Beruflich Dokumente

Kultur Dokumente

P 159 Content

Hochgeladen von

Aaditya Pratap Sanyal0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

83 Ansichten28 SeitenCost estimate details

Originaltitel

p 159 Content

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCost estimate details

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

83 Ansichten28 SeitenP 159 Content

Hochgeladen von

Aaditya Pratap SanyalCost estimate details

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 28

PDHonline Course P159 (3 PDH)

Cost Estimating and Tricks of

the Trade - A Practical Approach

2012

Instructor: Timothy D. Blackburn, MBA, PE

PDH Online | PDH Center

5272 Meadow Estates Drive

Fairfax, VA 22030-6658

Phone & Fax: 703-988-0088

www.PDHonline.org

www.PDHcenter.com

An Approved Continuing Education Provider

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 1 of 27

Cost Estimating and Tricks of the Trade A Practical Approach

Timothy D. Blackburn, PE, MBA

Course Content

Course Introduction

We as engineers, consultants, owner reps, and project managers are frequently asked to

provide estimates. How do we go about this? What minimum scoping/design is needed to

achieve a stated estimate accuracy? What accuracy can we be reasonably expected to attain at a

given scope/design level? This course will answer these questions and provide practical insights

to developing meaningful estimates. The course will also offer advice to avoid common pitfalls

and exclusions from estimates. This course is filled with practical insight from the Instructors

considerable experience with both the Consultant and Owners perspectives. The course

discusses estimates from the earliest stages to those with well-developed scopes.

What is an estimate?

What is an estimate? Many of our customers view an estimate as a menu. For example,

before you go to the grocery store, you could make a list of what you want. A gallon of milk,

bread, cookies, etc. By simply adding up the individual cost of items you then have an estimate

of your bill. However, construction estimating is not that simple. Rarely are two projects

identical. Webster defines an estimate as arriving at an often accurate but usually only

approximate statement of the cost of a job to be done. The Means Illustrated Construction

Dictionary defines it more closely for our purposes; The anticipated cost of materials, labor,

equipment, or any combination of these for a proposed construction project. In real-world

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 2 of 27

terms, a construction estimate is simply a projection of the likely cost of a project based on an

assumption of scope and cost data.

But there are more misconceptions . . .

Popular Estimating Misconceptions

Not only do customers (and sadly, some in the profession) oversimplify an estimate, there

are many other misconceptions as well that must be dispelled.

! All you need is a phone This can also be referred to as phone call engineering. J ust

call up a vendor or contractor, give a verbal, succinct description of the scope, and they

give a highly accurate estimate for you. Wrong. Many projects have failed financially

because of this approach. A vendor needs a defined, written scope to evaluate probable

costs (except for off-the-shelf items).

! An exact science Actually, estimating is more of an art, but requires a well-rounded

knowledge and experience in the profession. Estimating requires instinct based on

experience. An estimator will create an estimate with many line items, with the

expectation that the whole will be within the expected range of accuracy. A customer

might wish to check each line item of an estimate after bids come in, and probably none

will be an exact match with received bids. However, statistically, a well-developed

estimate should average out closely to the final aggregate bids. Some line items will be

high, and others low.

! Can be perfect on all projects Even with experienced and excellent estimators, there

will be projects which will be under or over-estimated. As above, estimating isnt an

exact science. There are just too many variables, especially prior to design (scope,

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 3 of 27

historical relevant costs, market influences, etc.). But as with a good estimate, the sum

total of the estimates should average out.

! Something all engineers are naturally good at Many customers (as well as

inexperienced engineers) can make this flawed assumption. Actually, a relatively small

percentage of professionals, unless specialized, are good at broad-scope estimating (in the

Instructors experience.)

! Something Architectural/Engineering firms are naturally good at Actually, in the

Instructors experience, the opposite is often true. A/E firms should be excellent in their

core business developing scope and design. Often, design disciplines are asked to

develop an estimate even though they do not have experience or hands-on knowledge of

market pricing. Later, we will learn a strategy to improve such estimates.

! Can accurately predict bids Bids can fluctuate wildly even after the design is final.

There are many dynamics that determine final bid values from subcontractor or vendors.

These include material pricing arrangements, workload, proximity, etc.

! It cant cost that much . . . Often, people have a preconceived notion as to what

something should cost. Budgets can even be set without proper knowledge of the scope.

However, things simply cost what they cost. The key is to agree to a well-defined scope,

and then estimate the project.

! Go with the lowest early price This category is akin to phone-call engineer. When

multiple vendors provide assistance with pricing, be careful of taking the lowest estimate.

They might not understand the scope adequately, or have performed only a cursory

review. On the other hand, also be cautious of such estimates when they appear high

the vendor could be covering itself.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 4 of 27

! You should be able to accurately estimate in a hurry The opposite is true. The accuracy

of an estimate is associated with the time to develop it. The time element is more

associated with scope development than actually entering cost data in a spreadsheet. It

simply takes time to properly determine the scope to a level a reasonable estimate can be

developed. (However, no amount of time can improve an estimate if the project design

steps arent properly developed.) The following chart illustrates this:

Estimating Time vs. Accuracy

Fundamental Scope and Budget

Schematic Design

Preliminary Design/

Design Development

+/- 50%

+/-10%

Hours Days/weeks Weeks/months

Now that weve learned common misconceptions, lets look at some truths of estimating.

The Truths of Estimating

! What you dont know will hurt you Estimating requires a great deal of practical

experience to anticipate scope. But even with experience there are simply things that

cant be anticipated. Therefore, we apply contingency at higher percentages early in

scope development (to be covered later.)

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 5 of 27

! Difficult, especially renovations Estimating is a difficult task. One must anticipate

scope, plus applied costs. To make the task more difficult, renovations add further

challenges. What is buried? Hidden behind a wall?

! Requires solid engineering experience as well as cost histories In order to anticipate

scope, one must have not only solid engineering training, but experience in the project

type as well. In addition, accurate cost histories of similar work are needed.

! Economically influenced Outside economic influences are generally outside the control

of the estimator. There can be unanticipated swings in material and energy costs that can

upset a budget. Labor shortages, strikes, and other factors can impact as well.

! Projects are one-of-a-kind, custom, without the benefit of a prototype Product

development engineering has the benefit to building prototypes before production.

However, facilities and other projects are usually one-of-a-kind. We cant build it, work

the bugs out, and know precisely all the details plus the cost. We must anticipate these.

! A discipline that includes all disciplines An individual estimating a project, when he or

she has multidiscipline estimating responsibility, should have a good idea as to other

disciplines and general working knowledge.

! Important Estimating is difficult; however, it remains important. We must get it right.

The cost of a project can significantly impact the bottom line of an Owner. As well, we

are often held accountable for the accuracy of our estimates.

! A success measure/metric A measure of our success is often how accurately we

estimated a project. Often, there is little room for error allowed. As noted above, we can

be impacted personally in our careers.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 6 of 27

! Essential to business success If we overstate an estimate, we could force the Owner not

to complete other important projects. If we understate an estimate, we could miss a

critical ROI (Return on Investment.) It is simply essential to the health of a business that

capital management be effective. In addition, yearly depreciation charges must be

considered, which go directly against P&L (Profit and Loss.)

! One of our hardest tasks This should be obvious by now. Estimating is difficult, and is

perhaps one of our hardest tasks. While most engineering problems can be quantitatively

resolved, estimating requires an element of intuition and experience that often falls in

areas less quantifiable.

Sources of Estimating Data

Now we begin the practical portion of the course. Where do we find sources of estimating

data that we can use to forecast costs?

! Experience/a good guess Believe it or not, there are times (especially early in a

project) that guesses based on experience are appropriate. However, these should be for

individual line items and not the entire project unless an identical project was just

completed.

! Histories This is the best and most reliable source of costs for early-stage estimating.

Keep track of what projects cost by major subcategories. These will be helpful later.

Remember to increase for inflation. We will cover how to do this later.

! Publications (Means, etc.) There are subscription services that provide cost data. Be

careful, however, and add indirect costs.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 7 of 27

! Contractor databases These are also very useful. Contractors often keep histories of

work that they can use later as sanity checks on proposals and to assist alliance customers

with estimates.

! Contractors/vendors Contractors/Vendors can provide early ball-park estimates.

However, beware of phone call engineering mentioned previously. Often, contractors

will leave out essential additional costs, such as contingencies, taxes, delivery, fees,

permits, design, etc.

! Accounting records You or your customer likely have good records based on

accounting standards as to what previous projects cost. In addition, CMMS

(Computerized Maintenance Management System) often have the costs embedded in

asset records.

Methods of Estimating

Now that we have learned the sources of estimating data, how do we actually perform the

estimate? The following are the primary methods of estimating (often called by different names

but include similar approaches):

! Benchmarking This occurs most frequently for projects in their early stages where data

exists from recent similar projects. Benchmarking can consist of Rules of Thumb (i.e. $

per ton, packaging line, kwh, person, etc.) that can be applied to your project.

! Squarefoot/Assembly Squarefoot estimates often also occur early in the project, using

historical data to determine current cost. Remember, however, to increase for

construction inflation, and to perform a scope gap analysis (add or remove line items for

scope differences rarely are two projects exactly the same.) Assembly estimates can

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 8 of 27

occur after a bit more scope development, projecting costs for assemblies (equipment,

HVAC, utilities, architectural systems, etc.) based on historical data. Often, assembly

estimating is safer than unit take-offs, since it is easy to miss an element.

! Unit takeoff This method is often mistakenly overused early in a project. This involves

counting up or measuring items, such as lineal feet of pipe, etc. and applying historical

unit cost data ($/sf, $/ton, $/lf, $/ea, etc.) this is similar to assembly estimating but at a

more detailed level. This requires a fairly developed design.

! Proposals/Vendor Estimates For this method to be accurate, a well-developed scope

and design are also required. Estimates in this category can come from sub-

contractor/vendor proposals especially.

! Actual material and labor detailed estimates This is only accurate for well-developed

designs, where experienced estimators intimately familiar with the work at hand perform

a material take-off and estimate the man-hours to install. Labor rates and material prices

are primary to the estimate. Typically, project managers and engineers/architects (asked

to be estimators for a day) for a design with low scope development should not attempt

this level of an estimate.

! A good guess/experience (line items) There are some things that we just will be unable

to get our hands around early, and we will need to guess based on our experience.

However, minimize and limit this to line items of an estimate.

! Most early estimates a combination of the above

Some estimate methods are better at projecting costs that others as well as require a higher

degree of scope development. The following graph illustrates relational accuracies and levels of

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 9 of 27

scope development. Note the Benchmarking approach can be used with low scope, but has a low

corresponding accuracy. However, vendor estimates require a high scope development if there is

to be a corresponding high degree of accuracy.

Comparison of Estimating Methods

Benchmarki ng Squarefoot/

Assembly

Unit Takeoff Proposals/

Vendor

Estimates

High

Low

Estimate

Accuracy

Level of Scope

Devel opment

Forgotten Costs

Leaving things out of an estimate is obviously problematic. Although scope is commonly

forgotten, omissions often are the intangibles associated with a project. First, we need to

understand Direct versus Indirect costs. Direct Costs are tangible costs associated with vendors,

equipment, and sub-contractors. Examples include actual equipment costs, subcontracts, etc.

Indirect costs are associated with other requirements necessary to complete the work. These can

include construction management/construction fees and overhead/general conditions, design,

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 10 of 27

pre-operating costs, permits, etc. Unfortunately, people often forget about indirect costs, which

can be 10-50% of the Direct Costs! This most often occurs when the phone call engineering

approach is employed.

The following are specific costs that are sometimes forgotten:

! Taxes

! Delivery

! Rigging

! Equipment Installation

! Insurance

! Design Fees (Rule-of-thumb 6-14% direct construction costs)

! Permit Fees (Rule-of-thumb 1% or higher direct construction costs)

! Premium time (Typicals: Overtime 1.5x, weekend/holiday, 2x)

! Temporary protections/walls

! Mark-up on materials (approx. 10% +)

! FF&E (Furniture, Fixtures & Equipment) Could represent up to 12% (or higher) of the

total cost of an integrated office project

! Utility/Infrastructure

! Sitework

! Data/Telephone

! Commissioning and Qualification (related to Instructors Biopharm industry) Recent

experience: 3% or more of the direct const costs

! Construction Management (CM) or General Contractor (GC) Fees and General

Conditions this category includes the following:

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 11 of 27

o Fee Applied to Direct Const. Costs and GCs. This usually is a percent the CM

charges to cover the following:

! Overhead and profit

! Some home office expenses

o General Conditions (GCs) Sometimes, clients mistakenly think the fee will

cover the following, but GCs are usually calculated based on the specific

requirements and schedule of the project:

! On-site staffing, such as superintendent, project manager, etc.

! Safety supplies

! Trailer, toilets

! Dumpster

! Miscellaneous supplies

! Temporary site Utilities

! Other costs associate with managing the subcontractors, etc.

o Rule-of-Thumb: GCs +Fee =8-15% direct construction costs

Contingency what it is used for?

Owners often view contingency (if permitted) as a source for a wish list later.

Sometimes, thinking estimating is an exact science, Owners will prohibit contingency. However,

contingency is necessary if we are to meet our budgets, whether expressly itemized or

incorporated into line items. Contingency can be applied to the total project, or most commonly

the Direct costs. The following table illustrates the typical applications of contingency. Not that

the purposes of contingency vary at each phase, as well as the typical amounts. Depending on

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 12 of 27

the phase, contingency can be used for scope to some degree, design uncertainties, estimating

uncertainties, hidden conditions, and limited human error. Early on, a higher percentage is

needed to cover for human error and scope inaccuracies. But later, the contingency should not

be primarily used for scope additions. The amounts shown are based on the Instructors

experience, and area applied to Direct Costs. Pause for a moment, and carefully study the

following table.

Contingency what it is used for

Purpose of

Contingency

Fund.,

Scope

and

Budget

(20-40%)

Schematic

Design

(15-30%)

Design

Development

(Preliminary

Engineering)

(>10%)

Design

Phase

(<10%)

Construction

Phase

Scope X Minor

Design

Uncertainties

(not fundamental

scope)

X X X

Estimating

Uncertainties

X X X X

Hidden

Conditions

X X

X

X X

Human Error X X

X

X X

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 13 of 27

As the project progresses, less contingency should be required. The following chart

illustrates the relationship between project phase and contingency needed:

Contingency needed

Fund. Scope &

Budget

Schematic

Design

Design

Devel opment

Detailed

Design

Constructi on Commissioni ng Qualification

& Validation

Project

Operation

L

o

w

H

i

g

h

5

-

1

0

%

3

0

%

+

Present Value Calculations

It is essential that we include construction inflation when utilizing historical data in an

estimate. Often, customers will base an expectation on the cost of a project related to what one

cost years ago. Also, estimates must be forecasted to the year in which the project is planned.

Warning: dont use inflation data you hear from the news. Often, construction inflation exceeds

this determine a reasonable rate based on experience in your market, and/or construction

journals. When increasing historical costs, use the following formula:

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 14 of 27

EV =OC * (1 +i)

^n

Where

! EV =Estimate Value for the time period of the project

! OC =Original Cost or base year of estimating data

! i =Construction inflation

! n =number of years between the OC and the time the

project is to be implemented

Example 1

You installed a utility in 2003 that cost $47/sf. You plan to install a similar system in

2007. What should you allocate as the cost/sf using a construction inflation factor of 4%?

Answer: EV =OC * (1 +i)

^n

= 47 * (1 +0.04)

^(2007-2003)

= $55/sf

Example 2

This approach can also be used to get an initial ball-park or order of magnitude (OOM)

estimate. For example, in 2008, you wish to construct a 60,000 sf warehouse with an attached

10,000 sf office. In 2004, you built a warehouse for $80/sf. You built an office (fully fitted) in

2003 for 150$/sf. What is the estimate assuming 4%/yr construction inflation?

! Warehouse =80 * (1 +0.04)

^(4)

* 60,000 = $5,615,321

! Office =150 * (1 +0.04)

^(5)

* 10,000 = $1,824,979

! Total = $7,440,300

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 15 of 27

(Note: There are dangers with this approach. If the SFs are not similar, you can experience

economies of scale distortions. Also, the older the project, the less accurate the extrapolation.

Finally, there are typically many gaps that must be rectified few projects are exactly the same.)

More Examples

Lets apply more of what weve learned. This section will illustrate sample estimates

similar to those developed by the Instructor for an actual project (prior to design, but for a small

project relatively easy for which to develop a scope.) The truth is, most early to mid estimates

require a combination of the estimating methods discussed earlier. The following illustrative

examples are for the scope of purchasing and installing an industrial piece of equipment, plus the

room in which it is to be installed. Note the methods used to arrive at the individual line items.

The estimates are for the early phases of a project, where the decision is to be made whether or

not to proceed. (Disclaimer: Dont apply the unit rates to your project. These are for illustration

only.)

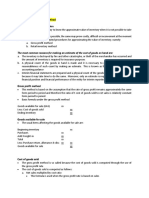

Example 3, Equipment

Item Units Unit Des. $/unit Total Method

Equipment 1 Ea $ 65,000 Vendor

600/day technician plus perdiem 5 Days $ 600 $ 3,000 Unit

VFD 1 Ea $ 5,000 $ 5,000 Unit

Shipping $ 1,500 Vendor

Taxes and fees $ 73,000 Perc 6% $ 4,380 Unit

Electrical connection $ 25,000 Vendor

Conveyor up $ 15,000 Vendor

Auger out $ 20,000 Vendor

Installation $ 12,000 Guess

Rigger $ 8,000 Guess

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 16 of 27

Item Units Unit Des. $/unit Total Method

J ib crane 1 ea $ 8,000 $ 8,000 Unit

Contingency $ 166,880 % 15% $ 25,032 Benchmark

Design fees, electrical connection $ 12,000 Guess

Total, Equipment $ 204,000

Example 4, Room for the Equipment

Item Units Unit Des. $/unit Total Method

Localized floor drain 1 ea $ 15,000 $ 15,000 Sq. Ft./As.

Exhaust ventilation ea $ 12,000 Guess

HVAC modifications ea $ 20,000 Guess

BMS interface 1 lot $ 12,000 $ 12,000 Sq. Ft./As.

Room construction (walls, ceiling,

doors, etc.) 1000 sf $ 74 $ 73,800 Benchmark

Demo allowance $ 10,000 Guess

Hose station, wash-down 1 ea 6000 $ 6,000 Sa. Ft./As.

Contingency $ 148,800 % 20% $ 29,760 Benchmark

GC's $ 148,800 % 12% $ 17,856 Benchmark

Design fees $ 148,800 % 10% $ 14,880 Benchmark

Permit fees $ 148,800 % 1% $ 1,488 Benchmark

Total, Room $ 213,000

Estimating during the Planning and Design Phases

Now that weve learned (or reviewed) the fundamentals of estimating, lets explore the

relationship of estimating to design phases. Estimates are typically required during the planning

and design phases of a project. At various levels of planning and design, there are different

requirements for levels of scope development and differing reasonable expectations for scope

accuracy. The following are the typical steps from project conception until the design is

complete. (These steps are often called by different names, but are similar). Steps are covered

further in the Lifecycle course.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 17 of 27

Fundamental

Scope &

Budget

Schematic

Design

Design

Development

Construction

Documents

Fundamental Scope and Budget

After a project is conceived, the initial planning step is Fundamental Scope and Budget

assessment. At this phase, the primary scope is defined with the primary goals. For example, the

following are typical decisions made during this phase.

1. Number of units to be produced

2. Approximate size of facilities needed

3. Major equipment identified

4. General approach to fit and finish

The above should be developed from interviews with affected parties. The following

documents are generally provided to define the above, and represent only about 2 5% design

completion:

1. Basic scope write-up

2. General Arrangements (floor plans showing major equipment)

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 18 of 27

Following the scope development, an estimate may be performed. The expected error

accuracy for this low level of detail is usually 20-40%. Because of the low level of detail,

estimates are usually based on benchmarks (recent similar projects), experience, and some

squarefeet extrapolations. A generous contingency of 20-40% should be applied to cover

uncertainties including scope, design issues, and estimating accuracies, as well as human error

and hidden conditions (especially for renovations greenfield projects are often easier to

estimate). Often, yearly capital budgets are assigned for this level of project scope development

but create problems later. If a higher accuracy of estimate is needed, proceed to the next step

before establishing the budget.

Schematic Design

At this phase, outside architectural/engineering consultants may be employed to assist the

Owner (if internal qualified resources are not available), especially for moderate and large-sized

projects. This phase builds on the previous, but develops more detail needed to arrive at a better

estimate. This often is the ideal level to develop yearly capital budgets. Design documents

typically needed at this level represent 5-25% design completion depending on project

complexity and typically include the following deliverables:

1. General Arrangement

2. Basic scope write-up

3. P&ID (Piping & Instrumentation Diagrams) and other diagrams

4. Detailed narratives of scope in a standard divisional format (such as CSI), with more

detail on materials and fit/finish.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 19 of 27

5. Narrative on major utility/infrastructure requirements

6. Draft of any required regulatory scoping documentation

Following development of the above, the cost estimate can be refined further, with a typical

expected error of estimate in the 15-30% range depending on project complexity. By this phase,

the estimate can be developed with the same resources as in the previous phase, except assembly

estimate techniques can also be applied, as well as limited unit take-off and vendor pricing

information. However, before final funding requests can be made and we proceed to final design,

the next phase should be considered to ensure a more accurate estimate. As before, there should

be a pause for a business decision before proceeding. The next phase may cost 1-4% of the total

project cost, and should not occur unless there is a business case for proceeding.

Design Development (Preliminary Engineering)

In this phase, the design effort continues to develop the scope to the point a highly accurate

estimate can be acquired. Some also call this phase preliminary engineering. For some small

projects, the next step after conception begins here. At this phase, documents are similar to final

construction drawings except specific details and specifications are lacking. The following are

the typical design document deliverables by this phase, building on and refining the previous.

1. General Arrangement

2. Basic scope write-up

3. P&ID (Piping & Instrumentation Diagrams) and other diagrams

4. Detailed narratives of scope in a standard divisional format (such as CSI), with more

detail on materials and fit/finish.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 20 of 27

5. Narrative on major utility/infrastructure requirements

6. Outline Specifications

7. Final draft of any required regulatory scoping documentation

8. Drawings and plans for all disciplines substantially complete without specific details

9. Typical general details

10. Major equipment schedules

The above deliverables represent approximately 20-50% of the design effort (depending on

the project complexity), and can result in an error of estimate +/-10%. To arrive at this estimate

accuracy, major design decisions/calculations must be complete, and qualified individuals are

needed to perform the estimate. Often, A/E firms (Architectural/Engineering) are excellent at

assigning scope, but poor at estimating. Conversely, construction firms are often excellent at

estimating cost, but poor at assigning scope. Therefore, a good approach is to have both perform

an estimate independently, and meet for a budget reconciliation.

Pause at this phase to again ensure the proper business decision to move forward; the next

step will typically cost 6-14% of the total project cost (usually less the costs incurred for Design

Development.) Complete any value engineering or design to budget exercises if there are

constraints on meeting the scope with an assigned budget.

Construction Documents (Final Design) Control Estimate

In this phase, the design is completed and drawings are finalized to enable permits to be

acquired and bids received. Specific details are added to the drawings, they are crosschecked,

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 21 of 27

and detailed specifications are written. For larger projects, a control estimate may be performed

to ensure there hasnt been scope creep and to further refine the previous estimate. Estimates

at 90% completion may be 5-10% accurate. Estimates at this phase include detailed unit take-

offs and vendor estimates.

The following table summarizes typical rules-of-thumb and approaches at various project

scoping/design steps.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 22 of 27

Table Considerations at various stages

Element Fundamental

Scope and

Budget

Schematic

Design

Design

Development

(Preliminary

Design)

Construction

Documents

(Final Design)

Design percent

completion

0-5% 5-25% 20-50% 90-100%

Typical cost as a

percent of total

1-5% 6-14%

Estimate accuracy 20-40% 15-30% +/-10% 5-10% @ 90%

completion

Contingency 20-40% 15-30% >10% <10%

Basic scope write-

up

X X

General

Arrangements

X X X X

P&ID X X X

Detailed Narratives

of scope

X X

Major equipment

schedules

In narrative X X

Regulatory

documentation

Draft Final Draft X

Drawings and plans Without

specific details

X

Specifications Outline X

S

c

o

p

e

a

n

d

D

e

s

i

g

n

D

o

c

u

m

e

n

t

a

t

i

o

n

Details General/typical X

Benchmarking X X

Squarefoot X X

Assembly X X X

Unit Takeoff Limited X X

Proposals/Vendor

Estimates

Limited X

E

s

t

i

m

a

t

i

n

g

M

e

t

h

o

d

s

Material and Labor

takeoffs

Limited X

Hazards

As we are fairly well along in our course, lets reemphasize and add additional hazards of

estimating, that obviously should be avoided or carefully handled.

! Phone engineering verbal estimates

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 23 of 27

! Scope gaps

! Leaving out other costs, only totaling direct construction costs

! Using previous projects without reconciling or filling in the gaps

! Forgetting escalation (historically 3-6%/yr, some trades higher)

! Impossible or no schedule; poor project organization

! Not considering or understanding customer constraints, production demands

! Not including a multi-discipline team early

! Treacherous team members Oh yes, this happens. Some team members working with

impunity can have an ulterior motive, or not be willing to be involved appropriately in the

beginning and wreck the project at the end with additional requests.

! Utility support Are adequate utilities available? If not, estimates for these as well must

be included.

! Treating early estimate as a menu Parts are usually more costly than the whole if parsed

out. Carefully analyze if portions are taken away that could require a larger percentage of

Indirect Costs for the remaining or other economies of scale.

! Limited local qualified resources =higher costs

Tricks of the Trade/Lessons Learned

! Have many line items Early in an estimate, we wont have the detail. But once scope is

available, more line items have a way of stabilizing the overall estimate. Some categories

will be high, and others low, but experience has shown that good estimates level out.

However, this approach works best when the scope is well defined. If not, you might

leave out essential line items, and the estimate could be less accurate.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 24 of 27

! Keep good records of previous projects. This will be your most reliable source of

historical data, and you will have the best knowledge as to how to apply it.

! On complex jobs, let the A/E and CM both do estimates and reconcile as discussed

previously. If you are a project manager, this should be a key take-away from this

course. Their initial estimates should be performed independently but using the same

scope. Then, follow up with a reconciliation meeting comparing CSI divisions for

differences. There will be a healthy tension that should result in a more accurate estimate

if properly managed. Why this is needed can be further summarized as follows.

o CM/GCs (Construction Managers or General Contractors) may be good at

estimating Divs 1-9, but often poor at 14-17 (MEP or Mechanical, Electrical,

Piping) which can account for >1/3 project cost. As well, they are often weak at

full scope understanding overall

o A/Es are often weak at estimating, but better at scope

! Always do a ball-park estimate as a sanity check before accepting estimates from

others estimate it another way, using benchmarks, etc.

! When little detail exists and for large projects, benchmarking-type estimates tend to be

more reliable

! Be careful when using benchmark $ from projects on which you are not familiar with the

scope

! Recheck mid-way through design watch out for scope creep or those items left out. Its

better to take the lumps early than later.

! Use multiple estimating methods as applicable

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 25 of 27

! Manage accrual/cashflow by a schedule. Often, customers will budget the entire amount

of a project in a year, but there is no way it can be completed in that time frame. With a

good estimate, accruals (financial liability) or cashflows (payout) can be accurately

measured and forecasted.

! Involve different disciplines in scope planning. Especially involve MEP (Mech. Elect.

Piping) trades

! Iron out firm scope as early as possible

! Get help when you need it

! Get an external sanity check! Ask someone else.

! Sleep on it! Let the estimate go a bit stale, then look at it again.

! Use CSI format The Construction Specification Institutes divisional format is useful

and easily recognizable across the industry and disciplines. In addition, it forces us to

think more thoroughly about the line items of the estimate. The following are the major

CSI divisions (slightly modified at places by the Instructor):

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 26 of 27

CSI Format/Divisions A great way to break

out an estimate

! Di v. 1: General Conditions

! Di v. 2: Sitework & Demolition

! Di v. 3: Concrete Work

! Di v. 4: Masonry Work

! Di v. 5: Metals

! Di v. 6: Woods And Plastics

! Di v. 7: Thermal & Moisture

Protection

! Di v. 8: Doors, Windows &

Glass

! Di v. 9: Finishes

! Di v. 10: Specialties

! Di v. 11: Equipment

! Di v. 12: Furnishings

! Di v. 13: Special Construction

! Di v. 14: Conveying Systems

! Di v. 15: Mechanical

! Di v. 16: Electrical

! Di v. 17: Controls & BMS

CSI = Construction Specification Institute, the group that

developed the divisions

Typical Costs Realized Categories as a Percent of Total

Because costs vary extensively across regions, time, and industry, this course does not

contain specific typical unit costs except for the purposes of example and typical percentages.

However, the following table indicates average project costs as a percent of the total for a wide

range of industrial, laboratory, and administrative projects (production equipment not included.)

Note that the costs are broken down in CSI formats. It is also interesting to note the higher

percentage categories. Often, GCs (General Conditions) will spend considerable effort

estimating Divisions 2-13, and underestimate the larger divisions 15-17 (often a third of the cost

of the total project). This table is for illustration purposes only, as your specific project may vary.

Also remember it is averaged across several representative projects.

www.PDHcenter.com PDH Course P159 www.PDHonline.org

Page 27 of 27

Category

Percent of

Total

Direct Costs

General Construction (Div. 2-9) 41%

Furniture, Fixtures, and Equipment (Div. 10-12) 7%

MEP (Mech., Elect., Piping) 31%

Indirect Costs (Design, GC's, fees, etc.) 21%

Total Project Cost (Less Production Equipment) 100%

Course Summary

In this course we learn practical estimating approaches and theory. Remember to develop

scope necessary for the required estimate accuracy, and include all the costs associated with the

project. Avoid misconceptions and pitfalls. Apply the tricks-of-the trade. Think total cost

Owners typically dont want only elements of a project with gaps remaining, but need the total.

Dont forget those things often left out!

Das könnte Ihnen auch gefallen

- Digital Agency WorkflowDokument20 SeitenDigital Agency WorkflowEcke100% (3)

- Cost Estimating PHD PDFDokument28 SeitenCost Estimating PHD PDFGeethaNoch keine Bewertungen

- Septic Tank DesignDokument66 SeitenSeptic Tank DesignAaditya Pratap Sanyal100% (4)

- Graphology (Full Dictionary)Dokument38 SeitenGraphology (Full Dictionary)Aaditya Pratap Sanyal100% (2)

- Prepaid Utility Service Offers Benefits but Also Raises ConcernsDokument13 SeitenPrepaid Utility Service Offers Benefits but Also Raises ConcernsJuliet LalonneNoch keine Bewertungen

- Derivatives Markets: Futures, Options & SwapsDokument20 SeitenDerivatives Markets: Futures, Options & SwapsPatrick Earl T. PintacNoch keine Bewertungen

- Ad SubcultureDokument20 SeitenAd Subculturethe9squadNoch keine Bewertungen

- Delays Claims Assessment ModelDokument246 SeitenDelays Claims Assessment Modelmisterd99100% (5)

- First Principles Estimating PDFDokument7 SeitenFirst Principles Estimating PDFMuaf Faizudeen67% (3)

- Capex Best PracticesDokument10 SeitenCapex Best PracticesPrasad RamanNoch keine Bewertungen

- Home Building Guide: A Step-by-Step ProcessDokument17 SeitenHome Building Guide: A Step-by-Step ProcessAnonymous RY91UFyQNoch keine Bewertungen

- The Open Timber Construction System Architectural DesignDokument116 SeitenThe Open Timber Construction System Architectural Designzdravkoiliev100% (8)

- A Project Manager's Guide To Cost Estimating and Cost PlanningDokument7 SeitenA Project Manager's Guide To Cost Estimating and Cost Planningsarathirv6Noch keine Bewertungen

- R33 Residual Income ValuationDokument34 SeitenR33 Residual Income ValuationAftab SaadNoch keine Bewertungen

- Green Building Guidelines: Meeting The Demand For Low-Energy, Resource-Efficient HomesDokument174 SeitenGreen Building Guidelines: Meeting The Demand For Low-Energy, Resource-Efficient HomesAaditya Pratap SanyalNoch keine Bewertungen

- Investment Opportunity in Edible Oil Manufacturing UnitDokument70 SeitenInvestment Opportunity in Edible Oil Manufacturing UnitMohamed Shuaib100% (1)

- Hotel Build Cost GuideDokument80 SeitenHotel Build Cost GuideAaditya Pratap SanyalNoch keine Bewertungen

- Sun Angle CalculatorDokument21 SeitenSun Angle CalculatorbudscriNoch keine Bewertungen

- Marketting Plan - Car LeasingDokument7 SeitenMarketting Plan - Car LeasingRavindra DananeNoch keine Bewertungen

- ConsultancyDokument45 SeitenConsultancyAaditya Pratap Sanyal100% (2)

- Effective Project Management: Lead your team to success on every projectVon EverandEffective Project Management: Lead your team to success on every projectNoch keine Bewertungen

- Calculating ROI for Design Tech InvestmentDokument15 SeitenCalculating ROI for Design Tech InvestmentkinoaurumNoch keine Bewertungen

- S - Curve PM Tool For EVADokument20 SeitenS - Curve PM Tool For EVAAmit BelladNoch keine Bewertungen

- Project Management Unit 2 PDFDokument16 SeitenProject Management Unit 2 PDFVaibhav MisraNoch keine Bewertungen

- Assignment II: Maple Case Study: Strategic ChoicesDokument4 SeitenAssignment II: Maple Case Study: Strategic ChoicesSudan KhadgiNoch keine Bewertungen

- Estimator Interview QuestionsDokument24 SeitenEstimator Interview QuestionsMustapha SamuelNoch keine Bewertungen

- Clean Coal Technologies For Power GenerationDokument315 SeitenClean Coal Technologies For Power GenerationAaditya Pratap Sanyal100% (1)

- Clean Coal Technologies For Power GenerationDokument315 SeitenClean Coal Technologies For Power GenerationAaditya Pratap Sanyal100% (1)

- Project Management: An Essential Guide for Beginners Who Want to Understand Agile, Scrum, Lean Six Sigma, Kanban and Kaizen When Applied to Managing ProjectsVon EverandProject Management: An Essential Guide for Beginners Who Want to Understand Agile, Scrum, Lean Six Sigma, Kanban and Kaizen When Applied to Managing ProjectsBewertung: 4 von 5 Sternen4/5 (1)

- Cost PlanningDokument20 SeitenCost PlanningsoloclarinetNoch keine Bewertungen

- Hidden DivergenceDokument5 SeitenHidden DivergenceAccess LimitedNoch keine Bewertungen

- Cost Management in Class NotesDokument18 SeitenCost Management in Class NotespriyankNoch keine Bewertungen

- chap1aCORRDINATION OF BUILDING WORKSDokument4 Seitenchap1aCORRDINATION OF BUILDING WORKST N Roland BourgeNoch keine Bewertungen

- Assignment 2 B.ed Code 8605Dokument12 SeitenAssignment 2 B.ed Code 8605Atif RehmanNoch keine Bewertungen

- MARK 420 Guest Speaker WorksheetDokument3 SeitenMARK 420 Guest Speaker WorksheetAJ MASCARENHASNoch keine Bewertungen

- Project ConstraintsDokument12 SeitenProject Constraintsshams kakarNoch keine Bewertungen

- Management Assignment 7Dokument3 SeitenManagement Assignment 7Rawr rawrNoch keine Bewertungen

- Estimating and Bidding I Lecture1Dokument22 SeitenEstimating and Bidding I Lecture1julius vergaraNoch keine Bewertungen

- Design Economics and Cost Planning (T022) GuideDokument3 SeitenDesign Economics and Cost Planning (T022) Guiderainbird7Noch keine Bewertungen

- Project Management A Managerial Approach 9Th Edition Meredith Solutions Manual Full Chapter PDFDokument50 SeitenProject Management A Managerial Approach 9Th Edition Meredith Solutions Manual Full Chapter PDFGeorgeAndersonkqmr100% (8)

- Chapter 5 Heba Sami-1Dokument41 SeitenChapter 5 Heba Sami-1Heba SamiNoch keine Bewertungen

- Project Management 1Dokument14 SeitenProject Management 1رؤى حسن نصيفNoch keine Bewertungen

- Value Abled ProjectDokument3 SeitenValue Abled ProjectTanveerAhmed NiaziNoch keine Bewertungen

- Is A Carefully Planned and Organized Effort To Accomplish A Successful ProjectDokument9 SeitenIs A Carefully Planned and Organized Effort To Accomplish A Successful ProjectFatima VeneracionNoch keine Bewertungen

- A Welcom White Paper: What Is The Health of My Project?Dokument18 SeitenA Welcom White Paper: What Is The Health of My Project?ahmad.rashidiNoch keine Bewertungen

- What Is Cost EngineeringDokument4 SeitenWhat Is Cost EngineeringsevNoch keine Bewertungen

- The 7 +/-2 Uses For An Estimation Tool: AbstractDokument13 SeitenThe 7 +/-2 Uses For An Estimation Tool: AbstractMoulay BarmakNoch keine Bewertungen

- Contemporary Project Management 3rd Edition Timothy Kloppenborg Solutions ManualDokument14 SeitenContemporary Project Management 3rd Edition Timothy Kloppenborg Solutions ManualCatherineJohnsonabpg100% (39)

- 2012-06 No Surprises ProjectControls v0Dokument2 Seiten2012-06 No Surprises ProjectControls v0Aayushi AroraNoch keine Bewertungen

- Tut4 SPMDokument6 SeitenTut4 SPMMinh TrangNoch keine Bewertungen

- Cost Analysis Project & Project CrashingDokument17 SeitenCost Analysis Project & Project CrashingDiksha SharmaNoch keine Bewertungen

- Unit - 2 Inception - UseCaseDokument54 SeitenUnit - 2 Inception - UseCasedhanush janasenani100% (1)

- What's The Difference Between A Cost Estimate and A Cost Plan?Dokument3 SeitenWhat's The Difference Between A Cost Estimate and A Cost Plan?Tech NestNoch keine Bewertungen

- Robel Asfaw Id 1102401Dokument13 SeitenRobel Asfaw Id 1102401Robel AsfawNoch keine Bewertungen

- Project Management (569) Assignment 2 (The Role of Budgets in Project Management)Dokument20 SeitenProject Management (569) Assignment 2 (The Role of Budgets in Project Management)Nabeel TirmaziNoch keine Bewertungen

- Procurement ManagementDokument11 SeitenProcurement ManagementKuljot VijNoch keine Bewertungen

- 6 Successful Project Estimation TechniquesDokument10 Seiten6 Successful Project Estimation TechniquesHerman AbdullahNoch keine Bewertungen

- The importance of business cases in project managementDokument2 SeitenThe importance of business cases in project managementkuttivasanthNoch keine Bewertungen

- Cost Controller Top SkillDokument6 SeitenCost Controller Top Skillgaliheskaputra1985Noch keine Bewertungen

- Course: Project Management Essentials Class: MSPM 1 Instructor: Zaigham Omer UsmaniDokument17 SeitenCourse: Project Management Essentials Class: MSPM 1 Instructor: Zaigham Omer UsmaniOsama SajjadNoch keine Bewertungen

- Financial ManagementDokument80 SeitenFinancial ManagementAbdela AyalewNoch keine Bewertungen

- Chapter 7 Written Discussion QuestionsDokument2 SeitenChapter 7 Written Discussion QuestionsMatthew Beckwith82% (11)

- A Quick Guide To Project Cost EstimatingDokument16 SeitenA Quick Guide To Project Cost EstimatingFarooq BhuttaNoch keine Bewertungen

- Standing On PrincipleDokument7 SeitenStanding On PrincipleCaius90Noch keine Bewertungen

- Budgeting & Cost EstimationDokument26 SeitenBudgeting & Cost Estimationrvsingh17Noch keine Bewertungen

- 2012-09 CostControlProfile v0Dokument2 Seiten2012-09 CostControlProfile v0Aayushi AroraNoch keine Bewertungen

- 11 LasherIM Ch11Dokument26 Seiten11 LasherIM Ch11jimmy_chou1314100% (1)

- Irm AdsDokument2 SeitenIrm AdsJay Ryan MapanaoNoch keine Bewertungen

- MB 0049 - Project ManagementDokument6 SeitenMB 0049 - Project Managementkavitachugh_45919851Noch keine Bewertungen

- Effective ESCO Project Management: Energy EngineeringDokument15 SeitenEffective ESCO Project Management: Energy EngineeringVictor RJ MNoch keine Bewertungen

- Approaches in Teaching Construction EstimatingDokument7 SeitenApproaches in Teaching Construction EstimatingShithin KrishnanNoch keine Bewertungen

- Capital Budgeting ThesisDokument5 SeitenCapital Budgeting Thesislauriegunlickssiouxfalls100% (2)

- Question EstimatotDokument2 SeitenQuestion EstimatotCaio CesarNoch keine Bewertungen

- Cost PMPDokument36 SeitenCost PMPMitsubishi FA Riyadh-Saudi ArabiaNoch keine Bewertungen

- Accent Estimating Mastering Building Estimating A Comprehensive Approach 3 641a9502Dokument14 SeitenAccent Estimating Mastering Building Estimating A Comprehensive Approach 3 641a9502sofy dessNoch keine Bewertungen

- Project Management Questions1Dokument14 SeitenProject Management Questions1ubadjateNoch keine Bewertungen

- Aeratedautoclavedconcrete 140329093526 Phpapp01Dokument19 SeitenAeratedautoclavedconcrete 140329093526 Phpapp01Omar DaghistaniNoch keine Bewertungen

- Light Steel Infill WallsDokument4 SeitenLight Steel Infill WallsAaditya Pratap SanyalNoch keine Bewertungen

- Building Resource Manual - Project Management Guidelines For Childcare FacilitiesDokument82 SeitenBuilding Resource Manual - Project Management Guidelines For Childcare FacilitiesAaditya Pratap SanyalNoch keine Bewertungen

- RCF's Rapidwall PanelsDokument98 SeitenRCF's Rapidwall PanelsAaditya Pratap SanyalNoch keine Bewertungen

- Integrated Architecrural SolutionsDokument24 SeitenIntegrated Architecrural SolutionsAaditya Pratap SanyalNoch keine Bewertungen

- Company ProfileDokument1 SeiteCompany ProfileAaditya Pratap SanyalNoch keine Bewertungen

- Aam Aadmi Series-1 Final6.2.09Dokument16 SeitenAam Aadmi Series-1 Final6.2.09gurumurthalNoch keine Bewertungen

- The Hindu - Property Plus Chennai - Planning Construction CostsDokument4 SeitenThe Hindu - Property Plus Chennai - Planning Construction CostsAaditya Pratap SanyalNoch keine Bewertungen

- IndianStandardsforBuildingWorks 74to83Dokument10 SeitenIndianStandardsforBuildingWorks 74to83Gopal SudhirNoch keine Bewertungen

- Project Management: © 2014 Lew HofmannDokument70 SeitenProject Management: © 2014 Lew HofmannAaditya Pratap Sanyal100% (1)

- A Novel Approach For Delay AnalysisDokument6 SeitenA Novel Approach For Delay AnalysisAaditya Pratap SanyalNoch keine Bewertungen

- GK QuestionsDokument3 SeitenGK QuestionsAaditya Pratap SanyalNoch keine Bewertungen

- Pert, CPMDokument53 SeitenPert, CPMAaditya Pratap SanyalNoch keine Bewertungen

- Contractors Project Managers Contributions To The Delays in Projects of Construction Industry in Gulf CountriesDokument10 SeitenContractors Project Managers Contributions To The Delays in Projects of Construction Industry in Gulf CountriesAaditya Pratap SanyalNoch keine Bewertungen

- AIS Glass SoDokument4 SeitenAIS Glass SoAaditya Pratap SanyalNoch keine Bewertungen

- Project Management For Construction - Cost Control, Monitoring and AccountingDokument29 SeitenProject Management For Construction - Cost Control, Monitoring and Accountingapi-27145250100% (1)

- Construction Project Management TechniquesDokument48 SeitenConstruction Project Management TechniquesAaditya Pratap SanyalNoch keine Bewertungen

- Staircase Types & Design ElementsDokument17 SeitenStaircase Types & Design ElementsAaditya Pratap SanyalNoch keine Bewertungen

- Spon's Civil Engineering and Highway Works Price B... - (PART 2 On Costs and Profit)Dokument6 SeitenSpon's Civil Engineering and Highway Works Price B... - (PART 2 On Costs and Profit)mohamedNoch keine Bewertungen

- Supply Budget ControlDokument16 SeitenSupply Budget ControlFolegwe FolegweNoch keine Bewertungen

- Engro CorDokument28 SeitenEngro CorAbNoch keine Bewertungen

- Order Details - Carter'sDokument4 SeitenOrder Details - Carter'sSura SeyidovaNoch keine Bewertungen

- NH-24 Tenders - ExtractsDokument4 SeitenNH-24 Tenders - Extractsshravan38Noch keine Bewertungen

- Brokers' Perceptions of Derivative Trading in Indian Stock MarketsDokument14 SeitenBrokers' Perceptions of Derivative Trading in Indian Stock MarketsJagannath G EswaranNoch keine Bewertungen

- Chapter 7 - Decision Making With Risk and UncertaintyDokument10 SeitenChapter 7 - Decision Making With Risk and UncertaintyJeremiah NcubeNoch keine Bewertungen

- Estimate Inventory Value Using Gross Profit MethodDokument2 SeitenEstimate Inventory Value Using Gross Profit MethodJoanne Rheena BooNoch keine Bewertungen

- Sri Mahila Griha Udyog Lijjat Papad: Strategic Management CourseDokument23 SeitenSri Mahila Griha Udyog Lijjat Papad: Strategic Management CoursePrachit ChaturvediNoch keine Bewertungen

- 18 Apr 2017 - Business BriefsDokument77 Seiten18 Apr 2017 - Business BriefshnmjzhviNoch keine Bewertungen

- Mayaderm AnalysisDokument3 SeitenMayaderm AnalysisHrishikesh Pardeshi100% (1)

- Unemployment and Inflation: Chapter Summary and Learning ObjectivesDokument27 SeitenUnemployment and Inflation: Chapter Summary and Learning Objectivesvivianguo23Noch keine Bewertungen

- Marketstructure PDFDokument15 SeitenMarketstructure PDFmihir kumarNoch keine Bewertungen

- P5-4, 6 Dan 8Dokument18 SeitenP5-4, 6 Dan 8ramaNoch keine Bewertungen

- 07 PVC - Pipe 2017Dokument17 Seiten07 PVC - Pipe 2017Nuzuliana EnuzNoch keine Bewertungen

- Comprehensive Problem 2 3Dokument2 SeitenComprehensive Problem 2 3Cheryll ElaineNoch keine Bewertungen

- Emami Fair and HandsomeDokument5 SeitenEmami Fair and HandsomeSiva KumaravelNoch keine Bewertungen

- TSN EstateDokument19 SeitenTSN EstateGrace EnriquezNoch keine Bewertungen

- NFCPAR-Auditing Problems: Description Machinery Others NotesDokument1 SeiteNFCPAR-Auditing Problems: Description Machinery Others NotesSano ManjiroNoch keine Bewertungen

- Module 1 - Derivatives Concepts & ETD - Student VersionDokument2 SeitenModule 1 - Derivatives Concepts & ETD - Student VersionNothingToKnowNoch keine Bewertungen

- TRANSFER PRICING GUIDEDokument30 SeitenTRANSFER PRICING GUIDEJade Tan33% (3)

- Chapter 8 Capital Budgeting Models NPV IRR PIDokument18 SeitenChapter 8 Capital Budgeting Models NPV IRR PIAdmire MamvuraNoch keine Bewertungen

- Academic Writing Task 1 Describing Data and Making Approximations2Dokument5 SeitenAcademic Writing Task 1 Describing Data and Making Approximations2kristian worabayNoch keine Bewertungen