Beruflich Dokumente

Kultur Dokumente

JSA Worksheetspd

Hochgeladen von

Nina Seimeni0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

115 Ansichten2 SeitenJob Safety Analysis (JSA) Worksheet For use by all Technicians working at: LMC "we believe that no job is done well unless it is done safely."

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenJob Safety Analysis (JSA) Worksheet For use by all Technicians working at: LMC "we believe that no job is done well unless it is done safely."

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

115 Ansichten2 SeitenJSA Worksheetspd

Hochgeladen von

Nina SeimeniJob Safety Analysis (JSA) Worksheet For use by all Technicians working at: LMC "we believe that no job is done well unless it is done safely."

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Job Safety Analysis (JSA) Worksheet

For use by all Technicians working at: LMC

We believe that no job is done well unless it is done safely.

Supervisor/Foreman: _____________________ Work Order No.: ___________________ Location: ____________________________________________

Date: _____/______/______Time: ______: _______ SIS Media #:_______________________________________________________________________________

Job Description from work order: ________________________________________________________________________________________________________

Initials of Technician(s) on the job:______________________________________________________________________________________

Consider and check the items that apply to the task The entire work crew shall review and be aware of this JSA

Personal Protective Equipment

Normal standard PPE

(Safety Glasses, Leather steel toe boots)

Rubber Leather Kevlar

Add Foot Protection___________

Leather / Kevlar apron/J acket

NFPA 70 E equipment/ FRC Clothing

Face Shield

Mono Goggles

Hearing Protection (Ear Plugs/Muffs)

Fall Protection (inspected before use)

Burning Goggles

Welding Hood / hardhat

Welding Hood / no hardhat

Flotation

Other___________________

Hard Hat

Respiratory Protection

Air Purified / Air Supplied

HF

FF

Type of cartridge _____________________

(Is there a change out schedule)

Tools

Current Insp./Good Tool Conditions

Proper Tools for the J ob

Other______________________

Lockout tagout

Locked and Tagged

Try Start/Stop Switch/Key

GFCI Test

Assured Grounding____________

Extension Cord Inspection

Attachments blocked, locked out?

Other_______________________

Lifting and Equipment

Motorized equipment:___________

Spotter needed

Blocking/Cribbing____________

Crane in Area (overhead lifting)

Proper Rigging Practices-barricade

Manual Lifting Equ.:____________

Inspection of Equipment up-to-date

Other______________________

Access

Scaffold Inspected

Ladder Tied Off & Inspected

Man lift or J LG/Scissor lift

(Current certification to operate equipment)

Personnel Basket

(Approved and Inspected)

Special Provision____________________

Barricades Maintained & Tagged

Signs (confined space, overhead work etc)

Hole Cover / Gaps in scaffold deck

Other Crews Working in Area

Other_____________________________

Welding

Welding Leads Inspected

Combustibles in Area/bottles secured

Spark Containment Required/ Fire Blanket

Welding Screens / Blinds Required

Grounding Close as possible

Fire Extinguisher / Water Hose

Fire watch w/ vest, horn

Other_______________________

Potential Hazards

(List checked items on Hazard Control)

Hotwork Exposure Hazards:

Is the work piece galvanized?

Will there be cutting or gouging?

Inside an Enclose Area?

Confined Space

Inside a Confined Space?

Is there a restriction to vertical airflow?

Yes No

Are there other workers present in the

Immediate vicinity?

Yes No

Are there >2 Welders working in a

Enclosed Area/Confined Space

Respirator Required: refer to PPE

Environmental Hazards

Spill / Leak

Weather conditions

Waste

Noise

Bacteria

Light levels low

Other____________________________

Chemicals

Chemical Burns Skin/Eyes

Flammable

Ingestion

Inhalation (Fumes, Smoke, Dust)

Skin Contamination

Cleaners / Degreasers

Compressed Chemicals

Radiation

Electrical

Other_______________________

Ergonomic/Physical

Fall Potential

Pinch Points

Slip-Trip Potential

Air borne, Particles

Electrical Shock

Heat / Cold

Heavy Objects

Hot/Cold surfaces

Over extension

Overexertion

Sharp Objects

Noise

Poor Access/Egress

Poor Housekeeping

Moving / Rotating parts

Awkward body position

Hands not in the line of sight

Vibration

Repetitive motion

Prolonged twisting / Bending

Working above your head

Working in a tight area

Handrail (missing?)

Parts of body in the line of fire

Suspended

Other_______________________

Emergency Info/Equ. Location

Fire Monitors________________________

Fire Extinguishers____________________

Safety Showers______________________

Evacuation Route____________________

Wind Direction _______________________

First aid kit _______________________

1. Think

through

the task

If you answer no to any question, do not proceed.

Contact your supervisor. Yes No N/A

Do I / we understand the scope & steps required to carry out the task?

Have I / we read and understood the procedure?

Do I / we have the necessary tools to complete the job safely?

Do I / we have valid training/ experience? (ie. crane/rigging, Forklift)

Have I / We identified a First Aid or medical facility in area

Are there any personnel in the crew that are on the job for the first time? Yes____No____

Employees Signature: ________________________________________________

Supervisors Signature: ________________________________________________

Specific Task or Segment What are the Hazards for this task? Control(s) for hazard

Risk

(L,M,H)

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

15)

16)

17)

HAZARD CONTROL

ORDER OF HAZARD CONTROL:

REMOVE THE HAZARD, ISOLATE OR BARRICADE THE HAZARD, ENGINEER THE HAZARD OUT, REORGANIZE THE JOB TO MINIMIZE RISK, WEAR THE RIGHT PPE

Risk Assessment

Step 1 - Determine Probability Step 2 - Determine Consequences (highest of the two)

People Plant, Property, Productivity or Environmental Consequences

A=Practically impossible 1=First aid injury 1=Under $5K damage and minimal productivity disruption, no environmental damage

B=Not likely to occur 2=Medical treatment injury 2=$5-$50K damage and/or slight productivity disruption, minor environmental damage

C=Could occur or I've heard of it happening 3=Disabling short term lost time injury 3=$50-$100K damage and/or productivity disruption, reversible environmental damage

D=Is known to occur or "it has happened" 4=Serious lost time injury or illness 4=$100-$500K damage and/or contingency plan required, serious environmental damage

E=Common or frequent occurrence 5=Fatality or permanent disability 5=More than $500K damage and/or large reorganization of premises, major environmental damage

Step 3 Calculate the Risk

A B C D E

1 Low Low Low Low Low

2 Low Low Low Moderate Moderate

3 Low Low Moderate Moderate High

4 Low Moderate Moderate High High

5 Low Moderate High High High

Note: Risks ranked moderate or high require supervisors involvement before work is started

Das könnte Ihnen auch gefallen

- KBR It It Sti InstructionsDokument2 SeitenKBR It It Sti InstructionsbotahraNoch keine Bewertungen

- July SMR RevDokument2 SeitenJuly SMR RevShyam SadanandanNoch keine Bewertungen

- Ppe Hazard AssessmentDokument4 SeitenPpe Hazard AssessmentNeha PatelNoch keine Bewertungen

- Site Safety OrientationDokument19 SeitenSite Safety OrientationKrischaEverNoch keine Bewertungen

- Weekly Safety ReportDokument3 SeitenWeekly Safety ReportFarhat SetharNoch keine Bewertungen

- Weekly Progress Report 21 To 27 OCT2017Dokument2 SeitenWeekly Progress Report 21 To 27 OCT2017Mehdi MessNoch keine Bewertungen

- Director Environmental Health Safety EHS in Philadelphia PA Resume Akhil BuchDokument3 SeitenDirector Environmental Health Safety EHS in Philadelphia PA Resume Akhil BuchAkhilBuchNoch keine Bewertungen

- Generic Mechanical Workshop Risk AssessmentDokument6 SeitenGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqNoch keine Bewertungen

- Appendix A-Job Safety Analysis FormDokument3 SeitenAppendix A-Job Safety Analysis Formjiks_i4uNoch keine Bewertungen

- Technical Drilling SafetyDokument4 SeitenTechnical Drilling SafetyjihadspiritNoch keine Bewertungen

- Daily Tool Box MeetingDokument1 SeiteDaily Tool Box MeetingVipul ShankarNoch keine Bewertungen

- Cold Work PermitDokument1 SeiteCold Work PermitherdianNoch keine Bewertungen

- Weekly HSE Statistic Report 29th June To 05th July-16Dokument3 SeitenWeekly HSE Statistic Report 29th June To 05th July-16jayanth100% (1)

- Copy of RC HSEDokument5 SeitenCopy of RC HSEAnwar Haji JavedNoch keine Bewertungen

- Weekly HSE Performance ReportDokument2 SeitenWeekly HSE Performance ReportBorislav VulićNoch keine Bewertungen

- Risk Assessment ActivityDokument5 SeitenRisk Assessment ActivityHarthwell CapistranoNoch keine Bewertungen

- Health, Safety, Environment (HSE) Training Matrix - Houston: Today's DateDokument4 SeitenHealth, Safety, Environment (HSE) Training Matrix - Houston: Today's Datemonica dwimandhaNoch keine Bewertungen

- Safety Training Presentations: Good HousekeepingDokument23 SeitenSafety Training Presentations: Good HousekeepingAhmet SenlerNoch keine Bewertungen

- Aerial Lift Inspection FormsDokument15 SeitenAerial Lift Inspection FormsianNoch keine Bewertungen

- CCTC Safety Training Attendance SheetDokument1 SeiteCCTC Safety Training Attendance SheetSainu Kalathingal0% (1)

- JHA 001 Welding OperationsDokument3 SeitenJHA 001 Welding OperationsAhmad alwaelyNoch keine Bewertungen

- Ed 155Dokument4 SeitenEd 155api-299330082Noch keine Bewertungen

- EHS is Everyone’s ResponsibilityDokument88 SeitenEHS is Everyone’s ResponsibilityMarthaNoch keine Bewertungen

- Weekly excavator checklist template for construction projectsDokument4 SeitenWeekly excavator checklist template for construction projectssamiran RouthNoch keine Bewertungen

- Workplace Safety SurveyDokument2 SeitenWorkplace Safety SurveyBuddy KertunNoch keine Bewertungen

- Hazard Identification Prompt CDokument2 SeitenHazard Identification Prompt CMohamed HamedNoch keine Bewertungen

- 1 45Dokument3 Seiten1 45nsadnan0% (1)

- FINAL Shivani Confined Space PermitDokument1 SeiteFINAL Shivani Confined Space PermitVimal SinghNoch keine Bewertungen

- CONTROL SHEETS & FORMS permit guideDokument3 SeitenCONTROL SHEETS & FORMS permit guideHenry WoartNoch keine Bewertungen

- Hse Bulletin: Cold & FluDokument2 SeitenHse Bulletin: Cold & FluRanjan PradhanNoch keine Bewertungen

- Pera JackhammerDokument7 SeitenPera Jackhammerjumansyahamid1988Noch keine Bewertungen

- FRM-2530-03 Daily Site Inspection Checkllist Ver - 00Dokument4 SeitenFRM-2530-03 Daily Site Inspection Checkllist Ver - 00Ali KaziNoch keine Bewertungen

- Confined Space Entry PermitsDokument7 SeitenConfined Space Entry PermitsCris SuyamNoch keine Bewertungen

- Weekly Hse ReportDokument2 SeitenWeekly Hse Reportengrabbas75100% (1)

- Arkansas Kraft Division Contractor Safety OrientationDokument63 SeitenArkansas Kraft Division Contractor Safety Orientationdavid_stephens_29Noch keine Bewertungen

- Health & Safety Handouts ComDokument52 SeitenHealth & Safety Handouts ComTyra GeorgesNoch keine Bewertungen

- Protect Workers from Heat StressDokument2 SeitenProtect Workers from Heat StressVivian GonzalesNoch keine Bewertungen

- Tool Box Talk MeetingsDokument5 SeitenTool Box Talk MeetingsSusyenSihiteNoch keine Bewertungen

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDokument20 SeitenQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106Noch keine Bewertungen

- Emergency Responce Plan For Gulf CryoDokument22 SeitenEmergency Responce Plan For Gulf CryoHabib ur rahman0% (1)

- Job Safety Analysis FormDokument4 SeitenJob Safety Analysis FormMohammed NayeemuddinNoch keine Bewertungen

- Safety Observation Formate - 01Dokument3 SeitenSafety Observation Formate - 01Peter LuvisNoch keine Bewertungen

- Fire Extinguisher Training: Health, Safety & Environment DeptDokument33 SeitenFire Extinguisher Training: Health, Safety & Environment DeptRosano D. ManamtamNoch keine Bewertungen

- 01 JSA CLEANING MgO Rev 05 017 BIDokument7 Seiten01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirNoch keine Bewertungen

- 01-Ppe Eng PDFDokument17 Seiten01-Ppe Eng PDFZaki AdamouNoch keine Bewertungen

- Saferad LTD: Health, Safety and Environmental Targets - 2016 2018Dokument3 SeitenSaferad LTD: Health, Safety and Environmental Targets - 2016 2018AkhilNoch keine Bewertungen

- Job Safety Analysis Blank FormatDokument2 SeitenJob Safety Analysis Blank FormatKumar KushNoch keine Bewertungen

- Director Manager Environmental Health Safety in Nashville TN Resume Neil SchwartzDokument2 SeitenDirector Manager Environmental Health Safety in Nashville TN Resume Neil SchwartzNeilSchwartzNoch keine Bewertungen

- Contractor Environ & Safety FormDokument6 SeitenContractor Environ & Safety Formsieged_rj3165Noch keine Bewertungen

- JSA WorkingWithHazardousSubstancesDokument2 SeitenJSA WorkingWithHazardousSubstancesCristina RicanNoch keine Bewertungen

- Sample Near Miss FormDokument2 SeitenSample Near Miss FormSuharto AriNoch keine Bewertungen

- Health and Safety Induction SampleDokument5 SeitenHealth and Safety Induction SampleMohamad Hafiz100% (1)

- FR - HSE - 061 - en Permit To Work Audit ChecklistDokument2 SeitenFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNoch keine Bewertungen

- Daily Safety Report TemplateDokument1 SeiteDaily Safety Report TemplateMarkNoch keine Bewertungen

- Water blasting SWMSDokument5 SeitenWater blasting SWMSjohney2Noch keine Bewertungen

- Incident Checklist: Other ActionsDokument1 SeiteIncident Checklist: Other Actionsloveson709Noch keine Bewertungen

- PPE Hazard Assessment Certification FormDokument4 SeitenPPE Hazard Assessment Certification FormHaleem Ur Rashid BangashNoch keine Bewertungen

- LG 42LE5500 LCDDokument40 SeitenLG 42LE5500 LCDundiablo100% (1)

- Samsung Ua40c6200uf Ua46c6200uf Ua55c6200uf Ua32c6900vf Ua40c6900vf Ua46c6900vf Ua55c6900vf Chassis N96a Led PDFDokument121 SeitenSamsung Ua40c6200uf Ua46c6200uf Ua55c6200uf Ua32c6900vf Ua40c6900vf Ua46c6900vf Ua55c6900vf Chassis N96a Led PDFNina SeimeniNoch keine Bewertungen

- Revo Uninstaller HelpDokument35 SeitenRevo Uninstaller HelpNina SeimeniNoch keine Bewertungen

- Samsung LE26S81BHX Chassis GJA26TSADokument159 SeitenSamsung LE26S81BHX Chassis GJA26TSANina SeimeniNoch keine Bewertungen

- M Sicc W enDokument52 SeitenM Sicc W enNina SeimeniNoch keine Bewertungen

- LTE Technology and Components 2010 LRWebinarDokument29 SeitenLTE Technology and Components 2010 LRWebinarNina SeimeniNoch keine Bewertungen

- Hydrogen ConverterDokument114 SeitenHydrogen ConverterFloreia SileNoch keine Bewertungen

- Fire and Arson Investigation Mid Terms NotesDokument67 SeitenFire and Arson Investigation Mid Terms NotesMid AcidNoch keine Bewertungen

- USCG Vessel Inspection Chklist For SafetyDokument12 SeitenUSCG Vessel Inspection Chklist For SafetySeamen 777Noch keine Bewertungen

- MSDS-CSP e - 4038 Acri 700 FinishDokument5 SeitenMSDS-CSP e - 4038 Acri 700 FinishAnkit VyasNoch keine Bewertungen

- School Disaster Risk Management PlanningDokument49 SeitenSchool Disaster Risk Management PlanningVon TatilNoch keine Bewertungen

- Confined SpaceDokument66 SeitenConfined SpaceamaliaNoch keine Bewertungen

- Laboratory Safety ChecklistDokument11 SeitenLaboratory Safety Checklistarif_fatur324872100% (1)

- DIVINE WORD COLLEGE CRIMINOLOGY FINALSDokument12 SeitenDIVINE WORD COLLEGE CRIMINOLOGY FINALSJovie Masongsong100% (1)

- Is-6382 In-Stallation of Fixed Carbon Dioxide Fire Extinguishing SystemDokument33 SeitenIs-6382 In-Stallation of Fixed Carbon Dioxide Fire Extinguishing SystemCharls James80% (5)

- David Packham OAMDokument5 SeitenDavid Packham OAMaussienewsviews5302Noch keine Bewertungen

- Siemens FC901 PDFDokument1 SeiteSiemens FC901 PDFmotaNoch keine Bewertungen

- 3024 L5A Winter Court (Kyuden Kakita)Dokument130 Seiten3024 L5A Winter Court (Kyuden Kakita)DruzillaNevenNoch keine Bewertungen

- Emergency Response PlanDokument10 SeitenEmergency Response PlanJaseelKanhirathinkal100% (1)

- Training ManualDokument15 SeitenTraining Manualrajeshrahul321Noch keine Bewertungen

- Prioritizing Causes of Fire, Explosion in External Floating Roof TanksDokument15 SeitenPrioritizing Causes of Fire, Explosion in External Floating Roof TanksPankaj Singh ChauhanNoch keine Bewertungen

- Fire Safety in Care Homes Regulation Prevention LottieDokument15 SeitenFire Safety in Care Homes Regulation Prevention LottieWendell de RidderNoch keine Bewertungen

- (DAV) Novel 01 - NosferatuDokument288 Seiten(DAV) Novel 01 - Nosferatublu666100% (7)

- Read The Text Carefully and Then Answer The Questions That Follow! Floods Force Thousands of People To Evacuate in GorontaloDokument2 SeitenRead The Text Carefully and Then Answer The Questions That Follow! Floods Force Thousands of People To Evacuate in GorontaloDella SagitaNoch keine Bewertungen

- DampersDokument25 SeitenDampersmpwasaNoch keine Bewertungen

- MSDS GraphiteDokument6 SeitenMSDS Graphitepentalight100% (1)

- Lm-Household ServicesDokument39 SeitenLm-Household ServicesLea CardinezNoch keine Bewertungen

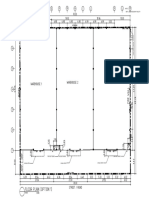

- Floor Plan (Option 1) : Warehouse 2 Warehouse 1 Warehouse 3Dokument1 SeiteFloor Plan (Option 1) : Warehouse 2 Warehouse 1 Warehouse 3John Carlo AmodiaNoch keine Bewertungen

- Inspection Check List - Fire Alarm System Rev 01Dokument5 SeitenInspection Check List - Fire Alarm System Rev 01Anonymous ixIhrPM2100% (1)

- Past Simple and Past ContinuousDokument2 SeitenPast Simple and Past ContinuousMitrofan DavidNoch keine Bewertungen

- Fire Technology and Arson Investigation Questionnaire GuideDokument4 SeitenFire Technology and Arson Investigation Questionnaire GuideYour Own Universe PerfumesNoch keine Bewertungen

- SWOC Analysis for Disaster Prevention and MitigationDokument11 SeitenSWOC Analysis for Disaster Prevention and MitigationMdrrmo Sigma-srt Srt100% (3)

- BoschDokument2 SeitenBoschAlmer J Becerra SNoch keine Bewertungen

- Major Accidents in Oil and Gas, Petrochemicals Slide PresentationsDokument16 SeitenMajor Accidents in Oil and Gas, Petrochemicals Slide PresentationsAimi Saari100% (1)

- FM200 Fire Suppression SystemDokument20 SeitenFM200 Fire Suppression Systemm2110100% (2)

- Tactics Ogre Spells Techniques GuideDokument129 SeitenTactics Ogre Spells Techniques GuideMichael CannonNoch keine Bewertungen

- Oxy Acetylene SopDokument1 SeiteOxy Acetylene SopLouise BNoch keine Bewertungen