 500 60 8.25 17.75 2.50 0.77

AK8 500 90 8.08 12.24 2.24 0.40

AK9 600 45 8.21 4.09 2.10 0.20

85

0

25

50

75

100

125

150

175

200

225

AK1 AK2 AK3 AK4 AK5 AK6 AK7 AK8 AK9

ACTIVATED CARBONS

I

O

D

I

N

E

N

U

M

B

E

R

,

m

g

/

g

0

10

20

30

40

50

60

70

80

90

100

M

E

T

H

Y

L

E

N

E

B

L

U

E

,

%

Iodine Number Methylene Blue

Fig. 1. The effect of the activation conditions on the iodine number and the percentage of methylene blue removal efficiency of the

activated carbons (notations of samples are given in Table 1)

0

20

40

60

80

100

120

0 20 40 60 80 100 120

Mixing time (min)

R

e

m

o

v

a

l

e

f

f

i

c

i

e

n

c

y

(

%

)

Fig. 2. Removal efficiency of methylene blue versus time for

sample AK6 (temp. = 70 C)

Figure 3 and Figure 4 show the Lagergren first order

and pseudo-second order plots, respectively. As shown, the

pseudo-second order plot gives a straight line with

correlation coefficient, R

2

= 0.9915 and k

ad

= 0.0282,

indicating that the applicability of the pseudo-second order

equation was the best result as compared to the Lagergren

first order plot with R

2

= 0.9368 and k

ad

= 0.1253 only.

y = -0.0544x + 1.1728

R

2

= 0.9368

-1.6

-1.4

-1.2

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0 20 40 60

Time (min)

l

o

g

(

q

e

-

q

t

)

Fig. 3. Lagergren first order rate plot for methylene blue

adsorption by activated carbon AK6

y = 0.2232x + 2.2192

R

2

= 0.9917

0

5

10

15

20

25

30

0 50 100 150

Time (min)

t

/

q

t

(

m

i

n

.

g

m

g

)

Fig. 4. Pseudo-second order rate plot for methylene blue

adsorption by activated carbon AK6

The adsorption data were applied to the linear

Langmuir equation (Figure 5):

e

m m e

e

C

X K X X

C 1 1

+ = (4)

and the Freundlich equation (Figure 6):

e F e

C

n

K X log

1

log log + = , (5)

where C

e

is the amount of adsorbate in the solution at

equilibrium, X

e

is the amount of adsorbate adsorbed, X

m

is

the amount of adsorbated adsorbed to form monolayer

coverage, and K, n and K

F

are the equation constants [9].

We found that the adsorption data fitted best to the

Langmuir model as indicated by its relatively linear

correlation coefficients, R

2

= 0.8352. Figure 4 and Figure 5

represent comparison of the experimental data of activated

carbons with Langmuir and Freundlich equations.

The surface chemistry of activated carbons was

determined by the type, quantity and bonding of oxygen-

containing functional groups such as hydroxyl and

carboxyl groups [18]. From the FT-IR spectra shown in

Figure 7, all the activated carbons had almost the same

functional groups due to the same precursor; guava seeds.

86

y = 62.977x + 0.1745

R

2

= 0.8352

0.00

1.00

2.00

3.00

4.00

5.00

6.00

0.00 0.02 0.04 0.06 0.08 0.10

Ce (mgL)

C

e

/

X

e

(

m

g

g

)

y = 0.3956x + 1.7512

R

2

= 0.5607

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

-3 -2 -1 0

Log Ce

L

o

g

X

e

Fig. 5. Fitting methylene blue adsorption data to Langmuir model

for sample AK6

Fig. 6. Fitting methylene blue adsorption data to Freundlich

model for sample AK6

Fig. 7. FT-IR spectra of the activated carbons prepared from guava seed

The only difference was the activation process (time and

temperature). The FT-IR spectrum of activated samples

shows medium broad overlapping bands in the range

between 3500 cm

1

and 3300 cm

1

and may be attributed to

NH stretching alkyl or aryl amine which may be present

in the amino acid of guava seeds protein. Two strong

bands observed in the range between 2962 cm

1

and 2853

cm

1

are assigned to asymmetric CH and symmetric CH

bands, respectively, present in alkyl groups such as methyl

and methylene groups. Stretching absorption band around

1700 cm

1

is assigned to carbonyl C=O present in esters,

aldehydes, ketones groups and acetyl derivatives. The

strong band at around 1600 cm

1

may be ascribed C=C.

The region of 1400 cm

1

1300 cm

1

may be ascribed

CH bending present in alkyl groups such as methyl. The

region of 1300 cm

1

1000 cm

1

is a superposition of

number of broad overlapping bands. The assignment in this

region is a complex nature, so they cannot be described in

terms of the simple motion of specific functional groups or

chemical bonds.

CONCLUSION

Production of activated carbons derived from guava

seeds with two step activation process had been

demonstrated to be feasible. Due to the activated carbon

produced with carbonization and followed by physical

activation in open system (without gas control), only low

temperature is needed to complete the decomposition of

organic constituents. Generally, lower yield of activated

guava seed produce as the pyrolysis temperature and time

increase. Activated carbon produce from guava seed was

basic due to the washing process. The average moisture

content of the activated carbon produced was in the range

of 2 % 3 %. The ash content decreased as the pyrolysis

time and temperature of activation increased. Both the

iodine number and removal efficiency of methylene blue

increased as the activation temperature and time were

increased, but decreased after 500 C or 60 minutes, due to

the pores being blocked by pyrolysis by-product. The

methylene blue adsorption kinetic of guava seed activated

carbon was of pseudo-second order with the Langmuir

adsorption isotherm. Infra-red spectra indicated that the

vast and varied surface functional groups were present.

These fuctional groups were generally not affected by the

activation temperature and time. Besides being an

adsorbent for aqueous based impurities, these activated

carbons have a potential to be used in the pharmaceutical

or medical industries as no chemicals were involved in the

activation process.

Acknowledgments

This research was supported by the Centre for

Management of Research and Conference, University

Malaysia Sabah (Grant No. B-0901-01-ER/U131) and is

87

gratefully acknowledged. The authors would also like to

express deepest gratitude to Prof. Datin Dr. Maryati

Mohamed, Director of the Institute for Tropical Biology

and Conservation, UMS, for the use of certain scientific

instruments.

REFERENCES

1. Anuar, K., Collin, G. J., Zulkarnain, Z., Hussein, M. Z.,

Haron, M.J., dan Abdullah, A. H. Surface Area and

Porosity Studies of Activated Carbons Prepared from Oil

Palm Shells (Elaeis Guineensis) using Physical and

Chemical Activators such as CO

2

, H

3

PO

4

, K

3

PO

4

and KOH

ASEAN Journal of Science and Technology for Development

20 (2) 2003: pp. 149 158.

2. Anuar, K., Collin, G. J., Zulkarnain, Z., Hussein, M. Z.,

Haron, M. J., dan Abdullah, A. H. Activated Carbons

Prepared from Oil Palm Shells: Application for Column

Separation of Heavy Metals Indian Chemical Society

81 (12) 2004: pp. 946 949.

3. Anuar, K., Collin, G. J., Zulkarnain, Z., Hussein, M. Z.,

Haron, M. J., dan Abdullah, A. H. Preparation and

Characterization of Activated Carbon from Resak Wood

(Vatica Hullettii): Surface Area and Porosity Studies

Oriental Journal of Chemical 18 (1) 2002: pp. 43 46.

4. Anuar, K., Collin, G. J., Zulkarnain, Z., Hussein, M. Z.,

Haron, M. J., dan Abdullah, A. H. Preparation and

Characterizations of Activated Carbon from Resak Wood

(Vatica Hullettii) Research Journal of Chemical

Environmental 5 (3) 2001: pp. 21 24.

5. Pradhan, B. K., Sandle, N. K. Effect of Different

Oxidizing Agent Treatments on the Surface Properties of

Activated Carbons Carbon 37 1999: pp. 1323 1332.

6. Hoffman, P. S., Pine, L., Bell, L. Production of Superoxide

and Hydrogen Peroxide in Medium Used to Culture

Legionella pneumophila: Catalytic Decomposition by

Charcoal Applied Environmental Microbiology 45 1983:

pp. 784 791.

7. Scharman, E. J., Cloonan, H. A., Durback-Morris, L. F.

Home Administration of Charcoal: Can a Mother Administer

a Therapeutic Dose? Journal of Emergency Medicine 21

2001: pp 357 361.

8. Minocha, A., Krenzelok, Spyker, D. Dosage Recom-

mendations for Activated Charcoal-Sorbitol Treatment

Journal of Toxicology & Clinical Toxicology 23 1988:

pp. 579 587.

9. Rahman, I. A., Saad, B. Utilization of Guava Seeds as a

Source of Activated Carbon for Removal of Methylene Blue

from Aqueous Solution Malaysian Journal of Chemistry

5 (1) 2003: pp. 8 14.

10. Ouensanga, A., Largitte, L., Arsene, M.-A. The depend-

ence of Char Yield on the Amounts of Component in

Precursors for Pyrolysed Tropical Fruit Stones and Seeds

Microporous and Mesoporous Materials 59 2003:

pp. 85 91.

11. Srinivasakannan, C., Mohamad Zailani Abu Bakar

Production of Activated Carbon from Rubber Wood

Sawdust Biomass and Bioenergy 27 2004: pp. 89 96.

12. SIRIM (1984) Specification of Powdered Activated Carbon,

MS 873: 1984. Standard and Industrial Research Institute,

Malaysia.

13. Jankowska, H., witkowski, A., Choma, J. Active

Carbon. Ellis Horwood Limited, Poland, 1991.

14. Gmez-Serrano,

V., Piriz-Almeida,

F., Durn-Valle.

C.

J.,

Pastor-Villegas, J. Formation of Oxygen Structures by Air

Activation. A Study by FT-IR Spectroscopy Carbon 37

1999: pp. 1517 1528.

15. DeSilva, F. Activated Carbon Filtration Water Quality

Products Magazine 2000.

16. Bapat, H., Manahan, S. E., Larsen, D. W. An Activated

carbon Product Prepared from Milo (Sorghum Vulgare)

Grain for Use in Hazardous Waste Gasification by

ChemChar Cocurrent Flow Gasification Chemosphere

39 (1) 1999: pp. 23 32.

17. Wang, S., Zhu, Z. H., Coomes, A., Haghseresht, F.,

Lu, G. Q. The Physical and Surface Chemical

Characteristics of Activated Carbons and the Adsorption of

Methylene Blue from Wastewater Journal of Colloid and

Interface Science 284 2005: pp. 440 446.

18. El-Hendawy, A.-N. A. Variation in the FTIR Spectra of a

Biomass under Impregnation, Carbonization and Oxydation

Conditions Journal of Analytical and Applied Pyrolysis

2005 (article in press).

Das könnte Ihnen auch gefallen

- Physical Characterization of Activated Carbon Derived From Mangosteen Peel PDFDokument5 SeitenPhysical Characterization of Activated Carbon Derived From Mangosteen Peel PDFMark Noel SanteNoch keine Bewertungen

- IOP Conference Series: Earth and Environmental Science - Activated Carbon from Palm Kernel ShellDokument8 SeitenIOP Conference Series: Earth and Environmental Science - Activated Carbon from Palm Kernel ShellIbnu SalehNoch keine Bewertungen

- Ref 3 RDDokument8 SeitenRef 3 RDFerdi habibNoch keine Bewertungen

- J. Inter Salaca Peel For Activated Carbon KOHDokument4 SeitenJ. Inter Salaca Peel For Activated Carbon KOHYolanda Priscilia GustantiaNoch keine Bewertungen

- Procurement of Activated Carbon from Jacaranda FruitDokument6 SeitenProcurement of Activated Carbon from Jacaranda FruitEnrique Franco ArizaNoch keine Bewertungen

- Preparation and Characterization of Phosphoric Acid Activated Carbon from Canarium Odontophyllum (Dabai) NutshellDokument6 SeitenPreparation and Characterization of Phosphoric Acid Activated Carbon from Canarium Odontophyllum (Dabai) NutshellAdil LagmarNoch keine Bewertungen

- Preparation and Characterization of Activated Carbon From Hura Crepitans Linn Seed ShellsDokument4 SeitenPreparation and Characterization of Activated Carbon From Hura Crepitans Linn Seed ShellstheijesNoch keine Bewertungen

- Cafei2012-170 Turbidity and Suspended Solid Reduction From Palm Oil Mill Effluent Using Coconut Shell CharcoalDokument8 SeitenCafei2012-170 Turbidity and Suspended Solid Reduction From Palm Oil Mill Effluent Using Coconut Shell CharcoalPriÑcé ȜßōðđyNoch keine Bewertungen

- Preparation and Characterization of Activated Carbon Derived From Fluted Pumpkin Stem Waste (Telfairia Occidentalis Hook F)Dokument8 SeitenPreparation and Characterization of Activated Carbon Derived From Fluted Pumpkin Stem Waste (Telfairia Occidentalis Hook F)Oguntimehin OlamilekanNoch keine Bewertungen

- Indonesian Journal of Science & Technology 4 (2) (2019) 229-240Dokument12 SeitenIndonesian Journal of Science & Technology 4 (2) (2019) 229-240kekeNoch keine Bewertungen

- Effects Activating AgentsDokument6 SeitenEffects Activating AgentsDiogo RafaelNoch keine Bewertungen

- Optimization of Conditions For The Preparation of Activated Carbon From Mango Nuts Using HCLDokument12 SeitenOptimization of Conditions For The Preparation of Activated Carbon From Mango Nuts Using HCLAJER JOURNALNoch keine Bewertungen

- 004 10199ny0509 18 25Dokument8 Seiten004 10199ny0509 18 25Erin WalkerNoch keine Bewertungen

- Lignin Recovery From Alkaline Hydrolysis and Glycerolysis of Oil Palm FiberDokument7 SeitenLignin Recovery From Alkaline Hydrolysis and Glycerolysis of Oil Palm FiberMriganabh SarmaNoch keine Bewertungen

- Activated Carbon from Aloe Vera Removes Toxic PollutantDokument10 SeitenActivated Carbon from Aloe Vera Removes Toxic PollutantÍcaro MychelNoch keine Bewertungen

- Activated Carbon From Durian Seed by H PO Activation: Preparation and Pore Structure CharacterizationDokument5 SeitenActivated Carbon From Durian Seed by H PO Activation: Preparation and Pore Structure CharacterizationBernadine HerreraNoch keine Bewertungen

- ArtigoDokument9 SeitenArtigo1986crisNoch keine Bewertungen

- Ekpete, 2017Dokument7 SeitenEkpete, 2017Muhammad Ramadhan SaputraNoch keine Bewertungen

- Contribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Dokument9 SeitenContribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Van AlifNoch keine Bewertungen

- Removal of Dye by Using Activated Carbon (Using Sugar Cane Bagasse)Dokument10 SeitenRemoval of Dye by Using Activated Carbon (Using Sugar Cane Bagasse)Supriya bhattacharjeeNoch keine Bewertungen

- Activated Carbons Derived From Oil Palm Empty-Fruit Bunches: Application To Environmental ProblemsDokument6 SeitenActivated Carbons Derived From Oil Palm Empty-Fruit Bunches: Application To Environmental ProblemsHusaini HagNoch keine Bewertungen

- SNI - AC Dari JengkolDokument8 SeitenSNI - AC Dari JengkolMathilda PasaribuNoch keine Bewertungen

- Articulo 1 Inmovilización Alginato PDFDokument6 SeitenArticulo 1 Inmovilización Alginato PDFCarolina MorenoNoch keine Bewertungen

- The Adsorption Efficiency of Chemically Prepared ActivatedDokument8 SeitenThe Adsorption Efficiency of Chemically Prepared Activatedshravan kumarNoch keine Bewertungen

- Efeovbokhan 2019 J. Phys. Conf. Ser. 1378 032035Dokument15 SeitenEfeovbokhan 2019 J. Phys. Conf. Ser. 1378 032035Felipe BarriosNoch keine Bewertungen

- MetododologiaDokument16 SeitenMetododologiaLuis Lozano SNoch keine Bewertungen

- Preparation of Activated Carbon From Walnut Shell and Its Application in Industrial WastewaterDokument5 SeitenPreparation of Activated Carbon From Walnut Shell and Its Application in Industrial WastewaterWILFREDO ROMAN PAUCARNoch keine Bewertungen

- 16234-Article Text-55935-3-10-20220117Dokument17 Seiten16234-Article Text-55935-3-10-20220117AJ ManurungNoch keine Bewertungen

- Comparative Adsorption Capacity of Modified Activated Carbon From Pennisetum Glaucum andDokument6 SeitenComparative Adsorption Capacity of Modified Activated Carbon From Pennisetum Glaucum andPraslita DishadewiNoch keine Bewertungen

- Producción de Carbón Activado A Partir de Una Nueva Melaza Precursora Por Activación Con Ácido Sulfúrico.Dokument5 SeitenProducción de Carbón Activado A Partir de Una Nueva Melaza Precursora Por Activación Con Ácido Sulfúrico.John TorrezNoch keine Bewertungen

- Tongpoothorn2011 PDFDokument6 SeitenTongpoothorn2011 PDFAndreamNoch keine Bewertungen

- Gumus Dan Iyonbe, 2015Dokument12 SeitenGumus Dan Iyonbe, 2015Muhammad Ramadhan SaputraNoch keine Bewertungen

- Effect of Activation Temperature On Properties of Activated Carbon Prepared From Oil Palm Kernel Shell (OPKS)Dokument4 SeitenEffect of Activation Temperature On Properties of Activated Carbon Prepared From Oil Palm Kernel Shell (OPKS)Aaron Jrz RamseyNoch keine Bewertungen

- Palm Oil Shell JURNALDokument6 SeitenPalm Oil Shell JURNALAmin SulaimanNoch keine Bewertungen

- Adsorption of Cadmium Ions Using Activated Carbon Prepared From Coconut ShellDokument5 SeitenAdsorption of Cadmium Ions Using Activated Carbon Prepared From Coconut ShellNastitiNoch keine Bewertungen

- Removal of Yellow 2G Dye From Aqueous Solutions Using Activated Carbon Prepared From Mosambi and Cotton An Agricultural WasteDokument6 SeitenRemoval of Yellow 2G Dye From Aqueous Solutions Using Activated Carbon Prepared From Mosambi and Cotton An Agricultural WasteInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- OBIDIKE TOCHUKWU EMMANUEL SeminarDokument44 SeitenOBIDIKE TOCHUKWU EMMANUEL SeminarEmmanuel TochukwuNoch keine Bewertungen

- วิธีคำนวน activated carbon PDFDokument7 Seitenวิธีคำนวน activated carbon PDFPépé TechopathamNoch keine Bewertungen

- Activated carbons for dye removal: A reviewDokument7 SeitenActivated carbons for dye removal: A reviewDiana CarolinaNoch keine Bewertungen

- Activated Carbon from Palm ShellsDokument8 SeitenActivated Carbon from Palm ShellsBayu Pramana PutraNoch keine Bewertungen

- Adsorption of Methylene Blue Dye by Activated Carbon Prepared From Malted Sorghum Mash and Plantain PeelsDokument8 SeitenAdsorption of Methylene Blue Dye by Activated Carbon Prepared From Malted Sorghum Mash and Plantain Peelsboatengcosmos09Noch keine Bewertungen

- Determination of Chemical Composition of Carob Pod (Ceratonia Siliqua LDokument6 SeitenDetermination of Chemical Composition of Carob Pod (Ceratonia Siliqua LalhachmiNoch keine Bewertungen

- Nurlina DKK 2015 Pengolahan Limbah Cair Dengan TawasDokument11 SeitenNurlina DKK 2015 Pengolahan Limbah Cair Dengan Tawasmay andy dwi wantoroNoch keine Bewertungen

- Betung Bamboo-Based Activated Carbon Bioadsorbent For The Separation of Hydrogen-Methane Gas MixtureDokument6 SeitenBetung Bamboo-Based Activated Carbon Bioadsorbent For The Separation of Hydrogen-Methane Gas MixtureChristian DennisNoch keine Bewertungen

- Activated Carbon PDFDokument10 SeitenActivated Carbon PDFDavid JoeventusNoch keine Bewertungen

- Edokpayi 2018Dokument5 SeitenEdokpayi 2018Osariemen Angela EdokpayiNoch keine Bewertungen

- Xinghui Chen, Ying Fang, Jian Zhu, Fuyong Wang, Teng Zhao and Dongli FanDokument6 SeitenXinghui Chen, Ying Fang, Jian Zhu, Fuyong Wang, Teng Zhao and Dongli FanRhea FayeNoch keine Bewertungen

- Activation of Oil Palm Empty Bunches With Hydrochloride Acid & Phosphoric Acid and Characterization Based Sni No. 06-3730-1995Dokument9 SeitenActivation of Oil Palm Empty Bunches With Hydrochloride Acid & Phosphoric Acid and Characterization Based Sni No. 06-3730-1995Addaska WahyuNoch keine Bewertungen

- Vol1 No1 2Dokument14 SeitenVol1 No1 2Nagwa MansyNoch keine Bewertungen

- Arunrat - Rice HuskDokument5 SeitenArunrat - Rice HuskAnitha RajNoch keine Bewertungen

- PB RemovalDokument7 SeitenPB RemovalMwemeziNoch keine Bewertungen

- Dilek Angin: HighlightsDokument8 SeitenDilek Angin: HighlightsMathilda Jowito PasaribuNoch keine Bewertungen

- IJERTV3IS10191Dokument8 SeitenIJERTV3IS10191Abdulwahab GIWANoch keine Bewertungen

- Optimization of Conditions For The Preparation of Activated Carbon From Mango Nuts Using ZNCLDokument7 SeitenOptimization of Conditions For The Preparation of Activated Carbon From Mango Nuts Using ZNCLIJERDNoch keine Bewertungen

- Microporous and Mesoporous Materials: Lingeswarran Muniandy, Farook Adam, Abdul Rahman Mohamed, Eng-Poh NGDokument8 SeitenMicroporous and Mesoporous Materials: Lingeswarran Muniandy, Farook Adam, Abdul Rahman Mohamed, Eng-Poh NGAditIqbalIskandarNoch keine Bewertungen

- Zhang 2021Dokument10 SeitenZhang 2021Val Andrea TuazonNoch keine Bewertungen

- Adsorption Studies of Fluoride On Activated CarbonDokument5 SeitenAdsorption Studies of Fluoride On Activated CarbonInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeVon EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeNoch keine Bewertungen

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesVon EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNoch keine Bewertungen

- Reaksi Pada Percobaan:: O H C Oh + H + 2e x2 ODokument2 SeitenReaksi Pada Percobaan:: O H C Oh + H + 2e x2 OAsriandy RamadhanNoch keine Bewertungen

- Conductometric Titration: Determination of HCl StrengthDokument4 SeitenConductometric Titration: Determination of HCl StrengthAsriandy Ramadhan100% (1)

- Ninhidrin reaction identifies amino acidsDokument4 SeitenNinhidrin reaction identifies amino acidsAsriandy RamadhanNoch keine Bewertungen

- The Geochemical Cycle of CarbonDokument2 SeitenThe Geochemical Cycle of CarbonAsriandy RamadhanNoch keine Bewertungen

- Asriandy Ramadhan Uji WilcoxonDokument2 SeitenAsriandy Ramadhan Uji WilcoxonAsriandy RamadhanNoch keine Bewertungen

- Variable Contituens of The AtmosphereDokument2 SeitenVariable Contituens of The AtmosphereAsriandy RamadhanNoch keine Bewertungen

- The Origin of ElementsDokument4 SeitenThe Origin of ElementsAsriandy RamadhanNoch keine Bewertungen

- Ligand-Field Theory Metal ComplexesDokument11 SeitenLigand-Field Theory Metal ComplexesAsriandy RamadhanNoch keine Bewertungen

- The Origin of ElementsDokument4 SeitenThe Origin of ElementsrifkasyaputriNoch keine Bewertungen

- Ultrasonic Wave Technique Utilize For Study The Behavior of Peptide-Carnosine in A Different SolventsDokument11 SeitenUltrasonic Wave Technique Utilize For Study The Behavior of Peptide-Carnosine in A Different SolventsAsriandy RamadhanNoch keine Bewertungen

- Jresv93n5p613 A1bDokument12 SeitenJresv93n5p613 A1bAsriandy RamadhanNoch keine Bewertungen

- Handout Optik Geometri EnglishDokument17 SeitenHandout Optik Geometri EnglishAsriandy RamadhanNoch keine Bewertungen

- Corrosion Resistance of Continuously Anodised AluminiumDokument10 SeitenCorrosion Resistance of Continuously Anodised AluminiumAsriandy RamadhanNoch keine Bewertungen

- CONSTRUCTION CHEMISTRY ROOF WATERPROOFINGDokument2 SeitenCONSTRUCTION CHEMISTRY ROOF WATERPROOFINGAmar WadoodNoch keine Bewertungen

- WS3Dokument2 SeitenWS3dextercitomanNoch keine Bewertungen

- Grivory HT3: The Durable High-Performance PolyamideDokument6 SeitenGrivory HT3: The Durable High-Performance PolyamideSpu XisterNoch keine Bewertungen

- Third Quarter Science 8: Content StandardDokument19 SeitenThird Quarter Science 8: Content StandardGypsie Ann Pacon100% (1)

- Protons, Neutrons, and Electrons Practice WorksheetDokument2 SeitenProtons, Neutrons, and Electrons Practice WorksheetRedHoeBeerNoch keine Bewertungen

- Overall Heat Transfer Coefficient and Pipe Length CalculationDokument2 SeitenOverall Heat Transfer Coefficient and Pipe Length CalculationCaleb FalcoteloNoch keine Bewertungen

- PV Module IonDokument4 SeitenPV Module IonrmalewarNoch keine Bewertungen

- Chem 16 LE-1 AnswerKeyDokument4 SeitenChem 16 LE-1 AnswerKeyAntonette OngNoch keine Bewertungen

- Эластомер 9045 MSDSDokument17 SeitenЭластомер 9045 MSDSElena KhotulevaNoch keine Bewertungen

- Elisa: Enzyme-Linked Immunosorbent AssayDokument12 SeitenElisa: Enzyme-Linked Immunosorbent AssayAmitNoch keine Bewertungen

- Guide To Expansion Joints (Choosing and Maintenance)Dokument16 SeitenGuide To Expansion Joints (Choosing and Maintenance)stevebeanNoch keine Bewertungen

- Microporous and Mesoporous Materials: Sean M.W. Wilson, Vida A. Gabriel, F.Handan TezelDokument11 SeitenMicroporous and Mesoporous Materials: Sean M.W. Wilson, Vida A. Gabriel, F.Handan TezelEcNoch keine Bewertungen

- Circulatum MinusDokument2 SeitenCirculatum MinusJoshua Arent100% (1)

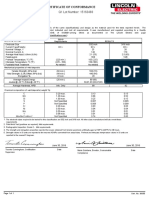

- Certificate of Conformance: Q1 Lot Number: 15163483Dokument1 SeiteCertificate of Conformance: Q1 Lot Number: 15163483interx00Noch keine Bewertungen

- Computational LaboratoryDokument31 SeitenComputational LaboratoryFrendick LegaspiNoch keine Bewertungen

- Refrigeration and Air ConditioningDokument76 SeitenRefrigeration and Air Conditioningmat_pran100% (3)

- s4 Chemistry Paper 1 Set 1 Marking GuideDokument11 Seitens4 Chemistry Paper 1 Set 1 Marking GuideNamuli MercyNoch keine Bewertungen

- Injection of Flux Into The BlastDokument8 SeitenInjection of Flux Into The BlastWesley CostaNoch keine Bewertungen

- Anti-Dandruff Shampoo With Zinc Pyrithione: INCI Name, Trade Name Weight % FunctionDokument2 SeitenAnti-Dandruff Shampoo With Zinc Pyrithione: INCI Name, Trade Name Weight % FunctionandreeaNoch keine Bewertungen

- Tell sth apart = distinguish between sth: phân biệt giữa 2 thứ gìDokument6 SeitenTell sth apart = distinguish between sth: phân biệt giữa 2 thứ gìHiền TrầnNoch keine Bewertungen

- Kanthal LT CatalogDokument3 SeitenKanthal LT CatalogRichard SyNoch keine Bewertungen

- CT TPDokument5 SeitenCT TPcesarchiletNoch keine Bewertungen

- Heat and Free Energy of Formation of Deuterium OxideDokument20 SeitenHeat and Free Energy of Formation of Deuterium OxiderifikoNoch keine Bewertungen

- PLAJEX SN Leaflet 2019Dokument2 SeitenPLAJEX SN Leaflet 2019pushpanjali singhNoch keine Bewertungen

- Packaging Materials and Articles For Food: Legislation and Codes of Good Manufacturing PracticeDokument10 SeitenPackaging Materials and Articles For Food: Legislation and Codes of Good Manufacturing PracticeMilanVukicNoch keine Bewertungen

- Mathematical Heat Transfer Model Research For The Improve-Ment of Continuous Casting Slab TemperatureDokument6 SeitenMathematical Heat Transfer Model Research For The Improve-Ment of Continuous Casting Slab TemperatureSanjeev SahuNoch keine Bewertungen

- APPENDIX B Filler Metal Comparison Chart ABS-AWSDokument3 SeitenAPPENDIX B Filler Metal Comparison Chart ABS-AWSplkv100% (1)

- Iso 13438 2018Dokument9 SeitenIso 13438 2018Phạm Hùng CườngNoch keine Bewertungen

- Physico-chemical Water Treatment Processes AssignmentDokument6 SeitenPhysico-chemical Water Treatment Processes AssignmentAbir HasanNoch keine Bewertungen

- Hawker Battery Service ManualDokument59 SeitenHawker Battery Service ManualBill Waters100% (1)