Beruflich Dokumente

Kultur Dokumente

Icst 1004

Hochgeladen von

International Jpurnal Of Technical Research And Applications0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten4 Seiten.

Originaltitel

ICST 1004

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten4 SeitenIcst 1004

Hochgeladen von

International Jpurnal Of Technical Research And Applications.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume-2, Special Issue 1 (July-Aug 2014), PP. 15-18

15 | P a g e

ACOUSTIC ABSORPTION AND

PHYSICOMECHANICAL PROPERTIES OF

SBR/RR FOAM

Bashir Algaily, Sombat Puttajukr

Division of Applied Physics, Department of Science

Faculty of Science and Technology, Prince of Songkla University

Pattani Campus, 94000 Thailand

Abstract This research focuses on the enhancement of

acoustic absorption coefficient () with a broadband frequency

response of a styrene butadiene rubber (SBR) blended with a

reclaimed rubber (RR) (SBR/RR foam) composites by

increasing the number of microstructure open cells using an

inorganic chemical blowing agent (sodium bicarbonate). The

effect of various compositions between RR and virgin SBR on

the Physicomechanical properties was investigated as well. The

results obtained clearly demonstrate that all samples provide

superior sound absorption and the accession of the RR to the

composition influenced the foams ability and respectively the

acoustic and the physical property of the blends. This new

material can be utilized in different sound absorption

applications and therefore helps to minimize hazards of the

noise and air pollutions.

Keywordsacoustic absorption coefficient, reclaimed

rubber, sodium bicarbonate and styrene butadiene.

I. INTRODUCTION

Nowadays there are more concerning on the

environmental pollution resulting from living and industrial

waste materials. Particularly among the waste materials,

waste tires were recorded as the most obvious hazard,

because it need very long time for natural degradation due to

cross-linked structure of rubbers and presence of stabilizers

and other additives. This leading to serious environmental

pollutions. Thus, it is necessary to find new methods for

reclaiming tires and recycling it for other applications [1]. On

the other hand, the acoustic noise from the traffic system and

modern industries become more serious issue in our life. One

way that used to reduce the acoustic noise by using sound

insulation and sound absorption materials. Enhancement of

acoustic absorber materials, particularly at low frequencies

have been attracted enormous interest for building or

transportation.

The audio frequencies are identified as frequency range

for human hearing roughly from 20 Hz - 20,000 Hz, also can

be affected by varying parameters such as physical condition

and age. The sound frequencies range from 500 - 2048 Hz is

most important for the oral communication [2]. Therefore,

attenuated or absorbed sound materials in this frequency

range are important tools to reduce the acoustic noise for

human. Acoustic absorbent materials are applied extensively

to manipulate the levels of the acoustic noise. Viscous losses,

Helmholtz resonance effect and the thermal damping are the

primary mechanisms for the acoustic absorption in the rubber

foam. A major drawback of conventional porous absorbers is

their performance in the low frequency range [3].

The terms rubber foam or sponge rubber refers to various

types of cellular rubber products from either dry natural

rubber or synthetic rubber. Open-cell sponge rubber has an

interconnecting cell structure similar to that of latex foam. In

contrast, closed-cell sponge rubber contains discrete non-

inter connecting cells. Open-cell sponge rubber compounds

contain blowing agents that are gas-producing chemicals.

Sodium bicarbonate was used as a blowing agent in most

open-cell sponge rubber compounds. Heat during the early

stages of vulcanization, causes the release of gas from the

blowing agent. The gas causes the rubber to expand. The

cure system present in the compound must be capable, at this

point of permitting the blown rubber to set up rapidly, so that

its cellular structure does not collapse prior to vulcanization.

The reclaiming of tires in alternative applications is

actually the use of base polymer in new formulations with

simultaneous cost saving in raw material and preserving both

natural resource and environment. The addition of reclaimed

rubber into virgin rubber play important roles towards the

market competition and production economy. By adding

reclaimed rubber to the virgin SBR with blowing agent to

obtain new polymer composites to behave as acoustic

absorption material. There are a few interesting to develop a

procedure for the design of material with high acoustic

properties, broadband sound absorption and to assess the

potential of used recycled tires as the main component of

acoustic materials for ceiling and walls.

Enhancement of sound absorption refers to large amount

of sound energy lose inside of the materials. Benkreira and

his group developed material from elastomeric waste residue

mixed with a foaming binder results in a new material with

micro porosity which can enhance the acoustic absorption

[4]. Najib and coworkers used an inorganic blowing agent

(sodium bicarbonate) mixed with the natural rubber

compounds. They found that it produces bubbles with an

open cell structure [5], resulting in an improvement of sound

absorption in the material.

In this research, SBR/RR foam added with blowing agent

sodium bicarbonate was performed in this study. Sodium

bicarbonate was used as an inorganic chemical blowing agent

that can release carbon dioxide gas during decomposition. It

decomposed at a relatively low temperature (145-150C) [5,

6] to enhance the acoustic absorption of the SBR/RR

material.

II. MATERIALS AND METHODS

Table 2 shows the materials and compounds

compositions used in this study. All materials were

commercial grade and used as supplied.

A. COMPOUNDING

Blending of virgin SBR, several compositions with RR

and other chemical ingredients were carried out in two-roll

milling machine, the entire time of mixing kept constant for

all composites (30 min) at ambient temperature.

Consequently, the blowing agent (sodium bicarbonate) and

sulfur was added at the last stage of mixing respectively.

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume-2, Special Issue 1 (July-Aug 2014), PP. 15-18

16 | P a g e

B. CURE CHARACTERISTICS

The cure characteristic of the mixing materials was

observed by an oscillating disc rheometer (ODR 2000) in

conformity with the ASTM D2084 at 160C. The optimum

curing time (t

90

) was determined from the rheometer chart.

The final compounded rubber mixture was sent to compress

in a molding machine to complete the curing (vulcanized

rubber) at 160C, respective to optimum curing time obtained

from the rheograph.

C. PHYSICOMECHANICAL PROPERTIES

Elongation at break and tensile strength were evaluated

using a tensile test machine (Hounsfield, model H10KS) at

ambient temperature (24C) with a constant speed of

separation of 50 mm/minute. In this study, the measurements

of the Crosslink density of SBR/RR blends were evaluated

using the Mooney-Rilvin relationship, which identified the

strain-strain behavior of the vulcanized rubber. The cross-

link density can be determined using equations below. By

plotting /2 (

-2

) against 1/, C

1

and C

2

are constants,

which, C1 value obtained from the intercept of the graph on

the /2 (

-2

) and C2 is the slope. C

1

can be utilized to

estimate them physical crosslink density (N

phys

), which is

merely given by Sombatsompop and Lertkamolsin [7]:

F = 2A

0

(

-2

) (C

1

+ C

2

-1

)

(1)

0

/ (

-2

) = 2C

1

+ 2C

2

/

(2)

N

phys

= C

1

/ RT

(3)

F stands for the strength desired for extension the sample

(Force), A

0

represents the unit area of the un-stretched

sample,

0

was defined as the force over cross-sectional area,

and is the elongation ratio. T is the absolute temperature,

and R is the gas constant.

The densimeter (MD-300S) was used to measure the

apparent rubber density of samples. The determination of the

exact density of samples was recurrent at sundry times to

hold the mean values. The density of the samples was

determined from the average from at least three

measurements.

D. SOUND ABSORPTION COEFFICIENT

MEASUREMENT

The sound absorption coefficient () was carried out

using a standing wave tube (Kundts tube). The standing

wave tube composed of an impedance tube, microphone,

speaker and digital analyzer. A sample with 3.0 mm of

thickness was placed at one end of the tube and a plane

acoustic wave propagates parallel to the axis of the tube, for

different frequencies in the range from 125 to 2000 Hz were

generated by a function generator. This method presents

several advantages with regard to other methods (i) needing

only small test specimens (ii) very fast and (iii) the values are

reproducible.

Sound absorption coefficient () can be determined as the

ratio of energy absorbed by a material to the total incident

energy at the surface. When the tube is forced out with

acoustic absorbing material, some of the incident sound

energy is taken up by the material presents a phase shift upon

reflection. The amplitude at a pressure, maximum pressure

(antinode) is A+B, and the amplitude at minimum pressure

(node) is A-B. Because it is not possible to measure A or B

directly. Nevertheless, the amplitude at a pressure node and

anti-node can be assessed utilizing a microphone probe,

which is put in a standing wave tube. The standing wave

ratio (SWR) defined as the ratio of pressure maximum to a

pressure minimum [8].

SWR = (A + B) / (A B) (4)

And

R = B/A = (SWR - 1) / (SWR + 1) (5)

Where R is the reflection coefficient. Then the sound

absorption coefficient defined by:

= 1 R

2

= 1 - (SWR - 1)

2

/ (SWR + 1)

2

(6)

TABLE 1. CHEMICAL ANALYTICAL DATA FOR RECLAIMED RUBBER

III. RESULTS AND ANALYSES

A. CURE CHARACTERISTICS

Curing characteristics of different SBR/RR blended

systems with sodium bicarbonate loading can be determined

by the cure time (t

90

) and were summarized in Table 2. The

results indicate that the t

90

increase with increasing of RR,

probably due to the chemical interaction during the curing

process with the presents the RR. Carbon dioxide gas (CO

2

)

behaves as an efficient solvent in most rubbers; the CO

2

molecules stack interstitially between the rubber chains,

hence increasing the mobility of the polymer chains as well

as enlarge the free volume consequently [5].

The measurement of the minimum torque (M

L

) represents

the hardness of an unvulcanized rubber by consider at the

lowest level of the curve, while the maximum torque (M

H

)

represents the value of hardness or the shear modulus of the

fully vulcanized rubber and also used to estimate the

Crosslink density of the rubber. The M

H

and M

L

from all

samples were summarized in Table 2, indicating that the M

H

and M

L

increase with an increasing of RR contents due to the

presence of cross-linked gel in the RR as mentioned in

elsewhere [9].

TABLE 2. MIX FORMULATION AND CURE CHARACTERISTICS OF THE

SBR/RR BLENDS.

B. PHYSICOMECHANICAL PROPERTIES

The physicomechanical properties of SBR/RR blended

with various compositions of the RR are shown in Table 2.

The elongation increases with an increasing RR content in

the composites due to the addition of the RR into SBR

compounds spontaneously increase a carbon black

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume-2, Special Issue 1 (July-Aug 2014), PP. 15-18

17 | P a g e

concentration in the mixture. This results in a molecular

interaction between the carbon black and the rubber phase.

Moreover, the tensile strength also increases with RR

concentration due to increasing of the crosslink density.

Table 2 illustrates that the adding the RR and sodium

bicarbonate influence the crosslink density. The additional of

RR into fresh SBR led to enhance the crosslink density due

to presence the active crosslinking sites in the RR. Greater

RR material added means large active crosslinking density

sites for the crosslink formation as reported by Kumnuantip

and Sombatsompop [10].

The average apparent density of samples is given in

Table 2, indicating that the density of the SBR/RR foams

increases with an increasing of RR content as well, and the

foaming effectiveness decreases similar found by Kim and

his group [11].

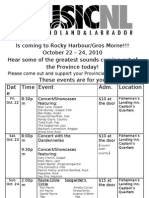

C. SOUND ABSORPTION

All rubber foams samples shown superior for sound

absorption as depicted in Figure 1. Foamed SBR foam with

zero RR (sample S1, line with circles) reveals maximum

acoustic absorption coefficient () around 500 Hz. The

frequency which provide highest acoustic absorption peak is

called a resonance frequency. For a sample S2 (line with

triangles) and S3 (line with crosses) contained 20.0 phr and

40.0 phr of RR respectively, the second resonant frequency

shift to the higher frequency around 800 Hz due to the solid

structure and morphology of materials were influenced by

presenting the RR and present of high concentration carbon

black obtained from the RR (see Table 1). This leads to a

reduction in the sound absorption similar found by Zhao et

al. [12]. They claimed that when incidence sound waves

reached materials with high carbon black composition, the

sound wave will involve dispersion, diffraction, refraction

and reflection phenomena, led to a reduction in the acoustic

absorption coefficient.

Figure 1. Acoustic absorption coefficient of SBR/RR foams as a

function of frequency.

In addition, this present study found that the RR in the

composition restricted the foam efficiency and reduce the

pore size [13], consequently, reduce the amount of sound

energy absorbed in the material. The sound pressure along a

solid structure may can lose energy by deform the skeletal. If

the solid surface of the materials is highly porous, fraction of

the sound pressure infiltrates the material before coming

across a strong surface. While for nonporous surface,

incident energy reflects back into the environments. A great

energy can transpose to the whole structure by the internal

reflections through frictional losses and efficiently absorb

sound. To achieve higher acoustic absorption performance,

the pressure wave must go deep enough inside the material

and not be reflected back directly into the surroundings.

When the pore size is too small, more energy is reflected

back from the surface and less is transferred into the solid

structure, the material become less useful as an acoustic

absorber [2].

IV. CONCLUSION

The reclaiming of tires in alternative applications is

actually the use of based polymer in new formulations with

simultaneous cost saving in raw material and preserving both

natural resource and environment. As a conclusion, the

composites made from the SBR/RR foam have been

investigated. The results indicated that the maximum and

minimum torque, elongation at break, tensile strength,

crosslink density and density increase with an increasing of

the reclaimed rubber content. The resonant frequency with

maximum sound absorption coefficient for the SBR foam

was observed at 500 Hz, while the resonant frequency of

SBR/RR form shift to higher frequencies at 800 Hz found

from both compositions independent with amount of RR

contents. Therefore, adding RR into SBR results in the

shifted of resonant frequency to a higher frequency. By

adding chemical blowing agent sodium bicarbonate, a

number of microstructure open cells were increased,

resulting in enhancement of acoustic absorption of the

material.

ACKNOWLEDGEMENTS

The authors would like to thank the SAT Scholarships for

International Students of Faculty of Science and Technology

Prince of Songkla University (SAT-PSU) for financial

support throughout this work.

REFERENCES

[1] Yang HS, Kim DJ, Lee YK, Kim HJ, Jeon JY, Kang CW

(2004) Possibility of using waste tire composites reinforced

with rice straw as construction materials. Bioresource

Technology 95: 61-65.

[2] Maria AK, James CJ (2011) Acoustic absorption in porous

materials. . Report No. NASA/TM.316995.

[3] Mahasaranon S, Horoshenkov KV, Khan A, Benkreira H

(2012) The Effect of Continuous Pore Stratification on the

Acoustic Absorption in Open Cell Foams. Journal of applied

physics 111: 084901.

[4] Benkreira H, Khan A, Horoshenkov KV (2011) Sustainable

acoustic and thermal insulation materials from elastomeric

waste residues. Chemical Engineering Science 66: 4157-4171.

[5] Najib NN, Ariff ZM, Bakar AA, Sipaut CS (2011) Correlation

between the acoustic and dynamic mechanical properties of

natural rubber foam: Effect of foaming temperature. Materials

& Design 32: 505-511.

[6] Najib NN, Ariff ZM, Manan NA, Bakar AA, Sipaut CS

(2009) Effect of Blowing Agent Concentration on Cell

Morphology and Impact Properties of Natural Rubber Foam.

Journal of Physical Science 20 (1): 13-25.

[7] Sombatsompop N, Lertkamolsin P (2000) Effects of Chemical

Blowing Agents on Swelling Properties of Expanded

Elastomers. Journal of Elastomers and Plastics 32: 311-328.

[8] Gayathri R, Vasanthakumari R, Padmanabhan C (2013)

Sound absorption, Thermal and Mechanical Behavior of

Polyurethane Foam Modified with Nano Silica, Nano Clay

and Crumb Rubber Fillers. International Journal of Scientific

& Engineering Research 4(5): 301-308.

[9] De D, De D (2011) Processing and Material Characteristics of

a Reclaimed Ground Rubber Tire Reinforced Styrene

Butadiene Rubber. Materials Sciences and Applications 2:

486-496.

[10] Kumnuantip C, Sombatsompop N (2003) Dynamic

Mechanical Properties and Swelling Behavior of

NR/Reclaimed Rubber Blends. Materials Letters 57: 3167-

3174.

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume-2, Special Issue 1 (July-Aug 2014), PP. 15-18

18 | P a g e

[11] Kim JH, Choi KC, Yoon JM (2006) The Foaming

Characteristics and Physical Properties of Natural Rubber

Foams: Effects of Carbon Black Content and Foaming

Pressure. J. Ind. Eng. Chem. 12 (5): 795-801.

[12] Zhao J, Wang XM, Chang JM, Yao Y, Cui Q (2010) Sound

Insulation Property of Wood-Waste Tire Rubber Composite.

Composites Science and Technology 70: 2033-2038.

[13] Xin ZX, Zhang ZX, Pal K, Kang DJ, Lee SH, Kim JK (2009)

Effects of Waste Ground Rubber Tire Powder (WGRT) and

Chemical Blowing Agent Content on the Cell Morphology

and Physicomechanical Properties of Injection-Molded

Polypropylene/WGRT Foams. Journal of Vinyl & Additive

Technology 15(4): 275-280.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Sheet Music - Persian Classical Music, Dastgah-E Mahour: Gusheh Chaharpareh.Dokument3 SeitenSheet Music - Persian Classical Music, Dastgah-E Mahour: Gusheh Chaharpareh.patrickduka123100% (2)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Soundproofing Solutions-En 2019 02 PDFDokument182 SeitenSoundproofing Solutions-En 2019 02 PDFTanase MariusNoch keine Bewertungen

- Energy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsDokument4 SeitenEnergy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsInternational Jpurnal Of Technical Research And Applications100% (1)

- Bechstein Piano CatalogueDokument31 SeitenBechstein Piano CatalogueCarlo SantosNoch keine Bewertungen

- Modulations - Grisey PDFDokument128 SeitenModulations - Grisey PDFRodrigo CardosoNoch keine Bewertungen

- P.A. SystemDokument52 SeitenP.A. SystemSylvester Delali DordziNoch keine Bewertungen

- Sumita PDFDokument5 SeitenSumita PDFInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Exponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisDokument7 SeitenExponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Postponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisDokument6 SeitenPostponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Study of Nano-Systems For Computer SimulationsDokument6 SeitenStudy of Nano-Systems For Computer SimulationsInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Sumita PDFDokument5 SeitenSumita PDFInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Qualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraDokument9 SeitenQualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Digital Compressing of A BPCM Signal According To Barker Code Using FpgaDokument7 SeitenDigital Compressing of A BPCM Signal According To Barker Code Using FpgaInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Aesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleDokument30 SeitenAesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleInternational Jpurnal Of Technical Research And Applications100% (2)

- An Experimental Study On Separation of Water From The Atmospheric AirDokument5 SeitenAn Experimental Study On Separation of Water From The Atmospheric AirInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Modelling The Impact of Flooding Using Geographic Information System and Remote SensingDokument6 SeitenModelling The Impact of Flooding Using Geographic Information System and Remote SensingInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Overview of TCP Performance in Satellite Communication NetworksDokument5 SeitenOverview of TCP Performance in Satellite Communication NetworksInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Pod-Pwm Based Capacitor Clamped Multilevel InverterDokument3 SeitenPod-Pwm Based Capacitor Clamped Multilevel InverterInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Li-Ion Battery Testing From Manufacturing To Operation ProcessDokument4 SeitenLi-Ion Battery Testing From Manufacturing To Operation ProcessInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- An Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionDokument5 SeitenAn Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Implementation of Methods For Transaction in Secure Online BankingDokument3 SeitenImplementation of Methods For Transaction in Secure Online BankingInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Scope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewDokument5 SeitenScope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewInternational Jpurnal Of Technical Research And Applications100% (1)

- Time Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsDokument5 SeitenTime Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- The Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting MethodDokument3 SeitenThe Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting MethodInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Evaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisDokument9 SeitenEvaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Open Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsDokument3 SeitenOpen Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Physico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.Dokument4 SeitenPhysico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.International Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Performance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueDokument3 SeitenPerformance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueInternational Jpurnal Of Technical Research And Applications100% (1)

- Effect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyDokument8 SeitenEffect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- A Study On The Fresh Properties of SCC With Fly AshDokument3 SeitenA Study On The Fresh Properties of SCC With Fly AshInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Investigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaDokument6 SeitenInvestigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Parametric Modeling of Voltage Drop in Power Distribution NetworksDokument4 SeitenParametric Modeling of Voltage Drop in Power Distribution NetworksInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Study of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiDokument9 SeitenStudy of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- Production of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationDokument4 SeitenProduction of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationInternational Jpurnal Of Technical Research And Applications100% (1)

- Structural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesDokument3 SeitenStructural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesInternational Jpurnal Of Technical Research And ApplicationsNoch keine Bewertungen

- HeadRush Guide - BlocksDokument48 SeitenHeadRush Guide - BlocksTodd CouchNoch keine Bewertungen

- G Coleman Symmetry ExeDokument2 SeitenG Coleman Symmetry ExeTiago CordeiroNoch keine Bewertungen

- A Review of Damage Risk Contours For Occupational Noise ExposureDokument43 SeitenA Review of Damage Risk Contours For Occupational Noise ExposureWilliam Lopez Jaramillo100% (1)

- WA300-600 BC300 Manual English 1Dokument14 SeitenWA300-600 BC300 Manual English 1Νεκτάριος ΛάκκοςNoch keine Bewertungen

- Manual Denon AVR-1910Dokument2 SeitenManual Denon AVR-1910liviugiurgi100% (1)

- A/D ConvertersDokument2 SeitenA/D ConvertersandrogynusNoch keine Bewertungen

- Ultrasonic Blind Stick With GPS and GSM TrackingDokument11 SeitenUltrasonic Blind Stick With GPS and GSM TrackingIJRASETPublicationsNoch keine Bewertungen

- Sa-Vs400h wvs500 ss-cn500 ms442 vf500Dokument3 SeitenSa-Vs400h wvs500 ss-cn500 ms442 vf500drishkNoch keine Bewertungen

- Communications Systems - PLM-4Px2x PLENA Matrix DSP AmplifiersDokument4 SeitenCommunications Systems - PLM-4Px2x PLENA Matrix DSP AmplifiersS.M. INJAMULNoch keine Bewertungen

- Music NLEventsDokument2 SeitenMusic NLEventsJackie HiscockNoch keine Bewertungen

- Last Name: - First Name: - Middle Initial: - Section: - Proctor: - DateDokument2 SeitenLast Name: - First Name: - Middle Initial: - Section: - Proctor: - DateDEXTER JOHN GOMEZNoch keine Bewertungen

- Owner'S Manual: 12-Channel Compact MixerDokument28 SeitenOwner'S Manual: 12-Channel Compact MixerAphra SchnaelNoch keine Bewertungen

- The Trumpet 3 User ManualDokument40 SeitenThe Trumpet 3 User ManualJesus NavarroNoch keine Bewertungen

- T.C. Electronic M3000 User ManualDokument78 SeitenT.C. Electronic M3000 User ManualStanleyNoch keine Bewertungen

- SNR For SI Auditorium Acoustics Design IndexDokument68 SeitenSNR For SI Auditorium Acoustics Design IndexRaphael ChristantoNoch keine Bewertungen

- Ultrasonic InterferometerDokument5 SeitenUltrasonic InterferometersilentNoch keine Bewertungen

- Rei Do Gado Tema GradeDokument17 SeitenRei Do Gado Tema GradeEvandro Muniz SoaresNoch keine Bewertungen

- Magicstomp Sound ListDokument2 SeitenMagicstomp Sound ListFabio VitaleNoch keine Bewertungen

- Ms12sd4 Om enDokument12 SeitenMs12sd4 Om enamal baik gintingNoch keine Bewertungen

- Zero-G Whoosh Designer: User ManualDokument10 SeitenZero-G Whoosh Designer: User ManualGörkem Berk AğarNoch keine Bewertungen

- Music: Music of Cordillera, Mindoro, Palawan, and The VisayasDokument10 SeitenMusic: Music of Cordillera, Mindoro, Palawan, and The VisayasJames JamesNoch keine Bewertungen

- Waves and Sound P2Dokument40 SeitenWaves and Sound P2Muhammad FaisalNoch keine Bewertungen

- Anya Specs RevaDokument10 SeitenAnya Specs RevaAugusto KozukiNoch keine Bewertungen

- Electrix Repeater User ManualDokument48 SeitenElectrix Repeater User ManualsteveauburnNoch keine Bewertungen