Beruflich Dokumente

Kultur Dokumente

Lesson Centrifugal Pump

Hochgeladen von

mister pogiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lesson Centrifugal Pump

Hochgeladen von

mister pogiCopyright:

Verfügbare Formate

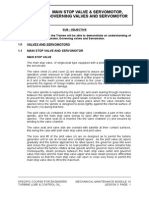

LESSON

2

LECTURE

CENTRIFUGAL PUMP

SUB-OBJECTIVE

At the end of this Lesson the Trinee !i"" #e #"e to de$onstrte n

%nderstndin& of Centrif%&" P%$'s(

)(* INTRO+UCTION

Although all centrifugal pumps operate on the same principle, they

differ from one another in several ways.

* One way is size

* Another ways is shape

But most important are the difference in design. These design variation

enable centrifugal pumps to meet a wide range of industrial

requirement.

)() PUMP PARTS +EFINITIONS

The basic parts name of a centrifugal pump almost are the same as

shown in ig. !"#$#!.

Fi&( )*-2-)( Bsi, 'rts of ,entrif%&" '%$'(

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 1 PUMP AND PUMP MAINTENANCE

2(* T-E IMPELLER

%mpeller shown in ig. !"#$#$, is the part of the pump that applies high

energy force to the fluid. &enter of the impeller is the 'ye of impeller

and partially determines the pump capacity.

2() IMPELLER VANES

That direct the flow of fluid with in the pump %mpeller (hrouds.

%mpeller shrouds enclose the blades.

A impeller &an be open, semi#open or closed impeller and normally

material used for impeller are cast iron, bronze and alloy steels.

Fi&( )*-2-2( A i$'e""er desi&n nd Fi&( .A. is o'en i$'e""er

B. is se$i o'en i$'e""er.

C. is ,"osed i$'e""er(

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 2

/(* T-E CASING

The casing is the enclosure surrounding the pump impeller, shaft and

pac)ing gland. %t direct the flow of liquid into and out of the pump.

&asing may a diagonal volute type, horizontal split as shown in ig. !"#

$#* +ertical split.

Fi&( )*-2-/( A +i&on" s'"it 0o"%te ,sin&(

/() MATERIAL FOR CASING

&ast iron is the preferred material for pump casing. or high

temperature and pressure steel and alloy steel are used for low

temperature saline material bronze is the best.

/(2 +IFFUSERS

,sually are not used in the construction of centrifugal pumps. -owever

they may be used sometimes to direct the flow.

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 3 PUMP AND PUMP MAINTENANCE

1(* PUMP S-AFT ASSEMBL2

The shaft is machined accurately to provide a precision fit for all parts.

A shaft assembly may contain, impeller )ey, impeller washer and bolt or

nut and coupling side )ey as shown in ig. !"#$#.. The shaft must be

made strong enough and anti corrosive.

Fi&( )*-2-1( A shft sse$#"3(

Fi&( )*-2-4( P%$' Berin& Csin&(

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 4

1() BEARING CASING

ig. !"#$#/. shows the bearing casing of the pump hold the bearings

and contain lubricant for bearings.

4(* 5EARING RINGS

0earing rings provide an easily and economically renewable lea)age

1oint between the impeller and casing it can be installed on either the

impeller or casing or on both.

There are various types of wearing#ring designs shown in ig. !"#$#2.

Fi&( )*-2-6( +ifferent t3'es of !erin& rin&s(

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 5 PUMP AND PUMP MAINTENANCE

6(* A PAC7ING GLAN+

A pac)ing gland seals the fluid flow in the pump and pac)ing gland may

a replaceable and ad1ustable or the mechanical seal type.

The pac)ing gland or mechanical seal )ept in stuffing bo3 which

normally created in casing cover for ad1ustable gland seal stuffing bo3

assembly shown in ig. !"#$#4 which contain.

!. A pac)ing which may be asbestos, teflon or braided.

$. A lantern ring which provides a space between rings for

supplying the lubricant and for providing seal.

*. A gland which hold and compress the pac)ing gland.

.. A throw#over or deflector which deflect the heavy gland

lea)s entering the bearing housing.

Fi&( )*-2-8( St%ffin& #o9 sse$#"3(

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 6

ig. !"#$#5 shown a mechanical seal. 6echanical seal have many

advantages it is suitable for hot and chemical application for zero

lea)age, it have low maintenance requirements.

Fi&( )*-2-:( A Me,hni," se" !ith #si, 'rts(

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 7 PUMP AND PUMP MAINTENANCE

8(* PUMP BEARING

Bearing of the pump provide supports for the shaft and confines or

restrains the radial and a3ial movements of the shaft and same time

reduce the friction.

The bearings used on most small pumps are single row deep groove

ball bearing, and for large pumps they can be double row ball bearing,

roller bearing or 1ournal bearings ig. !"#$#7 shown some bearing used

for pumps.

Fi&( )*-2-;( So$e ,o$$on #erin&s %sed in '%$'s(

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 8

:(* S-AFT COUPLING

The purpose of shaft coupling is to transmit torque or rotary motion and

same time compensate for angular and parallel misalignment ig. !"#$#

!" shows some coupling which mostly used in pumps. Basically there

are two types of couplings8

* 9igid coupling :flange coupling;

* le3ible coupling

Fi&( )*-2-)*( Co%'"in&s(

;(* OIL SEAL OR PAC7ING

A oil seal prevents lubricant lea)ing from out of bearing casing.

The oil seal consists generally of a rubber pieces, a steel plate and a

spring. <ormally oil seals fi3ed into the bearing casings cover. ig.

shown a oil seal in action.

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 9 PUMP AND PUMP MAINTENANCE

Fi&( )*-2-))( A oi" se"(

)*(* CLASSIFICATION OF CENTRIFUGAL PUMP

%n the beginning of that lesson, it is mention that all centrifugal pumps

operate on the same way but they differ from one, another such li)e in

size, shape and design ig. !"#$#!$ shows the centrifugal pumps

classification in detail.

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 10

Fi&( )*-2-)2( C"ssifi,tion of Centrif%&" '%$'s(

)*() RA+IAL FLO5 PUMP

9adial flow pump as shown in ig. !"#$#!*. %n these pumps, flow at

7" to the center line of the shaft.

)*(2 A<IAL FLO5 PUMP

%n a3ial flow pumps flow parallel to the a3is :the center line of the shaft

as shown in ig. !"#$#!* normally these pumps operate with high

volume low head capabilities.

)*(/ MI<E+ FLO5 PUMP

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 11 PUMP AND PUMP MAINTENANCE

A pump that uses both a3ial flow and radial flow components in one

impeller as shown in ig. !"#$#!* it is also operate with high volume

and comparatively higher head capacities than a3ial flow. A3ial flow

and

mi3ed flow pump are used in wet pit application.

Fi&( )*-2-)/( Rdi"= A9i" nd Mi9ed F"o!(

))(* SINGLE STAGE

(ingle stage pump have on impeller its discharge pressure is less than

multistage pump.

)2(* MULTI-STAGE

6ulti#stage pump have more than impeller is shown in ig. !"#$#!..

The purpose of multi#stage is to produce higher discharge pressure

than is normally possible with a single impeller.

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 12

)/(* SINGLE SUCTION= AN+ +OUBLE SUCTION

(ingle suction or double suction refers to the number of suction eyes of

the impeller as shown in ig. !"#$#!/. %n a single suction impeller, fluid

enters through one side only. The disadvantage of single suction is

unbalance thrust in one direction double suction impellers are designed

to eliminate this imbalance double#suction impellers have a suction on

each side.

Fi&( )*-2-)4( Sin&"e s%,tion nd do%#"e s%,tion i$'e""ers nd ,sin&s(

)1(* MET-O+S OF T-RUST BALANCING

The centrifugal pump is inherently an unbalanced machine. These

pumps are sub1ect to end thrust which means that some method must

be devised to counteract this load. +arious methods of balancing have

been tried as shown in ig. !"#$#!2.

MECHANICAL MAINTENANCE COURSE MODULE 10

LESSON 2 PAGE 13 PUMP AND PUMP MAINTENANCE

<atural balancing as by opposing impellers

6echanical balancing as by a balancing dis) or drum and in single

stage small pumps by thrust bearings.

Fi&( )*-2-)6( Methods of Thr%st B"n,in&(

MODULE 10 MECHANICAL MAINTENANCE COURSE

PUMP AND PUMP MAINTENANCE LESSON 2 PAGE 14

Das könnte Ihnen auch gefallen

- Lesson Globe Valves: Sub-ObjectiveDokument9 SeitenLesson Globe Valves: Sub-Objectivemister pogiNoch keine Bewertungen

- Lesson Pump Theory and Classifications: Sub-ObjectiveDokument7 SeitenLesson Pump Theory and Classifications: Sub-Objectivemister pogiNoch keine Bewertungen

- Lesson Piston Valves: Sub-ObjectiveDokument4 SeitenLesson Piston Valves: Sub-Objectivemister pogiNoch keine Bewertungen

- Lesson Introduction and Classification: Sub ObjectiveDokument7 SeitenLesson Introduction and Classification: Sub Objectivemister pogiNoch keine Bewertungen

- Lesson Check Valves: Sub-ObjectiveDokument7 SeitenLesson Check Valves: Sub-Objectivemister pogiNoch keine Bewertungen

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDokument26 SeitenLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNoch keine Bewertungen

- Lesson Main Stop Valve & Servomotor, Governing Valves and ServomotorDokument41 SeitenLesson Main Stop Valve & Servomotor, Governing Valves and Servomotormister pogiNoch keine Bewertungen

- Gas Turbine - Compressor AlignmentDokument2 SeitenGas Turbine - Compressor AlignmentNazmiNoch keine Bewertungen

- Valve Maintenance1Dokument11 SeitenValve Maintenance1mister pogiNoch keine Bewertungen

- AnsaldoThomassen Gas Turbine Engineering LRDokument4 SeitenAnsaldoThomassen Gas Turbine Engineering LRAshik ChungathNoch keine Bewertungen

- Valve Maintenance9Dokument21 SeitenValve Maintenance9mister pogi100% (1)

- Rim and Face AlignmentDokument4 SeitenRim and Face AlignmentJJNoch keine Bewertungen

- Mechatronics - Unit-Iii (Iv B.Tech I Sem Mech) : (Hydraulic Systems)Dokument36 SeitenMechatronics - Unit-Iii (Iv B.Tech I Sem Mech) : (Hydraulic Systems)Radha KrishnaNoch keine Bewertungen

- Polder Pumps ManualDokument7 SeitenPolder Pumps ManualHiren PatelNoch keine Bewertungen

- MAINTENANCE or MECHANICAL TECHNICIANDokument2 SeitenMAINTENANCE or MECHANICAL TECHNICIANapi-79058143Noch keine Bewertungen

- All Auxilary PumpsDokument10 SeitenAll Auxilary PumpsRana Yasir AyubNoch keine Bewertungen

- Alstom Vailbility AssessmentDokument29 SeitenAlstom Vailbility AssessmentSISWANTONoch keine Bewertungen

- Uk-Standard Asme Bladder AccumulatorDokument3 SeitenUk-Standard Asme Bladder AccumulatorRamin SoadNoch keine Bewertungen

- Thosiba TurbinesDokument16 SeitenThosiba Turbinesilusee100% (1)

- 1982 - Korner - Design Features of Steam PDFDokument6 Seiten1982 - Korner - Design Features of Steam PDFramakantinamdarNoch keine Bewertungen

- GENERator Auxilary System MonitoringDokument10 SeitenGENERator Auxilary System MonitoringdhirendracommonNoch keine Bewertungen

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDokument4 SeitenFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedNoch keine Bewertungen

- TH PP CH2 NewDokument38 SeitenTH PP CH2 NewAnonymous I43VxQYvNoch keine Bewertungen

- 9e ChinaDokument7 Seiten9e Chinanabil160874Noch keine Bewertungen

- 9.SOP Barring Gear or Turning GearDokument5 Seiten9.SOP Barring Gear or Turning GearDodik NugrohoNoch keine Bewertungen

- Gas Turbine Engine Operation V PDFDokument19 SeitenGas Turbine Engine Operation V PDFPappuRamaSubramaniamNoch keine Bewertungen

- Manual B4601Dokument159 SeitenManual B4601FER-ARTNoch keine Bewertungen

- Ger 4222a New High Efficiency Simple Cycle Gas Turbine Lms100Dokument20 SeitenGer 4222a New High Efficiency Simple Cycle Gas Turbine Lms100raghavendran raghuNoch keine Bewertungen

- 7 Hydraulic CKT 18P2Dokument17 Seiten7 Hydraulic CKT 18P2M RazzaqueNoch keine Bewertungen

- DSI Mar03 UpdateDokument437 SeitenDSI Mar03 UpdateAdel ALkhaligyNoch keine Bewertungen

- D 100017 X 012Dokument24 SeitenD 100017 X 012ErnestoNoch keine Bewertungen

- Owner Michael Calistrat and Associates Missouri City, TexasDokument8 SeitenOwner Michael Calistrat and Associates Missouri City, Texasjhchung111100% (1)

- BIRKOSIT - Sealing Compound Application ProcedureDokument1 SeiteBIRKOSIT - Sealing Compound Application ProcedureProject Sales CorpNoch keine Bewertungen

- Alignment Procedure PDokument8 SeitenAlignment Procedure PvinothenergyNoch keine Bewertungen

- Prepared By: Hemanthkrishnan R Roll No 44 S5Ma NssceDokument22 SeitenPrepared By: Hemanthkrishnan R Roll No 44 S5Ma NssceKingNoch keine Bewertungen

- Fisher Steam Turbines Application Guide August 2013Dokument11 SeitenFisher Steam Turbines Application Guide August 2013Juan Manuel Pardal100% (1)

- Steam Turbine BearingsDokument44 SeitenSteam Turbine Bearingsbalajieee88100% (1)

- Scope of Work FR 9Dokument3 SeitenScope of Work FR 9Dharmesh Kumar KewatNoch keine Bewertungen

- Centrifugal Pump OverloadingDokument2 SeitenCentrifugal Pump OverloadingAbdul AlimNoch keine Bewertungen

- Chapter-1 Steam Turbine TheoryDokument17 SeitenChapter-1 Steam Turbine TheorybhaskarNoch keine Bewertungen

- Gas Turbine in Cairo North Power StationDokument38 SeitenGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- Owner'S ManualDokument58 SeitenOwner'S ManualchrkiitmNoch keine Bewertungen

- Coupling and ApplicationDokument4 SeitenCoupling and Applicationekobudi94Noch keine Bewertungen

- SSS Clutch PrincipleDokument2 SeitenSSS Clutch PrincipleSyed Safiur RahmanNoch keine Bewertungen

- BHEL Bhopal STM Training ReportDokument20 SeitenBHEL Bhopal STM Training ReportMohit Assudani50% (2)

- Blower Installation and OperationDokument46 SeitenBlower Installation and OperationHassan Haroon100% (2)

- 03 - Steam Turbines Types PDFDokument49 Seiten03 - Steam Turbines Types PDFVimleshKumarSharma100% (1)

- F 0077 e 55Dokument6 SeitenF 0077 e 55Bùi Cảnh TrungNoch keine Bewertungen

- Feed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam AccumulatorsDokument74 SeitenFeed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam Accumulatorsbanukiran sambojuNoch keine Bewertungen

- Lesson Valve Maintenance and Valve Packing: Sub-ObjectiveDokument30 SeitenLesson Valve Maintenance and Valve Packing: Sub-Objectivemister pogi100% (1)

- Manual Cat Pump Model 45Dokument4 SeitenManual Cat Pump Model 45Jhon Jairo Maestre UribeNoch keine Bewertungen

- Vertical PumpsDokument16 SeitenVertical PumpsAdel ShatlaNoch keine Bewertungen

- Company Profile DetailedDokument54 SeitenCompany Profile DetailedRuby FernandesNoch keine Bewertungen

- VH60-100 Presentation Philippe ChabinDokument46 SeitenVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- Pump Motor TripDokument4 SeitenPump Motor TripKamal UddinNoch keine Bewertungen

- Theory of Steam TurbineDokument29 SeitenTheory of Steam Turbinefahdiarzz100% (1)

- Copt ManualDokument79 SeitenCopt ManualPradeep Shukla94% (17)

- Maintenance and Repair of Centrifugal PumpsDokument4 SeitenMaintenance and Repair of Centrifugal Pumpsaserf251Noch keine Bewertungen

- Lesson Positive Displacement Pumps Parts List & Function: Sub ObjectiveDokument14 SeitenLesson Positive Displacement Pumps Parts List & Function: Sub Objectivemister pogiNoch keine Bewertungen

- 325 Lanzhou 3NB1300C Instruction Manual PDFDokument21 Seiten325 Lanzhou 3NB1300C Instruction Manual PDFOilGasManNoch keine Bewertungen

- How To Acclimate Strawberry Plants - Stark Bro'sDokument5 SeitenHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNoch keine Bewertungen

- Growing Catfish in The PhilippinesDokument4 SeitenGrowing Catfish in The Philippinesmister pogiNoch keine Bewertungen

- 20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZDokument12 Seiten20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZmister pogi100% (1)

- Air Con 03 OverDokument30 SeitenAir Con 03 Overmister pogiNoch keine Bewertungen

- Lesson Introduction To CompressorsDokument12 SeitenLesson Introduction To Compressorsmister pogiNoch keine Bewertungen

- Manual For Welding InspectorDokument308 SeitenManual For Welding Inspectormister pogi100% (1)

- Atty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC ProceedingsDokument15 SeitenAtty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC Proceedingsmister pogiNoch keine Bewertungen

- Lesson Heating and CoolingDokument8 SeitenLesson Heating and Coolingmister pogiNoch keine Bewertungen

- SWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and SystemsDokument8 SeitenSWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and Systemsmister pogiNoch keine Bewertungen

- 10air Con04Dokument7 Seiten10air Con04mister pogiNoch keine Bewertungen

- Lesson Basic Air Conditioner SystemsDokument7 SeitenLesson Basic Air Conditioner Systemsmister pogiNoch keine Bewertungen

- Lesson Heat Pumps and Complete Air Conditioning SystemDokument14 SeitenLesson Heat Pumps and Complete Air Conditioning Systemmister pogiNoch keine Bewertungen

- Lesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration SystemsDokument4 SeitenLesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration Systemsmister pogiNoch keine Bewertungen

- Lesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet ValvesDokument15 SeitenLesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet Valvesmister pogiNoch keine Bewertungen

- Crane 2Dokument8 SeitenCrane 2mister pogiNoch keine Bewertungen

- Lesson Basic RiggingDokument15 SeitenLesson Basic Riggingmister pogiNoch keine Bewertungen

- Lesson Rigging SafetyDokument14 SeitenLesson Rigging Safetymister pogiNoch keine Bewertungen

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDokument26 SeitenLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNoch keine Bewertungen

- Steam Turbine Overhaul2Dokument7 SeitenSteam Turbine Overhaul2mister pogi100% (2)

- Lesson Guide For Periodic InspectionDokument3 SeitenLesson Guide For Periodic Inspectionmister pogiNoch keine Bewertungen

- Steam Turbine Overhaul1Dokument44 SeitenSteam Turbine Overhaul1mister pogi100% (2)

- Lesson Material Lifting & HandlingDokument3 SeitenLesson Material Lifting & Handlingmister pogiNoch keine Bewertungen

- Itp For Tank Fabrication & Installation Work1 - Rev02Dokument22 SeitenItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- Lesson Turbine Mainte0Ance ProgramDokument2 SeitenLesson Turbine Mainte0Ance Programmister pogiNoch keine Bewertungen

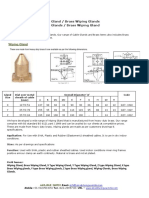

- Wiping Gland Brass Wiping Glands ManufacturerDokument3 SeitenWiping Gland Brass Wiping Glands ManufacturerUjjwal ShahNoch keine Bewertungen

- HORIZONTAL SPLIT CASE PUMPS SINGLE STAGE DOUBLE SUCTION Type AEFDokument20 SeitenHORIZONTAL SPLIT CASE PUMPS SINGLE STAGE DOUBLE SUCTION Type AEFKSBNoch keine Bewertungen

- Pengenalan DNDDokument53 SeitenPengenalan DNDAfiffudin Mukhlis Adtya100% (2)

- End Suction Frame Mounted Pumps: Series FDokument8 SeitenEnd Suction Frame Mounted Pumps: Series FSebei ChakibNoch keine Bewertungen

- Rotolok Rotary Valves Airlocks ATEX UK v5.6Dokument4 SeitenRotolok Rotary Valves Airlocks ATEX UK v5.6rheriNoch keine Bewertungen

- 1531 Pump LiteratureDokument6 Seiten1531 Pump LiteratureAnonymous 7xHNgoKE6eNoch keine Bewertungen

- 7600h - 7650h Cusher Pump Operation ManualDokument19 Seiten7600h - 7650h Cusher Pump Operation ManualYao WeiNoch keine Bewertungen

- 43877Dokument16 Seiten43877Carlos LagosNoch keine Bewertungen

- A - Series 332922DDokument20 SeitenA - Series 332922DИли.Я Или.ТыNoch keine Bewertungen

- WTA 11.9-S-SE DN15-125 NewDokument2 SeitenWTA 11.9-S-SE DN15-125 NewShah Rizal AbidNoch keine Bewertungen

- API 682 3rd For TrainingDokument46 SeitenAPI 682 3rd For TrainingJai-Hong Chung100% (3)

- ReM Product Accessory BOPDokument2 SeitenReM Product Accessory BOPgondhon069Noch keine Bewertungen

- Seal InstallationDokument1 SeiteSeal InstallationmriosqNoch keine Bewertungen

- AlphaFlo® - Warman Pump Replacement Parts ListDokument39 SeitenAlphaFlo® - Warman Pump Replacement Parts ListAlphaFloNoch keine Bewertungen

- Inspection of Compressors: OISD-120 Amended EditionDokument20 SeitenInspection of Compressors: OISD-120 Amended EditionNanu PatelNoch keine Bewertungen

- Iom FoupDokument60 SeitenIom FoupMuhammad Hasbi AsidiqiNoch keine Bewertungen

- M-28 PB Tapping MachineDokument70 SeitenM-28 PB Tapping MachinejuanchingarNoch keine Bewertungen

- OVHD Compressor Maintenance JobDokument8 SeitenOVHD Compressor Maintenance JobMuhammad Usman KaimkhaniNoch keine Bewertungen

- Fire Pump Brochure - BRISTOLDokument16 SeitenFire Pump Brochure - BRISTOLRudra Pandit0% (1)

- Ficha Tecnica Valvula Bola Acero Modelo 76 ApolloDokument8 SeitenFicha Tecnica Valvula Bola Acero Modelo 76 Apollogeorgeth21Noch keine Bewertungen

- Industrial Attachment ReportDokument20 SeitenIndustrial Attachment ReportAlbert OjiamboNoch keine Bewertungen

- Piping Plans Pocket Guide HorizontalDokument49 SeitenPiping Plans Pocket Guide Horizontalmuho1Noch keine Bewertungen

- Corrosion MonitorDokument79 SeitenCorrosion Monitorantony nirmalaNoch keine Bewertungen

- Merrimac Manufacturing BrochureDokument8 SeitenMerrimac Manufacturing BrochureChsymfniNoch keine Bewertungen

- Pressure Relief Valve: Disassembly, Inspection, and AssemblyDokument34 SeitenPressure Relief Valve: Disassembly, Inspection, and AssemblyVRV.RELATORIO.AVARIA RELATORIO.AVARIANoch keine Bewertungen

- Introduction To Booster Pump SystemDokument148 SeitenIntroduction To Booster Pump SystemWan Muhamad Faiz100% (1)

- Hydraulic Cylinder ServiceDokument8 SeitenHydraulic Cylinder Servicehesham farouk86100% (1)

- Installation, Operation and Maintenance Manual: JANUARY 31, 2018Dokument31 SeitenInstallation, Operation and Maintenance Manual: JANUARY 31, 2018DANIEL NICOLAS GONZALEZ SANCHEZNoch keine Bewertungen

- Barrier Cable Glands CMP PX2KX InstructionsDokument2 SeitenBarrier Cable Glands CMP PX2KX InstructionsMohammed MustafaNoch keine Bewertungen

- Clark 3 ManualDokument40 SeitenClark 3 ManualdavidNoch keine Bewertungen