Beruflich Dokumente

Kultur Dokumente

80 - PP 601-606

Hochgeladen von

vinay_lamkhade0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

65 Ansichten6 SeitenThis paper describes the development of a robotic arm, prepared by him, which is operated and controlled wirelessly with the help of hand gestures. It's a CLASS - 5 robot (Numerical Control Robot), which moves and acts in the manner depending on the gestures made by the fingers and hand from a distance. The Robot moves in up, down, left or right directions and picks up objects from one place and keeps at another desired place as directed by the movements of fingers and hand.

Originalbeschreibung:

Originaltitel

80_pp 601-606 (1)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis paper describes the development of a robotic arm, prepared by him, which is operated and controlled wirelessly with the help of hand gestures. It's a CLASS - 5 robot (Numerical Control Robot), which moves and acts in the manner depending on the gestures made by the fingers and hand from a distance. The Robot moves in up, down, left or right directions and picks up objects from one place and keeps at another desired place as directed by the movements of fingers and hand.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

65 Ansichten6 Seiten80 - PP 601-606

Hochgeladen von

vinay_lamkhadeThis paper describes the development of a robotic arm, prepared by him, which is operated and controlled wirelessly with the help of hand gestures. It's a CLASS - 5 robot (Numerical Control Robot), which moves and acts in the manner depending on the gestures made by the fingers and hand from a distance. The Robot moves in up, down, left or right directions and picks up objects from one place and keeps at another desired place as directed by the movements of fingers and hand.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

Advance in Electronic and Electric Engineering.

ISSN 2231-1297, Volume 3, Number 5 (2013), pp. 601-606

Research India Publications

http://www.ripublication.com/aeee.htm

Hand Gestures Remote Controlled Robotic Arm

Shamsheer Verma

B.Tech (ICE), Bharati Vidyapeeth College Of Engineering, New Delhi.

Abstract

In this paper author has explained the development of a robotic arm,

prepared by him, which is operated & controlled wirelessly with the

help of hand gestures. Its a CLASS 5 Robot (Numerical Control

Robot).The complete robotic assembly is made into 2 parts viz a

transmitter assembly put on the gloves comprising of APC-220

Module, Arduino Board, Gyroscope, Accelerometer and a receiver(

Robotic Arm) comprising of APC-220 Module, Arduino Board, Servo

Motors and arms mounted on circular revolving base made of acrylic

sheets.

Keywords: Components- Robotics, Gesture, Arduino, Gyroscope,

Accelerometer, Servo Motor.

1. Introduction

Robotics is a current emerging technology in the field of science. A number of

universities in world are working in this field. Robotics is the new emerging booming

field, which will be of great use to society in the coming years. These days many types

of wireless robots are being developed and are put to varied applications and uses. The

author has developed a robotic arm, with his own learning and resources, which is

operated & controlled wirelessly with the help of hand gestures which transmits

signals to the robot through an auto device fixed on the gloves put on hands rather than

controlling it manually through a conventional remote controller. The Robot moves

and acts in the manner depending on the gestures made by the fingers and hand from a

distance. The robot moves in up, down, left or right directions and picks up objects

from one place and keeps at another desired place as directed by the movements of

fingers and hand. It is a TYPE C Robot, Programmable, servo controlled with

continuous or point to point trajectories.

Shamsheer Verma

602

2. Methodology

2.1 Robotic glove:

Robotic glove houses the circuitry which controls the robotic arm. It consists of

Arduino Mega 2560 which is programmed in such a way that it transfers the required

data with the help of APC 220 Module as well as it receives the data transmitted by

the robotic arm.

The Gyroscope and Accelerometer installed takes the angles (alpha, beta and

gamma ) and acceleration in all three directions of the hand respectively, sends the

signals to the Arduino Mega via wires where the values are combined and processed

simultaneously. At the same time the Flex sensor is doing its job by sending the degree

of movement of the finger to the Arduino Mega. The processed values are then

transmitted from the Module (Trans-receiver ) to the robotic arm. The module takes

the feedback from the arm and sends the new processed signals to it.

2.2 Robotic arm:

It is the main instrument where implementation of the program from the robotic glove

takes place. It consists of total of 6 nos. of Servos, connected in such a way that it

provides 3 DOFs (Degrees of Freedom) to the system. A micro controller Arduino

UNO which inputs the values from the module and sends the data accordingly to the

servos. Both the circuitry and base are clipped upon the common base, made of acrylic

to improve the stability. The whole chassis is made of Acrylic; the lowest point servo

is attached in such a way that it moves the upper base horizontally from 0-180 degree

depending upon the values from the APC-220 Module. 4 more servos are attached for

controlling the direction of the robot in the vertical direction mounted on the base

servo. At the apex, a mini servo is connected with the help of gears to control the

Grabber of the robot.

As mentioned above, the robotic arm mimics the movement of glove worn by the

user, when the glove is tilted in the forward direction or any such direction, the arm

spontaneously follows suit.

The Grabber functions with the use of flex sensors attached to centre most finger,

the degree of movement of the finger determines the angle of the mini servo which is

attached to the gears controlling the movement of the grabber.

2.3 Constructional Details

The robotic arm developed by me consists of following parts:

TRANSMITTING END (Robotic Glove put on hands):

1. APC-220 module transmitter

2. Arduino Mega-2560

3. Gyroscope

4. Accelerometer

5. Gloves

Hand Gestures Remote Controlled Robotic Arm 603

RECEIVING END (Robotic Arm):

1. APC-220 module receiver

2. 6 nos. Servo Motors

3. Arduino UNO 328p

4. Chassis

5. Gears

The construction is explained in various steps as follows:

Step 1-Boards:

Two microcontroller boards were taken up as per the requirement for the project:

1. Arduino Duemilanove :

It contains Atmega AVR 328p micro controller. It has 14 digital Output/Input pins

(of which 6 can be used as PWM signals), 6 analog inputs, a 16 MHz crystal oscillator.

Operating voltage of the micro controller is 5V. Contains 32 KB of flash memory

enough to store the data for this particular project.

2. Arduino Mega :

It contains Atmega AVR 2560 R3 micro controller. It has 54 digital Output/Input

pins (of which 15 pins can be as PWM output) , 16 analog inputs, 4 UART (hardware

serial port), a 16 MHz crystal oscillator. Operating voltage of the micro controller is

5V.

Step 2- Sensors:

In order to have proper mechanism and response from the robot , proper readings had

to be taken for it. In this I have used 3 sensors:

ADXL335 :

It is a 3- axis accelerometer sensor, which can measures the forces applied on to the

sensor in all the 3 directions X, Y and Z axis. Further the raw data from the sensors are

converted into acceleration by using some complicated equations. The advantage of

the accelerometer was that the values do not change unless there is a change in

position. But the problem with the accelerometer was that it contained high level of

noise which makes the values inaccurate. So, to make these values accurate Gyroscope

sensor was used.

L3G4200D:

It is a 3- axis Gyroscope sensor which can measure the degree of rotation in all the 3

axis in form of alpha, beta and gamma. The values provided by the Gyroscope are very

accurate but values do not remain static and tend to drift to the position Zero. To make

the readings accurate as well as static both the values from the Accelerometer and

Gyroscope were combined by using Kalman filters.

Shamsheer Verma

604

Flex Sensor :

Flex is basically a strip of carbon material having metal pads inside it. As the sensor is

flexed, the resistance across the sensor increases. The resistance of the flex sensor

changes when the metal pads are on the outside of the bend. Straight (un-flexed)

resistance: 9000 ohm, 90 degree bend resistance : 14000 ohm and at 180 degree bend

resistance 22000 ohms. This resistance was calibrated and converted into angles and

further used for the for the grabbing purpose in the Robotic Arm.

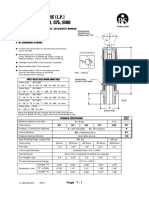

Figure 1: The figure shows flex sensor, accelerometer and Gyroscope as

parts of the transmitter fixed on the hand glove.

Step 3- Communication:

To get the most out of the system, it was better to transfer the data wirelessly. This was

done with the help of RF module communication between the Robotic Arm and glove.

The APC-220 Module was used in the process, which is highly integrated semi-duplex

low power transceiver module with high speed MCU and capability RF IC. It has high

sensitivity and strong interference circumstance as well.

Characteristics:

1000 meter of communication distance (2400bps)

Output power is 20 milli-watts.

Frequency is from 418 MHZ to 455MHZ

More than 100 channels

UART/TTL interface

Exceeds 256 bytes of data transfer

Step 4- Robotic Arm Mechanism:

Its a basic robotic arm mounted on a surface Controlled with the help of arduino

development board. Each joints of the robotic arm is connected to the servo motors.

Robotic arm contains 2 joints , total of 6 servo motors were used, 4 servo motor were

Hand Gestures Remote Controlled Robotic Arm 605

used in order to control these joints,1 servo motor to control the rotation of the surface

of the robotic arm and 1 more servo motor to control the lock of the grabber.

2.4 Functioning of robotic arm:

A small object of low weight is placed near the robotic arm at a distance within the

approach of arm. The system is made on. The operator stands at a distance from the

robot and moves the finger/hand up, down, left or right. The robotic arm follows the

direction. The arm is brought over the object and then lowered. The grabber is fully

opened to pick up the object. The robotic arm then is moved up and rotated to another

desired position, then lowered. When the arm reaches the ground floor, the grabber is

given a command to release the object, which places it at the desired location.

This way the robotic arm can be operated and controlled in any manner as deemed

necessary by the operator from a distance, usually up to 200 meters.

Figure-2: Shows assembly of Receiver

end

Figure-3: Complete assembly of Robotic

Arm

3. Applications:

Such types of robotic arms can be put to use in various types of applications as

follows:

i. Control of various functions of robots in arduous and dusty atmospheres

industrial jobs as in painting shops, shot blasting chambers etc. The operator

controls the robotic functions from outside the hazardous chambers looking

through a glass door.

Shamsheer Verma

606

ii. Automatic picking of small objects (bottles, bags, tumblers etc) moving on a

conveyor and placing at other desired location in industries manufacturing

various types of cosmetics, food products, medicines etc.

iii. Automatic metal cutting machines in particular desire profiles, which are

located in high temperature zones.

iv. Advanced robotic toys, operated with state-of-art hand operated control

systems.

v. Robots controlled cranes, lifting forks etc operated from a distance with

fingers/hands controlled remote system.

4. Acknowledgement

I thank my Father Mr. S.K. Verma for helping me with this work and my professor Mr.

Arvind Rehalia for the guidance and support.

References

[1] Appcon technologies

[2] www.bildlr.com

[3] http://www.arduino.cc/

[4] http://bildr.org/2011/06/l3g4200d-arduino/

[5] http://www.billporter.info/2011/05/30/easyt ransfer-arduino-library/

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SHB LTM 1095-5 1 Ow-02 Bis-62923 0000000 enDokument68 SeitenSHB LTM 1095-5 1 Ow-02 Bis-62923 0000000 enCristyan GabrielNoch keine Bewertungen

- Ahu ManualDokument15 SeitenAhu ManualAlan LaundrdayNoch keine Bewertungen

- ASK 21 Mi: To y and To Train Whenever You WantDokument4 SeitenASK 21 Mi: To y and To Train Whenever You WantahdickwongNoch keine Bewertungen

- Enerpac IP Series CatalogDokument4 SeitenEnerpac IP Series CatalogTitanplyNoch keine Bewertungen

- BIS Safety Relief ValveDokument1 SeiteBIS Safety Relief ValveRahimNoch keine Bewertungen

- Open Development EnvironmentDokument16 SeitenOpen Development EnvironmentMihaiNeacsuNoch keine Bewertungen

- Cec l-109-14Dokument5 SeitenCec l-109-14metaNoch keine Bewertungen

- JCBMulcherDokument1 SeiteJCBMulcherayush bansalNoch keine Bewertungen

- MF Tea20 Te20Dokument408 SeitenMF Tea20 Te20Samuel Herren100% (2)

- Yamaha XV250 Services ManualDokument291 SeitenYamaha XV250 Services Manualalitkeren92% (26)

- 17HX Stepper Hybrid 198-200 v6.09Dokument5 Seiten17HX Stepper Hybrid 198-200 v6.09dharmil.gopaniNoch keine Bewertungen

- U151E U250E VacTestDokument5 SeitenU151E U250E VacTestbyungchul kimNoch keine Bewertungen

- ForkliftsDokument21 SeitenForkliftsManual ForkliftNoch keine Bewertungen

- Test BookDokument112 SeitenTest BookJamel CharefNoch keine Bewertungen

- Dem 20487 Syh-LyDokument14 SeitenDem 20487 Syh-LyPreda AndreiNoch keine Bewertungen

- Pickup Bartolini Wiring ConductorDokument2 SeitenPickup Bartolini Wiring ConductorClau gomesNoch keine Bewertungen

- Microondas Manual Americano en EspañolDokument52 SeitenMicroondas Manual Americano en EspañolAlan SotoNoch keine Bewertungen

- Selenia WiringDokument54 SeitenSelenia WiringSwami MeeraNoch keine Bewertungen

- RF316Dokument2 SeitenRF316Marcelo Carneiro de PaivaNoch keine Bewertungen

- Renk MaagDokument12 SeitenRenk MaagDhananjay B KNoch keine Bewertungen

- Tda 8175Dokument4 SeitenTda 8175miniecateNoch keine Bewertungen

- Bugera Bvv3000 Infinium: Service ManualDokument31 SeitenBugera Bvv3000 Infinium: Service Manualne0bot100% (3)

- Daikin Manual BookDokument42 SeitenDaikin Manual Bookamsal koto0% (2)

- VMC Maintenance Manual (Alarm) : (Mynx 6500/)Dokument156 SeitenVMC Maintenance Manual (Alarm) : (Mynx 6500/)Sagar HankareNoch keine Bewertungen

- Dell Inspiron 15 3531 Compal LA-B481P ZBW00 Rev 2.0 SchematicsDokument42 SeitenDell Inspiron 15 3531 Compal LA-B481P ZBW00 Rev 2.0 SchematicsYosbelNoch keine Bewertungen

- Pelab NewDokument60 SeitenPelab NewRaghu PathyNoch keine Bewertungen

- Manual de Servicio 5329 (Ingles)Dokument305 SeitenManual de Servicio 5329 (Ingles)Tutcom Nguyen Thanh TrungNoch keine Bewertungen

- Electrical and Electronics Measurements EE42 EE402 SUPPLEMENTARY EXAM 4TH SEM AUG 2017Dokument2 SeitenElectrical and Electronics Measurements EE42 EE402 SUPPLEMENTARY EXAM 4TH SEM AUG 2017RT PRAJWAL KUMARNoch keine Bewertungen

- Dell™ E248WFP Flat Panel Monitor User's Guide: About Your Monitor Solving ProblemsDokument30 SeitenDell™ E248WFP Flat Panel Monitor User's Guide: About Your Monitor Solving Problemsmagitek0777Noch keine Bewertungen

- Series 9180/ 9270 Power AmplifierDokument20 SeitenSeries 9180/ 9270 Power AmplifierCouger ForuNoch keine Bewertungen