Beruflich Dokumente

Kultur Dokumente

Preboring Works To DWall With Air-Lift & RCD Core Barrer - 17.6.14 PDF

Hochgeladen von

Erick SmithOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Preboring Works To DWall With Air-Lift & RCD Core Barrer - 17.6.14 PDF

Hochgeladen von

Erick SmithCopyright:

Verfügbare Formate

1

PRE-BORING WORK

PRIOR TO

DIAPHRAGM WALL CONSTRUCTION

Rev. Date Description Status Prepared Approved

- 17.6.14 PRE-BORING WORK For Construction Spencer MJJung

2

CONTENTS

OBJECTIVE

PRE-BORE METHODOLOGY ------------------------------------------------------ 3

A) AIR-LIFT METHOD -------------------------------------------------------------- 4

Guide Wall and Casing Installation ---------------------------------------------- 4

Pre-boring --------------------------------------------------------------------------- 5

Pre-coring --------------------------------------------------------------------------- 6

Backfilling -------------------------------------------------------------------------- 8

Diaphragm Wall Soil Excavation ----------------------------------------------- 10

Pre-boring P3 & P4 --------------------------------------------------------------- 11

Pre-boring P5 & P6 --------------------------------------------------------------- 12

Diaphragm Wall Rock Coring --------------------------------------------------- 13

B) RCD(REVERSE CIRCULATION METHOD) ------------------------------- 15

APPENDIX A - LAYOUT PLAN OF PRE-BORING

- ENLARGE LAYOUT OF PRE-BORING

3

Objective: To remove hard strata prior to diaphragm wall construction

1. Pre-boring Methodology

Pre-boring is selected to ease the excavation for diaphragm wall at hard strata / high rock level in these

area prior to diaphragm wall excavation. It entails the process since inception of guide wall

construction, pre-casing installation, coring and backfill with LSS(Liquefied Soil Stabilizer) and lean

concrete at above rock bed and within rock bed zone for backfilling respectively.

Based on current available bore-log information, pre-boring of 1000mm diameter along Dwall

alignment, please see Appendix A have been selected for such works. Thus, 2 pre-boring methodology

will be used to carry out, namely; Air-lift and RCD(Reverse Circulation Drill) methods.

A) Air-lift method: Using a boring rig attach with kally-bar mounted with a self-collecting box core

barrel to perform pre-boring with air supply to create suction effect to clear out drilling

fragments from pile toe. The air-lift method of clearing the drilling from pile toe are air-lifted into

collection box situated above the core barrel, thus every interval of an hour may be required to

retrieve its kally-bar to empty those loose rock fragment being collected in the collection box or

deemed at the operator opinion that the collection box is fully filled.

B) RCD method: Using a boring rig attach with RCD rod instead of kally-bar, mounted with core

barrel with air supply to create suction effect to clear out drilling fragments. The RCD method

tends to be a one-time process to continuously clean out the drillings from pile toe.

The above 2 methodology of pre-boring are similar with the used of casing installed by either vibro-

hammer or BG rig with casing-driven adaptor until the stage of coring to be carried out on hard strata /

rock bed, the kally-bar and RCD rod used are different to disintegrate hard strata / rock bed.

4

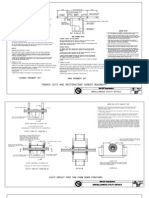

A) Air-lift method

Casing Installation

1. Construct the guide wall for diaphragm wall alignment accordingly to pre-bore location layout,

catering for the outer casing diameter of 1050mm.

2. Only applying for pre-bore location, its guide wall internal face to internal face width shall be

constructed as in Figure 1 to suit the casing installation for pre-boring works.

3. Pre-arrange with marking of each diaphragm wall(D-wall) joints on guide wall top for initial casing

setting out for pile 1 and 2 at every joint of D-wall.

4. Pre-excavate by means of backhoe or excavator to depth of guide wall if necessary at site discretion

for the initial insertion of casing setting/positioning. Commence pile 1 casing installation by vibro

hammer or casing-driving adapter of the boring rig into ground. Check the verticality of casing

during installation by spirit level. Drive casing until some refusal from ground. Commence boring

at pile 1, while pile 2 may continue to start installation of casing into hard strata by mean of vibro-

hammer, similarly casing installation shall be carried out at the rest of D-wall jointing marked on

guide wall at site discretion.

Figure 1 / Section A A (N.T.S)

P1 P2

5

Pre-boring

1. Pre-bore to clear out materials with boring bucket within casing at pile 1 until hard strata/rock top

level as shown below Figure 2; similarly for P2 casing and its pre-boring works as well as for all the

intended pre-boring location are apply.

Figure2

P1 P2

6

Pre-Coring

1. Replace boring bucket with Roller Bit Core Barrel, Figure 3 next page; to continue rock head

coring. The core barrel is fitted with a conceal pipe within its wall, and connected to the suction

channel to supply air from a compressor unit, so as to create a suction-effect within the suction

channel to air-lift the crush strata beneath the roller bit at pile toe level into the collection box

located above the roller bit.

Suction channel for

hard strata fragment

clearing from pile toe

Suction channel for

hard fragment clearing

from pile toe

Figure 3 Roller Bit Core Barrel

Residual soil

Hard strata / rock zone

casing

See next page enlarge details on core barrel rock

drilling

Note: Hard strata level shall be

recorded in the Confirmation of GIII

Rock Level and witness by all and in-

charge person to sign-off as in

Appendix B.

7

Enlarge Details on Core Barrel Process

Suction

channel

Air supply inlet

from compressor

Collection box collection point of fragment chip

transported by air-lift within core barrel during coring

Fragment chipping

Core barrel

Rock fragments

sink into

collection box

8

Backfilling

1. Once the desire depth of that D-wall panel is reached, retrieve core barrel and kelly-bar. Moved off

boring rig to pile 2 continue pre-boring works in similar manner described earlier.

2. While pile 1 is prepared with the lowering of tremie pipe, G20 shall be used for the backfilling from

pile toe to the earlier hard strata/rock level. Remaining from hard strata/rock level to guide wall

toe/base shall be backfilled with LSS/Grade7 lean concrete as shown below;

3. Once finished pouring of LSS/G7 lean concrete, extract casing by vibro or the casing-adaptor of the

boring rig. This casing may then be used to install at other pre-bore pile location, sequence will be

P1 P2

LSS / G7

9

in jumping manner at the construction manager discretion so as to provide a continuous pre-boring

within site constraint.

4. Pre-bore and cast in similar manner to the rest of the pile. In event of more pre-bore holes are

requires to carry out at others location other-than those shown in Appendix A, upon further

information are obtained from the probing soil investigation, new location to be pre-bored shall be

added and revised for information.

10

Diaphragm wall Soil Excavtion

1. Commence grabbing or use cutter with Bentonite slurry, if available to pre-excavate out those

earlier backfilled LSS/G7 lean concrete and remaining soil shown below until earlier hard strata /

rock head again;

Con'c

G20

D/Wall

Excavation

L=2,800 * W=1,050

Section 'A'

Elevation

A

B

Section 'B'

Re-excavate earlier

LSS & soil

Earlier hard strata /

rock head level

11

Pre-boring P3 & P4

1. Installed casing into excavated trench to setout remaining pre-bore location P3 and P4 on guide wall

top. Repeat using roller bit to desintegrate the hard strata / rock bed again at P3 & P4.

Con'c

G20

Guide Casing

Section 'A'

Elevation

Section 'B'

B

A

2. Retrieve core barrier and cast the bed rock zone with grade 20 at P3 & P4. Retrieve casing to install

at P5 & P6 as shown next page Figure 4

P2

P2

P1

P1

P4

P3 P4

P1 P3 P2

P3 P4

12

Pre-boring P5 & P6

1. Upon hard strata / rock bed are cleared. No backfilling of G20 is required for these last pre-bore

piles but to retrieve casing for the cutter for further excavation with Bentonite slurry.

Section 'A'

Elevation

Section 'B'

B

A

Guide Casing

Figure 4

P5 P6

P6 P5

13

Diaphragm Wall Rock Coring

1. After casing removal, position cutter for excavation as shown below with Bentonite slurry;

14

2. Continue excavation rock bed until desire Dwall design depth is reached. Proceed to desanding,

lower steel cages and casting.

15

B) RCD method

In RCD methodology, the pre-boring procedures and coring of hard strata / Rock bed drilling

arrangement is similar described as in air-lift method, but for RCD method, RCD drilling section of

pipe are used instead of kally-bar; core barrel is connected to RCD pipe with supply of air into RCD

pipe to create suction-effect within RCD pipe to air-lift the drilling chippings/fragments with

bentonite slurry within core barrel via RCD pipe into collection tank at ground level as shown below;

Air Flush &

Drill chips

16

APPENDIX A

PRE-BORED PILES LAYOUT

17

18

Das könnte Ihnen auch gefallen

- Bored Pile Foundation Implementation MethodDokument23 SeitenBored Pile Foundation Implementation MethodIda Bagus Gede Roma Harsana PutraNoch keine Bewertungen

- Metro Project LATESTDokument39 SeitenMetro Project LATESTRahul ChauhanNoch keine Bewertungen

- Method Statement Bored PileDokument9 SeitenMethod Statement Bored PileAsma Farah100% (3)

- Sec.1200 (Well Foundations)Dokument15 SeitenSec.1200 (Well Foundations)Jigar PatelNoch keine Bewertungen

- Method of Statement for Piling WorksDokument15 SeitenMethod of Statement for Piling Worksahmad100% (1)

- Method Statement: ApprovalDokument21 SeitenMethod Statement: ApprovalzhanghuiNoch keine Bewertungen

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDokument6 SeitenMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953Noch keine Bewertungen

- Methodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering CorporationDokument10 SeitenMethodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering Corporationvenkateswara rao PothinaNoch keine Bewertungen

- 9.0 Anchored RC WallDokument2 Seiten9.0 Anchored RC WallAdam Hussary AhmadNoch keine Bewertungen

- Vol IE Tender DrawingsDokument53 SeitenVol IE Tender DrawingsAnnisa Nabilah Mohd HashimNoch keine Bewertungen

- Construction Methodlogy For Well Foundation: - 1 - VKLR, QmeDokument4 SeitenConstruction Methodlogy For Well Foundation: - 1 - VKLR, QmeBalaji ManneNoch keine Bewertungen

- Method of Slotted DrainDokument5 SeitenMethod of Slotted Drainzultrsb689100% (1)

- CM14 Type V Floating RoofsDokument69 SeitenCM14 Type V Floating RoofsHuy Thieu Bui100% (2)

- Ms For Concrete PilesDokument16 SeitenMs For Concrete PilesahmadNoch keine Bewertungen

- Bored Cast In-Situ Pile Method StatementDokument10 SeitenBored Cast In-Situ Pile Method StatementVijay JamadarNoch keine Bewertungen

- SPDC Standard Drilling Procedures Manual Site: CHA Pter 07Dokument39 SeitenSPDC Standard Drilling Procedures Manual Site: CHA Pter 07Agaba Idu100% (1)

- Method Statement For Pipe Pile WorksDokument18 SeitenMethod Statement For Pipe Pile Worksymkawai224Noch keine Bewertungen

- Remove - Replace - J-PediaDokument2 SeitenRemove - Replace - J-PediamraskarmyNoch keine Bewertungen

- MOS DrainageDokument16 SeitenMOS DrainageMohammad Hadoumi Saldan100% (1)

- UnderpinningDokument30 SeitenUnderpinningAimi Athirah ZahibNoch keine Bewertungen

- Silo PresentationDokument21 SeitenSilo PresentationCrislynNoch keine Bewertungen

- MOS-CVL-08Pile Foundation + Bentonite MOSDokument4 SeitenMOS-CVL-08Pile Foundation + Bentonite MOSWaqar Ahmad MalikNoch keine Bewertungen

- Well Foundation (Jack Down) - Method Statement-R0!07!08-201Dokument10 SeitenWell Foundation (Jack Down) - Method Statement-R0!07!08-201SurinderPalSinghGillNoch keine Bewertungen

- Open Hole Side TrackingDokument8 SeitenOpen Hole Side Trackingmyounis82Noch keine Bewertungen

- New 170919 Method StatementDokument2 SeitenNew 170919 Method StatementZamaludin ZaimiNoch keine Bewertungen

- CP System Deep Well Anode Groundbed For PipelineDokument5 SeitenCP System Deep Well Anode Groundbed For PipelineMastram HatheshNoch keine Bewertungen

- CHAPTER - 2 Piers and CaissonsDokument43 SeitenCHAPTER - 2 Piers and CaissonsOromo Oromiya EtiophiaNoch keine Bewertungen

- Tankage Erection - Procedure - CPCL SiteDokument10 SeitenTankage Erection - Procedure - CPCL SiteAnantha Narayanan100% (1)

- 1.MS - FoundationDokument11 Seiten1.MS - FoundationMalik BilalNoch keine Bewertungen

- MS Installation Ductile Iron Water Supply (Scribd)Dokument17 SeitenMS Installation Ductile Iron Water Supply (Scribd)Mohd Asyhar91% (33)

- Northparkes Mines Crusher Station Ground Support ReportDokument13 SeitenNorthparkes Mines Crusher Station Ground Support ReportMO KHNoch keine Bewertungen

- Spe 22542 MSDokument10 SeitenSpe 22542 MSmohamedabbas_us3813Noch keine Bewertungen

- AST Nozzle Repair Req.Dokument10 SeitenAST Nozzle Repair Req.Irvansyah RazadinNoch keine Bewertungen

- Method Statement For Bored Piling of Peru II BridgeDokument3 SeitenMethod Statement For Bored Piling of Peru II BridgeRafael Abedes0% (1)

- Pile Instalation Methods 2Dokument9 SeitenPile Instalation Methods 2Bright MuzaNoch keine Bewertungen

- IS-2800 - 1 Construction of TubewellDokument14 SeitenIS-2800 - 1 Construction of TubewellRam Balak Roy100% (2)

- Project Execution Plan For TankDokument3 SeitenProject Execution Plan For Tankiwansalma100% (1)

- CONSTRUCTION DRAINAGE WORKS STATEMENTDokument5 SeitenCONSTRUCTION DRAINAGE WORKS STATEMENTYin Mohd100% (4)

- Precasting PSC Girder MethodologyDokument5 SeitenPrecasting PSC Girder MethodologyAkhilesh Dwivedi50% (2)

- Install Micropile Method StatementDokument9 SeitenInstall Micropile Method Statementkazauser67% (3)

- Mech Spec PDFDokument115 SeitenMech Spec PDFDayanandSonawaneNoch keine Bewertungen

- Soil InvestigationDokument19 SeitenSoil InvestigationmilindsmeherNoch keine Bewertungen

- Install PE Piping UndergroundDokument39 SeitenInstall PE Piping Underground1zorro1100% (1)

- Part BDokument175 SeitenPart BVigneshwar PalanirajaNoch keine Bewertungen

- Design and Construction For Ground Improvement - Guidelines: Indian StandardDokument9 SeitenDesign and Construction For Ground Improvement - Guidelines: Indian StandardUmar SabaNoch keine Bewertungen

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDokument3 SeitenTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNoch keine Bewertungen

- SamuelDokument6 SeitenSamuelhebiyev065Noch keine Bewertungen

- Construction Methodology For Test PIle NPBDokument8 SeitenConstruction Methodology For Test PIle NPBSheikh Nouman Mohsin RamziNoch keine Bewertungen

- Construction Methodology for Major and Minor Bridge SubstructuresDokument6 SeitenConstruction Methodology for Major and Minor Bridge Substructuresvenkateswara rao PothinaNoch keine Bewertungen

- Well Intervention Presssure Control (IWCF)Dokument316 SeitenWell Intervention Presssure Control (IWCF)rverret87% (23)

- Method Statement For Production and Laying of Cement Concrete Kerb and Kerb With ChannelDokument5 SeitenMethod Statement For Production and Laying of Cement Concrete Kerb and Kerb With ChannelKeerti Bongu100% (1)

- AssignmentDokument32 SeitenAssignmentsyedNoch keine Bewertungen

- Traduccion Apendice B API 650Dokument22 SeitenTraduccion Apendice B API 650Miguel Felipe PovedaNoch keine Bewertungen

- MOS CEILING CASSTEDokument12 SeitenMOS CEILING CASSTEService Han OnNoch keine Bewertungen

- Method Statement of Diaphragm Wall - Bored PileDokument45 SeitenMethod Statement of Diaphragm Wall - Bored PileKelvin Tsoi100% (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionVon EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNoch keine Bewertungen

- Scientific American Supplement, No. 611, September 17, 1887Von EverandScientific American Supplement, No. 611, September 17, 1887Noch keine Bewertungen

- Soil Investigation and Foundation DesignVon EverandSoil Investigation and Foundation DesignBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Longwall Mining at Shallow Depth of Cover in IndiaVon EverandLongwall Mining at Shallow Depth of Cover in IndiaNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- (AH) (LTK) (LKC) (LHP) (AH) : 187 - Casey CHNGDokument1 Seite(AH) (LTK) (LKC) (LHP) (AH) : 187 - Casey CHNGErick Smith100% (1)

- Telephone SM PDFDokument1 SeiteTelephone SM PDFErick SmithNoch keine Bewertungen

- SQUIRE MECH PTE LTD contact listDokument1 SeiteSQUIRE MECH PTE LTD contact listErick SmithNoch keine Bewertungen

- 01-Erp Annexd EvacguidelinesDokument45 Seiten01-Erp Annexd EvacguidelinesErick SmithNoch keine Bewertungen

- Aia Ihs Card: Once AIA IHS Card Is Issued, This Card MUST Be Presented at Any One of The Listed Panel GPDokument10 SeitenAia Ihs Card: Once AIA IHS Card Is Issued, This Card MUST Be Presented at Any One of The Listed Panel GPErick SmithNoch keine Bewertungen

- SDokument1 SeiteSErick SmithNoch keine Bewertungen

- SDokument1 SeiteSErick SmithNoch keine Bewertungen

- Medical Clinics PDFDokument37 SeitenMedical Clinics PDFErick SmithNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Aia Ihs Card: Once AIA IHS Card Is Issued, This Card MUST Be Presented at Any One of The Listed Panel GPDokument10 SeitenAia Ihs Card: Once AIA IHS Card Is Issued, This Card MUST Be Presented at Any One of The Listed Panel GPErick SmithNoch keine Bewertungen

- Aia Ihs Card: Once AIA IHS Card Is Issued, This Card MUST Be Presented at Any One of The Listed Panel GPDokument10 SeitenAia Ihs Card: Once AIA IHS Card Is Issued, This Card MUST Be Presented at Any One of The Listed Panel GPErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- Sop For Abc CompanyDokument13 SeitenSop For Abc CompanyErick SmithNoch keine Bewertungen

- ARTIFACTSDokument4 SeitenARTIFACTSErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- Install Contiguous Bored Piles (CBP) and Apply SurchargeDokument4 SeitenInstall Contiguous Bored Piles (CBP) and Apply SurchargeErick SmithNoch keine Bewertungen

- Install Contiguous Bored Piles (CBP) and Apply SurchargeDokument4 SeitenInstall Contiguous Bored Piles (CBP) and Apply SurchargeErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- Soil profile generation and reinforced concrete installationDokument8 SeitenSoil profile generation and reinforced concrete installationErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- HView SoilRpt PDFDokument85 SeitenHView SoilRpt PDFErick SmithNoch keine Bewertungen

- Pre-Q Application and Approval Form Nov16 (LATEST VERSION) PDFDokument3 SeitenPre-Q Application and Approval Form Nov16 (LATEST VERSION) PDFErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- Book 1Dokument3 SeitenBook 1Erick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- HView SoilRpt PDFDokument85 SeitenHView SoilRpt PDFErick SmithNoch keine Bewertungen

- Soil ParametersDokument1 SeiteSoil ParametersErick SmithNoch keine Bewertungen

- 2.0 Structural Analysis 3.0 Material Properties 4.0 Proposed Glass Fibre Reinforced Polymer (GFRP) Design 5.0 ReferencesDokument2 Seiten2.0 Structural Analysis 3.0 Material Properties 4.0 Proposed Glass Fibre Reinforced Polymer (GFRP) Design 5.0 ReferencesErick SmithNoch keine Bewertungen

- Architect's Schedule of Minimum Basic FeeDokument4 SeitenArchitect's Schedule of Minimum Basic FeeJellie Erika Abanador RodriguezNoch keine Bewertungen

- Nozzle OrientationDokument2 SeitenNozzle OrientationArindom KunduNoch keine Bewertungen

- 33kV Slash 22kVDokument192 Seiten33kV Slash 22kVShashi Kant ThakurNoch keine Bewertungen

- Single Row Deep Groove Ball Bearings - SKFDokument1 SeiteSingle Row Deep Groove Ball Bearings - SKFLuis EstradaNoch keine Bewertungen

- Is 883 - 2016 - Reff2021 Design of TimberDokument29 SeitenIs 883 - 2016 - Reff2021 Design of Timbermano chandranNoch keine Bewertungen

- CONT Five Year Fee Agreement-NMDC - DraftDokument37 SeitenCONT Five Year Fee Agreement-NMDC - Drafttarun78646Noch keine Bewertungen

- Main Report Nov 08 Final With Disclaimer June 09Dokument151 SeitenMain Report Nov 08 Final With Disclaimer June 09Arun KumarNoch keine Bewertungen

- PANORAMA Specifications Feb FINALDokument13 SeitenPANORAMA Specifications Feb FINALagmibrahim5055Noch keine Bewertungen

- Design ConsiderationsDokument2 SeitenDesign ConsiderationsKristine NatividadNoch keine Bewertungen

- Ahmed ElassalDokument8 SeitenAhmed ElassalElassal1979Noch keine Bewertungen

- LC300A-V3 LakshmiDokument177 SeitenLC300A-V3 LakshmiMODERN ACRYLICS PVT. LTD.Noch keine Bewertungen

- Movie Enola HolmesDokument6 SeitenMovie Enola HolmesMö AziziNoch keine Bewertungen

- Splicing of Reinforcement BarsDokument14 SeitenSplicing of Reinforcement BarsCj Barcelon100% (1)

- Diagrama Hidraulico Jumbo0 SandvikDokument20 SeitenDiagrama Hidraulico Jumbo0 SandvikwladimirNoch keine Bewertungen

- XBeam2d 2 ENDokument10 SeitenXBeam2d 2 ENAlem LoajnerNoch keine Bewertungen

- Module 5: Bearing Materials and TypesDokument126 SeitenModule 5: Bearing Materials and TypesArjun LalitNoch keine Bewertungen

- Castel Airco 2014-15Dokument68 SeitenCastel Airco 2014-15Anderson Giovanny Herrera DelgadoNoch keine Bewertungen

- Moderate Mary Ma ThewDokument4 SeitenModerate Mary Ma ThewShyam Kumar0% (2)

- Inventory of Fixtures, Fittings & Furnishings: Meter ReadingsDokument8 SeitenInventory of Fixtures, Fittings & Furnishings: Meter ReadingsdasaNoch keine Bewertungen

- Sapi Pompa Utama HT - en - 50hzDokument12 SeitenSapi Pompa Utama HT - en - 50hzHilary JawaNoch keine Bewertungen

- Design Proforma AmdDokument5 SeitenDesign Proforma AmdsantkabirNoch keine Bewertungen

- Performances of Concrete Repairs in PracticeDokument29 SeitenPerformances of Concrete Repairs in PracticeChris RodopoulosNoch keine Bewertungen

- Inspection Certificate: Zibo Wel-Fit Metal Products Co., LTD No.18 Lushan Road, Linzi, Zibo, China 255418Dokument1 SeiteInspection Certificate: Zibo Wel-Fit Metal Products Co., LTD No.18 Lushan Road, Linzi, Zibo, China 255418Sergio GuacanemeNoch keine Bewertungen

- Utility Duct Drawings From BCL Joydebpur-Mymensing 4 Lane Project - OptDokument1 SeiteUtility Duct Drawings From BCL Joydebpur-Mymensing 4 Lane Project - OptParvez Syed RafiNoch keine Bewertungen

- Factors of Safety for Cuttings in Normally Consolidated ClaysDokument5 SeitenFactors of Safety for Cuttings in Normally Consolidated ClaysAnonymous GnfGTwNoch keine Bewertungen

- Echivalenta Internationala MaterialeDokument2 SeitenEchivalenta Internationala Materialenelu dicanNoch keine Bewertungen

- Tappi Tip 0402-18Dokument19 SeitenTappi Tip 0402-18pedroNoch keine Bewertungen

- Piping QuizDokument3 SeitenPiping QuizAnji Reddy DNoch keine Bewertungen

- CTR Tubing Rotator Technical DatasheetDokument3 SeitenCTR Tubing Rotator Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen