Beruflich Dokumente

Kultur Dokumente

H 41

Hochgeladen von

Matei AlexandruOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

H 41

Hochgeladen von

Matei AlexandruCopyright:

Verfügbare Formate

Distributor Ignition (DI) Systems

The NE signal is generated by the Crankshaft Position Sensor (also called engine speed

sensor). The G signal is generated by the Camshaft Position sensor that may be located in the

distributor or on the engine.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 1 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

At the appropriate time during cylinder compression, the ECM sends a signal called IGT to the

igniter. This will turn on the transistor in the igniter sending current through the primary winding

of the ignition coil. At the optimum time for ignition to occur, the ECM will turn off IGT and the

transistor will turn off current flow through the primary winding. The induced current will travel

through the coil wire, to the distributor cap, rotor, to the distributor terminal the rotor is pointing

at, high tension wire, spark plug, and ground. The rotor position determines the cylinder that

receives the spark.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 2 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Firing Order

The firing order can be found in the New Car Features book. The cylinders are identified as

follows:

V-8 engine cylinders are numbered with odd numbered cylinders on the left bank and even

numbered cylinders on the right bank.

V-6 engine cylinders are numbered with even on left bank and odd numbered cylinders on

the right bank.

In-line 6 engines are numbered consecutively 1-6, with the number I cylinder at the front.

Four cylinder engines are numbered consecutively from front to back.

Many times, original equipment distributor caps have the firing order molded into the cap.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 3 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 4 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Distributorless & Direct Ignition Systems Overview

Essentially, a Distributorless Ignition System is an ignition system without a distributor.

Eliminating the distributor improved reliability by reducing the number of mechanical

components. Other advantages are:

Greater control over ignition spark generation - There is more time for the coil to build a

sufficient magnetic field necessary to produce a spark that will ignite the air/fuel mixture.

This reduces the number of cylinder misfires.

Electrical interference from the distributor is eliminated - Ignition coils can be placed on

or near the spark plugs. This helps eliminate electrical interference and improve

reliability.

Ignition timing can be controlled over a wider range - In a distributor, if too much advance

is applied the secondary voltage would be directed to the wrong cylinder.

All of the above reduces the chances of cylinder misfires and consequently, exhaust emissions.

Distributorless Ignition systems are usually defined as having one ignition coil with two spark

plug wires for two cylinders. Distributorless Ignition Systems use a method called

simultaneous ignition (also called waste spark) where an ignition spark is generated from one

ignition coil for two cylinders simultaneously.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 5 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Direct Ignition Systems (DIS) have the ignition coil mounted on the spark plug. DIS can come in

two forms:

Independent ignition - one coil per cylinder.

Simultaneous ignition - one coil for two cylinders. In this system an ignition coil is

mounted directly to one spark plug and a high tension cord is connected to the other

spark plug. A spark is generated in both cylinders simultaneously.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 6 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Distributorless (Simultaneous Ignition) Operation

Distributorless Ignition Systems and Direct Ignition Systems that use one coil for two cylinders

use a method known as simultaneous ignition. With simultaneous ignition systems, two

cylinders are paired according to piston position. This has the effect simplifying ignition timing

and reducing the secondary voltage requirement.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 7 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

For example, on a V-6 engine, on cylinders one and four, the pistons occupy the same cylinder

position (both are at TDC and BDC at the same time), and move in unison, but they are on

different strokes. When cylinder one is on the compression stroke, cylinder four is on the

exhaust stroke, and vice versa on the next revolution.

The high voltage generated in the secondary winding is applied directly to each spark plug. In

one of the spark plugs, the spark passes from the center electrode to the side electrode, and at

the other spark plug the spark is from the side to the center electrode.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 8 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Typically, the spark plugs with this style of ignition system are platinum tipped for stable ignition

characteristics.

The voltage necessary for a spark discharge to occur is determined by the spark plug gap and

compression pressure. If the spark plug gap between both cylinders is equal, then a voltage

proportional to the cylinder pressure is required for discharge. The high voltage generated is

divided according to the relative pressure of the cylinders. The cylinder on compression will

require and use more of the voltage discharge than the cylinder on exhaust. This is because

the cylinder on the exhaust stroke is nearly at atmospheric pressure, so the voltage

requirement is much lower.

When compared to a distributor ignition system, the total voltage requirement for distributorless

ignition is practically the same. The voltage loss from the spark gap between the distributor

rotor and cap terminal, is replaced by the voltage loss in the cylinder on the exhaust stroke in

the Distributorless Ignition System.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 9 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Direct Ignition System (DIS)

As DIS has evolved, there have been changes to the function and location of the igniter. With

independent ignition DIS, there may be one igniter for all cylinders or one igniter per cylinder.

On simultaneous ignition DIS there is one igniter for all coils. The following gives an overview of

the different types used on various engines.

1 MZ-FE 94 DIS

This DIS uses one igniter for all coils. The IGF signal goes low when IGT is turned on. The coils

in this system use a high voltage diode for rapid cutoff of secondary ignition. If a coil is

suspected of being faulty, swap with another coil.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 10 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

1 MZ-FE with DIS Simultaneous Ignition

This system uses three IGT signals to trigger the ignition coils in the proper sequence. When a

coil is turned on, IGF goes low.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 11 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 12 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 13 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

DIS with Independent Ignition

The DIS with independent ignition has the igniter built into the coil. Typically, there are four wires

that make up the primary side of the coil:

+13.

IGT signal.

IGF signal.

Ground.

The ECM is able to distinguish which coil is not operating based on when the IGF signal is

received. Since the ECM knows when each cylinder needs to be ignited, it knows from which

coil to expect the IGF signal.

The major advantages of DIS with independent ignition are greater reliability and less chance of

cylinder misfire.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 14 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 15 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 16 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Ignition Advance Service

Though the Diagnostic Tester shows the computed ignition, advance, using a timing light

confirms that advance took place and the timing marks are in the correct position.

With Distributor Ignition Systems, the point at which ignition occurs may vary because the base

reference point can be moved. It is critical that the base reference point be set to factory

specifications.

With DLI and DIS, the base reference point is determined by the Crankshaft Position Sensor

and rotor, which is non-adjustable.

The angle to which the ignition timing is set during ignition timing adjustment is called the

"standard ignition timing." It consists of the initial ignition timing, plus a fixed ignition advance

angle (a value that is stored in the ECM and output during timing adjustment regardless of the

corrections, etc., that are used during normal vehicle operation).

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 17 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Ignition timing adjustment is initiated by connecting terminal T1 (or TE 1) of the check connector

or TDCL with terminal E1, with the idle contacts on. This will cause the standard ignition timing

signal to be output from the back-up IC in the same way as during after-start ignition control.

The standard ignition timing angle differs depending on the engine model. When tuning up the

engine, refer to the repair manual for the relevant engine.

NOTE: Even if terminal T1 or TE1 and terminal E1 are connected, the ignition timing will not be

fixed at the standard ignition timing unless the idle contacts are on.

Where the G and NE signal generators are in a fixed position (distributorless or direct ignition

systems), ignition timing cannot be adjusted.

Diagnostics

When the igniter is built into the ignition coil, it is not possible to do a resistance check of the

primary coil winding. A bad primary winding will have to be determined by checking other

functions of the coil and the ignition circuit.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 18 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

DTC 1300 series will set, depending on the engine and type of ignition system, when the ECM

does NOT receive the IGF signal. IGF confirms the primary circuit of the ignition system is

working. Lack of IGF signal indicates a malfunction in the primary circuit or IGF signal related

components.

If the DTC 1300 is set based on IGF, visually check the ignition system and then check for

spark. If spark is present, the engine will start then stall when the ECM does not detect IGF

(EXCEPT on some engines equipped with DIS with integrated igniter). In addition, when spark

is present this confirms the secondary and primary circuits are good. The problem is most

likely with the IGF circuitry.

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 19 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

ASSIGNMENT NAME: ___________________________

1. Explain in the difference between Independent (Direct) and Simultaneous (Waste Spark)

Ignition systems: (include the number of coils used in each)

2. Explain in detail Simultaneous (Waste Spark) Ignition system operation:

3. Draw a basic 4 cylinder Simultaneous (Waste Spark) Ignition circuit below:

4. Explain in detail Independent (Direct) Ignition system operation:

5. Draw a basic 4 cylinder Independant (Direct) Ignition circuit below:

IGNITION #3 - DISTRIBUTOR AND DISTRIBUTORLESS TYPES

Page 20 Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

Das könnte Ihnen auch gefallen

- Fuse Box Diagram Ford EcoSport (2013-2017)Dokument8 SeitenFuse Box Diagram Ford EcoSport (2013-2017)chennaimaterialsupplyNoch keine Bewertungen

- Grand Am Continental Tire Sports Integrating ECU PDFDokument31 SeitenGrand Am Continental Tire Sports Integrating ECU PDFsenthilvlNoch keine Bewertungen

- Installation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Dokument24 SeitenInstallation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Dmentall IllNoch keine Bewertungen

- 2.0L FS & 1.6L ZM EngineDokument707 Seiten2.0L FS & 1.6L ZM EngineKamil Charmik Luža100% (1)

- Car BaseDokument90 SeitenCar BaseJUANNoch keine Bewertungen

- Fitting The EGR Cheater - Z22SE - CoDokument15 SeitenFitting The EGR Cheater - Z22SE - Cobnc1Noch keine Bewertungen

- 32d05 Control of ECTDokument12 Seiten32d05 Control of ECTMelvin MhdsNoch keine Bewertungen

- SRS warning light functionDokument37 SeitenSRS warning light functionChris TreadwellNoch keine Bewertungen

- LPG Lecho Sec Eco InstructionDokument37 SeitenLPG Lecho Sec Eco InstructionZoli Borbely100% (1)

- Tvip PDFDokument6 SeitenTvip PDFamart79196Noch keine Bewertungen

- Fuse Box E120Dokument3 SeitenFuse Box E120Shahmeer AhmedNoch keine Bewertungen

- Mercedes OBD II Diagnostic Connector Pinout Diagram @Dokument10 SeitenMercedes OBD II Diagnostic Connector Pinout Diagram @luc47gmNoch keine Bewertungen

- S13 SR20 Guide 08Dokument20 SeitenS13 SR20 Guide 08Алексей Иванченко100% (1)

- 2005 Nissan FrontierDokument336 Seiten2005 Nissan FrontierMerlin Meléndez RodríguezNoch keine Bewertungen

- Codigo DTC para Jeep JKDokument11 SeitenCodigo DTC para Jeep JKEmiliano Esquinca Ávila100% (1)

- BSD104DV H3axDokument21 SeitenBSD104DV H3axTiborNoch keine Bewertungen

- Power Source: 78 HIACE (EWD622E)Dokument4 SeitenPower Source: 78 HIACE (EWD622E)Egoro KapitoNoch keine Bewertungen

- Clarion Pu-2294a Pu-2325a Pu-2294b PDFDokument16 SeitenClarion Pu-2294a Pu-2325a Pu-2294b PDFseotut0% (1)

- Hyde.r Motor Works: Installation Guide BMW Supercharger Setup M5XSC14Dokument35 SeitenHyde.r Motor Works: Installation Guide BMW Supercharger Setup M5XSC14Jan KowalskiNoch keine Bewertungen

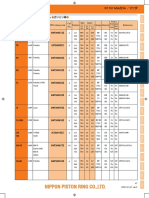

- NPR MazdaDokument4 SeitenNPR Mazda盧俊源100% (1)

- New Lanos Engine2 (Mech)Dokument47 SeitenNew Lanos Engine2 (Mech)Nhật ĐặngNoch keine Bewertungen

- Immob Overview All Models 2005Dokument30 SeitenImmob Overview All Models 2005BYU OTOVLOGNoch keine Bewertungen

- sb0341t09 PDFDokument7 Seitensb0341t09 PDFZool Car زول كارNoch keine Bewertungen

- NISSAN SUNNY User Manual Almera OM en PDFDokument165 SeitenNISSAN SUNNY User Manual Almera OM en PDFSUNGNoch keine Bewertungen

- How To Service Your RB25 Ignition SystemDokument9 SeitenHow To Service Your RB25 Ignition SystemJameel KhanNoch keine Bewertungen

- Range Rover - 1997 - 6th EditionDokument579 SeitenRange Rover - 1997 - 6th Editionainginer50% (2)

- Supplemental Restraint System (SRS) PDFDokument64 SeitenSupplemental Restraint System (SRS) PDFruanm_1Noch keine Bewertungen

- VY BCM ABS SRS Wiring Diagrams pcmhacking.netDokument5 SeitenVY BCM ABS SRS Wiring Diagrams pcmhacking.netJet64u86Noch keine Bewertungen

- Ford Focus Zetec PDFDokument36 SeitenFord Focus Zetec PDFolearydc9447Noch keine Bewertungen

- Maintenance and Care: Form No.8CC7-EA-11HDokument52 SeitenMaintenance and Care: Form No.8CC7-EA-11HChaiyakorn Aaron100% (1)

- Handy-Tig 210 AcdcDokument80 SeitenHandy-Tig 210 AcdcEdin Edin100% (1)

- 13OBDG09 Engine DiagnosticsDokument562 Seiten13OBDG09 Engine DiagnosticsEric Joseph GoldenNoch keine Bewertungen

- Subject: Information of New Auto Transmission & Tcu Models: Musso & Korando With Btra Auto Transmission ConditionDokument1 SeiteSubject: Information of New Auto Transmission & Tcu Models: Musso & Korando With Btra Auto Transmission Conditionfrancisca19Noch keine Bewertungen

- Mazda3 - FL - English ReparatiiDokument91 SeitenMazda3 - FL - English ReparatiiMihaiCapraruNoch keine Bewertungen

- Nissan Maxima 2003 .Dokument144 SeitenNissan Maxima 2003 .FranciscoNoch keine Bewertungen

- K-Suite 1.89Dokument3 SeitenK-Suite 1.89Fabio JuniorNoch keine Bewertungen

- Immobilizer ECU User's Manual: 1. GeneralDokument2 SeitenImmobilizer ECU User's Manual: 1. GeneralObd King TgiNoch keine Bewertungen

- Active Stability Control System (ASC) - 2010 LancerDokument306 SeitenActive Stability Control System (ASC) - 2010 Lancerbhanuka2009Noch keine Bewertungen

- Accent 97 TorquesDokument2 SeitenAccent 97 TorquescolectromecNoch keine Bewertungen

- Ethos User ManualDokument60 SeitenEthos User Manual2791957Noch keine Bewertungen

- EFDokument49 SeitenEFsurya100% (1)

- Wiring DiagramsDokument10 SeitenWiring DiagramsJose PichinteNoch keine Bewertungen

- All-New Ford Ranger: Preliminary Technical Specifications: FeaturesDokument13 SeitenAll-New Ford Ranger: Preliminary Technical Specifications: FeaturesLe VanNoch keine Bewertungen

- K20a6 Ecu Pinout Accord Rsx Dc5Dokument2 SeitenK20a6 Ecu Pinout Accord Rsx Dc5Uros GalovicNoch keine Bewertungen

- Cherokee 2.5 TD PCMDokument4 SeitenCherokee 2.5 TD PCMNazael DiazNoch keine Bewertungen

- 428L2 PDFDokument13 Seiten428L2 PDFesquisofNoch keine Bewertungen

- 2009 Mazda6 FSMDokument6.240 Seiten2009 Mazda6 FSMYousef ShishaniNoch keine Bewertungen

- Body Electrical SystemDokument104 SeitenBody Electrical SystemСергейУ-У100% (1)

- Diesel Information: Vehicle ElectronicsDokument6 SeitenDiesel Information: Vehicle ElectronicsAminadavNoch keine Bewertungen

- ECM I/O Signals DiagnosticsDokument5 SeitenECM I/O Signals Diagnosticskofo3000Noch keine Bewertungen

- Nissan X-Trail 32. Manual - Part 167Dokument3 SeitenNissan X-Trail 32. Manual - Part 167Grenyher Nieves SanchezNoch keine Bewertungen

- Tpi 2029086 - 1Dokument9 SeitenTpi 2029086 - 1Marius SuvarNoch keine Bewertungen

- EFI Engine Management Manual PDFDokument58 SeitenEFI Engine Management Manual PDFAbhijit BiswasNoch keine Bewertungen

- Building A 5SG EngineDokument5 SeitenBuilding A 5SG Enginedhendriadi69Noch keine Bewertungen

- Nissan-Altima 2009 en US 24a8c44ec3Dokument373 SeitenNissan-Altima 2009 en US 24a8c44ec3Joel ArguetaNoch keine Bewertungen

- HowIgnitionSystemsWorkChampionTechTips 1672911098518 PDFDokument8 SeitenHowIgnitionSystemsWorkChampionTechTips 1672911098518 PDFwayne chris YeungNoch keine Bewertungen

- Toyota: How To Find Toyota Ignition System Faults Fast!Dokument8 SeitenToyota: How To Find Toyota Ignition System Faults Fast!Akram SiddigNoch keine Bewertungen

- Recommendations For Gas Engine Spark PlugsDokument5 SeitenRecommendations For Gas Engine Spark PlugsNimNoch keine Bewertungen

- UntitledDokument1.003 SeitenUntitledsharon100% (1)

- Pengapian Tipe ESADokument12 SeitenPengapian Tipe ESAputram02Noch keine Bewertungen

- Elec06 PDFDokument0 SeitenElec06 PDFDong HungNoch keine Bewertungen

- Alternator Electronics Diagram ToyotaDokument26 SeitenAlternator Electronics Diagram ToyotatestingNoch keine Bewertungen

- Prossers 16 TheoremsDokument18 SeitenProssers 16 Theoremsjustrios100% (3)