Beruflich Dokumente

Kultur Dokumente

Manual FTLA2000 PDF

Hochgeladen von

Adenilton de DivaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual FTLA2000 PDF

Hochgeladen von

Adenilton de DivaCopyright:

Verfügbare Formate

FTLA2000 Series Laboratory FT-IR Spectrometers

User's Guide

This manual contains: Basic information on using your FTLA2000 Series spectrometer, as well as

safety, maintenance, and troubleshooting information.

IMZ8252

Revision 1-3 December 2002

ABB

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide iii

WARNING! All servicing of the equipment is to be performed by

Qualified Service Personnel only.

No user/operator adjustments inside the equipment are

necessary or recommended by the manufacturer.

2002 ABB Bomem Inc. All Rights Reserved. No information contained in

this document may be reproduced in any form, in full or in part, without prior

written permission from ABB Inc.

This document contains product specifications and performance statements that

may be in conflict with other ABB Inc. published literature, such as product

flyers and product catalogs. All specifications, product characteristics, and

performance statements included in this document are given as suggestive

specifications only. In case of conflict between product characteristics given in

this document and specifications given in the official ABB Inc. product catalogs,

the latter take precedence.

ABB Inc. reserves the right to make changes to the specifications of all

equipment and software, and to the contents of this document, without

obligation to notify any person or organization of such changes. Every effort has

been made to insure that the information contained in this document is current

and accurate. However, no guarantee is given or implied that the document is

error-free or that the information is accurate.

ABB Inc. provides product support services throughout the world. To receive

product support, either in or out of warranty, contact the ABB Inc. office that

serves your geographical area, or the office shown below:

ABB Inc.

Analytical and Advanced Solutions

585 Charest Blvd. East, Suite 300

Qubec, QC G1K 9H4

CANADA

Phone: 418-877-2944

North America: 800-858-3847

France: 0810 020 000

Fax: 418-877-2834

bomem_service@ca.abb.com

Important: Please be prepared to provide the serial numbers of all units.

You can also consult ABBs web site at www.abb.com/analytical

Copyright

Disclaimer

Customer support

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide v

TABLE OF CONTENTS

About this Manual ............................................................................................................................................ ix

1. FTLA2000 Series Laboratory FT-IR Spectrometers............................................................................. 1

1.1 Description.................................................................................................................................... 1

1.1.1 Arid-Zone sample station ................................................................................................. 2

1.1.2 Detector assemblies.......................................................................................................... 3

1.1.3 Purging ............................................................................................................................. 3

1.1.4 FT-IR Ethernet Interface .................................................................................................. 3

1.2 Options.......................................................................................................................................... 4

1.2.1 Optical side port ............................................................................................................... 4

1.2.2 External source module .................................................................................................... 6

1.3 Sampling accessories .................................................................................................................... 7

1.4 Computer ...................................................................................................................................... 7

2. Safety.......................................................................................................................................................... 9

2.1 Class of equipment........................................................................................................................ 9

2.2 Certification .................................................................................................................................. 9

2.3 Power connections ........................................................................................................................ 9

2.4 Fuse type....................................................................................................................................... 9

2.5 Moisture and dust........................................................................................................................ 10

2.6 Symbols ...................................................................................................................................... 10

2.7 Laser and high voltage................................................................................................................ 10

2.7.1 Laser specifications ........................................................................................................ 11

2.7.2 Laser labels..................................................................................................................... 11

2.8 Precautions.................................................................................................................................. 14

3. Operation................................................................................................................................................. 17

3.1 Control panel .............................................................................................................................. 17

3.1.1 Line voltage configuration ............................................................................................. 17

3.1.2 Ethernet cable, connector and indicators........................................................................ 18

3.1.3 Setting the resolution...................................................................................................... 18

3.2 Purge gas connections................................................................................................................. 18

3.3 Start up........................................................................................................................................ 19

3.3.1 Checking the status LEDs .............................................................................................. 19

3.3.2 Turning on the source..................................................................................................... 19

3.3.3 Warm up......................................................................................................................... 19

3.4 Avoiding detector saturation....................................................................................................... 19

vi FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

3.4.1 Setting the preamplifier gain........................................................................................... 20

3.5 Humidity ..................................................................................................................................... 21

4. Acquiring a Spectrum............................................................................................................................. 23

4.1 Check the signal .......................................................................................................................... 23

4.2 Acquire a background (reference) spectrum ............................................................................... 25

4.3 Acquire a sample spectrum......................................................................................................... 25

5. Validating the Spectrometer................................................................................................................... 27

5.1 Required tests .............................................................................................................................. 27

5.2 Validating for quantitative analysis............................................................................................. 27

6. Tips on Using your Spectrometer........................................................................................................... 29

6.1 Power .......................................................................................................................................... 29

6.2 Humidity ..................................................................................................................................... 29

6.2.1 Precautions for humidity-sensitive spectrometers .......................................................... 29

6.2.2 Humidity-insensitive spectrometers................................................................................ 30

6.2.3 Dry air generators ........................................................................................................... 30

6.3 Factors affecting the quality of spectra ....................................................................................... 30

6.3.1 Signal averaging versus time .......................................................................................... 31

6.3.2 Variation of external conditions during acquisition........................................................ 31

6.3.3 Local environment .......................................................................................................... 32

6.4 Using sampling accessories......................................................................................................... 32

6.5 Background (reference) spectra................................................................................................... 33

7. Maintenance............................................................................................................................................. 35

7.1 Preventive maintenance schedule................................................................................................ 35

7.2 Replacing the desiccant module .................................................................................................. 35

7.3 Replacing the internal source ...................................................................................................... 36

7.4 Replacing the laser ...................................................................................................................... 36

7.5 Replacing the fuse ....................................................................................................................... 37

7.6 Cleaning or replacing windows................................................................................................... 37

7.6.1 Optical side port windows .............................................................................................. 37

7.6.1.1 Cleaning the windows................................................................................... 37

7.6.1.2 Replacing the windows ................................................................................. 38

7.6.2 Other windows................................................................................................................ 38

7.6.2.1 Cleaning the windows................................................................................... 38

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide vii

8. Troubleshooting ...................................................................................................................................... 39

8.1 After power-up............................................................................................................................ 39

8.2 During use................................................................................................................................... 40

8.2.1 Software messages about hardware problems ................................................................ 42

8.2.1.1 On selecting a function in the Collect menu................................................. 42

8.2.1.2 After acquiring a spectrum........................................................................... 42

8.2.1.3 Other messages............................................................................................. 42

8.3 Contacting ABB.......................................................................................................................... 43

8.4 Examples of normal spectra........................................................................................................ 44

A Technical Information ............................................................................................................................ 47

A.1 Specifications.............................................................................................................................. 47

A.1.1 Electrical ...................................................................................................................... 47

A.1.2 Mechanical ..................................................................................................................... 47

A.1.3 Environmental ................................................................................................................ 47

A.1.4 Spectrometer................................................................................................................... 48

A.1.5 Interferometer................................................................................................................. 48

B Installing your MB Series Spectrometer ............................................................................................... 49

Purpose .................................................................................................................................................... 49

Site preparation......................................................................................................................................... 49

Line voltage configuration........................................................................................................................ 49

Main controls and connections ................................................................................................................. 50

Purge gas connections (if used) ................................................................................................................ 51

Safety .................................................................................................................................................... 52

Start up .................................................................................................................................................... 52

Ethernet configuration .............................................................................................................................. 52

Validation ................................................................................................................................................. 52

C Replacing the NIR Source in your MB Series Spectrometer............................................................... 53

Purpose .................................................................................................................................................... 53

Safety .................................................................................................................................................... 53

Removing the NIR source ........................................................................................................................ 53

Replacing the NIR source......................................................................................................................... 56

Aligning the NIR source........................................................................................................................... 56

Validation ................................................................................................................................................. 57

viii FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

D Replacing the MIR Source...................................................................................................................... 59

D.1 Purpose........................................................................................................................................ 59

D.2 Safety .......................................................................................................................................... 59

D.3 Removing the MIR source .......................................................................................................... 59

D.4 Replacing the MIR source........................................................................................................... 60

D.5 Validation.................................................................................................................................... 62

E Glossary.................................................................................................................................................... 63

F Index ......................................................................................................................................................... 77

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide ix

ABOUT THI S MANUAL

This manual is intended for personnel using an FTLA2000 Series spectrometer

for routine analysis, as well as personnel responsible for maintaining and

troubleshooting the analyzer.

For information on: Refer to Chapter/Appendix:

Installation App. B Installing your FTLA2000 Series

Laboratory FT-IR Spectrometer

The FTLA2000 Series Spectrometers Chap. 1 FTLA2000 Series Laboratory FT-

IR Spectrometers

Routine analysis Chap. 2 Safety

Chap. 3 Operation

Chap. 4 Acquiring a Spectrum

Getting the most out of your

spectrometer

Chap. 5 Validating the Spectrometer

Chap. 6 Tips on Using your Spectrometer

Maintenance and troubleshooting Chap. 7 Maintenance

Chap. 8 Troubleshooting

Software commands and dialog box names and are shown in boldface type.

Text to be entered into software is in sans serif type.

This symbol refers you to another manual or document.

Note: Supplemental information to help the reader.

Important: Information that is important, but that does not concern the safe use

of the equipment.

This symbol shows that Caution is required. Follow

the instructions carefully to avoid damage to the equipment.

WARNING! Failure to comply with warnings can result in serious injury

or loss of life.

Audience

Conventions used

in ABB manuals

C H A P T E R 1

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 1

FTLA2000 SERI ES LABORATORY FT-I R

SPECTROMETERS

FTLA2000 Laboratory FT-IR Series spectrometers are powerful and reliable

Fourier Transform Infrared (FT-IR) spectrometers designed for a wide range of

IR analyses in a variety of environments, including factories, field locations,

educational institutions, and quality control laboratories.

The FTLA2000 Series of FT-IR spectrometers includes the following models

covering both the mid infrared (MIR) and near infrared (NIR) spectral ranges:

Model Typical Spectral Range

(cm

-1

)

Humidity Sensitive

(hygroscopic optics)

FTLA2000-100 6500 350 MIR Yes

FTLA2000-102 5000 200 MIR Yes

FTLA2000-104 6500 500 MIR No

FTLA2000-154 12 000 500 NIR/MIR No

FTLA2000-155 12 000 450 NIR/MIR Yes

FTLA2000-160 14 000 - 3800 NIR No

Note: These spectral ranges are approximate. Refer to published specifications

for the exact spectral range of each model. The detector and/or other

devices may reduce the spectral range.

These spectrometers provide exceptionally high stability, sensitivity and

photometric accuracy. When the necessary measures are taken, the repeatability

(the precision of repeated measurements on the same instrument) and

reproducibility (the precision of repeated measurements on the different

instruments) are outstanding. Refer to Chapter 5 Validating the Spectrometer on

page 27 for further information.

The interferometer and the input/output optics of these instruments are factory

prealigned. There are no routine adjustments required.

FTLA2000 Series spectrometers are controlled by acquisition software running

on an external PC computer running under the Microsoft Windows

2000 or

Windows

NT. ABB can supply the FTLA2000 Series spectrometers with or

without a computer. The computer requires an Ethernet network adapter.

1.1 Description

S e c t i o n 1 . 1 De s c r i p t i o n

2 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

All FTLA2000 Series spectrometers can be used with various optional sampling

accessories that come with their own manuals. Several additional features are

also available as options.

The following items are included with each FTLA2000 Series spectrometer:

Arid-Zone sample station

a

(see Section 1.1.1)

One detector assembly (see Section 1.1.2)

Acquisition software (refer to the software manuals provided)

The Arid-Zone sample station comes as a standard accessory (see Figure 1-1

below). It eliminates waiting for purge without compromising spectrometer

performance. It also eliminates the need for water vapor compensation routines

for quantitative analysis applications.

Figure 1-1. FTLA2000 Series spectrometer with Arid-Zone sample station

For MIR analysis, the telescopic purge tubes of the Arid-Zone sample

compartment adjust to the sample cell and insure continuous purge right up to

the sample. This allows purging, yet leaves a wide, open space around

the IR beam for immediate access to the sample without breaking purge, as well

as sufficient space for all standard sample accessories. The Arid-Zone sample

station is compatible with all industry-standard accessories such as ATR,

DRIFT, and Liquid Cells.

a

A different sample station,

such as the HOval, may be

supplied instead of, or in

addition to, the Arid-Zone.

1.1.1 Arid-Zone

sample station

Output beam

cover

Humidity indicator /

Desiccant module

Source adjustment

access plug

(remove to adjust

source power)

Telescopic

purge tube (for

MIR analysis)

Detector cover

Control panel

C h a p t e r 1 F T L A 2 0 0 0 S e r i e s L a b o r a t o r y F T - I R S p e c t r o me t e r s

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 3

For NIR analyses, where purge is not required, the telescopic purge tubes are not

used. In their place, protective windows are installed to prevent contaminant

liquids or vapors from entering the spectrometer and causing damage.

ABB can supply the FTLA2000 Series spectrometers with detector assemblies

of different types and sensing element sizes, interchangeable by the user.

The power must be turned off when detector assemblies are

being interchanged.

FTLA2000 Series spectrometers are equipped with purge inlets. Purging is

recommended for spectrometers which have hygroscopic optical components

(models FTLA2000-100, FTLA2000-102, and FTLA2000-155) or if ambient

water vapor may interfere with measurements.

Purging should be done using dry nitrogen or CO

2

and H

2

O free air when

an application is sensitive to changes in air humidity, or when the sensitivity of

the analyzer is compromised by the absorption of CO

2

and H

2

O found in normal

concentrations in the ambient air. When water vapor alone is to be eliminated,

dry, oil-free instrumentation air can be used for purging.

The recommended purge flow rate into the spectrometer is 5 L/min. Once

the spectrometer is purged, a continuous flow rate of 1 L/min is normally

sufficient to maintain the purged condition. An automatic relief valve is installed

to prevent accidental over-pressurization of the spectrometer. This relief valve

opens if the internal pressure exceeds 1/3 psi.

The FT-IR Ethernet Interface is built into the FTLA2000 Series. It allows

communication between the FTLA Series and a computer over an Ethernet link

using standard network protocols. Communication is possible through a private

connection between the instrument and the computer, over a local area network,

or over the Internet. The computer must be equipped with a standard Ethernet

network adapter.

An Ethernet link offers many advantages over a serial or parallel link. For

example, an Ethernet link:

works over standard office and plant networks

1.1.2 Detector

assemblies

Detector assemblies can be

procured at the time of the

initial sale or later on.

1.1.3 Purging

1.1.4 FT-IR Ethernet

Interface

S e c t i o n 1 . 2 Op t i o n s

4 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

allows sharing of FT-IR instruments by multiple computers over

the network

allows control of multiple FT-IR instruments by a single computer over

the network

simplifies cabling and allows greater distances between the FT-IR

instrument and the computer

does not require special hardware in the computer

can be upgraded by loading a new version of the firmware

The following are some of the features of the FT-IR Ethernet Interface:

Uses a standard RJ45 phone type connector and twisted pair wiring

(10Base-T or 100Base-T)

Automatically detects network speed (10 Mbps or 100 Mbps)

Maximum network load of approximately 2 Mbps

Network traffic is not encrypted

Network traffic will not cross firewalls

Instruments are addressed by a unique name

Refer to the FT-IR Ethernet Interface and External Ethernet Interface

User's Guide for complete information on the FT-IR Ethernet Interface.

The following sections describe the principle options available for the

FTLA2000 Series spectrometers.

As an option, ABB can install one optical side port on the FTLA2000 Series

spectrometer. The different types are described below:

Optical outport (Figure 1-2 on page 5). This option allows the easy

interfacing of the spectrometer to accessories mounted on the side of

the spectrometer.

Once installed, the side accessory is selected by placing the position of

a manually operated flip mirror in the appropriate position. This directs

the IR beam from the interferometer through the side port, assures that

the spectrometer selects the signal coming from the detector located on

1.2 Options

1.2.1 Optical side port

C h a p t e r 1 F T L A 2 0 0 0 S e r i e s L a b o r a t o r y F T - I R S p e c t r o me t e r s

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 5

the side, and also assures that the interferometer adjusts to the optimum

scanning speed for the type of detector used at that location.

When the flip mirror is in the normal position, the IR beam goes to the top

sampling station, and the detector located on the top is selected.

Figure 1-2. Optical outport

Optical inport (Figure 1-3 on page 6). This option allows you to install

an external source module on the spectrometer.

Once the external source is installed, you can select the external or internal

source simply by turning one source on and turning the other off.

S e c t i o n 1 . 2 Op t i o n s

6 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

Figure 1-3. Optical inport

Note: After switching a source on or off, allow a temperature stabilization time

from 10 minutes to 2 hours, depending on the need for stability, before

performing analyses.

ABB offers optional external source modules that mount on the optional optical

side inport (or emission port) on the left side of the FTLA2000 Series

spectrometer. The optional external source module has an external regulated

power supply and optical filter holder (a filter may be useful to prevent detector

saturation under certain conditions).

Note: The optional external source modules are not compatible with

the optional optical side outport.

For complete instructions on installing (or replacing), testing, and using

a particular external source module, refer to the documentation supplied

with that external source module.

Specifications for the optional external sources are given in the following tables.

All values are nominal. (No user settings are required.)

1.2.2 External source

module

C h a p t e r 1 F T L A 2 0 0 0 S e r i e s L a b o r a t o r y F T - I R S p e c t r o me t e r s

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 7

External NIR source External MIR source

Rated line voltage: 90-265 VAC 90-265 VAC

Rated frequency: 50-60 Hz 50-60 Hz

Radiation source (absorption

spectroscopy)

Quartz-halogen lamp

(collimated to a 2.5 cm diameter beam)

SiC Globar

(collimated to a 2.5 cm diameter beam)

Range near IR range (15 000 cm

-1

to 4000 cm

-1

) mid IR range (7000 cm

-1

to 200 cm

-1

)

FTLA2000 Series spectrometers are compatible with industry-standard sampling

accessories from ABB and from other manufacturers. The following list shows

some accessories available from ABB.

Raw Material Identification FT-NIR Analyzer

Bag Sampling

Powder Sampling

Tablet Sampling

Vial Holder

For complete instructions on installing, testing, and using a particular

sampling accessory, refer to the documentation supplied with that

sampling accessory.

ABB can supply the FTLA2000 Series spectrometer with or without a computer.

If the computer is supplied by ABB, all software will be preinstalled and

configured.

The minimum configuration requirements for the computer depend on the

software you intend to use. Refer to your software manuals.

1.3 Sampling

accessories

1.4 Computer

C H A P T E R 2

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 9

SAFETY

The FTLA2000 Series spectrometer has an exposed metal chassis that is

connected directly to earth via a power supply cord and are therefore classified

as Safety Class I equipment.

WARNING! To avoid electrical shock, do not operate this equipment if it

bears any sign of damage to any portion of its exterior

surface.

Do not expose this equipment to any source of excessive

moisture.

Do not use this equipment in an explosive atmosphere.

ABB instruments receive the following safety certifications:

Canadian Standards Association (for Canada and the US)

Conformit europenne (European conformity)

In accordance with international safety standards, each powered unit uses a

three-wire power cord. When connected to an appropriate AC power receptacle,

this power cord grounds the chassis.

WARNING! To avoid the risk of injury or death:

Use only a power cord with a protective earthing

terminal. Never use an extension cord that is not

equipped with this feature.

Connect the power cord to a power outlet of the correct

voltage and that has a protective earth contact.

Disconnect all power cords before servicing any unit.

The main power fuse(s) are rated as follows:

T2A/250V (115 V line)

T1A/250V (230 V line)

2.1 Class of

equipment

2.2 Certification

2.3 Power

connections

2.4 Fuse type

S e c t i o n 2 . 5 Mo i s t u r e a n d d u s t

10 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

The FTLA2000 Series spectrometer is designed for indoor use in a laboratory-

type environment. It should not be exposed to excessive moisture and dust.

The following symbols may be used in documentation or on the instrument:

Symbol Meaning

WARNING!

or

WARNING

Failure to comply with warnings can result in

serious injury or loss of life.

Ensure that all conditions necessary for safe

handling and operation are met before

proceeding.

Danger: High voltage

Warning: Hot surface

Caution: Follow instructions carefully to

avoid damage to the equipment.

Protective earth conductor terminal

On (power)

Off (power)

Under normal conditions, the FTLA2000 Series spectrometer can be operated in

complete safety. However, since the instrument contains a laser and uses high

voltages (accessible only when the enclosure is open), observe the following

warnings:

2.5 Moisture and

dust

2.6 Symbols

2.7 Laser and

high voltage

Ch a p t e r 2 S a f e t y

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 11

WARNING! Opening the enclosure of the FTLA2000 Series

spectrometer may result in exposure to laser radiation and

high voltages. The enclosure is to be opened only by

authorized ABB Service Personnel.

Laser type: He-Ne

Laser class: 3B as per IEC-60825-1 and

Class IIIa as per 21 CFR 1040.10

Output power: 3.2 mW (maximum)

Wavelength: 632.8 nm

CAUTION: Use of controls or adjustments, or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

WARNING! High voltage is present at the red wire connected to

the laser tube inside the enclosure.

The voltage is approximately 7 kV at startup, and between

1200 V and 1400 V under normal operating conditions.

Because of the capacitors in the laser power supply,

the high voltage may be present even when the power is off.

The following table gives the specifications of the laser used in the FTLA2000

Series spectrometer.

Wavelength: 632.8 nm (vacuum)

Beam diameter: 0.75 mm 0.05 mm

Beam divergence: 1.2 mrad

Power output (at laser tube): 2 to 5 mW (TEM

oo

)

Class 3B

The following information describes the laser radiation warnings on

the equipment along with their location.

2.7.1 Laser

specifications

2.7.2 Laser labels

S e c t i o n 2 . 7 L a s e r a n d h i g h v o l t a g e

12 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

CAUTION

CLASS 3B LASER, RADIATION WHEN OPEN

AVOID EXPOSURE TO BEAM

IMZ6426

Figure 2-1. Laser caution label

Figure 2-2. Locations of laser caution labels

Under the spectrometer

On top plate, under

access cover

On access cover

Next to side port

(if installed)

Ch a p t e r 2 S a f e t y

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 13

MANUFACTURE DATE:

SERIAL NO.:

MODEL:

CLASS 1

LASER PRODUCT

ABB Inc.

Analytical and Advanced Solutions

585 Charest Blvd. East, Suite 300

Qubec, QC G1K 9H4 CANADA

Phone: 418-877-2944

C US

COMPLIES WITH FDA

RADIATION PERFORMANCE

STANDARDS.

21 CFR CHAPTER 1

SUBCHAPTER J.

Figure 2-3. Nameplate with Class 1 laser label

S e c t i o n 2 . 8 P r e c a u t i o n s

14 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

Figure 2-4. Location of nameplate with Class 1 laser label and laser caution label

WARNING! Failing to comply with any of the instructions, precautions

or warnings contained in this manual is in direct violation of

the standards of design, manufacture, and intended use of

the equipment.

ABB Inc. assumes no liability for the users failure to

comply with any of these safety requirements.

The following precautions must be observed whenever the equipment is

operated, serviced, or repaired.

Before operating the equipment:

Inspect the equipment for any signs of damage, and read this manual

thoroughly.

Install the equipment as specified in the documentation provided.

2.8 Precautions

Ch a p t e r 2 S a f e t y

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 15

Make sure the system is configured to use the available line voltage and that

the correct fuse(s) for that voltage is (are) installed. Use only the fuse(s)

specified as appropriate for this equipment (see Section 2.4 on page 9).

Ensure that equipment and any devices or power cords connected to it are

properly earthed.

While operating the equipment:

Do not operate the equipment in the presence of flammable gases, fumes,

or dust.

Do not operate the equipment when its covers or panels have been removed.

Do not interrupt the protective earthing connection. Any such action can

lead to a potential shock hazard that could result in serious personnel injury.

Do not operate the equipment if an interruption to the protective earthing is

suspected. Ensure that the equipment remains inoperative.

Do not use repaired fuses and avoid any situations that could short-circuit

the fuse.

Unless absolutely necessary, do not attempt to adjust or perform any

maintenance or repair procedure when the equipment is opened and

connected to a power source at the same time. Any such procedure should

only be carried out by a qualified service professional.

Do not attempt any adjustment, maintenance, or repair procedure to

the equipment if immediate first aid is not accessible.

WARNING! High voltages may be present inside the enclosure even

when the equipment is not connected to the power source

because some of the capacitors may be charged.

C H A P T E R 3

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 17

OPERATI ON

Figure 3-1 shows the spectrometer control panel. All controls and connections,

except for the preamplifier gain adjustment, are located on this panel.

Figure 3-1. Control panel

The FTLA2000 Series spectrometer is delivered preconfigured for the line

voltage of your country. This voltage should be visible on the voltage

configuration plate behind the sliding fuse cover. Should it be necessary to

change the line voltage configuration, unplug the spectrometer, and remove the

fuse. Then pull out the voltage configuration plate using pliers and reinsert it so

that the correct line voltage is showing.

Be sure to use the fuse type specified for the actual line

voltage. Refer to Section 2.4 on page 9.

3.1 Control panel

3.1.1 Line voltage

configuration

Power switch

1 or 2 Source

breaker-switches

Power connector

Resolution switch

Status LEDs

Fuse and voltage

configuration plate

(behind sliding fuse cover)

Ethernet cable connector

S e c t i o n 3 . 2 P u r g e g a s c o n n e c t i o n s

18 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

Two Ethernet cables are supplied (see Figure 3-2), a crossover cable for making

a private (direct) connection to the computer and a straight-pinned cable for

connecting the instrument to a network. Be sure to use the correct type of cable.

Figure 3-2. Ethernet cables for private and network connection

The Ethernet cable must be connected to the RJ45 connector identified as

10/100 BASE T on the control panel. The MAC address of the FT-IR Ethernet

Interface is indicated on the panel.

Two LEDs are associated with the Ethernet connector:

LINK is on when the instrument is properly connected.

ACT is on when there is activity on the link.

Refer to the FT-IR Ethernet Interface and External Ethernet Interface

User's Guide for complete information on making the Ethernet

connection and configuring the FT-IR Ethernet Interface.

The resolution can be changed at any time before making a new spectroscopic

measurement.

Make sure the same resolution setting is used for both the reference spectrum

and the sample spectra.

Refer to the Installing manual (reproduced on page 51) for instructions

on connecting the purge gas, if used.

3.1.2 Ethernet cable,

connector and

indicators

3.1.3 Setting

the resolution

3.2 Purge gas

connections

For private (direct) connection

to computer

For network connection

Ch a p t e r 3 Op e r a t i o n

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 19

Turn on the spectrometer, the computer, and all other powered components.

After turning on the spectrometer, the status LED sequence should be:

LED Normal State

POWER ON

SCAN OFF (a few seconds after power on)

ZPD OFF (a few seconds after power on)

DATA Flashing (usually within one minute after power on)

This sequence confirms the correct operation of the spectrometer. During

operation, the POWER LED should be ON and the DATA LED should be

flashing. If you encounter problems, refer to Chapter 8 on page 39.

Set the source breaker-switch to ON. Dual source models such as the

FTLA2000-154 or the FTLA2000-155 can have an IR (MIR) and an NIR

source, each of which can be turned on or off independently.

Note: After switching on a source, allow a temperature stabilization time from

10 minutes to 2 hours, depending on the need for stability, before

performing analyses.

When turned on at room temperature, the spectrometer will need about 4 hours

to allow its infrared source and internal temperature to stabilize; for critical

measurements, more time may be required. The spectrometer can be used

immediately after being turned on but the resulting spectra may not be within

published specifications.

Important: The spectrometer should be left ON at all times.

Each time it is turned OFF then back ON, it will take several hours

for the internal temperature to stabilize.

Some sensitive near-IR detectors are provided with selectable preamplifier gain.

After installing a sampling accessory, the preamplifier gain must be set so that

sufficient signal amplitude is obtained and detector saturation is avoided

(see Section 3.4.1 on page 20).

3.3 Start up

3.3.1 Checking

the status LEDs

3.3.2 Turning on

the source

3.3.3 Warm up

3.4 Avoiding

detector

saturation

S e c t i o n 3 . 4 A v o i d i n g d e t e c t o r s a t u r a t i o n

20 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

When performing quantitative analysis without normalization, a new reference

spectrum must be taken when the preamplifier gain is changed. Make sure

the same preamplifier gain setting is selected for both the reference spectrum

and the sample spectrum.

For qualitative analysis, or quantitative analysis with normalization, it is

possible to use different gain settings for reference and sample spectra.

The preamplifier gain must be set so that detector saturation is avoided.

The preamplifier gain is set using a rotary switch located on the preamplifier

box that is part of the detector assembly.

Refer to the manual of your acquisition software for instructions on

checking for detector saturation before carrying out this procedure.

Note: A neutral density filter may be required to attenuate the optical beam if

saturation cannot be eliminated by reducing the preamplifier gain.

To set the preamplifier gain, use the following procedure:

1. If you are using a sampling accessory, make sure the accessory is in place,

but that it contains no sample.

2. Turn the two screws holding the detector cover of the Arid-Zone sample

station (see Figure 3-3 on page 21) turn counterclockwise, and remove

the cover.

3. Set the gain using the rotary switch (see Figure 3-4 on page 21).

The following table shows the available settings:

Setting Gain

A 1

B 2

C 4

D 8

E 16

4. Replace the detector cover, and turn the two screws turn clockwise to

secure the cover.

3.4.1 Setting the

preamplifier gain

Ch a p t e r 3 Op e r a t i o n

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 21

Figure 3-3. Arid-Zone sample station

Figure 3-4. Rotary switch used to set the preamplifier gain

The spectrometer may require protection from humidity.

Refer to Section 6.2 on page 29.

3.5 Humidity

Detector cover

screws (2)

C H A P T E R 4

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 23

ACQUI RI NG A SPECTRUM

This chapter guides you in acquiring the transmittance spectrum of a sample

using any Windows-based acquisition software program supplied by ABB Inc. It

assumes that the software is installed and configured.

Note: The commands used in this section are in the Collect menu of

the acquisition program.

For detailed information on using a particular acquisition program, refer

to the manual supplied with that program.

1. Make sure there are no objects in the sampling area and that the sample

holder is in position. (This condition is called open beam.)

2. Using the Setup command, select the FTLA2000 Series spectrometer and

make sure all parameters are set correctly.

3. Set the spectrometer resolution to 4 cm

-1

.

4. Select the alignment command to display the alignment dialog box.

Set the parameters as follows:

Spectral Range:

for MIR: 4000 to 400 cm

-1

for NIR: 14 000 to 1000 cm

-1

Data type: Single-Beam (or Raw spectrum)

5. Click OK Align to begin data acquisition. During data acquisition,

the display will be continuously updated until the halt command is selected.

6. Observe the displayed spectrum. The word Align, followed by a percentage,

indicates the interferogram amplitude as a percentage of the maximum

allowed. This percentage should be between 40% and 90%.

7. Check for any unusual spectral features such as a strong signal below

the detector cut-off frequency (usually caused by detector saturation).

Figure 4-1 on page 24 shows typical spectra for MIR and NIR. Figure 4-2

on page 24 presents MIR spectra showing detector saturation.

4.1 Check the signal

S e c t i o n 4 . 1 Ch e c k t h e s i g n a l

24 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

Figure 4-1. Typical open-beam spectra

Figure 4-2. MIR spectra showing detector saturation

Refer to Section 8.4 on page 44 for more examples of normal open-beam

spectra for different system configurations.

8. Select the halt command to stop data acquisition.

Normal

Saturated

Highly

saturated

Ch a p t e r 4 A c q u i r i n g a S p e c t r u m

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 25

1. Select the command for acquiring a background spectrum (Background

Scanning or Collect).

In the dialog box, set the parameters as follows:

Spectral Range (if available):

for MIR: 4000 to 400 cm

-1

for NIR: 14000 to 4000 cm

-1

Number of Scans: 10

File Name: (enter a file name)

If available, select the Background acquisition type.

2. Click the OK button to begin data acquisition. During data acquisition

the spectrum of each individual scan will be displayed on the page. When

all the spectra are acquired, the coadded spectrum is displayed and saved.

1. When the background spectrum has been acquired, insert the sample in

the sample holder.

For MIR, use the polystyrene sample supplied with the spectrometer

(see Figure 4-3 below).

Figure 4-3. Inserting the polystyrene sample into the sample holder

For NIR, do not use the polystyrene sample. Instead, place an ordinary

plastic bag over the sample holder.

4.2 Acquire

a background

(reference)

spectrum

4.3 Acquire

a sample

spectrum

S e c t i o n 4 . 3 A c q u i r e a s a mp l e s p e c t r u m

26 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

2. Select the command for acquiring a normal spectrum. (Scanning or

Collect).

In the dialog box, set the parameters as follows:

Spectral Range: (same as for background spectrum)

Number of Scans: 10

File Name: (enter a file name)

Data type: %Trans

If available, select the Normal acquisition type.

3. Click the OK button to begin data acquisition. During data acquisition

the spectrum of each individual scan will be displayed on the page. When

all the spectra are acquired, the coadded spectrum is displayed and saved.

4. Observe the acquired spectrum.

Figure 4-4 shows an example of the transmittance spectrum of a polystyrene

sample in the MIR range and the transmittance spectrum of a plastic bag in

the NIR range.

Figure 4-4. Transmittance spectra

C H A P T E R 5

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 27

VALI DATI NG THE SPECTROMETER

FTLA2000 Series spectrometers can be used in many different applications.

However, there are three broad categories of spectrometers users, and each

category has its own requirements concerning the tests necessary to ensure

proper performance.

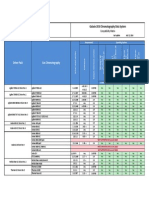

The following table shows the validation tests required for each type of user:

Tests required

Type of user

Check for detector

saturation

*

Frequency validation

Spectral quality

All other available

validation tests

Users performing qualitative analysis only

Users of an ABB dedicated analyzer

(e.g. PROTA)

Users performing quantitative analyses

or who may do so in the future

*

Check for detector saturation before using the spectrometer and each time you install a different sampling accessory.

Adjust the preamplifier gain if necessary (see Section 3.4 on page 19).

With ABB spectrometers, models (calibrations) for quantitative analysis can be

developed using one spectrometer (e.g. in a laboratory), and then transferred to

other spectrometers (e.g. in a plant), without having to adjust the model for each

spectrometer. However, a complete performance validation of each spectrometer

is necessary to guarantee transferability of models.

Before using a spectrometer for quantitative analysis, it is recommended that

you perform all of the available validation tests.

We strongly recommend that all validation tests be performed when

the spectrometer is first installed, and afterwards on a regular basis, even if

you do not foresee the need to transfer models to another spectrometer.

For information on performing the validation tests, refer to the SpecTest

Users Guide.

For further information on transferability of models, refer to the chapter

entitled Quantitative Analysis and Calibration Transfer of the FT-IR

Reference Manual.

5.1 Required tests

5.2 Validating for

quantitative

analysis

C H A P T E R 6

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 29

TI PS ON USI NG YOUR SPECTROMETER

Leave the spectrometer ON at all times. This not only ensures thermal stability,

but also helps protect the spectrometer from humidity. However, it is possible to

turn the source off when the spectrometer is not in use. After switching a source

on or off, allow a temperature stabilization time from 10 minutes to 2 hours,

depending on the need for stability, before performing analyses.

The average source life when left on continuously is:

MIR source: 4 years

NIR source: 1 year

Your FTLA2000 Series spectrometer

b

may contain some hygroscopic

components (components that can be damaged by humidity). Although the

spectrometer is sealed, it is not vacuum tight; there will always be some

exchange of air between the interferometer cavity and the outside. For this

reason, a number of precautions must be taken to ensure minimal long-term

damage due to humidity. These are described below.

For more specific information on hygroscopic materials, refer to

the Chapter Handling and Care of Hygroscopic Materials of the FT-IR

Reference Manual.

To assure maximum life for humidity-sensitive spectrometers

(models FTLA2000-100, FTLA2000-102, and FTLA2000-155), the following

precautions should be taken:

Leave the spectrometer ON at all times.

If possible, purge the spectrometer at all times using dry, oil-free

instrumentation air or dry nitrogen. Before interrupting the purging gas,

make sure the internal desiccant module is installed and that the desiccant is

fresh.

If the spectrometer is not left ON at all times, or if the relative humidity is

extremely high:

Put external desiccant around exposed hygroscopic windows where

possible. Use as much desiccant as possible without partially blocking

6.1 Power

6.2 Humidity

b

Models FTLA2000-100,

FTLA2000-102, and

FTLA2000-155, are

sensitive to humidity,

others models are not.

6.2.1 Precautions for

humidity-

sensitive

spectrometers

S e c t i o n 6 . 3 F a c t o r s a f f e c t i n g t h e q u a l i t y o f s p e c t r a

30 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

the beam. Note however that if the ambient humidity decreases rapidly,

the desiccant will release absorbed moisture that could damage

the windows.

If the spectrometer is not purged continuously:

Change the internal desiccant module regularly. Exhausted desiccant

will release substantial quantities of water when warmed by

the elevated temperature inside the spectrometer, causing rapid failure

of the beamsplitter.

Where humidity is a potential problem, we recommend the use of the

FTLA2000-104 (mid IR region) and FTLA2000-154 (mid and near IR region)

spectrometers, if either of these spectrometers meets the requirements of your

application.

If a supply of dry nitrogen is not available, the spectrometer can be purged with

dry, oil-free instrumentation air. For this, ABB recommends the use of a dry air

generator.

Whatman Inc. manufactures excellent dry air generators that either work from

plant compressed air (model 75-45 is recommended) or from its own compressor

(model 74-5021 is recommended). Both units can deliver up to 14 liters per

minute of water free (-73

o

C dew point) and CO

2

free (<1 ppm) purging gas.

These dryers have proven to be a good, cost-effective alternative to the use of

nitrogen.

For installation, operation and maintenance of Whatman dry air generator

model 75-45, refer to the chapter entitled Purging in the FT-IR Reference

Manual.

The results obtained with a FTLA2000 Series spectrometer will depend on

several different factors:

signal averaging versus time

variation of external conditions during acquisition

local environment

6.2.2 Humidity-

insensitive

spectrometers

6.2.3 Dry air

generators

6.3 Factors affecting

the quality of

spectra

C h a p t e r 6 T i p s o n Us i n g y o u r S p e c t r o me t e r

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 31

Understanding the effect of these factors on the resulting spectra should help to

optimize and improve the quality of acquired spectra.

The spectra acquired by all spectrometers are more or less affected by noise,

or random error introduced by variations in light and electrical signals.

The noisy signal appears as random fluctuations in the spectral response.

The amount of noise present in a spectrum is inversely proportional to the square

root of the signal averaging time, or the number of scans. For example, spectra

acquiring using 50 scans will have approximately one fifth the noise level of

spectra acquired using 2 scans.

The number of scans required will depend on various factors such as how much

energy the sample transmits and the spectral range of interest. However,

the same number of scans should usually be used to acquire the reference and

sample spectra.

Interferograms are not obtained instantaneously because of the necessity of

averaging to improve spectral quality. Unfortunately, this makes the results

dependent on variations of the instrument, sample or other conditions during

the scans.

Some examples of variations are:

A change in the fraction of water vapor or carbon dioxide in the air in

the sample path of the instrument. This can occur if you breathe or talk

near an unprotected sample during the scan.

A significant change in temperature (more than 10

o

C) during the scan.

This can cause a change in dimensions and cause temporary optical

misalignment.

A sudden displacement or mechanical shock. This will cause a change

of scan velocity that could yield a distorted spectrum. If the shock is

severe enough, the instrument will reject the scan and thereby waste

measurement time.

Even gradual changes of conditions can cause problems when

the background and sample spectra are acquired too far apart in time.

6.3.1 Signal averaging

versus time

6.3.2 Variation of

external

conditions during

acquisition

S e c t i o n 6 . 4 Us i n g s a mp l i n g a c c e s s o r i e s

32 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

If conditions may vary, acquire the sample spectrum immediately after

the reference spectrum.

The FTLA2000 Series spectrometer is designed for harsh environments. There

are nevertheless limits to its adaptability.

The following conditions have a direct effect on performance:

Vibration: Excessive vibration will cause degradation of the highly

precise scanning of the instrument, increasing the noise in

spectra. Built-in vibration isolators shield the instrument

from normal levels of vibration. However, the instrument

must not be in contact with vibrating surfaces except

through its base.

Temperature: The detector of the instrument produces more electrical

noise as the ambient temperature increases. To achieve

optimal performance, the temperature must be maintained

within 5C.

c

All FTLA2000 Series spectrometers can be used with various optional sampling

accessories that come with their own manuals. Some sensitive near-IR detectors

are provided with selectable preamplifier gain. After installing or removing

an accessory, it may be necessary to adjust the preamplifier gain to obtain a

strong signal while avoiding detector saturation. Refer to Section 3.4 on page 19.

When performing quantitative analysis without normalization, a new reference

spectrum must be taken when the preamplifier gain is changed. Make sure

the same preamplifier gain setting is selected for both the reference spectrum

and the sample spectrum.

For qualitative analysis, or quantitative analysis with normalization, it is

possible to use different gain settings for reference and sample spectra.

For complete instructions on installing, testing, and using a particular

sampling accessory, refer to the documentation supplied with that

sampling accessory.

6.3.3 Local

environment

c

For example, the spectrometer

should not be located near an

outside door, a fan, or a heat

source such as an oven.

6.4 Using sampling

accessories

C h a p t e r 6 T i p s o n Us i n g y o u r S p e c t r o me t e r

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 33

It is good practice to acquire a new background spectrum at least every two

hours of operation. Make sure the same resolution setting is used for both

the background spectrum and the sample spectrum. For quantitative analysis

without normalization, the same gain setting must be used for both

the background and the sample spectra.

A new background spectrum must be acquired every time the IR beam geometry

is changed, such as when a different sample accessory is used, or when

the position of the sample accessory is changed or realigned.

The background spectrum should be acquired using the same number of scans

(coaddition) as will be used for the sample spectrum. It is important to acquire

the background spectrum first by running the spectrometer with the cell, or

sample accessory, in place, but without the sample.

6.5 Background

(reference)

spectra

C H A P T E R 7

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 35

MAI NTENANCE

WARNING! Maintenance must be done by trained and qualified

personnel only.

WARNING! Laser replacement must be done by an ABB-trained Service

Engineer only.

Note: The replacement of consumables (other than the laser assembly) does not

require opening the spectrometer.

ABB Bomem recommends that an ABB Bomem trained Service Engineer

perform all servicing of the instrument. The spectrometer is permanently aligned

and should not require optical realignment during its life span. The following

items should be replaced periodically for preventive maintenance:

Item Expected life

Recommended

replacement frequency

Laser 4 years 2 years

NIR source (if installed)

1year 6 months

MIR source (if installed)

4 years 2 years

Desiccant module

(if spectrometer is not

purged)

Depends

on use

6 to 12 months

(3 months in very humid

environment)

Instruments use either a NIR (near infrared) or a MIR (mid infrared) source, or both.

To replace the desiccant module (standard model desiccant assembly

SPL6300G), proceed as follows:

1. Leave the spectrometer on. This will keep the internal optics warm and

gives added protection against humidity.

2. Unscrew the desiccant module (SPL6300G) on the side of the spectrometer

(see Figure 7-1 on page 36).

3. Remove the desiccant module and replace it with a new desiccant module

(SPL6300G).

7.1 Preventive

maintenance

schedule

7.2 Replacing the

desiccant module

S e c t i o n 7 . 3 R e p l a c i n g t h e i n t e r n a l s o u r c e

36 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

4. Install the new desiccant module.

Figure 7-1. Location of the SPL6300G desiccant module

The FTLA2000 Series Spectrometer uses different types of internal sources;

make sure you replace the source with the correct replacement model (usually

the same source model as was originally installed in the spectrometer). Contact

your ABB representative for information.

Attempting to install an incompatible source in your

spectrometer may damage both the source and the

spectrometer. It will also result in poor reproducibility.

To replace a standard near-IR internal source, refer to the document

Replacing the NIR Source in your FTLA2000 Series Laboratory

Spectrometer. This document is reproduced in Appendix C of this manual

on page 53.

To replace a standard mid-IR internal source, refer to the Appendix D.

The laser assembly must be replaced by authorized ABB service personnel.

Please contact your ABB representative.

7.3 Replacing the

internal source

7.4 Replacing

the laser

Desiccant module

C h a p t e r 7 Ma i n t e n a n c e

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 37

To replace the fuse:

1. Turn the power off and unplug the spectrometer.

2. Move the sliding fuse cover on the control panel to the left.

3. Remove the fuse by pulling out the black plastic handle.

4. Replace the fuse with one of the same type (please refer to Section 2.4 on

page 9 for fuse types).

5. Move the sliding fuse cover back to the right.

6. Plug in the spectrometer and turn the power on.

The surfaces of optical windows can sometimes accumulate dust, grease or other

contaminants, leading to noisy spectra and undesired absorption bands. In this

case, the windows should be cleaned or replaced.

Never touch the windows surfaces with bare hands.

Avoid exhaling near window surfaces.

Never remove the mirror or the mirror support that is under

the left (output beam) cover of the spectrometer.

WARNING! Cleaning optical elements may result in an exposure of

Class II laser radiation, do not stare into the beam or view

with optical instruments.

7.6.1.1 Cleaning the windows

If dust is on the window surfaces:

gently blow dry, oil-free instrumentation air or dry nitrogen across

the surface. Do not use a high-pressure jet.

7.5 Replacing

the fuse

7.6 Cleaning

or replacing

windows

7.6.1 Optical side port

windows

S e c t i o n 7 . 6 Cl e a n i n g o r r e p l a c i n g wi n d o ws

38 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

If grease or other contaminants are on the window surfaces:

windows replacement may be necessary. Optical side port window

surfaces should never be wiped.

7.6.1.2 Replacing the windows

For spectrometers with hygroscopic beamsplitter (FTLA2000-

100, FTLA2000-102, and FTLA2000-155), do not replace

windows if the relative humidity is higher than 50%.

Windows are optical components and should be handled with

care. Never touch their optical surfaces with bare hands. Hold

them by the rim.

1. Leave the spectrometer on.

2. Unscrew the four screws holding the window ring.

3. Remove the window assembly from the side plate.

4. Install the new window assembly on the side plate.

5. Tighten the four screws holding the window ring.

7.6.2.1 Cleaning the windows

If dust is on the window surfaces:

Gently blow dry, oil-free instrumentation air or dry nitrogen across

the surface. Do not use a high-pressure jet.

If grease or other contaminants are on the window surfaces (except for

KBr, KCl, and CsI windows):

Clean dirt off with a cotton or optical cloth, or laboratory wiping tissue,

wetted with methanol or acetone.

Make sure to dry off the excess liquid.

7.6.2 Other windows

C H A P T E R 8

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 39

TROUBLESHOOTI NG

WARNING! Opening the enclosure may result in exposure to laser

radiation and high voltages.

The enclosure is to be opened only by authorized ABB Inc.

Service Personnel.

Laser type: He-Ne

Laser class: 3B as per IEC-60825-1 and

Class IIIa as per 21 CFR 1040.10

Output power: 3.2 mW (maximum)

Wavelength: 632.8 nm

High voltages are present inside the enclosure. Always

proceed with care when the enclosure is open.

This chapter describes the main problems that may be encountered immediately

after applying power to the spectrometer or during its use.

The following table provides troubleshooting information for problems that may

be encountered after applying power to the FTLA2000 Series spectrometer:

Problem Possible cause Solution

POWER LED not lit Spectrometer not plugged in or

not turned on

Plug in spectrometer and turn on.

Fuse blown Replace the fuse.

(See Section 7.5 on page 37.)

Power outlet dead Test outlet.

LED sequence incorrect

(on start up)

Internal problem Contact ABB Inc.

(See Section 8.3 on page 43.)

DATA LED not flashing

(after start up)

Internal problem Contact ABB Inc.

(See Section 8.3 on page 43.)

8.1 After power-up

S e c t i o n 8 . 2 Du r i n g u s e

40 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

The following table provides troubleshooting information for problems that may

be encountered during use of the FTLA2000 Series spectrometer:

Problem Possible cause Solution

No signal Ethernet cable not properly

connected

FT-IR Ethernet Interface or

computer network adapter not

properly configured

Connect Ethernet cable and configure devices

as shown in the FT-IR Ethernet Interface and

External Ethernet Interface User's Guide.

Instrument not selected Make sure the correct instrument is selected in

the software.

Network problem Check with network administrator.

Detector saturation Reduce preamplifier gain.

Install a neutral density filter to attenuate

the beam.

Preamplifier / detector failure Check detector status.

Check preamplifier connections.

Contact ABB (see Section 8.3).

Noise only Source breaker switch is OFF

or tripped

Set source breaker switch to ON.

Source failure Replace the source (see Section 7.3).

Weak signal IR beam blocked Remove obstacle.

Preamplifier / detector

malfunction

Check detector status.

Check preamplifier connections.

Contact ABB (see Section 8.3).

Low S/N Electromagnetic interference Observe raw spectra.

Separate from interfering equipment.

Mechanical vibration Isolate or remove vibration source.

Dirty windows Clean or replace windows (see Section 7.6).

Strong, undesired water lines in

spectra (in the region of 1500 cm

-1

and 3700 cm

-1

)

Exhausted desiccant or purge

gas failure

Replace desiccant (see Section 7.2).

Check supply of purge gas

Abnormal spectra

(see Figure 8-1 and Figure 8-2)

Source contamination Replace the source (see Section 7.3).

If problem persists, inspect to determine source

of contamination.

Detector saturation Adjust preamplifier gain

8.2 During use

C h a p t e r 8 T r o u b l e s h o o t i n g

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 41

Figure 8-1. MIR spectra showing source contamination

Figure 8-2. MIR spectra showing detector saturation

Highly

contaminated

Normal

Contaminated

Normal

Saturated

Highly

saturated

S e c t i o n 8 . 2 Du r i n g u s e

42 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

This section provides examples of typical warning and error messages that may

be displayed on the computer when a hardware problem is encountered.

Note: The actual messages may be somewhat different than those shown here,

depending on the software program and operating system you are using.

8.2.1.1 On selecting a function in the Collect menu

Possible cause Solution

No instruments were detected by the Ethernet

software.

Make sure the FT-IR Ethernet Interface of the spectrometer and

the Ethernet network adapter in the computer are properly

configured.

Refer to the FT-IR Ethernet Interface and External

Ethernet Interface User's Guide.

8.2.1.2 After acquiring a spectrum

Warning Possible cause Solution

Warning: background file is

saturated

The detector was saturated

during acquisition of the

reference spectrum.

Reduce the preamplifier gain (refer to Section 3.4 on

page 19).

Install a neutral density filter to attenuate the beam

Optical saturation detected The detector was saturated

during acquisition of the

reference spectrum.

Reduce the preamplifier gain (refer to Section 3.4 on

page 19).

Install a neutral density filter to attenuate the beam

8.2.1.3 Other messages

Refer to the manuals and release notes for your software program.

8.2.1 Software

messages about

hardware

problems

C h a p t e r 8 T r o u b l e s h o o t i n g

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 43

If you are unable to solve a problem, contact ABB (see Customer support on

page iii). Please be prepared to give the serial numbers of all units.

Before contacting ABB, please check the following:

Power is applied to each device check the power outlet, the power

cable(s), and the fuse(s).

The spectrometer POWER LED is ON and the DATA LED is flashing

(see Section 3.3.1 on page 19).

The spectrometer source breaker switch (if present) is turned ON.

There is light coming from the spectrometer output(s) (unless an optical

filter is installed).

All cables are properly installed (refer to the installation guide).

All pertinent troubleshooting steps in this manual have been followed.

Note down the serial number of the spectrometer and of each

instrument and accessory.

Using Bomem-GRAMS, try to acquire a reference spectrum, and

a transmittance spectrum. Acquire both spectra open beam (i.e. with no

sample present).

Perform the BASIC test sequence in SpecTest.

Send the following to your ABB representative:

The serial numbers

The two spectra

The BASIC test report file

The name, phone number, and e-mail address of the person to

contact

Indicate if a modem and pcAnywhere are installed on the

computer

See note on next page.

8.3 Contacting ABB

S e c t i o n 8 . 4 E x a mp l e s o f n o r ma l s p e c t r a

44 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

Note: SpecTest stores the instrument test reports in the subdirectories

INSTALL, EXTENDED, and BASIC. Each instrument configuration has

a separate subdirectory CONFIGn, within which is a subdirectory for the

current month YYYY_MM. The instrument test report file is named

YYYY MM DD hh mm ss.QAL:

where n is the configuration number

YYYY is the year

MM is the month

DD is the day

hh is the hour

mm is the minute

ss is the second

For example, the instrument test report file for the BASIC test of

configuration 1 performed on May 8, 2000 at 11:23:45 AM is:

C:\SPECTEST\INSTALL\CONFIG1\2000_05\2000 05 08 11 23 45.QAL

Figure 8-3 and Figure 8-4 show typical examples of normal open-beam spectra

for both MIR and NIR spectrometry using different configurations.

8.4 Examples of

normal spectra

C h a p t e r 8 T r o u b l e s h o o t i n g

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 45

MIR NIR

Figure 8-3. Examples of normal open-beam spectra

S e c t i o n 8 . 4 E x a mp l e s o f n o r ma l s p e c t r a

46 FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide

MIR NIR

Figure 8-4. Examples of normal open-beam spectra

A P P E ND I X A

FTLA2000 Series Laboratory FT-IR Spectrometers Users Guide 47

TECHNI CAL I NFORMATI ON

The following information includes specifications and performance statements

that may be in conflict with other ABB published literature, such as product

flyers and product catalogs. In case of conflicts between information given

below and specifications given in the ABB official flyers and product catalogs,

the later take precedence.