Beruflich Dokumente

Kultur Dokumente

Caloritech Technical Data SCR PDF

Hochgeladen von

Roberto Leon MendezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Caloritech Technical Data SCR PDF

Hochgeladen von

Roberto Leon MendezCopyright:

Verfügbare Formate

1 sec.

30 waves

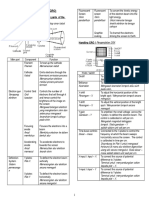

FIGURE 1 - Fixed (one second) time base at 50% output

TIME

V

O

L

T

S

For single phase circuits, one triac will be sufficient to

control the load. For three phase circuits, two triacs are

normally used.

Controls are available which can apply a current to the

gate at rapid intervals, blocking out some of the waveforms

or a part of each waveform. The load output will then vary

as a percentage of the blocked to the total cycles.

Two gate switching methods are in use to provide

variable output from the load:

i) Zero crossover fired or burst firing where only full

cycles of the voltage waveform are permitted to pass

through the SCR to the load. Again, there are several

variations as to how this can be done.

(a) Fixed time base where the cycle interval is built into the

controller at the factory and the power is switched through

only one on and one off cycle during that time. For

example, if the time base is 1 second, at 60 cycles per

second, any sequential number of the 60 voltage waves

could be allowed to pass through to the load. At 50%

demand the first 30 waves would pass and the last 30

would be blocked.

TRIAC

etc.

TIME V

O

L

T

S

LOAD

GATE

SCR

AC VOLTAGE

GATE

CURRENT

GATE

CATHODE ANODE

N P N P

combined in this fashion make up a triac. Atriac is generally

depicted as follows:

the single SCR will act as a half wave rectifier, and at best,

it will only allow the positive (+) part of the AC voltage to

reach the load.

If we connect a supply voltage and load (resistance) to

the above circuit

However, for electrical circuits, the SCR is depicted as

follows:

To allow the negative (-) part of the voltage waveform to

get through to the load requires a second SCR of opposite

polarity in parallel with the first.

For example, the circuit below will allow the full

waveform or a part of it to reach the load. Two SCR's

SCRS, THYRISTORS, TRIACS & SSR'S

An SCR (Silicon Controlled Rectifier) as a component is

one commonly used type of thyristor. Essentially, it consists

of four layers of silicon which, in their normal state, are non-

conductive.

The SCR can be made to conduct by applying a very

small current to its gate. This feature allows a combination

of SCRs to have broad application, one of which is the

switching of resistive loads characteristic of electric heating.

Diagramatically, the SCR is represented as follows:

SCR'S, THYRISTORS, TRIACS & SSR'S Technical Data

1/2 sec. 1/2 sec.

D34

ANODE

CATHODE

CURRENT

V

O

L

T

S

SCR

1/15 sec

time base

TIME

V

O

L

T

S

FIGURE 3 - Variable time base at 75% output

1/30 sec

time base

1/60 sec 1/60 sec

TIME

V

O

L

T

S

FIGURE 2 - Variable time base at 50% output

Phase angle firing is most frequently used on inductive

loads with high inrush currents. If possible, it is best to avoid

phase angle type SCR's since RFI may be generated.

Zero crossover firing is used to control resistive loads

which change little with aging and temperature. Since the

voltage is switched at zero amplitude, negligible radio

frequency interference (RFI) is generated.

ii) A second method of gate switching is phase angle

firing where a part of each waveform is blocked.

SCR'S, THYRISTORS, TRIACS & SSR'S Technical Data

FIRING BOARDS

Packaged SCRs incorporate a firing board which is

essentially an electronic circuit that accepts various inputs

from a temperature controller and converts these inputs into

a corresponding gate signal.

HEAT SINKS

All solid state switches have an internal resistance which

is converted into heat when the SCR is in the conduction

mode. High surface area aluminum heat sinks are used to

transfer this heat away from the silicon wafer. For larger

SCRs, cooling fans are also required for this purpose.

SCR - AS A PACKAGED CONTROL

As a matter of convenience, current practice is to call the

combination of component SCRs, firing board, heat sink,

fusing, fan, enclosure, interconnecting wiring, etc. an SCR!

Its probably best to adopt this control meaning as opposed

to the more limited (but more correct) component meaning.

FIGURE 4 - SCR with back-up contactors

BACK UP

CONTACTORS

I

2

T

FUSES

HRC

FUSES

TIME

at 75% demand the time base would be 1/15 of a second

or four cycles, etc.

The SCR is equipped with circuitry (firing board) that will

modify or proportion the on and off time during each

subsequent cycle based on the amplitude of the temperature

related signal it receives from an external controller.

Earlier SCRs employed fixed time bases up to 90

seconds. However, typical controls now in use tend to have

time bases set at ten seconds or less. Most Caloritech

SCRs have four second or one second fixed time bases.

SSRs (solid state relays) employ a similar method of

control except that the time base is set by an external

controller which signals the SSR's built-in firing circuitry when

it should fire (conduct).

(b) Variable time base (also burst fired) where the time base

depends on the demand. At 50% demand the time base

would be 1/30 of a second or two cycles;

Fortunately, with Caloritech equipment we seldom

have to resort to this type of control.

ADVANTAGES

SCR switching has as its main advantage the ability to

switch loads at high speed. Properly employed, they can

contribute to excellent system temperature control and

prolong heater service life.

They are silent during operation and, if sized

conservatively, will prove to be low maintenance devices.

PROTECTION

SCR's can fail "ON" and it is vital to protect the device

against short circuits at the load. Special I

2

t semi-

conductor fuses are utilized for this purpose. Back-up

fused magnetic contactors are frequently employed as in

Figure 4. These contactors can be de-energized by a limit

device but in the normal state they remain closed allowing

the full load to be switched by the SCR.

With contactors, it is most economical to limit switching

to 45 amps, and for this reason the load is usually divided

into smaller circuits.

D35

BLOCKED

WAVEFORM

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hallite Metric Fluid Power CatalogDokument342 SeitenHallite Metric Fluid Power CatalogOscar Acevedo Miranda100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 09 1HAZOPStudyTrainingCourseDokument55 Seiten09 1HAZOPStudyTrainingCoursehelton_bsbNoch keine Bewertungen

- Some Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsDokument10 SeitenSome Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsRoberto Leon MendezNoch keine Bewertungen

- Non Conventional Machining PDFDokument55 SeitenNon Conventional Machining PDFMarthande100% (1)

- Technical Guidance Notes: Level 2, No. 13Dokument4 SeitenTechnical Guidance Notes: Level 2, No. 13Τε ΧνηNoch keine Bewertungen

- Theamsterdam ConnectionDokument4 SeitenTheamsterdam ConnectionIrene FernandezNoch keine Bewertungen

- H2SO4Dokument24 SeitenH2SO4Karina Sutanto SilvanNoch keine Bewertungen

- Pid Legend PDFDokument1 SeitePid Legend PDFSocMed Dtk UI0% (1)

- 10.1.2 Costing Data: Chapter 10 - Integrated Cost-Based Design and Operation 457Dokument6 Seiten10.1.2 Costing Data: Chapter 10 - Integrated Cost-Based Design and Operation 457WONG TS75% (4)

- Standard Static Mixers - Brochure PDFDokument11 SeitenStandard Static Mixers - Brochure PDFdendyNoch keine Bewertungen

- HDPE CatalogDokument241 SeitenHDPE CatalogRoberto Leon MendezNoch keine Bewertungen

- L Uk SulphDokument24 SeitenL Uk SulphypyeeNoch keine Bewertungen

- Chemical Resistance Chart PDFDokument20 SeitenChemical Resistance Chart PDFRoberto Leon MendezNoch keine Bewertungen

- Yamada Corrosion Guide CR0214Dokument23 SeitenYamada Corrosion Guide CR0214Eddie GuillénNoch keine Bewertungen

- CO2 - Safety-Precautions-For-Carbon-Dioxide PDFDokument46 SeitenCO2 - Safety-Precautions-For-Carbon-Dioxide PDFRoberto Leon MendezNoch keine Bewertungen

- Desalination, With A Grain of Salt (Ca, 2006)Dokument100 SeitenDesalination, With A Grain of Salt (Ca, 2006)Sergey Frolov100% (1)

- Wae Oarp WebDokument8 SeitenWae Oarp WebRoberto Leon MendezNoch keine Bewertungen

- Chemical Resistance Chart PDFDokument20 SeitenChemical Resistance Chart PDFRoberto Leon MendezNoch keine Bewertungen

- Type-21 Ball Valve For Sodium HypochloriteDokument2 SeitenType-21 Ball Valve For Sodium HypochloriteRoberto Leon MendezNoch keine Bewertungen

- Ullmann Filtration FundamentalsDokument33 SeitenUllmann Filtration FundamentalspastorgeeNoch keine Bewertungen

- Filtration - High Rate Filterswaternet.0050185Dokument14 SeitenFiltration - High Rate Filterswaternet.0050185Roberto Leon MendezNoch keine Bewertungen

- Genesol 703Dokument1 SeiteGenesol 703Roberto Leon MendezNoch keine Bewertungen

- 04 Ro Water ChemistryDokument8 Seiten04 Ro Water ChemistryRajesh Kumar RoshanNoch keine Bewertungen

- Leopold Type S UnderdrainsDokument4 SeitenLeopold Type S UnderdrainsRoberto Leon MendezNoch keine Bewertungen

- 780 SpecDokument2 Seiten780 SpecRoberto Leon MendezNoch keine Bewertungen

- Caloritech Technical Data Pressure Ratings PDFDokument1 SeiteCaloritech Technical Data Pressure Ratings PDFRoberto Leon MendezNoch keine Bewertungen

- Energy recovery device performance curvesDokument1 SeiteEnergy recovery device performance curvesRoberto Leon MendezNoch keine Bewertungen

- Ferric Chloride - SolubilityDokument2 SeitenFerric Chloride - SolubilityRoberto Leon MendezNoch keine Bewertungen

- TSB341commissioning of A HYDRAcapDokument10 SeitenTSB341commissioning of A HYDRAcapRoberto Leon MendezNoch keine Bewertungen

- Sewage Treatment Cost EstimateDokument2 SeitenSewage Treatment Cost Estimatesalah_uafNoch keine Bewertungen

- Fouling Prevention in Desalination Plants... 5 PDFDokument13 SeitenFouling Prevention in Desalination Plants... 5 PDFRoberto Leon MendezNoch keine Bewertungen

- Alpha Eritrean Engineers Community's Magazine (October's Issue)Dokument8 SeitenAlpha Eritrean Engineers Community's Magazine (October's Issue)meharigrwNoch keine Bewertungen

- Inverting Power Supply Using A TPS54202 BuckDokument25 SeitenInverting Power Supply Using A TPS54202 Buckg4okkNoch keine Bewertungen

- FD-SOI and FinFET Technologies ComparedDokument25 SeitenFD-SOI and FinFET Technologies ComparedDhanishtha SinghNoch keine Bewertungen

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDokument1 SeiteMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNoch keine Bewertungen

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Dokument20 SeitenSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarNoch keine Bewertungen

- PDFDokument16 SeitenPDFOsanebi Chukwudi Lucky0% (1)

- Heat Exchangers: T T T TDokument11 SeitenHeat Exchangers: T T T Tcjc0706Noch keine Bewertungen

- Farris 2700 ManualDokument12 SeitenFarris 2700 ManualNelson AlvarezNoch keine Bewertungen

- Ma3022 Propeller Drydockingworks 1 Aug05Dokument18 SeitenMa3022 Propeller Drydockingworks 1 Aug05NAGENDRA KUMAR DNoch keine Bewertungen

- Mastertop TC 458 PDFDokument3 SeitenMastertop TC 458 PDFFrancois-Noch keine Bewertungen

- Singly Linked Lists AlgorithmDokument18 SeitenSingly Linked Lists AlgorithmGSX-R 1100Noch keine Bewertungen

- Naval Arch - Incline TestDokument11 SeitenNaval Arch - Incline TestDheerajKaushalNoch keine Bewertungen

- Mine Design and SchedulingDokument10 SeitenMine Design and SchedulingLeandro FagundesNoch keine Bewertungen

- Topaz HTC English Manual PDFDokument232 SeitenTopaz HTC English Manual PDFRafael AdrianNoch keine Bewertungen

- Cathode Ray Oscilloscope (Cro)Dokument2 SeitenCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comNoch keine Bewertungen

- HTML DOM TutorialDokument11 SeitenHTML DOM Tutorialapi-3819971100% (1)

- QSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualDokument86 SeitenQSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualTechne PhobosNoch keine Bewertungen

- Ktu Laca Solved Question PaperDokument22 SeitenKtu Laca Solved Question PaperSofiyaNoch keine Bewertungen

- Catalogue Cable Tray RevDokument40 SeitenCatalogue Cable Tray RevhardiyantodonniNoch keine Bewertungen

- Weigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyDokument53 SeitenWeigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyKevin Luis Perez QuirozNoch keine Bewertungen

- Pilot Operated Safety Relief ValvesDokument6 SeitenPilot Operated Safety Relief ValvesfabioNoch keine Bewertungen

- Effects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesDokument9 SeitenEffects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesChirag JainNoch keine Bewertungen

- Um String Code 2 0 eDokument46 SeitenUm String Code 2 0 ehydrasearchNoch keine Bewertungen

- TUK EECQ 5291 - Professional Engineering Practice - April 2018Dokument314 SeitenTUK EECQ 5291 - Professional Engineering Practice - April 2018gaza manNoch keine Bewertungen

- Satrack Full Report New2Dokument17 SeitenSatrack Full Report New2ammayi9845_930467904Noch keine Bewertungen

- Geotech Civ150 CompressDokument4 SeitenGeotech Civ150 CompressismaeelNoch keine Bewertungen

- Defense Acquisition GuidebookDokument927 SeitenDefense Acquisition GuidebookJudkerrNoch keine Bewertungen