Beruflich Dokumente

Kultur Dokumente

Us Customary Units

Hochgeladen von

Herbert P. Bacosa0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

28 Ansichten9 SeitenThe document consists of a comprehensive design example of a Prestressed Concrete girder bridge. The superstructure consists of two simple spans made continuous for live loads. The document also includes instructional commentary based on the aashto-LRFD bridge design specifications.

Originalbeschreibung:

Originaltitel

Fhwanhi04043 - Copy

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document consists of a comprehensive design example of a Prestressed Concrete girder bridge. The superstructure consists of two simple spans made continuous for live loads. The document also includes instructional commentary based on the aashto-LRFD bridge design specifications.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

28 Ansichten9 SeitenUs Customary Units

Hochgeladen von

Herbert P. BacosaThe document consists of a comprehensive design example of a Prestressed Concrete girder bridge. The superstructure consists of two simple spans made continuous for live loads. The document also includes instructional commentary based on the aashto-LRFD bridge design specifications.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

COMPREHENSIVE DESIGN EXAMPLE FOR PRESTRESSED

CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE

WITH COMMENTARY

(Task order DTFH61-02-T-63032)

US CUSTOMARY UNITS

Submitted to

THE FEDERAL HIGHWAY ADMINISTRATION

Prepared By

Modjeski and Masters, Inc.

November 2003

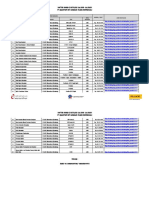

Technical Report Documentation Page

1. Report No. 2. Government Accession No. 3. Recipients Catalog No.

FHWA NHI - 04-043

4. Title and Subtitle 5. Report Date

Comprehensive Design Example for Prestressed Concrete (PSC) November 2003

Girder Superstructure Bridge with Commentary 6. Performing Organization Code

(in US Customary Units)

7. Author (s) Wagdy G. Wassef, Ph.D., P.E., Christopher Smith, E.I.T. 8. Performing Organization Report No.

Chad M. Clancy, P.E., Martin J . Smith, P.E.

9. Performing Organization Name and Address 10. Work Unit No. (TRAIS)

Modjeski and Masters, Inc.

P.O.Box 2345 11. Contract or Grant No.

Harrisburg, Pennsylvania 17105 DTFH61-02-D-63006

12. Sponsoring Agency Name and Address 13. Type of Report and Period Covered

Federal Highway Administration Final Submission

National Highway Institute (HNHI-10) August 2002 November 2003

4600 N. Fairfax Drive, Suite 800 14. Sponsoring Agency Code

Arlington, Virginia 22203

15. Supplementary Notes

Modjeski and Masters Principle Investigator and Project Manager :

Wagdy G. Wassef , Ph.D., P.E.

FHWA Contracting Officers Technical Representative: Thomas K. Saad, P.E.

Team Leader, Technical Review Team: J erry Potter, P.E.

16. Abstract

This document consists of a comprehensive design example of a prestressed concrete girder bridge. The superstructure

consists of two simple spans made continuous for live loads. The substructure consists of integral end abutments and a

multi-column intermediate bent. The document also includes instructional commentary based on the AASHTO-LRFD

Bridge Design Specifications (Second Edition, 1998, including interims for 1999 through 2002). The design example and

commentary are intended to serve as a guide to aid bridge design engineers with the implementation of the AASHTO-

LRFD Bridge Design Specifications. This document is offered in US Customary Units. An accompanying document in

Standard International (SI) Units is offered under report No. FHWA NHI-04-044.

This document includes detailed flowcharts outlining the design steps for all components of the bridge. The flowcharts

are cross-referenced to the relevant specification articles to allow easy navigation of the specifications. Detailed design

computations for the following components are included: concrete deck, prestressed concrete I-girders, elastomeric

bearing, integral abutments and wing walls, multi-column bent and pile and spread footing foundations.

In addition to explaining the design steps of the design example, the comprehensive commentary goes beyond the

specifics of the design example to offer guidance on different situations that may be encountered in other bridges.

17. Key Words 18. Distribution Statement

Bridge Design, Prestressed Concrete, Load and Resistance This report is available to the public from the

Factor Design, LRFD, Concrete Deck, Intermediate Bent, National Technical Information Service in

Integral Abutment, Wingwall, Pile Foundation, Spread Springfield, Virginia 22161 and from the

Footings Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402.

19. Security Classif. (of this report) 20. Security Classif. (of this page) 21. No. of Pages 22. Price

Unclassified Unclassified 381

Form DOT F 1700.7 (8-72) Reproduction of completed page authorized

This page intentionally left blank

ACKNOWLEDGEMENTS

The authors would like to express appreciation to the review teams from the Illinois Department of Transportation,

Minnesota Department of Transportation and Washington State Department of Transportation for providing review and

direction on the Technical Review Committee.

The authors would also like to acknowledge the contributions of Dr. J ohn M. Kulicki, President/CEO and Chief

Engineer of Modjeski and Masters, Inc., for his guidance throughout the project.

Table of Contents Prestressed Concrete Bridge Design Example

Task Order DTFH61-02-T-63032 i

TABLE OF CONTENTS

Page

1. INTRODUCTION .........................................................................................................1-1

2. EXAMPLE BRIDGE ....................................................................................................2-1

2.1 Bridge geometry and materials.............................................................................2-1

2.2 Girder geometry and section properties ...............................................................2-4

2.3 Effective flange width ........................................................................................2-10

3. FLOWCHARTS ............................................................................................................3-1

4. DESIGN OF DECK .......................................................................................................4-1

5. DESIGN OF SUPERSTRUCTURE

5.1 Live load distribution factors ..............................................................................5-1

5.2 Dead load calculations.......................................................................................5-10

5.3 Unfactored and factored load effects.................................................................5-13

5.4 Loss of prestress ...............................................................................................5-27

5.5 Stress in prestressing strands.............................................................................5-36

5.6 Design for flexure

5.6.1 Flexural stress at transfer ......................................................................5-46

5.6.2 Final flexural stress under Service I limit state ....................................5-49

5.6.3 Longitudinal steel at top of girder.........................................................5-61

5.6.4 Flexural resistance at the strength limit state in positive

moment region .....................................................................................5-63

5.6.5 Continuity correction at intermediate support ......................................5-67

5.6.6 Fatigue in prestressed steel ...................................................................5-75

5.6.7 Camber..................................................................................................5-75

5.6.8 Optional live load deflection check ......................................................5-80

5.7 Design for shear ................................................................................................5-82

5.7.1 Critical section for shear near the end support......................................5-84

5.7.2 Shear analysis for a section in the positive moment region..................5-85

5.7.3 Shear analysis for sections in the negative moment region..................5-93

5.7.4 Factored bursting resistance................................................................5-101

5.7.5 Confinement reinforcement ................................................................5-102

5.7.6 Force in the longitudinal reinforcement including the effect of

the applied shear .................................................................................5-104

6. DESIGN OF BEARINGS .............................................................................................6-1

Table of Contents Prestressed Concrete Bridge Design Example

Task Order DTFH61-02-T-63032 ii

7. DESIGN OF SUBSTRUCTURE ..................................................................................7-1

7.1. Design of Integral Abutments

7.1.1 Gravity loads...........................................................................................7-6

7.1.2 Pile cap design .....................................................................................7-11

7.1.3 Piles.......................................................................................................7-12

7.1.4 Backwall design....................................................................................7-16

7.1.5 Wingwall design ...................................................................................7-30

7.1.6 Design of approach slab........................................................................7-34

7.1.7 Sleeper slab...........................................................................................7-37

7.2. Design of Intermediate Pier

7.2.1 Substructure loads and application .......................................................7-38

7.2.2 Pier cap design......................................................................................7-51

7.2.3 Column design ......................................................................................7-66

7.2.4 Footing design.......................................................................................7-75

Appendix A - Comparisons of Computer Program Results (QConBridge and Opis)

Section A1 - QConBridge Input.............................................................................................. A1

Section A2 - QConBridge Output ........................................................................................... A3

Section A3 - Opis Input......................................................................................................... A10

Section A4 - Opis Output ...................................................................................................... A47

Section A5 - Comparison Between the Hand Calculations and the Two Computer

Programs.......................................................................................................... A55

Section A6 - Flexural Resistance Sample Calculation from Opis to Compare with

Hand Calculations ........................................................................................... A58

Appendix B - General Guidelines for Refined Analysis of Deck Slabs

Appendix C - Example of Creep and Shrinkage Calculations

Task Order DTFH61-02-T-63032 1-1

Design Step 1 - Introduction Prestressed Concrete Bridge Design Example

1. INTRODUCTION

This example is part of a series of design examples sponsored by the Federal Highway

Administration. The design specifications used in these examples is the AASHTO LRFD Bridge design

Specifications. The intent of these examples is to assist bridge designers in interpreting the

specifications, limit differences in interpretation between designers, and to guide the designers through

the specifications to allow easier navigation through different provisions. For this example, the Second

Edition of the AASHTO-LRFD Specifications with Interims up to and including the 2002 Interim is

used.

This design example is intended to provide guidance on the application of the AASHTO-LRFD

Bridge Design Specifications when applied to prestressed concrete superstructure bridges supported on

intermediate multicolumn bents and integral end abutments. The example and commentary are intended

for use by designers who have knowledge of the requirements of AASHTO Standard Specifications for

Highway Bridges or the AASHTO-LRFD Bridge Design Specifications and have designed at least one

prestressed concrete girder bridge, including the bridge substructure. Designers who have not designed

prestressed concrete bridges, but have used either AASHTO Specification to design other types of

bridges may be able to follow the design example, however, they will first need to familiarize themselves

with the basic concepts of prestressed concrete design.

This design example was not intended to follow the design and detailing practices of any

particular agency. Rather, it is intended to follow common practices widely used and to adhere to the

requirements of the specifications. It is expected that some users may find differences between the

procedures used in the design compared to the procedures followed in the jurisdiction they practice in

due to Agency-specific requirements that may deviate from the requirements of the specifications. This

difference should not create the assumption that one procedure is superior to the other.

Task Order DTFH61-02-T-63032 1-2

Design Step 1 - Introduction Prestressed Concrete Bridge Design Example

Reference is made to AASHTO-LRFD specifications article numbers throughout the design

example. To distinguish between references to articles of the AASHTO-LRFD specifications and

references to sections of the design example, the references to specification articles are preceded by the

letter S. For example, S5.2 refers to Article 5.2 of AASHTO-LRFD specifications while 5.2 refers to

Section 5.2 of the design example.

Two different forms of fonts are used throughout the example. Regular font is used for

calculations and for text directly related to the example. Italic font is used for text that represents

commentary that is general in nature and is used to explain the intent of some specifications provisions,

explain a different available method that is not used by the example, provide an overview of general

acceptable practices and/or present difference in application between different jurisdictions.

Task Order DTFH61-02-T-63032 2-1

Design Step 2 - Example Bridge Prestressed Concrete Bridge Design Example

2. EXAMPLE BRIDGE

2.1 Bridge geometry and materials

Bridge superstructure geometry

Superstructure type: Reinforced concrete deck supported on simple span prestressed girders made

continuous for live load.

Spans: Two spans at 110 ft. each

Width: 55-4 total

52-0 gutter line-to-gutter line (Three lanes 12- 0 wide each, 10 ft. right

shoulder and 6 ft. left shoulder. For superstructure design, the location of the

driving lanes can be anywhere on the structure. For substructure design, the

maximum number of 12 ft. wide lanes, i.e., 4 lanes, is considered)

Railings: Concrete Type F-Parapets, 1- 8 wide at the base

Skew: 20 degrees, valid at each support location

Girder spacing: 9-8

Girder type: AASHTO Type VI Girders, 72 in. deep, 42 in. wide top flange and 28 in. wide

bottom flange (AASHTO 28/72 Girders)

Strand arrangement: Straight strands with some strands debonded near the ends of the girders

Overhang: 3-6 from the centerline of the fascia girder to the end of the overhang

Intermediate diaphragms: For load calculations, one intermediate diaphragm, 10 in. thick, 50 in. deep, is

assumed at the middle of each span.

Figures 2-1 and 2-2 show an elevation and cross-section of the superstructure, respectively. Figure 2-3

through 2-6 show the girder dimensions, strand arrangement, support locations and strand debonding

locations.

Typically, for a specific jurisdiction, a relatively small number of girder sizes are available to select from.

The initial girder size is usually selected based on past experience. Many jurisdictions have a design aid

in the form of a table that determines the most likely girder size for each combination of span length and

girder spacing. Such tables developed using the HS-25 live loading of the AASHTO Standard

Specifications are expected to be applicable to the bridges designed using the AASHTO-LRFD

Specifications.

Das könnte Ihnen auch gefallen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Concrete Superstructure SIDokument384 SeitenConcrete Superstructure SIMuhammad ImranNoch keine Bewertungen

- Reinforcement Shape Codes: Table of Minimum DimensionsDokument1 SeiteReinforcement Shape Codes: Table of Minimum DimensionsAburvarajNoch keine Bewertungen

- Bridge Design Manual - Ohio Department of Transportation 2010Dokument396 SeitenBridge Design Manual - Ohio Department of Transportation 2010Davide Del CarloNoch keine Bewertungen

- 철근콘크리트 휨부재의 최소 철근 규정Dokument9 Seiten철근콘크리트 휨부재의 최소 철근 규정jinwook75Noch keine Bewertungen

- Shear in Inclined WebsDokument2 SeitenShear in Inclined WebsjologscresenciaNoch keine Bewertungen

- MultiPier Soil Table PDFDokument24 SeitenMultiPier Soil Table PDFRonnie1478Noch keine Bewertungen

- Sofistik Basic v.2010Dokument155 SeitenSofistik Basic v.2010HesskymNoch keine Bewertungen

- VSL Strand Post Tensioning Systems PDFDokument41 SeitenVSL Strand Post Tensioning Systems PDFJonathan GallegosNoch keine Bewertungen

- Suspended Manual English Volume 1 Community Development - 2011 PDFDokument14 SeitenSuspended Manual English Volume 1 Community Development - 2011 PDFErnie ErnieNoch keine Bewertungen

- Bridge Inventory Guidelines JICA SrilankaDokument54 SeitenBridge Inventory Guidelines JICA SrilankaAdamNoch keine Bewertungen

- Buckling of Arch Bridge: ISSN: 2454-132X Impact Factor: 4.295Dokument4 SeitenBuckling of Arch Bridge: ISSN: 2454-132X Impact Factor: 4.295Vignesh VickyNoch keine Bewertungen

- UseAndAbuseOfSpringsToModelFoundationsDokument112 SeitenUseAndAbuseOfSpringsToModelFoundationsjoaozinho_scNoch keine Bewertungen

- Honshu-Shikoku Bridge Authority - Wind Resistant Design Code (2001) PDFDokument20 SeitenHonshu-Shikoku Bridge Authority - Wind Resistant Design Code (2001) PDFtony13touchNoch keine Bewertungen

- Civil2015 v2 1 Release NoteDokument30 SeitenCivil2015 v2 1 Release NoteJorge Luis Molluni BalconaNoch keine Bewertungen

- Caltrans Bridge DesignDokument24 SeitenCaltrans Bridge DesignAinie ButtNoch keine Bewertungen

- Concept Refinement ReportDokument110 SeitenConcept Refinement ReportkfdaniNoch keine Bewertungen

- SOFiSTiK 7 Reasons enDokument2 SeitenSOFiSTiK 7 Reasons enMikeNoch keine Bewertungen

- Steel Bridge Design HandbookDokument127 SeitenSteel Bridge Design HandbookAdamHudsonNoch keine Bewertungen

- 07 2016 RADBUG BRR Post Tensioned Box Presentation SWoodDokument31 Seiten07 2016 RADBUG BRR Post Tensioned Box Presentation SWoodMaria Plaza GarciaNoch keine Bewertungen

- RM E Cable Stayed Bridge DINDokument38 SeitenRM E Cable Stayed Bridge DINphanoanhgtvtNoch keine Bewertungen

- Comparative Analysis of Composite Structure by STADD Pro SoftwareDokument6 SeitenComparative Analysis of Composite Structure by STADD Pro SoftwareIJRASETPublicationsNoch keine Bewertungen

- Design of Type C and Aashto Type IV Girder BridgesDokument473 SeitenDesign of Type C and Aashto Type IV Girder BridgesRey SolNoch keine Bewertungen

- ICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side MountDokument44 SeitenICPLG1247 - 2m Post Spacing - Ezy-Guard HC - Bridge Barrier Side Mountvisva scgNoch keine Bewertungen

- Two-Span Continuous Straight Composite Steel Wide-Flange Beam BridgeDokument96 SeitenTwo-Span Continuous Straight Composite Steel Wide-Flange Beam BridgeMuhammad Aquilur RahmanNoch keine Bewertungen

- LRFD-8 AppendexE5Dokument159 SeitenLRFD-8 AppendexE5diablopapanatasNoch keine Bewertungen

- Midas Gen Report TemplateDokument6 SeitenMidas Gen Report Templatekdb92uceNoch keine Bewertungen

- Staad - Pro Syllabus FinalDokument3 SeitenStaad - Pro Syllabus FinalAtul ManchalwarNoch keine Bewertungen

- Lib CivilDokument13 SeitenLib CivilPandal RajNoch keine Bewertungen

- Alberta Infrastructure Bridge AestheticsDokument70 SeitenAlberta Infrastructure Bridge AestheticsShikhar SinghNoch keine Bewertungen

- SOFiSTiK 1Dokument55 SeitenSOFiSTiK 1Philip RichNoch keine Bewertungen

- Structural Analysis of The Sutong BridgeDokument8 SeitenStructural Analysis of The Sutong BridgeMahmood MuftiNoch keine Bewertungen

- Galvanizing Report For SteelDokument1 SeiteGalvanizing Report For SteelindunilNoch keine Bewertungen

- State Dearptment of Housing & Urban Development PDFDokument81 SeitenState Dearptment of Housing & Urban Development PDFly0039Noch keine Bewertungen

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Dokument11 SeitenPart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaNoch keine Bewertungen

- Design and Analysis of Double-Hole Box Culvert STR PDFDokument7 SeitenDesign and Analysis of Double-Hole Box Culvert STR PDFThành LuânNoch keine Bewertungen

- Brass Culvert 2.7 TechnicalManualDokument35 SeitenBrass Culvert 2.7 TechnicalManualEdelyn Lindero AmbosNoch keine Bewertungen

- LARSA Steel Girder BrochureDokument4 SeitenLARSA Steel Girder Brochuresasidhar029Noch keine Bewertungen

- HSC in As5100Dokument21 SeitenHSC in As5100Mahbub AlamNoch keine Bewertungen

- Comparative Analysis and Design of Box Girder Bridge Sub-Structure With Two DiDokument6 SeitenComparative Analysis and Design of Box Girder Bridge Sub-Structure With Two DiNelly BuquironNoch keine Bewertungen

- Notes On Updated Seismic Codes in Ethiopia Samuel Kinde Kassegne Et Al March2012Dokument36 SeitenNotes On Updated Seismic Codes in Ethiopia Samuel Kinde Kassegne Et Al March2012Sudhakar Krishnamurthy100% (1)

- Homework No. 1 (10 Points) : CES-5325 / CGN-4930 Design of Highway Bridges - Spring Term 2005Dokument2 SeitenHomework No. 1 (10 Points) : CES-5325 / CGN-4930 Design of Highway Bridges - Spring Term 2005ingamarraNoch keine Bewertungen

- TeklaS-Midas v20 ManualDokument10 SeitenTeklaS-Midas v20 ManualNikola RajićNoch keine Bewertungen

- 2007-S2 Cven9818Dokument2 Seiten2007-S2 Cven9818Suman SahaNoch keine Bewertungen

- OTEC (Kanawha River Bridge) S WilliamsonDokument59 SeitenOTEC (Kanawha River Bridge) S Williamsonstevewv100% (1)

- Guidelines Report Writing PDFDokument13 SeitenGuidelines Report Writing PDFShubham PawarNoch keine Bewertungen

- Adecco Thailand Salary Guide 2019 PDFDokument55 SeitenAdecco Thailand Salary Guide 2019 PDFอรรถพล บอย อรรถพลNoch keine Bewertungen

- Dyna 1Dokument69 SeitenDyna 1Marko Šimić100% (1)

- Vibration Serviceability of Footbridges Under Human-Induced Excitation: A Literature ReviewDokument74 SeitenVibration Serviceability of Footbridges Under Human-Induced Excitation: A Literature ReviewFernanda LagoNoch keine Bewertungen

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDokument18 SeitenJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Noch keine Bewertungen

- COMPREHENSIVE DESIGN Example For PRESTRESSED CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE WITH COMMENTARY SI UNITSDokument384 SeitenCOMPREHENSIVE DESIGN Example For PRESTRESSED CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE WITH COMMENTARY SI UNITSvNoch keine Bewertungen

- PB 2007100014Dokument396 SeitenPB 2007100014Pipi KNoch keine Bewertungen

- Design Example 02Dokument114 SeitenDesign Example 02mt100% (2)

- Steel Bridge Design Handbook: Design Example 2B: Two-Span Continuous Straight Composite Steel Wide-Flange Beam BridgeDokument84 SeitenSteel Bridge Design Handbook: Design Example 2B: Two-Span Continuous Straight Composite Steel Wide-Flange Beam BridgemtNoch keine Bewertungen

- Designexample04 PDFDokument159 SeitenDesignexample04 PDFmtNoch keine Bewertungen

- Steel Bridge Design HandbookDokument26 SeitenSteel Bridge Design HandbookmtNoch keine Bewertungen

- Volume04 PDFDokument281 SeitenVolume04 PDFdxzaberNoch keine Bewertungen

- Volume04 AASHTODokument281 SeitenVolume04 AASHTOsayedNoch keine Bewertungen

- Expanded MetalDokument20 SeitenExpanded MetalHerbert P. BacosaNoch keine Bewertungen

- GeoTechnical FormulasDokument34 SeitenGeoTechnical FormulasTptaylor100% (3)

- Plate Girder Steel Seminar PDFDokument44 SeitenPlate Girder Steel Seminar PDFfrancisNoch keine Bewertungen

- AWA AS1288 Glass GuideDokument96 SeitenAWA AS1288 Glass GuideChristian Bar100% (2)

- Weld StressDokument10 SeitenWeld StressHerbert P. BacosaNoch keine Bewertungen

- SettlementDokument62 SeitenSettlementmrnaeemNoch keine Bewertungen

- SettlementDokument62 SeitenSettlementmrnaeemNoch keine Bewertungen

- RAPT User ManualDokument738 SeitenRAPT User ManualrakhbirNoch keine Bewertungen

- Flaubert Release-Readme!Dokument3 SeitenFlaubert Release-Readme!Herbert P. BacosaNoch keine Bewertungen

- CE 632 Bearing Capacity PDFDokument48 SeitenCE 632 Bearing Capacity PDFNoel Malinao CablindaNoch keine Bewertungen

- Summary of Rock Armour Cost For Option A, B & C S/No Description Unit Rate Qty AmountDokument3 SeitenSummary of Rock Armour Cost For Option A, B & C S/No Description Unit Rate Qty AmountHerbert P. BacosaNoch keine Bewertungen

- HK CS2 - 2012Dokument50 SeitenHK CS2 - 2012bobbyccwNoch keine Bewertungen

- Quality Traffic PlanDokument44 SeitenQuality Traffic PlanHerbert P. BacosaNoch keine Bewertungen

- Load Calculation SheetDokument2 SeitenLoad Calculation SheetHerbert P. BacosaNoch keine Bewertungen

- Column DesignDokument1 SeiteColumn DesignHerbert P. BacosaNoch keine Bewertungen

- Wide Beam DesignDokument6 SeitenWide Beam DesignNaveen RevannaNoch keine Bewertungen

- Bolt and Weld Capacities - BS5950Dokument1 SeiteBolt and Weld Capacities - BS5950Helena DomičićNoch keine Bewertungen

- Esub FaqsDokument12 SeitenEsub FaqsHerbert P. BacosaNoch keine Bewertungen

- COMPREHENSIVE DESIGN Example For PRESTRESSED CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE WITH COMMENTARY SI UNITSDokument384 SeitenCOMPREHENSIVE DESIGN Example For PRESTRESSED CONCRETE (PSC) GIRDER SUPERSTRUCTURE BRIDGE WITH COMMENTARY SI UNITSvNoch keine Bewertungen

- Moment DistributionDokument153 SeitenMoment DistributionHerbert P. BacosaNoch keine Bewertungen

- Esub FaqsDokument12 SeitenEsub FaqsHerbert P. BacosaNoch keine Bewertungen

- WWW - Bca.gov - SG StructuralPlan Others Piling RequirementsDokument80 SeitenWWW - Bca.gov - SG StructuralPlan Others Piling RequirementsLiu JianqiNoch keine Bewertungen

- Us Steel ExtractsDokument95 SeitenUs Steel ExtractsHerbert P. BacosaNoch keine Bewertungen

- Bolt and Weld Capacities - BS5950Dokument1 SeiteBolt and Weld Capacities - BS5950Helena DomičićNoch keine Bewertungen

- Us Steel ExtractsDokument95 SeitenUs Steel ExtractsHerbert P. BacosaNoch keine Bewertungen

- Natural Philosophy: Language Watch EditDokument7 SeitenNatural Philosophy: Language Watch Editlin ًNoch keine Bewertungen

- Chemistry Investigatory ProjectDokument19 SeitenChemistry Investigatory ProjectShreyySNoch keine Bewertungen

- The Colonization of Tiamat V (Phoenix III, Daniel) PDFDokument44 SeitenThe Colonization of Tiamat V (Phoenix III, Daniel) PDFKonstantina GlezakouNoch keine Bewertungen

- ResumeDokument2 SeitenResumeapi-252798605Noch keine Bewertungen

- Vibration Learning 1Dokument51 SeitenVibration Learning 1mubashirNoch keine Bewertungen

- Simulation Analysis of Compression Refrigeration Cycle With Different RefrigerantsDokument5 SeitenSimulation Analysis of Compression Refrigeration Cycle With Different RefrigerantsSpicyNoch keine Bewertungen

- Biplots of Compositional Data: University of Glasgow, UKDokument18 SeitenBiplots of Compositional Data: University of Glasgow, UKStefhany ArdilaNoch keine Bewertungen

- Problems Based On AgesDokument2 SeitenProblems Based On AgesHarish Chintu100% (1)

- Guide To Better Geotextile Specifying US FABRICSDokument19 SeitenGuide To Better Geotextile Specifying US FABRICSOladunni AfolabiNoch keine Bewertungen

- Rr211402 Mechanics of SolidsDokument8 SeitenRr211402 Mechanics of SolidsSrinivasa Rao GNoch keine Bewertungen

- Specian Quori Hardware HRI Workshop 2018Dokument6 SeitenSpecian Quori Hardware HRI Workshop 2018Upendra VaddeNoch keine Bewertungen

- Projectile Motion: AP Physics CDokument26 SeitenProjectile Motion: AP Physics CCedric VargasNoch keine Bewertungen

- Biok 3Dokument22 SeitenBiok 3Hazizi HanapiNoch keine Bewertungen

- PP DL Pipe and Fittings PDFDokument8 SeitenPP DL Pipe and Fittings PDFakash dabhadeNoch keine Bewertungen

- NI Vision: NI 17xx Smart Camera User ManualDokument90 SeitenNI Vision: NI 17xx Smart Camera User ManualDushyant GuptaNoch keine Bewertungen

- Force Calculation Description Result Unit 0: Graphical IllustrationDokument14 SeitenForce Calculation Description Result Unit 0: Graphical IllustrationvenkateswaranNoch keine Bewertungen

- High Tensile Steel 4340Dokument2 SeitenHigh Tensile Steel 4340Arun KumarNoch keine Bewertungen

- 03 Uppercat Free Upcat KeyDokument40 Seiten03 Uppercat Free Upcat Keyadrian suppNoch keine Bewertungen

- (CO5) Chemical EquilibriumDokument35 Seiten(CO5) Chemical EquilibriumAya Evangelista AlmandresNoch keine Bewertungen

- Design and Fabrication of Power Scissor JackDokument39 SeitenDesign and Fabrication of Power Scissor Jackmohamedovic100% (4)

- SBF BK A07025 Accelerating Admixtures For ConcreteDokument53 SeitenSBF BK A07025 Accelerating Admixtures For ConcreteSandeep ReddyNoch keine Bewertungen

- Guia para Expandido de TubosDokument3 SeitenGuia para Expandido de Tubosjafc986Noch keine Bewertungen

- Homeopathic Materia Medica PDFDokument216 SeitenHomeopathic Materia Medica PDFRavi Ranjan Jha100% (1)

- Mandavya Integrated Pu CollegeDokument4 SeitenMandavya Integrated Pu CollegeSahaana VMNoch keine Bewertungen

- Silicon CarbideDokument10 SeitenSilicon CarbideTushar AneyraoNoch keine Bewertungen

- PL Fluke Biomedical (Ekatalog Link) 2018 - 2020Dokument2 SeitenPL Fluke Biomedical (Ekatalog Link) 2018 - 2020lukas adi nugrohoNoch keine Bewertungen

- Electroanalytical Chemistry A Series of Advances Volume 22 Electroanalytical ChemistryDokument329 SeitenElectroanalytical Chemistry A Series of Advances Volume 22 Electroanalytical ChemistryAyça OrbayNoch keine Bewertungen

- Water Turbine - Wikipedia, ..Dokument9 SeitenWater Turbine - Wikipedia, ..manbkkNoch keine Bewertungen

- Advanced Functions and Introductory Calculus v2Dokument480 SeitenAdvanced Functions and Introductory Calculus v2Karen Feng100% (3)

- A Tutorial in Logistic RegressionDokument14 SeitenA Tutorial in Logistic RegressionOmar MsawelNoch keine Bewertungen

- Advanced Modelling Techniques in Structural DesignVon EverandAdvanced Modelling Techniques in Structural DesignBewertung: 5 von 5 Sternen5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- A Welder’s Handbook to Robotic ProgrammingVon EverandA Welder’s Handbook to Robotic ProgrammingBewertung: 5 von 5 Sternen5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (137)

- Marine Structural Design CalculationsVon EverandMarine Structural Design CalculationsBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Von EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Bewertung: 4 von 5 Sternen4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityVon EverandDark Aeon: Transhumanism and the War Against HumanityBewertung: 5 von 5 Sternen5/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksVon EverandArtificial Intelligence: From Medieval Robots to Neural NetworksBewertung: 4 von 5 Sternen4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsVon EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNoch keine Bewertungen

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Pile Design and Construction Rules of ThumbVon EverandPile Design and Construction Rules of ThumbBewertung: 4.5 von 5 Sternen4.5/5 (15)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Von EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Bewertung: 4 von 5 Sternen4/5 (5)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesVon EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesVon EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesBewertung: 2.5 von 5 Sternen2.5/5 (3)