Beruflich Dokumente

Kultur Dokumente

Lesson Plug, Ball and Butterfly Valves: Sub-Objective

Hochgeladen von

mister pogiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lesson Plug, Ball and Butterfly Valves: Sub-Objective

Hochgeladen von

mister pogiCopyright:

Verfügbare Formate

LESSON

4

LECTURE

PLUG, BALL AND BUTTERFLY VALVES

SUB-OBJECTIVE

At the end of thi !eon, the t"#inee $i!! %e #%!e to de&ont"#te #n

'nde"t#ndin( of P!'(, B#!! #nd B'tte"f!) V#!*e+

,+- INTRODUCTION

Plug, Ball and Butterfly valves are distinguished from other types of valves

by the fact that they are not made with discs that rise and descend from the

valve seating area.

These valves design not to provides the same tight sealing as a globe

valve. The seats are often made of plastic coated, self- lubricating. The

disc on these valves open by rotation. When the valve is actuated the disc

makes a one-quarter turn, to close or open the part. Plug Ball !alves can

be constructed with more than one part for flow through the valve.

,+, PLUG VALVE .COC/0

Plug valves, also called cocks, generally are used for the same full flow

service as gate valves, where quick shut-off is required. They are used for

steam, water, oil, gas, and chemical liquid service.

Plug valves are not generally designed for the regulation of flow.

"evertheless, in some applications, these valves are used for this purpose,

particularly for gas-flow throttling. #or low flow regulation, special plugs are

available.

$any differences in design and detail adapt the valve to various services.

!ariations on the basic concept can borrow from other types of valve, too.

#low resistance is low if the port, usually oblong #ig. %-& is anywhere near

line si'e. The plug valve can throttle on moderately demanding services.

(ts plug has two orifices, which helps in breaking down high pressure drops.

)learances and leakage prevention are the chief considerations in plug

valves. $any plug valves are of all metal construction #ig. %-*. (n these

versions, the narrow gap around the plug can allow leakage. (f the gap is

reduced by sinking the taper plug deeper into the body, actuation torque will

climb rapidly and galling can occur.

+ubrication remedies this. , series of grooves around the port openings, in

plug or body, is supplied with grease prior to actuation, not only to lubricate

the plug motion but also to seal the gap. -rease in.ection into a fitting at

stem top travels down through a check valve in the passage way and then

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ & !,+!/4 ,"5 !,+!/ $,("T/",")/

past the plug top to the grooves on the plug and down to a well below the

plug.

Fi(+ 4-,+ P!'( V#!*e+

,5!,")/5 )1234/ $/)0,"(),+ $,("T/",")/ )1234/

!,+!/4 ,"5 !,+!/ $,("T/",")/ +/441" % P,-/ *

Fi(+ 4-1+ P!'( V#!*e+

(n some older types of taper plug valves without lubricant, mechanisms to

.ack the plug up slightly before turning serve to break corrosion and give

clearance for turning. ,fter actuation, the mechanism is released to set the

plug firmly.

5evelopments in plastics, principally T#/ and nylon, have e6tended the

plug valve7s range. (f the service is under the temperature limit for T#/, a

lining sleeve or shell of T#/ in a plug valve #ig. %-8 can solve the sealing

problem for the metal plug. #riction of T#/ on a metal plug is low enough

to allow easy actuation. The lining method has certain restrictions and calls

for certain design measures not necessary in metal-to-metal sealing.

Fi(+ 4-2+

,+1 LUBRICANT-SEAL VALVES

(n lubricant seal valves, channels for the admission of the lubricant

surround the ports to insure positive sealing against internal or e6ternal

leakage. The lubricant pressure developed by a turn of the lubricant screw

or in.ection of lubricant with a pressure gun e6erts a powerful hydraulic

.acking action on the plug, momentarily lifting it from the seat and making it

easy to turn. 4ince the lubricant pressure is greater than the line pressure,

it is virtually impossible for solids to lodge between the valve body and plug.

The lubricant must be compatible with the temperature and nature of the

fluid of course. The most common fluids controlled by plug valves are

gases and liquid hydrocarbons. 4ome water lines have these valves, too, if

lubricant contamination is not a serious danger. This type can go to *% in.

si'e, with pressure capability psig in si'es to &9 in. 4teel or iron bodies are

available. The plug can be cylindrical or tapered. The functions of

pressure lubrication in plug valves are :

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ 8 !,+!/4 ,"5 !,+!/ $,("T/",")/

&. 0ydraulic action, keeping the plug in free working condition

*. $aintenance of positive seal against internal and e6ternal leakage.

8. #ree turning even of the largest si'es and against heavy differential

pressure, and

%. Protection of working surfaces from wear and corrosion. This

principle of pressure lubrication makes it possible to take full

advantage of the inherent simplicity, compactness, and positive

rotary action of the tapered plug valve.

,+2 DESIGN FEATURES

The basic design of plug valves #ig. %-% is similar to the old fashioned

wooden spigot. #ull flow is obtained when the opening in the tapered plug

faces in the direction of flow. When the plug is rotated a quarter of a turn,

flow is stopped.

The body and tapered plug represent the essential features in plug valves.

)areful design of the internal contours of the valve produces ma6imum flow

efficiency.

,5!,")/5 )1234/ $/)0,"(),+ $,("T/",")/ )1234/

!,+!/4 ,"5 !,+!/ $,("T/",")/ +/441" % P,-/ %

Fi(+ 4-4+ P!'( *#!*e $ith !'%"i3#nt )te&, # 4e3ified in API

St#nd#"d 5--+

The hole, or port, in the tapered plug is generally rectangular. 0owever,

valves are also available with round port design.

$a.or valve patterns or types are identified as regular, venturi, short,

roundport, and multiport.

The regular pattern employs the tapered form of port opening, the area of

which is from ;< to &<< per cent of the internal pipe area. (n some cases,

the face-to-face lengths are greater than those of standard gate valves.

The venturi pattern, available in flanged si'es 9 in. and larger, provides

streamlined flow and thus permits reduction in the port si'e. The port

opening area is appro6imately 8= per cent of the internal pipe area.

The short pattern has face-to-face lengths that conform with &=< and 8<< lb

steel gate valves.

The roundport full-bore pattern has a circular port through the plug and

body efficiency is equal to or greater than that of gate valves of the same

si'e.

2se of multiport valves %-= is advantageous in many installations because

it provides simplification of piping and convenience in operation. 1ne 8-

way or %-way multiport valve may be used in place of two, three, or four

straightway valves.

$a.or types of plug valves involve lubricated and non-lubricated designs.

+ubricant seal plug valves are less sub.ect to sei'ing or wear and may

e6hibit somewhat greater resistance to corrosion in some service

environments.

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ = !,+!/4 ,"5 !,+!/ $,("T/",")/

"on-lubricated plug valves are used where maintenance must be kept to a

minimum. Both types of valves provides a bubble tight closure and are of

compact si'e.

Fi(+ 4-6+ 7'!ti4o"t *#!*e+

These valves generally can be readily repaired or cleaned without

necessitating removal of the body from the piping system. They are

available for pressure service from vacuum to &<,<<< psi and temperatures

from -=< to &=<< #.

,+4 BALL VALVES

(n the past , the use of ball valves %-9 has been rather limited as bubble

tight service was not possible because of problems in the sealing ability of

metal-to-metal seats.

(n recent years, the use of plastics, such as nylon, delrin, synthetic rubbers,

and fluorinated polymers for seating, has substantially increased the use of

ball valves.

With fluorinated polymer seats, ball valves are used for service

temperatures ranging from %=< to =<< (. With graphite seats, temperatures

as high as &<<< # are possible. Ball valves, similar to plug valves, are

quick opening, needing only a quarter turn from full open to full close.

To open the valve, the ball is rotated so that the through port lines up with

the seat openings. When the valve is closed, line pressure forces the ball

against the downstream seat, in an action similar to that of a gate valve.

Ball valves are non-sticking, and they provide tight closure. They also

e6hibit a negligible pressure drop because of their smooth, full-opening

port. These valves are easy to repair, and maintenance costs are low.

$a.or components of the ball valve are the body, spherical plug, and seats.

Ball valves are made in three general patterns venturi port, full port, and

reduced port. The full-port valve has an inside diameter equal to the inside

diameter of the pipe. The reduced port generally involves one pipe si'e

smaller than the line si'e. 4tem sealing is by bolted packing glands and 1-

ring seals.

,5!,")/5 )1234/ $/)0,"(),+ $,("T/",")/ )1234/

!,+!/4 ,"5 !,+!/ $,("T/",")/ +/441" % P,-/ 9

Fi(+ 4-5+ B#!! V#!*e Co&4onent+

Below in #ig. %-; and #ig. %-> we can see a Ball valve in the open and

closed position.

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ ; !,+!/4 ,"5 !,+!/ $,("T/",")/

Fi(+ 4-8+ B#!! *#!*e in 3!oed 4oition+

Fi(+ 4-9+ B#!! *#!*e in o4en 4oition+

The seats of these valves are often made for plastic coated or self sealing

materials. ,lthough providing a good seal at low pressures, they are not

usually found in high pressure steam systems. They are very good in

systems carrying dirty materials such as mud or slurry. ,nother advantage

is that fluid can flow through the valve in either direction.

,5!,")/5 )1234/ $/)0,"(),+ $,("T/",")/ )1234/

!,+!/4 ,"5 !,+!/ $,("T/",")/ +/441" % P,-/ >

Fi(+ 4-:+ V#"i#tion of B#!! *#!*e dei(n+

Fi(+ 4-,-+ ;Vee< B#!! V#!*e+

1+- ;VEE< BALL VALVE

+ike the pinch valve, it has very low pressure drop characteristics and is

designed to maintain the rate of flow through it, it is also highly resistant to

clogging, which makes it adaptable to a wide variety of flow materials.

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ ? !,+!/4 ,"5 !,+!/ $,("T/",")/

The @!//A ball operates .ust like the standard ball valve, but slurries such

as pulp, coal, or ash can also be controlled through @!//A ball valve.

)ontrol is applied by a wedge shearing action. ,s the ball is rotated to

close any material that may clog the passage is seared off.

1+, BUTTERFLY VALVES

Butterfly valves of e6tremely simple design, which are used to control and

regulate flow. They are characteri'ed by fast operation and low differential

pressure drop. They required only a quarter turn from closed to full open

position. Butterfly valves are not intended for pressure-tight service. ,

typical flanged butterfly valve is illustrated in #ig. %-&&.

The disc is attached to the stem, and used primarily for isolation of flow. (n

addition to shut off function, butterfly valves can be used for throttling

application not frequently because poor throttling characteristics. The disc

is always the same diameter as the piping on which the valve is attached.

Fi(+ 4-,,+ T)4i3#! f!#n(ed-end %'tte"f!) *#!*e+

When the operating lever is in line with the piping, the valve is open. When

the valve operator is perpendicular to the piping, the valve is closed. $ost

Butterfly valves are constructed with a resilient, natural rubber seat that

provide a firm fit and a tight seal when the disc close on it. The sealing

area must be resilient, but a rigid back up is usually provided, either of non-

metallic type as metal ridges on the body rings or as encapsulated metal

rings in a rubber seat ring.

,5!,")/5 )1234/ $/)0,"(),+ $,("T/",")/ )1234/

!,+!/4 ,"5 !,+!/ $,("T/",")/ +/441" % P,-/ &<

Butterfly valves must be removed from a system for all repairs e6cept

packing. 4ince butterfly valves generally hold a single ring of packing,

ad.ustment are rarely made.

1+1 VALVE SEAT DESIGN

5epending upon the type of valve, the valve seat may consist of a bonded

resilient liner, a mechanically fastened resilient liner, an inert-type reinforced

resilient liner a mechanically fastened resilient seal or an integral #ig. %-&*.

Fi(+ 4-,1+

#ig. %-&8. Below shows a butterfly valve in the open position.

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ && !,+!/4 ,"5 !,+!/ $,("T/",")/

Fi(+ 4-,2+

The position of the butterfly valve disc can easily be seen. The operating

lever is in line with the pipe when it is open, and perpendicular or across

the pipe when closed. This is also usually the case with plug and ball

valves. The seats of butterfly valves are often made from a resilient natural

gum rubber to provide a good seal. They are commonly used for

controlling the petrolBair mi6ture in the carburetor of your car. +arger

butterfly valves are servo assisted by electric motors, hydraulics,

diaphragms etc. because they are difficult to move against the flow of the

fluid. The disc is always the same diameter as the piping to which it is

attached. This gives the advantage of a smoother flow and less pressure

drop.

The combination of seating geometry and seal material alloys this type of

eccentric butterfly to close very tightly on liquids and gas at pressures as

high as 8;=< psig. This ability has led the manufactures of the spherical-

seat eccentric butterfly with T#/ seats to call it @high performanceA.

#le6ibility of the ring varies from design to design. (n fig. %-&% , is

comparatively in fle6ible. The B and ) profiles are more fle6ible.. (n any

profile, a ring of T#/ filled with glass fiber or graphite is inherently less

fle6ible than a ring of unfilled T#/. #or ring protection against debris and

e6trusion as the disc nears its seat, rings tend to be recessed in grooves

between retainer and body.

Work continues on metal and graphite seat rings for high temperatures.

4ometimes the rings are assisted by T#/ rings to give superior tightness at

low temperatures, keeping the metal rings for sealing during a high-

temperature e6cursion. The metal seat rings have complicated profiles to

give fle6ibility and ability to survive closure on hard foreign bodies. #luid

pressure assists sealing and often there is a double contact on the disc.

,5!,")/5 )1234/ $/)0,"(),+ $,("T/",")/ )1234/

!,+!/4 ,"5 !,+!/ $,("T/",")/ +/441" % P,-/ &*

Fi(+ 4-,4+

$/)0,"(),+ $,("T/",")/ )1234/ ,5!,")/5 )1234/

+/441" % P,-/ &8 !,+!/4 ,"5 !,+!/ $,("T/",")/

Das könnte Ihnen auch gefallen

- Valve Refurbishment - Technical Presentation-FinalDokument16 SeitenValve Refurbishment - Technical Presentation-FinalSarathiraja Sekar100% (1)

- Cat 350-375 TDokument60 SeitenCat 350-375 TFernando Sabino100% (1)

- Series 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Dokument12 SeitenSeries 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Gopinath GunasekaranNoch keine Bewertungen

- Valves: Types, Functions, Uses, Maintenance & TroubleshootingDokument68 SeitenValves: Types, Functions, Uses, Maintenance & TroubleshootingToniNoch keine Bewertungen

- Pressure Vacuum Vent Cap Test ProcedureDokument3 SeitenPressure Vacuum Vent Cap Test ProcedureDadang Ibnu SetyawanNoch keine Bewertungen

- Valve Maintenance1Dokument11 SeitenValve Maintenance1mister pogiNoch keine Bewertungen

- Lesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-ObjectiveDokument8 SeitenLesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-Objectivemister pogiNoch keine Bewertungen

- Checking Valves Design and TypesDokument7 SeitenChecking Valves Design and Typesmister pogiNoch keine Bewertungen

- Lesson Piston Valves: Sub-ObjectiveDokument4 SeitenLesson Piston Valves: Sub-Objectivemister pogiNoch keine Bewertungen

- 2011 03 02 Kelly Valves Family Low 01Dokument4 Seiten2011 03 02 Kelly Valves Family Low 01Sasan AbbasiNoch keine Bewertungen

- Hydo Test ProcedureDokument2 SeitenHydo Test ProcedureAbdulMajidYousoffNoch keine Bewertungen

- Control Valves ExplainedDokument58 SeitenControl Valves ExplainedNIKHIL SHINDENoch keine Bewertungen

- Lesson Globe Valves: Sub-ObjectiveDokument9 SeitenLesson Globe Valves: Sub-Objectivemister pogiNoch keine Bewertungen

- Valve Maintenance9Dokument21 SeitenValve Maintenance9mister pogi100% (1)

- ValveDokument127 SeitenValveAgung SubektiNoch keine Bewertungen

- 2P36784, Plug ValveDokument34 Seiten2P36784, Plug ValveEdwin HernandezNoch keine Bewertungen

- Contorl ValvesDokument8 SeitenContorl ValvesGaurav MishraNoch keine Bewertungen

- Gate Valve Maintenance ManualDokument27 SeitenGate Valve Maintenance ManualLeandro100% (1)

- Lesson Valve Maintenance and Valve Packing: Sub-ObjectiveDokument30 SeitenLesson Valve Maintenance and Valve Packing: Sub-Objectivemister pogi100% (1)

- Serck Arduco Plug ValvesDokument20 SeitenSerck Arduco Plug ValvesRominaNoch keine Bewertungen

- How to select gland packing cross sectionDokument2 SeitenHow to select gland packing cross sectionPramod Kumar GiriNoch keine Bewertungen

- Gate ValveDokument27 SeitenGate ValveYogesh Kumar Bhatnagar0% (1)

- Pneumatic Control ValvesDokument59 SeitenPneumatic Control Valvespatil_raaj7234Noch keine Bewertungen

- EPRV Installation ManualDokument21 SeitenEPRV Installation ManualdrlijothomasNoch keine Bewertungen

- PSV TestingDokument26 SeitenPSV Testingmanoj thakkar100% (1)

- G.V. Manual (FC Type)Dokument20 SeitenG.V. Manual (FC Type)sambhajiNoch keine Bewertungen

- Texsteam-Ñ Bomba QuímicaDokument8 SeitenTexsteam-Ñ Bomba QuímicarivomarNoch keine Bewertungen

- Api Q2 atDokument7 SeitenApi Q2 atDheeraj MenonNoch keine Bewertungen

- Valve Symbols: Saudi Aramco Valve InspectionDokument20 SeitenValve Symbols: Saudi Aramco Valve InspectionVenkat Gokila DTNoch keine Bewertungen

- Te ValveDokument30 SeitenTe Valvecrni roko100% (2)

- Choke ManifoldDokument2 SeitenChoke Manifoldjay_rajeshirke100% (1)

- Grove API 6d Gate Valve IomDokument21 SeitenGrove API 6d Gate Valve Iomanon_793851477Noch keine Bewertungen

- Regulator's Swegelok (High PressuDokument64 SeitenRegulator's Swegelok (High PressuhoangcokhiNoch keine Bewertungen

- Manual Adjustable ChokeDokument36 SeitenManual Adjustable ChokeWill CastellanosNoch keine Bewertungen

- Manual Torque WrenchDokument2 SeitenManual Torque WrenchVipul ShahNoch keine Bewertungen

- Choke Valve MSPDokument26 SeitenChoke Valve MSPabbas1368Noch keine Bewertungen

- Lesson Centrifugal PumpDokument14 SeitenLesson Centrifugal Pumpmister pogiNoch keine Bewertungen

- Boiler Hydrostatic TestingDokument2 SeitenBoiler Hydrostatic Testingbonginkosi mathunjwaNoch keine Bewertungen

- HH SwivelDokument3 SeitenHH SwivelHoracio LafuenteNoch keine Bewertungen

- FMC Flowline Product CatalogDokument80 SeitenFMC Flowline Product CatalogRodrigo França100% (2)

- FC Gate Valve Bonnet Assemble 1-13/16" 10k 15kDokument1 SeiteFC Gate Valve Bonnet Assemble 1-13/16" 10k 15kPetrotrim ServicesNoch keine Bewertungen

- Brochure 1Dokument20 SeitenBrochure 1련서긔Noch keine Bewertungen

- Breather Valve - PV Valve - CNC380Dokument2 SeitenBreather Valve - PV Valve - CNC380mhidayat108Noch keine Bewertungen

- Ball Valve GuideDokument22 SeitenBall Valve GuideBalakrishna BisoyiNoch keine Bewertungen

- Drillstring Hardbanding: Arcraft Plasma IndiaDokument10 SeitenDrillstring Hardbanding: Arcraft Plasma Indiapavi32Noch keine Bewertungen

- 290 08 PDFDokument4 Seiten290 08 PDFmlevNoch keine Bewertungen

- Butterfly ValveDokument25 SeitenButterfly ValveRahul JadhavNoch keine Bewertungen

- Ball Valve Overhaul ProcedureDokument7 SeitenBall Valve Overhaul Procedurerocket789Noch keine Bewertungen

- Catalogo Fluid Control FMCDokument80 SeitenCatalogo Fluid Control FMCGustavo JassoNoch keine Bewertungen

- Gate Valve Trim ChartDokument5 SeitenGate Valve Trim ChartWaseem IqbalNoch keine Bewertungen

- Intermediate Inspection CriteriaDokument2 SeitenIntermediate Inspection CriteriaKaleem UllahNoch keine Bewertungen

- Ring Type Joint GasketsDokument24 SeitenRing Type Joint GasketsProsenjit Das100% (1)

- NewayGateValveAPI 6DDokument44 SeitenNewayGateValveAPI 6DAndersson Benito HerreraNoch keine Bewertungen

- HWDP HardfacingDokument6 SeitenHWDP HardfacingHatem RagabNoch keine Bewertungen

- Safety ValveDokument56 SeitenSafety ValveAbhishek KumarNoch keine Bewertungen

- Butterfly Valve Info PDFDokument14 SeitenButterfly Valve Info PDFCS100% (1)

- OMB BALL ValveDokument44 SeitenOMB BALL Valveale_f_79Noch keine Bewertungen

- ValvesDokument82 SeitenValvespuru55980Noch keine Bewertungen

- Valve & Type of ValesDokument82 SeitenValve & Type of Valesvipinct83% (6)

- Plug ValveDokument5 SeitenPlug ValveNyoman RakaNoch keine Bewertungen

- Making of Most of ValvesDokument12 SeitenMaking of Most of ValvesShaikh MateenNoch keine Bewertungen

- Growing Catfish in The PhilippinesDokument4 SeitenGrowing Catfish in The Philippinesmister pogiNoch keine Bewertungen

- 4air Con02Dokument9 Seiten4air Con02mister pogiNoch keine Bewertungen

- How To Acclimate Strawberry Plants - Stark Bro'sDokument5 SeitenHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNoch keine Bewertungen

- 20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZDokument12 Seiten20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZmister pogi100% (1)

- Lesson Introduction To CompressorsDokument12 SeitenLesson Introduction To Compressorsmister pogiNoch keine Bewertungen

- Air Con 03 OverDokument30 SeitenAir Con 03 Overmister pogiNoch keine Bewertungen

- Manual For Welding InspectorDokument308 SeitenManual For Welding Inspectormister pogi100% (1)

- How To Acclimate Strawberry Plants - Stark Bro'sDokument5 SeitenHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNoch keine Bewertungen

- Atty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC ProceedingsDokument15 SeitenAtty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC Proceedingsmister pogiNoch keine Bewertungen

- Air Con 02 OverDokument50 SeitenAir Con 02 Overmister pogiNoch keine Bewertungen

- Msfpt2 LesDokument9 SeitenMsfpt2 Lesmister pogiNoch keine Bewertungen

- 3air Con03Dokument10 Seiten3air Con03mister pogiNoch keine Bewertungen

- Stub End LengthDokument1 SeiteStub End Lengthmister pogi100% (1)

- SWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and SystemsDokument8 SeitenSWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and Systemsmister pogiNoch keine Bewertungen

- Air Con 01overDokument19 SeitenAir Con 01overmister pogiNoch keine Bewertungen

- 4air Con05Dokument6 Seiten4air Con05mister pogiNoch keine Bewertungen

- 10air Con04Dokument7 Seiten10air Con04mister pogiNoch keine Bewertungen

- 4air Con04Dokument24 Seiten4air Con04mister pogiNoch keine Bewertungen

- Lesson Heating and CoolingDokument8 SeitenLesson Heating and Coolingmister pogiNoch keine Bewertungen

- 10air Con03Dokument10 Seiten10air Con03mister pogiNoch keine Bewertungen

- Lesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration SystemsDokument4 SeitenLesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration Systemsmister pogiNoch keine Bewertungen

- 3air Con02Dokument12 Seiten3air Con02mister pogiNoch keine Bewertungen

- Lesson Heat Pumps and Complete Air Conditioning SystemDokument14 SeitenLesson Heat Pumps and Complete Air Conditioning Systemmister pogiNoch keine Bewertungen

- Lesson Basic Air Conditioner SystemsDokument7 SeitenLesson Basic Air Conditioner Systemsmister pogiNoch keine Bewertungen

- Turbine 3Dokument11 SeitenTurbine 3mister pogiNoch keine Bewertungen

- Lesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet ValvesDokument15 SeitenLesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet Valvesmister pogiNoch keine Bewertungen

- Turbine 2Dokument32 SeitenTurbine 2mister pogiNoch keine Bewertungen

- Lesson Rigging SafetyDokument14 SeitenLesson Rigging Safetymister pogiNoch keine Bewertungen

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDokument26 SeitenLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNoch keine Bewertungen

- Lesson Basic RiggingDokument15 SeitenLesson Basic Riggingmister pogiNoch keine Bewertungen

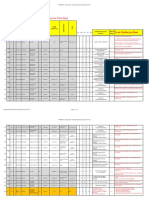

- Technical Bid Tabulation: Vendor Description SpecificationDokument8 SeitenTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNoch keine Bewertungen

- Parker Store - (Series PCM, PCCM) - Valves, Flow Control Valves, Pressure CompensatedDokument1 SeiteParker Store - (Series PCM, PCCM) - Valves, Flow Control Valves, Pressure Compensatedmahmod alrousanNoch keine Bewertungen

- CTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsDokument3 SeitenCTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsSri100% (1)

- VDFR 38-12: Flow Regulator Pressure CompensatedDokument2 SeitenVDFR 38-12: Flow Regulator Pressure CompensatedSachin RamadasanNoch keine Bewertungen

- Monitor Electric & Hydraulic Sales KitsDokument6 SeitenMonitor Electric & Hydraulic Sales Kitsedgardo_sepulvedaNoch keine Bewertungen

- 336el 03 HydraulicDokument15 Seiten336el 03 Hydraulicrjan7pe100% (1)

- P260 - HP220 WymDokument174 SeitenP260 - HP220 Wymvictor75% (4)

- Widearea Eye/Face Washes G1704: Guardian EquipmentDokument2 SeitenWidearea Eye/Face Washes G1704: Guardian Equipmenteisenbarger5607Noch keine Bewertungen

- 78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BDokument13 Seiten78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BGemasgoodasdf DjdjdjNoch keine Bewertungen

- 92.5 MLD Design and Drawing ListDokument3 Seiten92.5 MLD Design and Drawing ListBallNoch keine Bewertungen

- BERMAD Fire Protection CatalogueDokument274 SeitenBERMAD Fire Protection Cataloguepjanic79100% (1)

- Advantages of Bladder Surge TanksDokument8 SeitenAdvantages of Bladder Surge TanksChrisHogbenNoch keine Bewertungen

- Control - Pressure Control ValveDokument4 SeitenControl - Pressure Control Valvesajad jasmNoch keine Bewertungen

- UuuuuuuDokument2 SeitenUuuuuuuNandNNoch keine Bewertungen

- 6-44-0013 Rev 5-FLUSHING AND TESTING OF PIPING SYSTEM PDFDokument9 Seiten6-44-0013 Rev 5-FLUSHING AND TESTING OF PIPING SYSTEM PDFsumit tiwariNoch keine Bewertungen

- Valvulas Watts PDFDokument140 SeitenValvulas Watts PDFJuan PerazaNoch keine Bewertungen

- Chapter 03 - Flow in PipesDokument83 SeitenChapter 03 - Flow in PipesSamnang HangNoch keine Bewertungen

- Rowan Rig 0082 BOP Control System Operation and Maintenance ManualDokument38 SeitenRowan Rig 0082 BOP Control System Operation and Maintenance Manualcarlosorizaba100% (1)

- BKH-F Flange Ball Valve Steel: Available Sizes ConnectionsDokument2 SeitenBKH-F Flange Ball Valve Steel: Available Sizes ConnectionsDanielNoch keine Bewertungen

- SRV (Female BSP Threaded Version) : Diffusers 52 - 55Dokument3 SeitenSRV (Female BSP Threaded Version) : Diffusers 52 - 55MaxNoch keine Bewertungen

- Ebara PumpDokument25 SeitenEbara PumpMark CentenoNoch keine Bewertungen

- PDFDokument100 SeitenPDFharshkumar patelNoch keine Bewertungen

- VP 226 012 SK 001Dokument2 SeitenVP 226 012 SK 001ritoh8657Noch keine Bewertungen

- Butterfly Torque Selection GuideDokument3 SeitenButterfly Torque Selection Guidedragon2065Noch keine Bewertungen

- Standard Dimensions of Spectacle Blind - 8 Blind - EnggCyclopedia PDFDokument12 SeitenStandard Dimensions of Spectacle Blind - 8 Blind - EnggCyclopedia PDFMohamed AdelNoch keine Bewertungen

- 20 Artificial LiftDokument94 Seiten20 Artificial Liftashrafsaber100% (1)

- HydraulicDokument10 SeitenHydraulicDewan VidanageNoch keine Bewertungen

- 755 Operating Instructions PDFDokument4 Seiten755 Operating Instructions PDFPatricio AguilarNoch keine Bewertungen

- Brida SwivelDokument2 SeitenBrida SwivelJuan Roberto López Betanzos100% (1)