Beruflich Dokumente

Kultur Dokumente

1200 185 PDF

Hochgeladen von

tuanvutt0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten12 SeitenThe APEX Series surge suppressor models are designed specifically for the following configurations. Once activated, the suppressor remains operative until excess transient energy is dissipated and instantaneous peak line voltage falls below the approximate 120% overvoltage threshold.

Originalbeschreibung:

Originaltitel

1200-185.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe APEX Series surge suppressor models are designed specifically for the following configurations. Once activated, the suppressor remains operative until excess transient energy is dissipated and instantaneous peak line voltage falls below the approximate 120% overvoltage threshold.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten12 Seiten1200 185 PDF

Hochgeladen von

tuanvuttThe APEX Series surge suppressor models are designed specifically for the following configurations. Once activated, the suppressor remains operative until excess transient energy is dissipated and instantaneous peak line voltage falls below the approximate 120% overvoltage threshold.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 12

Thank you for selecting Transtector Systems to

safeguard your equipment from the damaging

effects of lightning and transient overvoltages.

NOTE: The installation instructions for the APEX MOV

Series is identical to those for the APEX Series

suppressors configured with silicon protection.

The APEX Series surge suppressor models are designed

specifically to operate on the following configurations:

Suppression is accomplished in parallel between phase

conductors and/or between phase and the neutral conductors,

depending upon the voltage configuration. Once activated, the

suppressor remains operative until excess transient energy is

dissipated and instantaneous peak line voltage falls below the

approximate 120% overvoltage threshold. At that time the

suppressor automatically deactivates, resets to a ready state,

and awaits further transient activity.

Please take a moment to read and understand the installation

instructions included with this product. If any questions should

arise concerning the proper installation of this product, please

contact us.

120V 1

120/240 Split 1

120/208 3 Wye

240V 1

240V 3 Delta

220/380 3 Wye

230/400 3 Wye

240/415 3 Wye

800.882.9110 or 208.772.8515

Step 1:

Select a location along the electrical distribution system as physically close to critical

equipment loads as practical to install the surge suppressor. The suppressor can be

installed at distribution panels, at equipment AC power inputs, or at the secondary

windings of isolation transformers. The suppressor must be positioned within four (4)

feet (122 cm) of the AC power source. It is recommended that the suppressor be installed

within two (2) feet (61 cm) of the AC power source, if possible.

CAUTION: Increasing electrical impedance values to the inputs of any transient

suppressor, regardless of manufacturer, can increase the devices voltage limiting

levels. Suppressors should be installed as physically close to the protected

electrical distribution panel or critical load as possible using the largest size wiring/

conductors as practical.

Step 2:

Verify that the maximum current rating of the electrical service to be protected does not

exceed specified amperage rating of the suppressor model to be installed.

Mechanical Installation

Table One

Application Rating:

APEX II

APEX III

APEX IV

225 Amps and below

400 Amps and below

1000 Amps and below

CAUTION: Transtectors Applications Engineering Department must be contacted

prior to installing the APEX Series suppressor when the maximum current rating of

the electrical service to be protected exceeds the specified amperage rating of the

surge suppressor.

Step 3:

Unpack the surge suppressor from its shipping container and visually inspect for shipping

related damage. Open the suppressor door and verify that all components, lights, displays,

and electrical connections are secure.

Step 4:

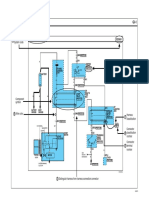

Refer to the APEX Series enclosure diagram (Figure 1). Note the suggested locations on

either the bottom or the left side of the suppressor enclosure to drill holes to route conduit

from the AC power source to the suppressor assembly. Apertures intended to provide a

path for AC wiring conductors can be bored anywhere into the suppressor enclosure as

long as suppression components are not damaged or obstructed in the process.

Step 5:

Refer to the mounting illustration (Figure 1) for the APEX Series suppressor. Drill four (4)

mounting holes anyplace on the mounting surface. Insure mounting holes are spaced 8"

(20.38 cm) apart from each other horizontally and are separated 13" (31.7 cm) vertically.

Step 6:

Physically position the surge suppressor as close as possible to the AC power source

and securely mount it to any surface capable of permanently supporting 20 pounds

(9.1 Kg) of weight. (Mounting hardware is not included).

800.882.9110 or 208.772.8515

WARNING: Serious and/or fatal electrical shock hazards exist if extreme

care is not exercised during all phases of mechanical and electrical

installation procedures.

Figure 1

Mounting Details

Electrical Installation

NOTE: These instructions are intended to guide the equipment installer through a

step-by-step procedure resulting with the surge suppressor being electrically

connected in parallel with its AC power source.

Figure 2

120T configuration

Typical Installation consists

of two phase conductors

with one neutral

Figure 3

120S configuration

Typical Installation consists

of one phase conductor

with one neutral

800.882.9110 or 208.772.8515

Figure 4

240S configuration

Typical Installation consists

of two phase conductors

with no neutral

NOTE: Phase L, or Phase L

2

can

be substituted for neutral in

international applications.

Figure 5

120W, 240W

configuration

International installation

consists of voltages ranging

from 380 to 415 between

phase conductors; and

ranging from 220 to 240

between phase conductors

and neutral

Figure 6

240D configuration

Typical Installation

WARNING: AC Power to the surge suppressor, at the surge suppressor, and

in the vicinity of the surge suppressor MUST be disconnected prior to

performing the following mechanical and electrical installation procedure.

WARNING: All international, national, local, and other applicable electrical codes

must be followed and adhered to during all phases of the electrical installation. If any

of the following electrical installation procedures conflict with applicable electrical

codes, the suppressor installation must be discontinued and Transtector Systems

Applications Engineering department must be contacted for further instructions.

Step 1:

Ensure that the electrical installation is accomplished by qualified personnel that are

certified and/or licensed to service and install equipment upon the appropriate

electrical services.

Step 2:

Verify at the AC power source, at the point where the surge suppressor will be

electrically attached, that the surge suppressor is designed to protect upon that

specificed voltage configuration.

Step 3:

Verify that the maximum current rating of the electrical service to be protected does

not exceed the specified amperage of the surge suppressor.

800.882.9110 or 208.772.8515

WARNING: Serious and/or fatal electrical shock hazards exist if extreme

care is not exercised during all phases of mechanical and electrical

installation procedures.

WARNING: Serious and/or fatal electrical shock hazards exist if extreme care is not

exercised as the following voltage measurements are accomplished.

Step 4:

Measure AC voltages between phase(s) and neutral and/or between phases as

appropriate using an AC voltmeter. Verify that the measured RMS voltages between

the fore mentioned conductors complies to the nominal values appropriate for the

electrical distribution.

Step 5:

Disconnect power at the AC power source at the point where the APEX Series will be

connected. Verify that AC power is disabled.

NOTE: The mechanical and electrical installation illustrations are referenced in Figures

1 through 6 and are applicable with the remaining electrical installation procedural steps.

WARNING: Wiring conductors utilized to attach Phases L1, L2, L3, the Neutral

and Safety Ground from the AC power source to the APEX Series should be

color-coded to conform with appropriate electrical codes and/or accepted wiring

practices. It is very important to make no assumptions that wiring colors on existing

electrical installations correspond to proper phase, neutral, or ground connections.

WARNING: AC Power to the surge suppressor, at the surge suppressor, and

in the vicinity of the surge suppressor MUST be disconnected prior to

performing the following mechanical and electrical installation procedure.

Identify and verify each specific phase, neutral, and ground references at the AC power

source prior to proceeding with these electrical installation procedures.

WARNING: The disconnect utilized in the current path from the electrical distribution

and the APEX Series must be coordinated to operate properly in conjunction with

all other disconnects contained within the same electrical distribution.

WARNING: Proper electrical connections must be accomplished in accordance

with applicable International, National, and/or Local electrical code requirements.

Step 6:

Tap into the three (3) phase conductors via an approved disconnect, i.e. circuit breaker

that is sized appropriately (typically 60 Amps) on the load side of the main circuit

breaker of the AC power service requiring surge suppression. If neutral is required

for the system, tap into the neutral/bus wire. These wiring conductors must be sized

accordingly dependent upon the following parameters:

If the APEX Series suppressor is positioned within two (2) feet (61 cm.) from the AC

power source, then a minimum of #6 (4.1 mm.) sized wiring conductors are recommended.

If the APEX Series suppressor is positioned within four (4) feet (122 cm.) from the AC

power source, then a minimum of #4 (5.2 mm.) sized wiring conductors are recommended.

800.882.9110 or 208.772.8515

WARNING: Serious and/or fatal electrical shock hazards exist if extreme

care is not exercised during all phases of mechanical and electrical

installation procedures.

CAUTION: Contact Transtectors Application Engineering Department before

proceeding with the installation if the suppressor cannot be installed within four (4)

feet of the AC power source requiring protection from transient overvoltages.

Step 7:

If a breaker cannot be supplied in the protected panelboard, install either three (3) external

fuses or an external three pole thermal/magnetic circuit breaker to be used as a disconnect

in series with the surge suppressor and the AC power source. Fuses should be rated at

ten (10) AMPs less than the service disconnect to a maximum of 100 AMPS (Typically

BUSSMAN LPN Series fuse). A 60 AMP circuit breaker can be used in conjunction with

#6 AWG. (4.1 mm.) sized wire if the surge suppressor is installed within two (2) feet (61

cm.) of the AC power source. Ensure that the disconnect is installed initially in its OPEN

state so that AC power cannot pass through it until it is reset.

CAUTION: The disconnect addressed in the above procedural step serves a dual

purpose. It provides a means for maintenance personnel to de-energize AC power

supplied to the APEX Series suppressor to allow for servicing the device. It also

allows the suppressor to be electrically removed from the AC power source in the

event of catastrophic failure modes without disrupting AC power to critical loads. Its

current rating must be rated lower than that of the main disconnect supplying power

to the protected electrical loads.

WARNING: AC Power to the surge suppressor, at the surge suppressor, and

in the vicinity of the surge suppressor MUST be disconnected prior to

performing the following mechanical and electrical installation procedure.

Step 8:

Route wiring conductors through metal conduit from the disconnect installed in the previous

step at the AC power source to the suppressor enclosure. Mate the conduit to the suppressor

enclosure at the hole bored in Step 4 of the Mechanical Installation procedures on page 3.

Ensure that the conduit is properly grounded at the AC power source.

WARNING: Adequate and proper grounding practices must be heeded to insure

that human safety is accomplished during electrical fault conditions.

Step 9:

Open the front door of the suppressor enclosure and insure that conduit and/or external

grounding conductors are securely fastened to Ground lug designated with the letter G

on the terminal block at the left side of the backpanel assembly where the three suppressor

modules attach. Locate the labeled terminal block providing the means to attach the

electrical wiring conductors from the AC power source the APEX Series suppressor. The

designated labels on the terminal block correspond to specific Phase and/or Neutral

conductors from the AC power wiring positions on the terminal block.

WARNING: In Wye configurations verify that the neutral conductor from the AC power

source is connected properly to the N designated position on the terminal block identified

in Step 9. If any phase conductor should accidentally be connected to that N designated

connection point severe suppressor damage will result and human safety will be compromised

as AC power is applied to the APEX Series suppressor.

Step 10:

After electrical wiring hook-up is complete and prior to energizing electrical power, each

suppressor card must be firmly inserted into its respective backpanel slot. Refer to the

installation instruction sheet located inside of the enclosure door and note the phase

labeling on each card.

Proper slot placement will align the cards with lable on the outside of the door. Cards

must be inserted into their respective slots, with the card fingers engaging the electrical

stab-down contacts, and pressed completely into place. Figure 7 depicts the card finger

alignment into the slots. Press adjacent cards together sideways to snap the interlock

pins on the top and bottom for added stability.

WARNING: the card interlock pins must be separated before removing individual

cards for services.

Figure 7

Card Installation

NOTE: Depending on the configuration of your Apex Series

suppressor, this unit could have between 1 and 6 cards to install.

800.882.9110 or 208.772.8515

Das könnte Ihnen auch gefallen

- SWICOM Release Notes - 2.6Dokument4 SeitenSWICOM Release Notes - 2.6tuanvuttNoch keine Bewertungen

- MA - 1VCD601602 - SWICOM Operational (EN) DDokument28 SeitenMA - 1VCD601602 - SWICOM Operational (EN) DtuanvuttNoch keine Bewertungen

- Ma - 1VCD601687 - SWICOM Modbus Point List Manual (EN) BDokument42 SeitenMa - 1VCD601687 - SWICOM Modbus Point List Manual (EN) BtuanvuttNoch keine Bewertungen

- MA - 1VCD601601 - SWICOM Engineering (EN) CDokument52 SeitenMA - 1VCD601601 - SWICOM Engineering (EN) CtuanvuttNoch keine Bewertungen

- 1VLG100520 - Installation Guide of IR Temperature Sensors - RevbDokument46 Seiten1VLG100520 - Installation Guide of IR Temperature Sensors - RevbtuanvuttNoch keine Bewertungen

- 9AKK108466A1909 - PD Measurement and Monitoring Systems ComparisonDokument2 Seiten9AKK108466A1909 - PD Measurement and Monitoring Systems ComparisontuanvuttNoch keine Bewertungen

- 9AKK107992A0049 - PDCOM Application Validation ProcedureDokument18 Seiten9AKK107992A0049 - PDCOM Application Validation ProceduretuanvuttNoch keine Bewertungen

- 9AKK107992A1008 - PDCOM Data SheetDokument4 Seiten9AKK107992A1008 - PDCOM Data SheettuanvuttNoch keine Bewertungen

- 9AKK107992A1474 - PDCOM Partial Discharge Monitoring of SWICOM System - PresentationDokument25 Seiten9AKK107992A1474 - PDCOM Partial Discharge Monitoring of SWICOM System - PresentationtuanvuttNoch keine Bewertungen

- FAQ Swicom With IR Temperature SensorsDokument4 SeitenFAQ Swicom With IR Temperature SensorstuanvuttNoch keine Bewertungen

- Grammar Review: CHÑ NG÷ (Subject)Dokument2 SeitenGrammar Review: CHÑ NG÷ (Subject)tuanvuttNoch keine Bewertungen

- REJ603 PG 1MDB07217-YN ENeDokument24 SeitenREJ603 PG 1MDB07217-YN ENetuanvuttNoch keine Bewertungen

- Susol VCS EDokument40 SeitenSusol VCS EtuanvuttNoch keine Bewertungen

- HY10WZ1-51/134 SURGE ARRESTOR: Appearance and Installation SizeDokument2 SeitenHY10WZ1-51/134 SURGE ARRESTOR: Appearance and Installation SizetuanvuttNoch keine Bewertungen

- OSUNG ControllerDokument3 SeitenOSUNG ControllertuanvuttNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- PDS S-Series Electronic Marshalling PDFDokument33 SeitenPDS S-Series Electronic Marshalling PDFAnonymous gxPWG8c9KuNoch keine Bewertungen

- Redur Katalog Engl Regulus Ipng Mai 2022Dokument35 SeitenRedur Katalog Engl Regulus Ipng Mai 2022cengizNoch keine Bewertungen

- Ram 55 QH 5Dokument108 SeitenRam 55 QH 5Clement DelzenneNoch keine Bewertungen

- Iec TR 61010-3-031-2003Dokument32 SeitenIec TR 61010-3-031-2003Vasko MandilNoch keine Bewertungen

- Capacitor BankDokument12 SeitenCapacitor BankMostafa Azab0% (1)

- Greenpower Handbook 2012Dokument34 SeitenGreenpower Handbook 2012Sagar BajajNoch keine Bewertungen

- 400 Series ECGDokument51 Seiten400 Series ECGJaimeCoello100% (1)

- Piaggio 125-250 Maintenance ManualDokument94 SeitenPiaggio 125-250 Maintenance ManualPiotr LewoszNoch keine Bewertungen

- 800MW Genrator Data SheetDokument24 Seiten800MW Genrator Data SheetRukma Goud ShakkariNoch keine Bewertungen

- Notice D'Installation Operation and Installation ManualDokument65 SeitenNotice D'Installation Operation and Installation ManualAndaç ÖzkanNoch keine Bewertungen

- Asc LB Ds 3040Dokument2 SeitenAsc LB Ds 3040Francisco MartinezNoch keine Bewertungen

- 2019.1 - Middle East Catalogue LRDokument72 Seiten2019.1 - Middle East Catalogue LRj658503Noch keine Bewertungen

- System Pro M CompactDokument826 SeitenSystem Pro M Compactdekosokol100% (1)

- Troubleshooting Directory For LHB Type RMPU EOG AC Coach-Eng PDFDokument44 SeitenTroubleshooting Directory For LHB Type RMPU EOG AC Coach-Eng PDFdivisional electrical engg100% (2)

- Mark Scheme For Oxford AQA IGCSE Physics Paper 2 June 19Dokument21 SeitenMark Scheme For Oxford AQA IGCSE Physics Paper 2 June 19Pop VNoch keine Bewertungen

- LC240CP, LC340CP - Service Manual (3828A20911A) - 122206Dokument61 SeitenLC240CP, LC340CP - Service Manual (3828A20911A) - 122206Lim JohnvynNoch keine Bewertungen

- 90002Dokument46 Seiten90002Simon SchrNoch keine Bewertungen

- F21 - F24 Manual 4aDokument48 SeitenF21 - F24 Manual 4alukasNoch keine Bewertungen

- ATL610NHP: Atl Ats 100-240V Ac+12-24V DC Expandable Catalogue NoDokument4 SeitenATL610NHP: Atl Ats 100-240V Ac+12-24V DC Expandable Catalogue NoiScribdNoch keine Bewertungen

- Welborne Labs Apollo - 2xDokument28 SeitenWelborne Labs Apollo - 2xjason23456789Noch keine Bewertungen

- AC Servo ASD-B2Dokument337 SeitenAC Servo ASD-B2Thai Trinh CongNoch keine Bewertungen

- TOPLED-Service ManualDokument28 SeitenTOPLED-Service ManualPABLO ZAMUDIO100% (1)

- Indian Standard: Specification For Distribution Pillars For Voltages Not Exceeding 1 000 V Ac and 1 200 V DCDokument18 SeitenIndian Standard: Specification For Distribution Pillars For Voltages Not Exceeding 1 000 V Ac and 1 200 V DCGnanavel GNoch keine Bewertungen

- Intimidator Spot 355Z IRC QRG Rev3 ML6 WODokument56 SeitenIntimidator Spot 355Z IRC QRG Rev3 ML6 WOJavierNoch keine Bewertungen

- Electrical Cab & ChassisDokument353 SeitenElectrical Cab & ChassisAhmad NursalimNoch keine Bewertungen

- Operating and Maintenance Manual 6" To 8" Rewound Submersible MotorsDokument24 SeitenOperating and Maintenance Manual 6" To 8" Rewound Submersible MotorsgeiyaulNoch keine Bewertungen

- Intrinsic SafetyDokument85 SeitenIntrinsic Safetycaigithe852456100% (2)

- Linear Plus Series Uninterruptible Power Supply Operating ManualDokument44 SeitenLinear Plus Series Uninterruptible Power Supply Operating ManualMuhammad HassanNoch keine Bewertungen

- 06.01.01 - 01 - POWER SUPPLY, 24 V (1) VogueleDokument4 Seiten06.01.01 - 01 - POWER SUPPLY, 24 V (1) VogueleEnriqueNoch keine Bewertungen

- 2006 Hyundai Santa FE Electrical Wiring Diagram PDFDokument233 Seiten2006 Hyundai Santa FE Electrical Wiring Diagram PDFEnil Perez Rivera78% (27)