Beruflich Dokumente

Kultur Dokumente

4 2 Hirarc Compatibility Mode

Hochgeladen von

Imzara AmeaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4 2 Hirarc Compatibility Mode

Hochgeladen von

Imzara AmeaCopyright:

Verfügbare Formate

TITLE

Prepared by:

PART 4: IMPLEMENTATION & OPERATION

4.1 Hazard Identification, Risk

Assessment and Risk Control (HIRARC)

Learning Objectives

To define what is

hazard, risk and

danger.

To assess the hazard

identification, risk

assessment and risk

control process.

To describe the

method of identifying

hazard.

To construct the risk

assessment matrix.

Hazard: A source or a situation with a potential

for harmin terms of human injury or ill

health, damage to property, damage to the

environment or a combination of these.

Danger: Relative exposure to hazard

Definitions

Risk: A combination of the likelihood of an

occurrence of a hazardous event with specified

period or in specified circumstances and the

severity of injury or damage to the health of

people, property, environment or any combination

of these caused by the event.

Definitions

What is Risk assessment: The process of

evaluating the risks to safety and health arising from

hazards at work.

Risk assessment results is documented and used for:

1. Risk control in OSH management

2. Future reference and review

Risk Assessment

1. Integrate Risk Management as part of planning

at all levels of business

2. Accept all risks

3. Make risk decisions appropriately (depending on

level of risk)

4. Manage the risk

Basic Principles Of Risk Management

Gives organisations a more effective way of managing

hazards

Requirement of the law e.g.

OSHA 1994, CIMAH Regulations 1996 & USECHH Regulations

2000

Requirement of OSH management system

standards:

MS 1722:2003,

OHSAS 18001 and

ISO 14001, etc.

Why Carry Out Risk Assessment?

Routine and non-routine activities including

emergencies;

Activities of all personnel having access to the workplace

(including subcontractors and visitors);

Facilities at the workplace, whether provided-by the

organization or others.

Risk Assessment Should Be Carried Out

For:

Before Operation

During Operation

After Operation

When To Carry Out Risk Assessment

Types of review:

initial review, and

periodic review.

When To Review Risk Assessment

Review whenever there are changes:

internal

Before modification, changes or introduction of new

Materials, machinery or processes, working procedures,

external

Amendments of national laws and regulations

Developments in OSH knowledge and technology

When To Review Risk Assessment

Person or persons trained to identify hazard and

risk assessment

In some cases legally competent person, example : Chemical

Health Risk Assessor

Consultation with and involvement of workers

Safety and health committee OR workers and their

representatives

Involvement of supervisors

Who Will Carry Out Risk Assessment

Hazard Identification

Risk Assessment

Risk Control

Review

Basic Components Of Risk Management

Classify Activities

(Work, Product, Services, Activities)

Determine Risk

Decide if Risk is Tolerable

Risk Control Action Plan

Identify Hazards

ReviewAdequacy of Risk Control

Start

Risk = Severity X Likelihood

The Process Of Risk Management

Hazard Identification

Man Unsafe acts

Machinery Installation, layout and design of equipment

Materials Substances such as chemicals and gases use in

the workplace

Method The way people carry out their work

Media Workplace condition i.e. air quality, ventilation,

lighting, noise, vibration etc.

Sources Of Hazards

Classification

of Hazards

Example of Potential Sources of

Hazards

Mechanical Pinch points, sharp points and edges,

overload or force a tool beyond its

capabilities and grinding wheel without

guard

Electrical Electrical cord insulation damaged,

electrical face plate or cover broken or

missing and fan cord insulation pulled

loose

Biological Exposed to airborne and blood borne

viruses, bacteria and fungus

Classification & Potential Sources Of

Hazards

Classification

of Hazards

Example of Potential Sources of

Hazards

Chemical Exposed to carcinogens chemicals,

sensitizers and corrosive chemicals.

Ergonomics Repeated exposure to unnatural

postures and unnatural movement,

wrong design of workstation, tools and

task.

Psychological Stress, sexual harassment and violent at

work.

Classification & Potential Sources Of

Hazards

Information on the facilities, processes and

activities of the organization, including:

Area Map

Site plan(s); own and neighbor

Process flow-charts

Inventory of materials (raw materials, chemicals,

wastes, products, sub-products)

Toxicology and other health and safety data

Monitoring data

Pre-Assessment : Information Gathering

Geographical areas within/outside the premises;

Stages in a production process, or in the

provision of a service;

Defined the tasks (e.g. driving, window cleaning);

Identify the working groups;

Land use; previous property use, future use.

Pre-Assessment : Classifying Work

Activities

Review of documents and publications

Inspection and observation at the workplace

Measurement of the atmosphere, monitoring

the environment or medical surveillance of

workers

Hazard Analysis

Methods Of Identifying Hazards

Reports of accidents, accident investigation and

audits

Information from publications

Acts, Regulations and Codes of Practice

Statistics

Handbooks

Chemical Safety Data Sheet (CSDS)

Document Review

Types of inspections: statutory inspection, periodic

inspection, formal and informal inspection

Documentation - Checklist and inspection worksheet

(standard approach and record)

Inspection & Observation

Activities - to involve supervisors, managers and

employees

Inspection outcome - to include actions and

timeframes

Ensure follow up on action - to ensure effectiveness

Inspection & Observation

Types of monitoring: area and personal monitoring.

Monitoring of:

Noise

Heat

Radiation

Air contaminants

Chemicals etc.

Exposure Monitoring

Biological monitoring is a regular measuring activity

where selected validated indicators of the uptake of

toxic substances in the human body are determined

in order to prevent health impairment.

This form of monitoring could entail examination of, for

example, blood, urine, saliva and expired air.

Biological Monitoring

Biological monitoring commonly features in the

health or medical surveillance of persons exposed

to hazardous environments especially complying to

legal requirement i.e. USECHH Regulations 2000 etc.

Biological Monitoring

Health Surveillance is Warranted if:

Substance is used in workplace

Substance is hazardous

Evidence or reason to suspect injury

Atmospheric monitoring insufficient

Medical Surveillance

Method use: (example)

Job Safety Analysis (JSA)

Hazards and Operability Studies (HAZOP)

Fault Tree Analysis etc.

Hazards Analysis

Job described in less than 10 steps

Action verb used to describe job

List things that can go wrong

Job Safety Analysis (JSA)

Note:

The term JSA includes the formulation of

safe work procedures using written

instructions for workers

May still require other risk controls

Supervisor and workers assist

Ideally all jobs should have a JSA

Job Safety Analysis (JSA)

To identify and evaluate safety hazard in the

process plant

To identify operability problems

New design or process

Multidisciplinary brainstorming

What If questionnaire method

Focus on fire, explosion, toxic release etc.

Hazards & Operability Studies (HAZOP)

To analyse how and why incident could occur.

Graphic technique - traces branches of events.

To calculate probability of end event.

Example: Water pumping system

Fault Tree Analysis

Pump failure (A) Pump failure (B)

(automatic

standby pump)

Pump failure Control valve (C)

failure to regulate

flow of water through

pump

No Flow (T)

No water flow occurs if both pumps fail or if the control valve fails.

If the individual initiating event probabilities P(A), P(B), and P(C) are known,

then the probability of P(T) the top or end event can be calculated.

Fault Tree Analysis

Risk Assessment

Approach:

Qualitative Risk Assessment

Semi-Quantitative Risk Assessment

Quantitative Risk Assessment

Types of Risk Assessment

Severity in terms of:

Harm to health

Damage to property

Damage to environment

Or the combination of the above

Determining Severity

Determine severity categories i.e.:

Fatality

Major injuries (normally irreversible injury or

damage to health)

Minor injuries (normally reversible injury or

damage to health requiring days off work)

Negligible injuries (first aid)

Severity

Based on statistic & data, professional judgement.

Determine likelihood categories i.e.:

highly likely,

likely,

highly unlikely.

Determining Likelihood of Occurrences

of Hazard

Very likely - could happen frequently

Likely - could happen occasionally

Unlikely - could happen, but only rarely

Highly unlikely - could happen, but probably

never will

Likelihood

Severity

Likelihood

Very Likely(4) Likely (3) Unlikely(2)

Highly

Unlikely(1)

Fatality(4) High-16 High-12 High-8 Medium-4

Major Injuries(3) High-12 High-9 Medium-6 Medium-3

Minor Injuries(2) High-8 Medium-6 Medium-4 Low-2

Negligible

Injuries(1) Medium-4 Medium-3 Low-2 Low-1

Qualitative Risk Table

Determine severity categories i.e. :

4: Fatality & Permanent Disability

3: More than 4 days MC

2: Less than or 4 days MC

1: First aid and near misses

Semi Quantitative Risk Assessment

Determining Likelihood of Occurrence of

Hazard

4: Daily

3: Weekly

2: Monthly

1: Yearly

Semi Quantitative Risk Assessment

LIKELIHOOD

S

E

V

E

R

I

T

Y

Yearly Monthly Weekly Daily

1 2 3 4

First Aid

and Near

Misses

1 1 2 3 4

Less than

or 4 days

MC

2 2 4 6 8

More than

4 days MC

3 3 6 9 12

Fatality &

Permanent

Disability

4 4 8 12 16

Semi Quantitative Risk Assessment

Where the hazards presented by the undertaking are

numerous and complex, and may involve novel

processes, for example in the case of large chemicals

process plants, detailed and sophisticated risk

assessments will be needed, and it is appropriate to carry

out a detailed quantitative risk assessment.

Quantitative Risk Assessment

Quantitative risk assessment involves obtaining a

numerical estimate of the risk from a quantitative

consideration of event probabilities and consequences.

Quantitative Risk Assessment

In carrying out quantitative risk assessments, special

quantitative tools and techniques will be used for

hazard identification, and to estimate the severity of the

consequences and the likelihood of realisation of the

hazards.

Quantitative Risk Assessment

Where such methods and techniques are used it is

important that they are carried out by suitably qualified

and experience assessors.

Quantitative Risk Assessment

LEVE

L

OF

RISK

AS LOW AS REASONABLY PRACTICABLE (ALARP)

PRINCIPLE

Risk cannot be

justified

on any grounds

A

L

A

R

P

Risk is undertaken if

a benefit is desired

Reduce risk

No need for detailed

action

TOLERABLE IF:

Reduction

Impractical

or

Cost / gain grossly

Disproportionate

Intolerable (e.g. H,H or >10)

Trivial

Decision For Action

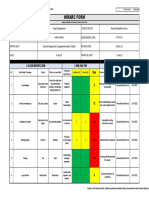

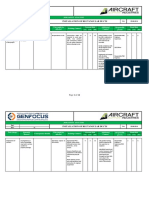

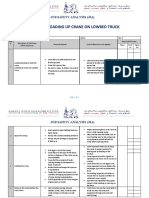

Activities / process /

facilities/ equipment

Hazard Effect

Current Risk

Control

Legal

Reqmt

Risk

Action &

Recommendations

Severity. Likelihood

Risk

Rating

Kimpalan arka

1. Radiasi Pedih mata,

berair, berpasir Face shield

FMA,

OSHA

2 3 6

PPE-goggles, eye

wash station, job

rotation

2. Fumes Pernafasan

terganggu -

FMA,

OSHA

2 3 6

Exhaust fan,

respirator, job

rotation

3. Spark Melecur kulit,

pakaian

terbakar

Gloves,

overall, kasut

FMA,

OSHA

2 3 6

Overall tahan api,

glove berkualiti, fire

extinguisher,

emergency shower

Risk Assessment Form

Risk Control

Substitution

Modify process

Enclosure

Local exhaust

Fugitive

emission control

Isolation

Housekeeping

General

ventilation

Continuous area

monitoring

Dilution

ventilation

Automation or

remote control

Training and

education

Worker rotation

Enclosure of

worker

Personal

monitoring

Personal

protective devices

Principle of Control

Review measures regularly; modify if necessary

Comply with national laws and regulations

Reflect good management practice; and

Consideration In Implementing Risk

Control

Consider the current state of knowledge

Include information or reports from organizations

such as:

DOSH, OSH services, and others.

Consideration In Implementing Risk

Control

Hierarchy Of Control

MOST EFFECTIVE

Elimination - remove the hazard.

FAIRLY EFFECTIVE

Substitution - use less hazardous one.

Isolation isolate the work area i.e. X-ray machine in restricted

room

Engineering Control design, isolation at source, barricade,

guarding,

LEAST EFFECTIVE

Administrative Control safe work procedure, isolation i.e. reduce

exposure time and limit, training, signage etc

PPE - last resort.

The basis of OSH management is the identification of

hazard, risk assessment and control

Ways of identifying hazards varies from inspection of

the workplace to reviewing legislation

Risk assessment allows an organisation to build a

sound basis for managing hazard

Hierarchy of hazard control starts by elimination; use

PPE as protection is the last resort

Summary

Das könnte Ihnen auch gefallen

- CHP 6 - HirarcDokument34 SeitenCHP 6 - HirarcFirdaus KhairiNoch keine Bewertungen

- Hazard Identification, Risk Assessment & Risk Control (Hirarc)Dokument26 SeitenHazard Identification, Risk Assessment & Risk Control (Hirarc)Satrio ReksoNoch keine Bewertungen

- Fma PDFDokument25 SeitenFma PDFasyraf_zamanNoch keine Bewertungen

- Hirarc NoteDokument35 SeitenHirarc NotesyakirohNoch keine Bewertungen

- Brochure HIRACDokument2 SeitenBrochure HIRACaentiliNoch keine Bewertungen

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Dokument77 SeitenHazard Identification, Risk Assessment and Risk Control (Hirarc)Md Khairul100% (1)

- Schedule Waste - Basic ModuleDokument16 SeitenSchedule Waste - Basic ModuleRobert R. RaoNoch keine Bewertungen

- NADOPODDokument27 SeitenNADOPODsyoolove100% (1)

- Module4 HIRARC (Ergonomics)Dokument16 SeitenModule4 HIRARC (Ergonomics)Ferly Dela Cruz ArganosaNoch keine Bewertungen

- Osh Legis Topic 1 2 and 3Dokument44 SeitenOsh Legis Topic 1 2 and 3SUHAILI BINTI BOHORI STUDENTNoch keine Bewertungen

- Job Hazard Analysis Training 2011Dokument76 SeitenJob Hazard Analysis Training 2011322399mk7086100% (3)

- XBLR3103 - OSH Legislation W1-W2Dokument49 SeitenXBLR3103 - OSH Legislation W1-W2Islah Dean100% (1)

- CHP 3 ManagementDokument52 SeitenCHP 3 ManagementAmir SallehNoch keine Bewertungen

- Book ManagingDokument235 SeitenBook ManagingDheena NagarajanNoch keine Bewertungen

- Guideline USECHHDokument28 SeitenGuideline USECHHYo Soy MasriNoch keine Bewertungen

- Chapter 3 - OSH ManagementDokument51 SeitenChapter 3 - OSH ManagementayuimranNoch keine Bewertungen

- Occupational Safety and Health Management: Prepared By: Puan Masliza MaskinDokument43 SeitenOccupational Safety and Health Management: Prepared By: Puan Masliza MaskinAugustine JR RobertNoch keine Bewertungen

- Bosh Module 8Dokument19 SeitenBosh Module 8Ging FreecsNoch keine Bewertungen

- Safety and Health HandbookDokument24 SeitenSafety and Health HandbookCharlamagne MirandaNoch keine Bewertungen

- Health, Safety, Environmental & Security ManagementDokument28 SeitenHealth, Safety, Environmental & Security ManagementSalem El Saber0% (1)

- Enhancing Best Practice in Health and Safety: Peter CorfieldDokument31 SeitenEnhancing Best Practice in Health and Safety: Peter CorfieldsohaibNoch keine Bewertungen

- Tugas 3 HIRAC - Nico Yudianto (1106139600)Dokument5 SeitenTugas 3 HIRAC - Nico Yudianto (1106139600)Nico YudiantoNoch keine Bewertungen

- Chapter 1 OSH Legislations in MalaysiaDokument81 SeitenChapter 1 OSH Legislations in MalaysiaMaizatul Akmar ManshorNoch keine Bewertungen

- Principles of Employee Welfare Service: EmployeesDokument9 SeitenPrinciples of Employee Welfare Service: Employeesfahd_alam005Noch keine Bewertungen

- RHM Consultant SDN BHDDokument50 SeitenRHM Consultant SDN BHDRidzwan HussainNoch keine Bewertungen

- Safe Handling of Ammonia Refrigeration System and Accident PreventionDokument49 SeitenSafe Handling of Ammonia Refrigeration System and Accident PreventionKFFNoch keine Bewertungen

- Exit Routes, Emergency Action Plans, Fire Prevention Plans, and Fire ProtectionDokument54 SeitenExit Routes, Emergency Action Plans, Fire Prevention Plans, and Fire ProtectionPriyasha RayNoch keine Bewertungen

- Safety Engineering Certificate CoursesDokument3 SeitenSafety Engineering Certificate CoursesjoemsambiNoch keine Bewertungen

- Xbep4103 Final Question Sep 2013Dokument5 SeitenXbep4103 Final Question Sep 2013Roy Seven SymptomsNoch keine Bewertungen

- Conlit Firestop Systems Installation Method StatementDokument2 SeitenConlit Firestop Systems Installation Method StatementramtsanNoch keine Bewertungen

- Osh Monthly Report (October 2013) : Section 5 (A) - Understanding The Occupational Safety and Health Act 1994 (OSHA)Dokument2 SeitenOsh Monthly Report (October 2013) : Section 5 (A) - Understanding The Occupational Safety and Health Act 1994 (OSHA)Mohd IzNoch keine Bewertungen

- Section 4 Health Safety and Environment Hse RequirementDokument26 SeitenSection 4 Health Safety and Environment Hse RequirementndNoch keine Bewertungen

- OSHA Leading IndicatorsDokument18 SeitenOSHA Leading IndicatorseerrddeemmNoch keine Bewertungen

- Osha UthmDokument19 SeitenOsha UthmWan Muhammad Faiz Bin Mohd RoslanNoch keine Bewertungen

- Everythingohs Workplace Inspection ChecklistDokument4 SeitenEverythingohs Workplace Inspection ChecklistsandyskadamNoch keine Bewertungen

- Hirarc FormDokument2 SeitenHirarc FormAusNoch keine Bewertungen

- Safety and Health PlanDokument7 SeitenSafety and Health PlanRobins MsowoyaNoch keine Bewertungen

- Health & Safety: Presented By: Group NoDokument13 SeitenHealth & Safety: Presented By: Group NoRay FaustinoNoch keine Bewertungen

- OSH Safety CommitteeDokument34 SeitenOSH Safety CommitteeSyed Haamid SaggaffNoch keine Bewertungen

- Hirarc SharpDokument29 SeitenHirarc Sharpczhong16Noch keine Bewertungen

- Sample HEALTHDokument8 SeitenSample HEALTHRobin RubinaNoch keine Bewertungen

- Manual Gabungan StrategikDokument97 SeitenManual Gabungan StrategikSachi AnandNoch keine Bewertungen

- Initial Ergonomic Risk Assessment: by MR XXXXXDokument26 SeitenInitial Ergonomic Risk Assessment: by MR XXXXXIma Hisham100% (2)

- Adroz Paramedic Resources Course Schedule: MonthDokument3 SeitenAdroz Paramedic Resources Course Schedule: MonthHse Consultancy SgsbNoch keine Bewertungen

- Jsa PDFDokument23 SeitenJsa PDFIbnu MuariefNoch keine Bewertungen

- RSPO Credits Sellers Guide - EnglishDokument2 SeitenRSPO Credits Sellers Guide - EnglishRavi KumarNoch keine Bewertungen

- Duw10022-C05 - Fire SafetyDokument46 SeitenDuw10022-C05 - Fire SafetyMuhd Imran Kasyidi Omar100% (1)

- 6.DOSH Reporting An Accident 17Dokument1 Seite6.DOSH Reporting An Accident 17alexcus1539Noch keine Bewertungen

- HIRARC RiskmanagementDokument38 SeitenHIRARC RiskmanagementEky SusilowatiNoch keine Bewertungen

- Safety Program SampleDokument30 SeitenSafety Program Samplerael MijaresNoch keine Bewertungen

- Use of Personal Protective Equipments: Manoj Kr. Ray SM (F&S)Dokument33 SeitenUse of Personal Protective Equipments: Manoj Kr. Ray SM (F&S)mujeebtalibNoch keine Bewertungen

- Office Health SafetyDokument21 SeitenOffice Health SafetyJerry EnocNoch keine Bewertungen

- Osha (Autosaved)Dokument33 SeitenOsha (Autosaved)Rishindran ParamanathanNoch keine Bewertungen

- SOP First Aid TrainingDokument4 SeitenSOP First Aid TrainingshreyasNoch keine Bewertungen

- Safety, Health and Environment Manual and ProceduresDokument20 SeitenSafety, Health and Environment Manual and ProceduresYan's Senora BescoroNoch keine Bewertungen

- HIRARC Administrative Documentation SG Klad (LATEST)Dokument16 SeitenHIRARC Administrative Documentation SG Klad (LATEST)alias che ismailNoch keine Bewertungen

- 4 Risk AssessmentDokument58 Seiten4 Risk AssessmentMatthew Shields100% (1)

- Element 3 (3.4)Dokument51 SeitenElement 3 (3.4)Arianna KhanNoch keine Bewertungen

- Osha HirarcDokument62 SeitenOsha HirarcanesseNoch keine Bewertungen

- Day 2 - Module 2.2.3 Risk AssessmentDokument77 SeitenDay 2 - Module 2.2.3 Risk Assessmenteacesconsultancy100% (1)

- Identification of Relationship On Soil Nutrient (N, P, K) of Harum Manis Mango (Ma 128)Dokument6 SeitenIdentification of Relationship On Soil Nutrient (N, P, K) of Harum Manis Mango (Ma 128)Imzara AmeaNoch keine Bewertungen

- Quiz 3 Answer ScriptDokument6 SeitenQuiz 3 Answer ScriptImzara AmeaNoch keine Bewertungen

- Choosing The Best Embedded Processing Platform For On-Board UAV Image ProcessingDokument11 SeitenChoosing The Best Embedded Processing Platform For On-Board UAV Image ProcessingImzara AmeaNoch keine Bewertungen

- Soil NPK Variability Mapping For Harumanis Mango Grown in Greenhouse at Perlis, MalaysiaDokument7 SeitenSoil NPK Variability Mapping For Harumanis Mango Grown in Greenhouse at Perlis, MalaysiaImzara AmeaNoch keine Bewertungen

- Quiz 2 Answer ScriptDokument4 SeitenQuiz 2 Answer ScriptImzara AmeaNoch keine Bewertungen

- Quiz 1 Answer ScriptDokument5 SeitenQuiz 1 Answer ScriptImzara AmeaNoch keine Bewertungen

- Eng - Logbook Cover PDFDokument1 SeiteEng - Logbook Cover PDFImzara AmeaNoch keine Bewertungen

- Engineering Rubrics INTRA 05 (A) Logbook: Update: 12 February 2019Dokument2 SeitenEngineering Rubrics INTRA 05 (A) Logbook: Update: 12 February 2019Imzara AmeaNoch keine Bewertungen

- Host Company Satisfaction SurveyDokument1 SeiteHost Company Satisfaction SurveyImzara AmeaNoch keine Bewertungen

- Host Company Acknowledgement FormDokument1 SeiteHost Company Acknowledgement FormImzara AmeaNoch keine Bewertungen

- Useful Laplace TransformDokument1 SeiteUseful Laplace TransformImzara AmeaNoch keine Bewertungen

- Lathe SafetyDokument8 SeitenLathe SafetyImzara AmeaNoch keine Bewertungen

- Verification FormDokument1 SeiteVerification FormImzara AmeaNoch keine Bewertungen

- References: Web PageDokument2 SeitenReferences: Web PageImzara AmeaNoch keine Bewertungen

- Dictionary For MenDokument2 SeitenDictionary For MenImzara AmeaNoch keine Bewertungen

- Jsa For Crawler Crane Installation Form PDF FreeDokument3 SeitenJsa For Crawler Crane Installation Form PDF FreeMuhammad SadiqNoch keine Bewertungen

- #23 Installing Tubing Spool and Nipple Up BOPDokument1 Seite#23 Installing Tubing Spool and Nipple Up BOPkhurramNoch keine Bewertungen

- Jsa FormDokument7 SeitenJsa FormDheeraj Chowdary DhanekulaNoch keine Bewertungen

- JSA-Manual Lifting of MaterialsDokument3 SeitenJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Multiple Choice Questions (MCQ) With Answers On Industrial Safety - ScholarexpressDokument4 SeitenMultiple Choice Questions (MCQ) With Answers On Industrial Safety - ScholarexpressAmit Singh50% (6)

- 10-12 - AeroSafety World MagazinesDokument68 Seiten10-12 - AeroSafety World MagazinesJoao MeloNoch keine Bewertungen

- Chapter - I - MSDS: Q.1-What Is MSDS? Q.3 - What Q.4 - Where Q.5 - What Q.6 - What Q.7 - Q.8 - WhatDokument36 SeitenChapter - I - MSDS: Q.1-What Is MSDS? Q.3 - What Q.4 - Where Q.5 - What Q.6 - What Q.7 - Q.8 - Whatmohammad QutubuddinNoch keine Bewertungen

- Health, Safety and Environmental Manual: Protouch Engineering SDN BHDDokument63 SeitenHealth, Safety and Environmental Manual: Protouch Engineering SDN BHDsaraNoch keine Bewertungen

- JSA - Turning Spectacle BlindDokument4 SeitenJSA - Turning Spectacle BlindJJ WeldingNoch keine Bewertungen

- JSA. Cleaning ToiletsDokument1 SeiteJSA. Cleaning ToiletsSajid HussainNoch keine Bewertungen

- Jsa Slip FormDokument5 SeitenJsa Slip Formputrasejahtra50% (2)

- Tender Form C Work Execution PlanDokument87 SeitenTender Form C Work Execution Plannuvie ohwoefeNoch keine Bewertungen

- JSA For DuctDokument13 SeitenJSA For DuctRakeshkasarlaNoch keine Bewertungen

- HaGun Gantry Crane + Method of Works Install Stator Generator+Strand Jack + 03JuLy14 PDFDokument23 SeitenHaGun Gantry Crane + Method of Works Install Stator Generator+Strand Jack + 03JuLy14 PDFHaGun Gantry100% (1)

- Boiler JSADokument42 SeitenBoiler JSApankajbhatt376Noch keine Bewertungen

- JSA-Filling, Gauging and Hydrostatic TestingDokument3 SeitenJSA-Filling, Gauging and Hydrostatic TestingRidha BennasrNoch keine Bewertungen

- Installation of Rectangular DuctsDokument14 SeitenInstallation of Rectangular DuctsAnandu AshokanNoch keine Bewertungen

- SAB-JSA - Loading Crane On The TruckDokument3 SeitenSAB-JSA - Loading Crane On The TruckaymenmoatazNoch keine Bewertungen

- Method Statement First Flush Interceptor Leak Test-2Dokument10 SeitenMethod Statement First Flush Interceptor Leak Test-2Daniel MartinezNoch keine Bewertungen

- Monthly HSE Performance ReportDokument17 SeitenMonthly HSE Performance ReportKhuda BukshNoch keine Bewertungen

- Job Safety Analysis FormDokument1 SeiteJob Safety Analysis FormAhsan IqbalNoch keine Bewertungen

- HSE Officer CVDokument4 SeitenHSE Officer CVayesha siddiquiNoch keine Bewertungen

- Causation Factors For The Banjar Panji No. 1 Blowout Neil Adams CDokument29 SeitenCausation Factors For The Banjar Panji No. 1 Blowout Neil Adams CrejosentonoNoch keine Bewertungen

- Accident InvestigationDokument25 SeitenAccident InvestigationJai AntijaNoch keine Bewertungen

- 022-PRO For FENCE & GATE PDFDokument14 Seiten022-PRO For FENCE & GATE PDFKöksal Patan100% (1)

- JSA #34 - N2 PurgingDokument1 SeiteJSA #34 - N2 PurgingHelza RahmanniaNoch keine Bewertungen

- JSA - Electrical Testing - Circuit Breaker Field TestDokument4 SeitenJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Back Filling-Job Safety AnalysisDokument5 SeitenBack Filling-Job Safety AnalysisNitesh KumarNoch keine Bewertungen

- SBJ H2 HSE PlanDokument51 SeitenSBJ H2 HSE PlanMohammad Arif RasheedNoch keine Bewertungen

- JSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Dokument23 SeitenJSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Shaikh Abu bakarNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)