Beruflich Dokumente

Kultur Dokumente

I 360041 A 007

Hochgeladen von

Abhijeet H Thaker0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten8 SeitenZeolite catalysts for hydrocracking and Hydroisomerization of n-dodecane. With a Pt / ca / Y-zeolite, a maximum of 48% I s obtained, and up to a 100% cracking conversion of the C12 pure primary cracking is achieved. The total observed branching of the cracked products is correlated to contributions of primary and secondary isomerization.

Originalbeschreibung:

Originaltitel

i360041a007

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenZeolite catalysts for hydrocracking and Hydroisomerization of n-dodecane. With a Pt / ca / Y-zeolite, a maximum of 48% I s obtained, and up to a 100% cracking conversion of the C12 pure primary cracking is achieved. The total observed branching of the cracked products is correlated to contributions of primary and secondary isomerization.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten8 SeitenI 360041 A 007

Hochgeladen von

Abhijeet H ThakerZeolite catalysts for hydrocracking and Hydroisomerization of n-dodecane. With a Pt / ca / Y-zeolite, a maximum of 48% I s obtained, and up to a 100% cracking conversion of the C12 pure primary cracking is achieved. The total observed branching of the cracked products is correlated to contributions of primary and secondary isomerization.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

Ze o I i te Cat a I ys t s

Hydrocracking and Hydroisomerization of n-Dodecane

Hans F. Schulzl and Jens H. Weitkamp

Carl Engler und Hans-Bunte-Institut f ur Lliineralol-und Kohleforschung und I nstitut f ur Gastechnik,

Feuerungstechnik und Wasserchemie der Universitat, Karlsruhe, West Germany

With a Pt/Ca/Y-zeolite, a C12-isomerization conversion maximum of 48% i s obtained, and up to a 100%

cracking conversion of the C12 pure primary cracking i s achieved. Pd/Mn-H/Y-zeolite and Pd/H/Y-zeolite

catalysts give poorer isomerization and show secondary cracking even at low cracking conversion level. Rel-

ative rates of individual primary and secondary cracking reactions ate given and related to the Clz-isomeri-

zate composition showing /3-scission proceeding from tertiary carbonium ions. 2-Methylisomers are primary

cracked products. Paraffin isomers with quaternary C-atoms could be produced by n-dodecane hydrocrack-

ing. The total observed branching of the cracked products i s correlated to contributions of primary and secon-

dary isomerization.

T he use of zeolites for heterogeneous catalysis, in particular

for mineral oil processing through reactions involving car-

bonium ions, in catalytic cracking, hydrocracking, and hydro-

isomerization is of increasing importance. Acidity and hydro-

genation activity of bifunctional zeolite catalysts may easily

be varied by ion exchange. Active components for hydro-

genation, normally noble metals such as platinum or pal-

ladium, are introduced to the pores of zeolites as ammonia

complexes and reduced to their elemental forms with hy-

drogen at ca. 500C. Thus, the metal is finely distributed,

probably mainly atomically in the pores of the zeolite

lattice (10, 16).

The composition of the reaction products from hydro-

cracking is principally dependent on reaction temperature

and the relationship of hydrogenation-dehydrogenation

activity to the acidity responsible for the cracking activity

of the bifunctional catalyst (1, 6, 8, 9, 11). The principal and

widely accepted reaction scheme of hydrocracking (6, 8, 12)

starts with the formation of olefins from paraffins at metallic

centers and the formation of carbonium ions from these

olefins at acidic centers. The ions may undergo rearrangement

and splitting according to certain rules of carbonium ion

behavior. Olefins resulting from carbonium ions are in turn

saturated to give a mostly paraffinic product. This general

reaction path of hydrocracking is by far simpler than that of

catalytic cracking, which involves additional polymerization,

alkylation, cyclization and aromatization, hydrogen transfer,

and coke formation that rapidly deteriorate catalyst activity.

Thus, hydrocracking is more accessible than catalytic crack-

ing to kinetic investigations.

Results of hydroisomerization on zeolite noble metal

catalysts have been publiqhed (3, 14, 16, bl ) , however, only

'To whom correspondence should be addressed.

by use of low molecular paraffins up to C7 as feed materials

which may easily be converted by isomerization associated

only with minor cracking. The products are analyzed without

great efforts. Hydrocracking of higher molecular paraffinic

hydrocarbons on highly active platinum on an amorphous

AlzO3- SiOz- catalyst has been reported by Coonradt and

Garwood (6) who pointed out the possibility of pure primary

cracking and the high degree of isomerization of the un-

cracked feed. However, no detailed analyses of cracked and

isomerized products were given. Literature on hydrocracking

of pure hydrocarbons with zeolite catalysts is limited (2,4,21).

Experimental

For the present investigation the following three catalysts

were used: 0.5% Pt/Ca/Y-zeolite (SK 200), 0.5% Pd/Mn-

H/Y-zeolite (SK 110), 0.5% Pd/H/Y-zeolite (SK loo), all

supplied from Union Carbide I nternational Corp., Linde

Division. The reaction conditions were molar ratio Hl/n-

dodecane =20, LHSV =1.0 h-l, and pressure =40 atm.

The reaction temperature was varied in the range from 250-

400C according to catalyst activity and required degree of

conversion. The high analytical sensitivity permitted quan-

titative results even at low conversion levels. Purity of n-

dodecane feed material was controlled by gas chromatography.

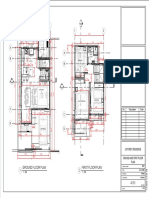

The flow type fixed bed reactor was designed for quantita-

tive experiments at small throughputs of 1-5 grams of hydro-

carbon feed per hour (Figure 1). The problem of continuously

feeding at a constant rate-e.g., only 1 gram n-dodecane per

hour to the reactor-was solved with a special saturator.

The n-dodecane in an amount of 50 grams was impregnated

on inactivated kieselguhr (100/100 g/g). This material was held

at an appropriate temperature in the saturator where the

stream of hydrogen passed the packing. The equilibrium

vapor pressure was attained even in about 1 mm of bed

46 Ind. Eng. Chem. Prod. Res. Develop., Vol. 1 1 , No. 1 , 1972

height. Thus, the hydrocarbon concentration in the feed gas

is independent of flow, and almost all of a saturator filling

can be used without changes in feed rate. For long duration

tests a second saturator in a parallel feed line is used.

For quantitative recovery of the hydrocarbons from the

product stream, two traps at liquid air temperature were used,

the second filled with activated carbon for quantitative ad-

sorption of methane. Condensate and adsorbate were sepa-

rated in fractions of liquid and gaseous hydrocarbons whose

quantities were accurately determined at room temperature.

The gaseous hydrocarbons with compounds up to CS were

analyzed with a reoplex modified Ak1203gas chromatographic

column by applying a temperature program up to 190OC.

The liquid hydrocarbons were separated with 100-mm film

capillaries containing polypropylene glycol and squalane as

liquid phases. Temperature programmed capillary gas chroma-

tography of complex hydrocarbon mixtures Ca-Cle was re-

ported in earlier publications (18, 19).

Quantitat'ive values for individual hydrocarbons could be

derived from the chromatogram for almost all compounds

produced by cracking and in the (212-isomerizate fraction for

methylundecanes and ethyldecanes. Multiple branched Clz-

hydrocarbons were calculated cumulatively.

The electronically int'egrated values of peak areas from the

different chromatograms and the values of fraction quantities

were fed to a digital computer for total evaluation of each

experiment.

Results and Discussion

Cracking and I somerization Conversion. At a sufficient

high hydrogenat,ion activity of the catalyst and correspond-

ing high hydrogenation and dehydrogenation rat'es, a

ready exchange of chemisorbed CI 2-carbonium ions with

Clz-olefins from t,he gas phase takes place. Part of the

CI:-carbonium ions desorbs from the catalyst surface after

rearrangement (but before C-C cleavage) to give branched

olefins which, in turn, are hydrogenated to branched Clz-

paraffins. At low hydrogenation activity of the catalyst, in

general, only reactions in the sequence Clz-paraffin -+C12-

olefin - Clz-carbonium ion -+cracked products <Clz are

possible, and only low concentrations of branched feed hydro-

carbons can be detected in the reaction product.

Figure 2 shows the cracking and isomerization conversion

0 P t/ C O/ Y - ZEOLI TE

A Pd/Mn-H/Y-ZEOLI TE

N -DODECANE-

SATURATOR ''

C

EACTOR

G H

Figure 1 . Scheme of small scale reaction apparatus for

hydrocracking

(A) Active carbon plus molecular sieve tube for Hz-purification; (B) molten

salt bat h f or saturator t emperat ure control; (C) n-dodecane on kieselguhr;

(D) heat ed connection tube; (E) preheati ng zone; (F) 2 ml of catal yst, 0.2-

0.3 mm; ( G) liquid ai r cooling t r ap; (H) act i vat ed carbon t rop at liquid

ai r t emperat ure

as a function of temperature for different hydrocracking

catalysts. The additional curves for Co-Uo-&0s-SiO2,

sulfided CO-I LI O-A~~O~-S~OZ, and Co-hIo-Al2O~ were ob-

tained with n-hexadecane under similar conditions (23, 20).

The various catalysts are active in different regions of re-

action temperature-e.g., Pt/Ca/Y-zeolite below 300C

and CO-?\.IO-AIZOS at about 450OC. But the principal shape

of the curves is similar in most cases where there is a sufficient

hydrogenation activity related to cracking activity. The

conversion by isomerization increases with temperature and

then goes through a maximum when increasingly isomerized

Clz-molecules are cracked.

The different behavior of the sulfided Co-Mo-AlzO~-

SiO& catalyst with its relatively low hydrogenation activity

as related to its high acidity shows the transition in reactions

to normal catalytic cracking with a low maximum of feed

hydrocarbon isomerization conversion of only ca. 5%. On

Pt/Ca/Y-zeolite the maximum of isomerization conversion

of 48% is found at a cracking conversion of only 17% at

Figure 2. Hydrocracking and hydroisomerization conversion

Dependence on reacti on t emperat ure f or di f f erent bi functi onal catalysts

Ind. Eng. Chem. Prod. Res. Devel op., Vol. 1 1 , No. 1, 1972 47

Tabl e I. Mol ar Di stri buti on of Cracked Products wi t h Pt/Ca/-, Pd/Mn-H/-, and Pd/H/Y-Zeol i t e

Catal ysts at Di fferent Reacti on Temperatures

Moles of cracked products per 100 moles of C12cracked

Catalyst Pt/Ca/Y-zeolite . ~~_ _ PdlMn-H/Y-zeolite Pd/H/Y-zeolite

Temp, OC 265 275 285 300 350 250 275 300 325 350 400 275 300 325 350

CL2--

Conversion, yo

Cracking

Clz-isomerization

Methane

Ethane

Propane

13utaiies

Pentanes

Hexanes

Heptanes

Octanes

Konanes

Decanes

Undecanes

- c.4 +Cs 29.6 30.5 31.2 30.4

cs+c7 42.3 41.5 41.4 41.7

5 17

34 48

. . . . . .

. . . . .

6.7 6.7

29.7 30.4

42 3 41.9

43.5 43.5

42.3 41.2

29.5 30.7

6.3 6.0

. . . . . .

. . . . . .

' 12-*

56

35

. . .

, . .

7. 0

31.8

41.9

42.9

41.0

30.6

5.9

. . .

+ e4+cs 31.2 18.6 15.3

+ C6 +c7 41 4 33.7 32.3

C6 +c6 21.4 22.1 22.2

- c3+C4 +cs . . . 16.6 20.8

99.5 100

0.47 . . .

0.1 0.5

0.1 0.6

9.0 48.5

38.9 101.2

46.3 66.4

44.2 43.3

40.3 8.1

25.9 . . .

3.4 . . .

. . . . . .

. . . . . . .

5

5

0.1

11.7

48.0

48.9

43.8

36.7

23.0

2.7

. . .

. . .

. . .

12 50

18 31

0.2 0.2

14.8 17.5

52.6 55.0

50.6 51.6

44.0 44.2

34.7 33.7

20.8 18.6

2.1 2.1

. . . . . .

. . . . . .

. . . . . .

100

. . .

0.1

0.3

19.6

57.3

53.2

44.2

32.9

16.9

1.6

. . .

. . .

100

. . .

0.4

1.1

42.9

89.9

62.0

45.6

16.2

1. 4

0.1

. . .

. . .

00

. . .

2.9

4.6

76.0

05.8

64.6

35.1

0.4

. . .

. . .

. . .

. . .

16

2.9

0.2

18.2

55.6

52.5

43.7

34.0

17.2

2.5

. . .

. . .

30

3.0

0.2

20.9

56.8

52.2

43.1

33.4

16.9

2. 3

. . .

. . .

. . .

49

3.0

0.2

22.1

57.8

53.9

44.3

32.3

15.3

2.1

. . .

. . .

63

2.2

0.1

0. 4

27.3

63.8

55.1

44.4

28.1

12.6.

2.5*

. . .

. . .

Total moles 200 200 201 208 269 215 220 223 226 260 289 224 226 228 234

a Inrluding 0.6 mole aromatics. * Including 0.8 mole aromatics.

275OC. Complete cracking of the Clz-feed is attained already

at 300C. The conversion of n-Clz by isomerization at low

temperatures (250-265C) on Pt/Ca/Y-zeolite is 7-10

times greater than that by cracking, showing a much greater

rate for carbonium ion rearrangement than for carbonium

ion cleavage. With Pd/Mn-H/Y-zeolite the lower hydro-

genation-dehydrogenation activity of the catalyst is limiting

for isomerization conversion, its maximum being only 30%.

At low temperatures conversion by isomerization is slightly

higher than that of cracking.

Distribution of Cracked Products. Table I gives the

molar distributions of the cracked products on the basis of

100 moles of n-dodecane cracked. On Pt/Ca/Y-zeolite

the sum of moles of cracked products is approximately

equal to 200 over almost the total region of cracking

conversion from 0- loo%, showing pure primary cracking.

There is a sufficient supply of C12-olefins by fast dehydro-

genation for immediate displacement of lower carbonium ions

from the acidic sites to prevent their secondary cracking.

The distribution of cracked products is symmetrical to C g

(half the C12feed molecule) with approximately equal values

for Cg, (26, and (27. Values for CS and are about 2/ 3 of the

former, and values for Cs and CB are relatively small. C1, Cz

and Cln, CI1 products are materially absent.

With Pd/Mn-H/Y-zeolite, even at a low conversion level

secondary cracking occurs and ranges from 15-26% with

increasing primary cracking conversion from 0 to ea. 100%.

The molar distribution of cracked products is correspondingly

asymmetrical with higher values for Cs, C4, and C3than for

C7, CS, and CQ, respectively. At higher temperatures than those

necessary for 100% of cracking conversion, the sum of moles

increases rapidly, and a sharp maximum at Cq is obtained.

Probability of Cracking Reactions. From the molar

distribution of cracked products, the relative probabilities

of distinct cracking reactions can be derived. This is

particularly true for the exclusive n-dodecane primary

cracking on the Pt/Ca/Y-zeolite catalyst. I n Table I1

this selectivity of dodecane cracking to CB +CS, C4 +CS,

C6 +C7, and C6 +C6 is reported.

The low values of cleavage to CB +CS could be related to

energetic effects since the C3fragment cannot form a tertiary

ion. But a remarkably low value of ea. 30Y0for the reaction

to C4 +CS cannot easily be explained because both fragments

can form energetically favored tertiary carbonium ions.

I sobutane is a common product of ionic hydrocarbon cracking.

A slight increase in the probability of this reaction with tem-

perature is observed. This selectivity will be discussed later

in coiinectioii with isomerization reactions which inseparably

accompany ioiiic cracking.

The probabilities of overall cracking reactions on Pd/Mn-

H/Y-zeolite and Pd/H/Y-zeolite can also be calculated from

48 Ind. Eng. Chem. Prod. Res. Develop., Vol. 11, No. 1 , 1972

the molar distributions of the cracked products and are

listed in Table I11 along with those for primary cracking on

Pt/Ca/Y-zeolite for a 50% cracking conversion level.

The different values are obtained as follows: Reaction to

Cg +C3as moles of Cg, to Cs +Cq as moles of CS, to C? +

C5 as moles of C7, to Cg +cgas half the moles of C6, to C3+

C4 +Cg as the mean value of the differences of moles C3 -

C9and C5 - C7, and to C4 +Cq +C4 as l / 3 of the difference

between (C4 - Cs) and (C3 - Cg)/2 +(C5 - C7)/2. For

extensive secondary cracking at higher temperatures, the

negligence of t'he reaction c12to e6+C3 +c3is not tenable.

I n t'he case of secondary cracking, the reaction to C3 +

Cq+C s is obviously favored to C4 +C4 - t C4. h'ote the minor

secondary cracking of ( 26 as is seeii from almost the same

values for C6in all three distributions.

Thorough examination of all experimental data showed

that, as a good approximation, averaging the values of pri-

mary cracking observed with Pt/Ca/Y-zeolite (Table 11)

yields the probabilities of primary cracking reactions on

Pd/hln-H/Y-zeolite and Pd/H/Y-zeolite. On this basis the

probabilities of the single secondary cracking reactions can

be calculated and are given for the Pd/Mn-H/Y-zeolite at

5070 conversion in Table IV.

The contributious of the primary cracking products as

sources for secondary cracking follow the order C,S (11.8) >

CI (8.0) >cs (4.3) >C6 (<0.2) whereas the percentage

of primary products converted to lower molecular-weight

compounds by secondary cracking follows the sequence

C9 (67%) >CS (39%) >C7 (19%) >c6(<I %) with the

principally expected relative cracking probability in de-

pendence of molecular weight.

The remarkably sharp decrease in cracking reactivit,y from

C7 to Ce is the reason why n-paraffinic fractions up to C6

can be extensively isomerized with only minor cracking.

There is a surprising selectivity of these secondary cracking

reactions-e.g., 4.3 C9 convert to 0.9 (C3 +C6) and 3.4

(C4 +Cs), but 11.8 CS convert to 5.2 (C3 +Cj) and 6.6

(C4 +Cq), showing for cracking of CS an almost equal prob-

ability of splitting a C3 or C4fragment from a CS chain, but a

much lower probability for C3 t'haii C4 to be split from a Cg

chain.

Isomeri zati on of Cracked Products and Feed Hydro-

carbon. The extensive determination of individual iso-

mers in t,he reaction products is the basis for the discussion

of carbonium ion rearrangements involved in the hydro-

cracking reactions. I n principle one must question whether

isomerization takes place before or after the cracking steps

and how great tlie respective coutribution of these possi-

bilities is to total isomerization. I n spite of the important

mechanistic role of olefins, the reaction products may gener-

ally be regarded as paraffinic. Other types of hydrocarbons are

present only i u minute quantities (olefins <O.l %, naphthenes

<I %).

I n Table V the composition of the carbon number fractions

of the reaction products of n-dodecaue hydrocracking with the

three noble metal zeolite catalyst's at different characteristic

temperatures is listed.

Thermodynamic Considerations. The isomer composition

of paraffinic cracked products from hydrocracking with

bifunctional catalysts, especially at low temperatures, is

mainly governed by the kinetics of the reactions. I n particular

tlie ratios of iiidividual monomethyl paraffins to the corre-

sponding n-para%iis are greater than those for thermodynamic

equilibrium whereas the amounts of dimethyl compounds, es-

pecially those with quaternary C-atoms, are much smaller.

EOUILIBRIUM PI/Co/Y-ZEOLITE Pd/Mn-H/Y-ZEOLITE P d/H/Y - ZEOLl 'i

3- ME- PENI ANE 3-ME-PENTANE

P

1 2-ME-PENTANE 1 2- ME- f ' ENI AN~ 2-HE-PENTANE 2-ME-PENTANE

]

Mo

TEMPERAIURE. ' C

Figure 3. Thermodynamic equilibrium and experimental

composition of hexane fraction for different catalysts and

temperatures

Tabl e IV. Rel at i ve Probabi l i t y of Pri mary and Secondary

Cracki ng Reacti ons of n-Dodecane on Pd/Mn-H/Y-

Zeol i t e at 50% Cracki ng Conversi on

Temp, 3OOOC

Pri mary cracking Secondary cracking

I n Figure 3 the composition of the C6-fraction of the cracked

products from n-dodecane with Pt/Ca/Y - zeolite, Pd/Mn-

H/Y - zeolite, and Pd/H/Y-zeolite is plotted over the

reaction temperature along with the equilibrium com-

position. The accuracy of isomer equilibrium cornposition

calculated from thermodynamic values of literature (1 7 )

is debatable. According to our results considerable discrepan-

cies seem to exist, but the calculated values reflect the trends

in changes of isomer composition with temperature.

With increasing temperature the experimental composi-

tion alters toward that of equilibrium. The products at

low temperature are characterized by high values for 2-

methylpentane and low values for 2,2-dimethylbutane. At a

reaction temperature higher than that necessary for 100%

cracking conversion, there is a fast increase for 2,2-dimethyl-

butane, especially with Pt/Ca/Y- zeolite, indicating a fast

increase of secondary isomerization possibilities. This is of

importance under the practical aspects of producing high

octane number gasoline by hydrocracking and will be reported

in detail in a later publication. It is also of theoretical interest,

since i t has bren repeatedly stated in the literature that com-

pounds with quaternary C-atoms do not form by hgdro-

cracking ( 7, 8) .

Ind. Eng. Chem. Prod. Res. Devel op., Vol. 1 1 , No. 1 , 1972 49

Tabl e V. Composi ti on of Reacti on Products f r om n-Dodecane Hydrocracki ng

Cat al yst

Temp, " C

n-Butane

I sobutane

%-Pentane

I sopentane

%-Hexane

2-Methylpentane

3-Methy lpentane

2,3-Dimethylbutane

2,2-Dimethylbutane

n-Hep t ane

2-Methylhexane

3-Me thylhexane

3-Ethylpentane

2,3-Dimethylpentane

2,4-Dimethylpentane

2,2-Dimethylpentane

3,3-Dimethylpentane

2,2,3-Trimethylbutane

n-Octane

2-Methylheptane

3-Methylheptane

3-E thylhexane

4-Methylheptane

2,3-Dimethylhexane

2,CDimethylhexane

2,5-Dimethylhexane

3,4-Dimethylhexane

2,2-Dimethylhexane

3,3-Dimethylhexane

2-Ne thyl-3-ethylpentane

n-Sonane

2-Methyloctane

4-Methyloctane

3-Methyloctane

3-Ethylheptane

2,3-Dimethylheptane

2,4-Dimethylheptane

2,5-Dimethylheptane

3,5-Dimethylheptane

2,6 +4,4-Dimethylheptaneo

3,4-Dimethylheptane

2,2-Dimethylheptane

3,3-Dimethylheptane

n-Dodecane

2-Methyluhdecane

3-Methylundecane

4-Methy lundecane

5-Methy lundecane

6-Methylundecane

3-Ethyldecane

4-Ethyldecane

5-Ethyldecane

Multiple branched dodecanes

Mol % in carbon number fraction

Pt/Ca/Y-zeol i te

275 300 ' 350

32.6

67.4

a5.3

74.7

21.9

47.5

26.4

3.9

0 . 3

17.2

40.0

32.7

1. 8

4. 3

3. 2

0. 5

0. 3

0.0

14.2

28.9

28.1

3. 3

9. 8

2.6

5.2

5. 4

1 .o

0. 9

0. 5

0.1

8. 9

39.7.

22.0

3. 1

1. 9

3. 6

9. 5

2. 2

3. 8

4. 1

0. 7

0.5

42.9

5. 5

7. 1

6. 3

7. 0

3.7

1. 2

2.2

2. 3

21.8

34.8

65.2

25.7

74.3

24.1

43.5

26.3

3.7

2. 4

19.3

31.7

32.3

2. 2

5.0

3. 5

3. 4

2. 3

0. 3

15.1

21.3

24.6

3. 6

9. 1

3. 8

7. 9

5.5

1. 9

3. 8

2. 8

0.6

10.2

30. Se

17.3

3. 1

3. 4

5.5

10.1

2. 9

5. 9

5. 2

3. 1

2.5

11.5

6.7

8.1

6. 4

8. 3

4. 5

1. 5

2. 9

3.6

46.5

36.2

63.8

33.3

66.7

21.4

32.1

24.7

7. 4

14.4

15.7

26.1

30.4

2. 2

8. 2

5. 6

5. 6

4.4

1. 8

a

Pd/Mn-H/Y-zeolite

275 300 350

29.3

70.7

19.1

80.9

15.3

47.7

28.1

8. 3

0. 6

11.8

36.5

32.2

1.7

IO. 1

6. 3

0. 6

0. 5

0. 3

9. 5

24.4

29.2b

9. 8

5. 4

9. 0

9. 2

2. 1

0. 8

0. 4

0. 2

6.9

19.5

16.0

17.5

2. 3

4.9

5. 1

16.7f

6. 1

4.6

0. 2

0. 2

79.6

2.0

2. 8

2. 6

2. 8

1. 5

0.6

0. 8

0. 9

6. 4

33.3

66.7

20.9

79.1

19.2

44.6

27.5

7. 9

0. 8

15.6

34.3

31.9

2.0

8. 8

5.7

0. 8

0. 6

0.3

14.6

23.5

28.7b

9. 6

4. 7

8. 2

6. 4

2. 0

1. 2

0. 8

0. 3

10.2

19.2

15.6

17.6

3. 2

3.9

5. 4

13.2f

5. 0

4. 5

1. 1

1. 1

38.6

5. 0

6.6

6. 0

6. 4

4. 1

1. 6

2. 5

2.6

26.6

37 4

62 6

27 2

72 8

23 5

36 4

26 5

7 4

6 2

18 1

25 8

30 3

2 4

8 1

5 3

4 6

3 9

1 5

17 1

16 6

24 7b

8 0

4 1

8 1

10 l c

3 8

3 7

3 3

0 5

d

Pd/H/Y-zeol i te

275 300 350

25.5

74.5

11.7

88.3

9. 2

50.6

29.1

10.5

0. 6

7. 3

36.9

32.9

1. 6

11.7

8. 6

0.5

0. 3

0. 2

6. 4

24.1

28.3'~

9.2

6. 0

12.3

11.1

2.0

0. 3

0.2

0. 1

6.2

18.8

15.8

16.4

1. 5

3. 5

11.9

15.5'

6. 8

3. 6

0.0

0.0

96.53

0.25

0.39

0.28

0.40

0.21

0.06

0.09

0.09

1.70

30.9

69.1

18.0

82.0

14.5

46.7

27.8

10.4

0. 6

11.4

35.3

32.4

1. 6

10.5

7. 6

0. 5

0.4

0. 3

10.3

23.2

28.4b

10.1

5. 3

10.7

9. 0

2. 1

0. 5

0. 3

0.1

8. 5

18.0

15.9

16.3

1. 7

3. 5

10.9'

14.6f

6. 6

4.0

0.0

0.0

95.68

0.34

0.51

0.41

0.54

0.28

0.10

0.13

0.16

1.85

36.7

63.3

20.0

80.0

15.5

45.1

28.4

10.3

0. 7

12.2

34.3

32.8

1. 9

10.3

7. 1

0. 5

0. 5

0. 4

11.8

23.0

29.6b

9. 7

4.9

9. 8

7. 8

2. 2

0. 6

0. 3

0. 3

11.4

16.9

15.8

17.5

2. 4

3. 6

9.2

12,2/

5. 8

4. 4

0. 4

0. 4

94.08

0.46

0.73

0.62

0.80

0.43

0.15

0.25

0.27

2.21

a At 350C, no octanes, nonanes, and dodecanes in product. 3-RIethylheptane aqd 3-ethylhexane not resolved. Peak overlapping with

At 35OoC, no nonanes and dodecanes in product. e 2-Methyloctane and 4-methyloctane not resolved. 1 2, s- a naphthenic compound.

Dimethylheptane and 3,5-dimethylheptane not resolved. Q 2,6-Dimethylheptane and 4,4-dimethylheptane not resolved.

50 Ind. Eng. Chem. Prod. Res. Devel op., Vol. 11, No. 1, 1972

I ' " ' ' I " ' ' ' ' I ' T I

P I /Co/Y - ZEOLI TE PdIMn-HIY-ZEOLIIE Pd/H/Y-Zf OLllE

I

1M 180 300

P 2u

L

260 280 30

I f MPEPAI URE, 'C

280 100 310 340

Figure 4. Influence of temperature on isomerization of f eed

and cracked products

Influence of Reaction Temperature. Figure 4 shows the sum

of moles of branched paraffins in carbon number fractions

of the products in dependence of reaction temperature for the

three zeolite catalysts. Note the following interrelationships:

For all catalysts at higher reaction temperatures, the con-

tent of branched hydrocarbons in the CIZ feed fraction in-

creases but decreases in the cracked products. A comparison

of the three catalysts shows that branching in the cracked

products gives the highest values and branching in the C12-

fraction the lowest. But the differences between the three

catalysts are much greater in the degree of isomerization of

the '212-fraction than of the cracked products.

The difference in the degree of Clz-isomerization with the

three catalysts can be related to the differences in hydrogena-

tion activity, permitting a high isomerization when the re-

action Clz paraffin + CIZ olefin is fast, compared with that

of carbonium ion cleavage. The chemisorbed Clz secondary

carbonium ions resulting from n-olefin addition to the proton

of an acidic center are mainly rearranged to tertiary ions.

For fast exchange of n-Clz olefins from the gas phase with

branched C12carbonium ions, the mean degree of branching

of the chemisorbed C12carbonium ions is lowered, resulting

in a decrease of branching in the cracked products. I n addition

the degree of branching in the cracked products is lowered by

easy availability of Cl2 olefins and fast exchange between Clz

olefins with lower carbonium ions from cracking, resulting

in a shorter residence time of the cracked products at the

acidic centers and a corresponding reduction of their secon-

dary rearrangement and cleavage probabilities.

With increasing reaction temperature the C12-isomerization

conversion increases because of the increase in C12 olefin

and carbonium ion exchange rate. But the degree of isomer-

ization in the cracked products is lowered because of the in-

crease in relative stability of secondary carbonium ions re-

lated to that of the tertiary ones. A different hydrocracking

reaction is observed with bifunctional catalysts of only

minor acidity as Co-hIo-A120s. I n contrast to our results,

hydrocracking of n-hexadecane at a low cracking conversion

level yields almost totally n-paraffinic cracked products,

indicating a hydrogenolytic cleavage of carbon-carbon bonds.

Feed isomerization is nevertheless observed at higher con-

version levels and is supposed to proceed at the weakly

acidic centers of the A1203(IS, 20).

Temperature Influence for Individual Isomers. If we assume

that carbonium ion cleavage generally starts from tertiary

ions (according to the rule of 0-scission) , 2-methylparaffins

should be kinetically favored cracked products. However,

- Hz

0.8 1 i

in m 19 Irn

Figure 5. Influence of reaction temperature on ratio 2-

Me-al kane/3-Me-al kane in hexane and heptane fraction

with different catalysts

I EMP ERAI URi . 'C

Figure 6. Influence of reaction temperature on n-dodecane

isomerization with Pt/Ca/Y-zeolite

this selectivity is widely reduced by the fast methylshift

isomerization reaction and can only be observed in the com-

position of the cracked products where it is favored by low

temperature arid conditions of low secondary isomerization,

in particular, with a high hydrogenation activity of the

catalyst when there is a rapid displacement of the cracked

product ions from the acidic centers by C ~Z olefins. These

interrelationships are confirmed by Figure 5 which shows the

ratio of 2-methyl to 3-methylisomers for Cg and C, for the

three catalysts in dependence of reaction temperature.

The experiment,al ratios for the cracked products start with

high values at low temperature, the corresponding ratios at

low temperature being greater for Pt/Ca/- than for Pd/SIii-

H/- and for Pd/H/Y-zeolit'e. With increasing temperature

a decrease of ratios 2-Me-alkane/3-hIe-alkaneJ especially in

the range of temperature necessary for lOOyocracking coii-

version, is observed. Further increase in temperature does

not change the ratios substantially. Their values are in agree-

ment with those reported for equilibrium by CiaIIett'a arid

Hunter (b). This is proof of the primary character of 2-

methylparaffins as products of n-paraffin cracking and a fast

methylshift reaction as compared with desorption rate of the

carbonium ions. The same behavior occurs for the ratio 2-

methyl- to 3-methylparaffins at C,.

Composition of C12Fraction. With increasing temperature

occurs an increase in monobranched paraffins. With a greater

gradient an increase in multiple-branched paraffins in the C ~Z

product fraction is observed (Figure 6). EthyIparaffins C12

are kinetically derived from methylparaffins C12 by a fast

Ind. Eng. Chem. Prod. Res. Devel op., Vol . 1 1 , No. 1, 1972 51

---A-

t

N-OOOECANE - CL + i g

c5 c 7

'1-2 H I I

wy' -

N-OOOECENE

'1, H@

CARBONIUM SEC:C,2 I ONS -

A- *

c e

-

I I - H @ +2 H

METHYLUNOECANES

Figure 7. Mechanism of primary n-dodecane hydrocracking

alkylshift reaction ( I S , 20) and, therefore, kinetically belong

to the same group of isomers.

At higher isomerization conversion levels, the increasing

gradient for the formation of multiple-branched paraffins

can be partially related to multiple adsorption and desorption,

but at a low conversion level the observed degree of isomeriza-

tion, even to dimethyl CI, compounds, should be produced

during one chemisorption step. The extensive hydroisomer-

ization associated with hydrocracking of paraffins results in

Considerably low pour points of the products, a quality es-

pecjally demanded for jet fuels.

The composition of the monomethyl C12fraction (Table VI )

varies only gradually with temperature. The small value for

6-methylundecane is due to only half the statistical prob-

ability for formation of this isomer as compared with the

~ ~ ~ ~~~~

Tabl e VI. Composi t i on of Cl z-Monomet hyl i somers

(Mol %) on Pt /Ca/Y-Zeol i t e at Di f f erent

React i on Temperat ures

Temp, OC

Isomer 2 5 0 265 275 205 300

2-Methylundecane 13 6 16 8 18 7 19 9 19 7

3-Methylundecane 24 3 24 3 24 1 24 0 23 8

4-Methylundecane 23 0 21 9 21 2 20 4 19 0

5-Methylundecane 26 3 24 7 23 5 22 9 24 4

6-Methylundecane 12 8 12 3 12 5 12 8 13 1

others. The low values for 2-methylundecane correspond for

the first to a general thermodynamic tendency for methyl-

branching in the 2-position as compared to branching at

internal positions of a paraffinic chain. But considerably low

values for 2-methylundecane at low temperatures do occur,

indicating a remarkably low rate of its formatioii from the

n-aliphatic chain. This kinetically controlled trend for 2-

methylparaffins as isomerization products follows the opposite

direction than that of 2-methylparaffins as cracked products

when changing the temperature.

Relationship Between CI2 Isomerizate Composition and Prob-

ability of Individual Cracking Reactions. As pointed out earlier,

carbonium ion cleavage at low temperatures substantially

proceeds after rearrangement and starts from the tertiary

ions, thus making possible an interrelationship between C1.

isomerizate composition and probability of individual crack-

ing reactions as indicated in the reaction scheme of Figure 7.

I n Table VI1 a comparison is given between the composi-

Tabl e VII. Rel at i onshi p Bet ween Composi t i on of Monomet hyl undecanes (Mol yo) and

Probabi l i t y of Pr i mar y Cracki ng Reacti ons on Pt /Ca/Y-Zeol i t e

265' Ct % - 275' C, %

Met hyl - Met hyl -

205' C, %

Methyl -

undecaner Reaction undeca.ner Reaction undecaner Reaction

2-Methylundecane

- c4 +cs

6-Methylundecane

- c4 +cs

3-Methylundecane

- cs+c7

5-Methylundecane

-+Cs +CTi -+ Ca +CS

4-Methylundecane

* C6 +c6

29.1 29.6 31.2 30.5 32.7 31.2

49.0 48.8 47.6 47.8 46.9 47.6

21.9 21.7 21.2 21.7 20.4 21.4

Tabl e VIII. Tot al , Pri mary, and Secondary Isomeri zat i on Branchi ng Steps f or n-Dodecane

Hydrocracki ng wi t h Di f f erent Cat al yst s and Temperat ures

Values related to 100 moles of Clz cracked

Reaction Pt/Co/Y-zeol i te Pd/Mn-H/Y-zeolite Pd/H/Y-zeolite

temp, Pri mary Secondary

Total Pri mary Secondary Total Pri mary Secondary Tot al

OC

250

265

275

285

300

163 115

163 127

163 138

163 149

167 153

48

36

25

14

14

190 127 63

183 132 51

174 143 31

196 149

182 143

47

39

52 Ind. Eng. Chem. Prod. Res. Devel op., Vol. 1 1 , No. 1, 1972

tion of the rnonon.iethylisomers Cl, and the probability of

individual cracking reactions at different reaction tempera-

tures in the temperature range of pure primary cracking

mit,h Pt/Ca/Y - zeolite.

These values show remarkable consistency and are re-

garded as proof of the reaction scheme in Figure 7. I n par-

ticular t'his reaction scheme explains the low values for the

cracking react'ion of Clz to C4 +CS as a consequence of the

low values of the tertiary 2-methylundecyl and &methyl-

undecyl cations from which the primary products Cc +CS

we derived. In addition t'he reaction scheme holds for t'he

slight increase in probability of this particular primary

cracking reaction with temperature, owing to the small rate

of formation of the 2-methylundecyl cation at low tempera-

tures. The selectivity of primary cracking reactions does not

substantially alter with increasing Clz-isomerization to di-

met'hylparaffins because a similar suppression of 2-methyl

branching for t'his group of isomers is expected.

Pri mary and Secondary I somerization of Cracked

Products. On the basis that n-paraffin hydrocracking at

I OK temperatures includes isomerizat,ion of secondary

to tertiary carbonium ions and these are cleaved, it is

possible to distinguish between primary isomerization

taking place at the stage C12 before cracking and secondary

isomerization at the stage of the smaller cracked products

after cracking (Table VIII).

Total isomerization of the cracked products is calculated as

the number of tertiary C-atoms in the cracked products per

100 moles of cracked dodecane. A quat'ernary C-atom is

taken as two tertiary C-at,oms because it is probably formed

by alkylshift from a dialkylisomer with two tertiary C-atoms,

and thus two branching steps are involved for its formation.

Primary isomerization is derived from the composition of the

C12 isomerizate as the number of tertiary atoms per 100

moles of branched C1? paraffins in the product. Secondary isom-

erization is calculated as the difference of total and primary

isomerizat,ion.

The values of Table VI I I show that at low temperature

at least */ 3 of the total isomerization originates from branching

steps before cracking. Total isomerization increases with

decreasing hydrogenation activity, especially because of a

greater contribution of secondary isomerization owing to a

greater residence time of the smaller carbonium ions from

cracking at the acidic sites. The decrease of the values for

secondary cracking with increasing temperature may occur

partially because with increasing t'emperature, more secondary

carbonium ions might be cleaved. Thus, by the applied method

of calculating, a greater proportion of total isomerization is

regarded as primary iustead of secondary.

Conclusions

The reactions of chemisorbed carbonium ions have been the

subject of intensive scientific discussions in connection with

catalyt8ic cracking on acidic catalysts. But the complexity of

the sit'uation, owing to iiumerous consecutive reactions at the

necessary high temperature level, only allowed the decision

of general trends but no determination of individual reaction

paths. With strongly acidic molecular sieves combined with a

highly active dehydrogenation-hydrogenation catalyst in the

presence of hydrogen, a much lower reaction temperature can

be applied. If the formation of carbonium ions is feasible via

olefins, the selectivity of the primary reactions of the car-

bonium ions becomes observable. Thus, from the present re-

sults i t appears that secondary carbonium ions, derived from

n-paraffins and n-olefins, respectively, are rearranged to

tertiary cations. These are split under formation of 2-methyl-

branched chains as primary products which might be re-

arranged, in turn, with the relative rates of individual

reactions strongly governed by competitive chemisorption.

Acknowledgment

The authors express their sincere gratitude to H. Pichler,

Director of the Carl Engler und Hans-Bunte-I nstitut fiir

Rlineralol-und Kohleforschung and the I nstitut fiir Gastech-

nik, Feuerungstechnik und Wasserchemie der Universitat

Karlsruhe.

literature Cited

(1) Archibald, R. C., Greensfelder, B. S., Holemann, G., Rowe,

I). H., Ind. Eng. ChPm., 52, 745 (1960).

(21 Beecher. R.. Voarhies. A,. .J r.. Eberlv. P.. J r.. Ind. Ena.

" I I I

Chem. Prod.'Res'. Develop., '7, 2b3 (i968).

(3) Rolton, A. P., Lanewala, 11. A, , J . Catal., 18, 1 (1970).

(4) Ciapetta, F. G., I,a Chimica e L' lndustria, 51, 1173 (1969).

(5) Ciapetta, F. G., Hunter, J . B., Ind. Eng. Chem., 45, 147

/ l O i 7)

j I .I. I U , .

(6) Coonradt. H. L.. Garwood. W. E.. Ind. Ena. Chem. Process

Des. DeveIop.,'3, 38 ('1964). '

(7) Flinn, R. 4., Larson, 0. A, , Beiither, H., Ind. Eng. Chem.,

52, 1.53(1960).

(8) Langlois, G. E., Siillivan, R. F., Prepr., Div. Petrol. Chem.,

(9) Larson. 0. A. . hIacIver. 11. S. . Tobin. H. H.. Flinn. R. A, .

ACS, 14 (4), 11-18 (1969).

Ind. Ena. Chem. Process Des. Deve1b.n.. 1. $00 (1962).

'

(10) Lewis, P. H., J . Catal., 11, 162 (1968).

(11) Mills, G. A., Heinemann, H., Milliken, T. H., Oblad, A. G.,

I nd. Eng. Chem., 45, 134 (1953).

(12) P\Iyers, C. G., AIunns, G. W., J r., ibid. , 50, 1727 (1958).

(13) Pichler, H.. Schulz, H., Reitemever, H. 0.. Erdol Kohle.

Erdgas, Petrochem., 22, 617 (1969).

(14) Pickert, P. E., Itabo, J . A. , Dempsey, E., Schomaker, V.,

Proc. Third I nt. Congress on Catalvsis, 1964, Vol I, p 714, North-

Holland Publishing, Amsterdam, Holland, 196,j.

(1.5) Ilabo, J . A., Pickert, P. E., Mays, R. L., Ind. Eng. Chem., 53,

733 (1961).

(16) Rabo, J . A, , Schomaker, V., Pickert, P. E., Pror. Third

I nt. Congress on Catalysis, 1964, Vol 11, p 1265, North-Holland

Pnblishing, Amsterdam, Holland, 196.5.

( 17) Rossini, F. D., Pitzer, K. S. , Arnett, R. L., Brann, R. M.,

Pimentel, G. C., "Selected Values of Physical and Thermody;

namic Properties of Hydrocarhons and Related Compounds,

Pittsburgh, Pa., 19.53.

(18) Schulz, H., Reitemeyer, H. O., Chromalographia, 1, 315

(1968).

(19) Schulz, H., Reitemeyer, H. O., i bi d. , p 364.

(20) Schulz, H., Reitemeyer, H. O., private communication.

(21) Voorhies, A. , J r., Hatcher, W. J ., J r., Ind. Eng. Chem.

Prod. Res. Dewlop., 8, 361 (1969).

RECEIVED for review J une 21, 1971

ACCEPTED September 20, 1971

Presented at the Division of Petroleum, 161st hleeting, ACS,

Lo? Angeles, Calif., April 1971.

Ind. Eng. Chem. Prod. Res. Develop., Vol. 1 1 , No. 1 , 1972 53

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Dnvgl-Ru-Ships (2015) Part 3 Ch-10 TrolleyDokument7 SeitenDnvgl-Ru-Ships (2015) Part 3 Ch-10 TrolleyyogeshNoch keine Bewertungen

- Mandat 040310062548 21Dokument379 SeitenMandat 040310062548 21Sujeet BiradarNoch keine Bewertungen

- Electrical SubstationsDokument16 SeitenElectrical SubstationsEngr Syed Numan ShahNoch keine Bewertungen

- Drying AgentDokument36 SeitenDrying AgentSo MayeNoch keine Bewertungen

- Green Line TransformerDokument4 SeitenGreen Line TransformerwakasNoch keine Bewertungen

- Floor Plans & ElevationsDokument6 SeitenFloor Plans & Elevationsbryan cardonaNoch keine Bewertungen

- Adequate Bearing Material and Heat TreatmentDokument20 SeitenAdequate Bearing Material and Heat TreatmentdavideNoch keine Bewertungen

- Recent Developments in Crosslinking Technology For Coating ResinsDokument14 SeitenRecent Developments in Crosslinking Technology For Coating ResinsblpjNoch keine Bewertungen

- 2011 TH 18205 Awad Nassib PdfaDokument95 Seiten2011 TH 18205 Awad Nassib PdfahafosaamrNoch keine Bewertungen

- JAVA Stack Installation in ERPDokument2 SeitenJAVA Stack Installation in ERPsai_balaji_8Noch keine Bewertungen

- Cold Rolled Steel Sheet-JFE PDFDokument32 SeitenCold Rolled Steel Sheet-JFE PDFEduardo Javier Granados SanchezNoch keine Bewertungen

- Shock AbsorberDokument0 SeitenShock AbsorberSahaya GrinspanNoch keine Bewertungen

- Form WorkDokument12 SeitenForm Workdharul khairNoch keine Bewertungen

- DualityDokument27 SeitenDualitySuprabhat TiwariNoch keine Bewertungen

- Hadron XX ManualDokument41 SeitenHadron XX ManualEverton DenardiNoch keine Bewertungen

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/4Dokument4 SeitenAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2020. Page 1/4Muthu KumarNoch keine Bewertungen

- Inspection and Quality Control in Production ManagementDokument4 SeitenInspection and Quality Control in Production ManagementSameer KhanNoch keine Bewertungen

- Moody DiagramDokument18 SeitenMoody DiagramWilson JustinoNoch keine Bewertungen

- Planning For Information NetworkDokument32 SeitenPlanning For Information NetworkChandraAdsenubiiNoch keine Bewertungen

- Metalband SawDokument7 SeitenMetalband SawRichard JongNoch keine Bewertungen

- McLaren Artura Order BKZQG37 Summary 2023-12-10Dokument6 SeitenMcLaren Artura Order BKZQG37 Summary 2023-12-10Salvador BaulenasNoch keine Bewertungen

- Black Invention MythsDokument16 SeitenBlack Invention MythsjoetylorNoch keine Bewertungen

- E Insurance ProjectDokument10 SeitenE Insurance ProjectChukwuebuka Oluwajuwon GodswillNoch keine Bewertungen

- Programmable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461Dokument18 SeitenProgrammable Safety Systems PSS-Range: Service Tool PSS SW QLD, From Version 4.2 Operating Manual Item No. 19 461MAICK_ITSNoch keine Bewertungen

- Digital Indicating Controller: Bcs2, Bcr2, Bcd2Dokument10 SeitenDigital Indicating Controller: Bcs2, Bcr2, Bcd2Bui TAN HIEPNoch keine Bewertungen

- Economics BasisDokument14 SeitenEconomics BasiskumarNoch keine Bewertungen

- Pd5500 Flange CalculationDokument6 SeitenPd5500 Flange CalculationMakrand SakpalNoch keine Bewertungen

- Abstract of ASTM F1470 1998Dokument7 SeitenAbstract of ASTM F1470 1998Jesse ChenNoch keine Bewertungen

- SW Product SummaryDokument64 SeitenSW Product SummaryFabio MenegatoNoch keine Bewertungen

- Host Interface Manual - U411 PDFDokument52 SeitenHost Interface Manual - U411 PDFValentin Ghencea50% (2)