Beruflich Dokumente

Kultur Dokumente

An Electrical Conductivity Method For Axial Gas and Solid Holdup Determination in Three Phase Fluidized Beds

Hochgeladen von

BONFRINGOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

An Electrical Conductivity Method For Axial Gas and Solid Holdup Determination in Three Phase Fluidized Beds

Hochgeladen von

BONFRINGCopyright:

Verfügbare Formate

Bonfring International Journal of Industrial Engineering and Management Science, Vol. 2, No.

2, June 2012 5

ISSN 2277 - 5056 | 2012 Bonfring

Abstract--- Fluidization is an operation in which solid

particles are kept under suspension supported by the upward

flow of liquid/gas phase. In classic fluidization the solids

density are higher than the liquid, where as in Inverse

fluidization the solids density are lower than that of

continuous liquid phase. The phase holdup measurements in

three phase classic/inverse fluidized beds are very important

and difficult to measure. The phase holdups can be estimated

with the help of pressure drop data and height of the

bed/solids mass balance with an assumption of axial uniform

solid holdup. In most of the fluidized bed operations, such as

Catalytic fluidized bed and slurry bubble columns the solids

holdup varies axially. Such type of systems, holdups

estimation is very difficult. The present study is focused on

electrical conductivity method to get directly the cross

sectional liquid holdup and pressure drop to solve the above

problem of axial solid holdup variation and can readily be

obtained the cross sectional three phase holdups.

The averaged normalized conductance and the liquid

holdup are related with liquid conductivity with a power law

mode of equation. The dependency of conductivity on liquid

also varies with electrode size and non-conducting medium

(gas/solid). The experimental results showed that the

conductivity method developed in this work was convenient for

use and had a good accuracy in a wide range of liquid holdup

(0.4 to 1) in the Gas-LiquidSolid three-phase fluidized bed

systems. The effect of temperature on conductivity of liquid

phase was also verified and successfully correlated.

Keywords--- Fluidize Bed, Conductivity, Three Phase

Holdups, Power Law Relation, Temperature Effect

I. INTRODUCTION

HREE phase fluidized beds are widely used in process

industries. The solids are kept under suspension by the

upward liquid and or gas phase. The liquid forms as

continuous phase while gas and solid are dispersed. Though

these are widely used in process industries, design of such

reactors is complicated due to the following factors axial

variation of various properties i.e phase hold-ups, effective

density. At high liquid and or gas flow rates these variations

are very important. For example slurry bubble columns are

used widely in process industries where the size variation of

catalyst is very high. The catalyst is axially distributed non

B.S.V.S.R. Krishna, Associate Professor, Department of Chemical

Engineering, Manipal Institute of Technology, Manipal University, Manipal-

576104, India. E- mail: krishna.bandaru@manipal.edu

uniformly due to the size variation. Many researchers have

used the following equations to determine the phase holdups

in three phase fluidized beds

( )g

dz

dP

s cs s l cs l g cs g

, , ,

+ + = --(1)

=

s

s

cs s

AH

M

,

---(2)

1

, , ,

= + +

cs s cs l cs g

----(3)

Where the bed height in equation (2) is visually observed. At

low and high liquid /gas flow rates neither method is

satisfactory. At the same time, the apparent density or solid

size is sufficiently small, the axial distribution further

complicates the measurement.

II. CONDUCTIVITY METHOD

For providing an alternative solution to the above problem,

many authors tried various techniques such as optical fibre,

electrical conductive probe, process tomography, static-

pressure, ultra sound and isokinetic separation [1]. Out of

these methods, the electrical conductivity method has

advantages such as simplicity of construction & operation,

accuracy of measurement, negligible hydrodynamic

disturbance, no requirement of phase modification and

measurement of local phase holdups. Indirect measurement

requiring prior calibration and dependency on spatial

distribution of the phases are the minor disadvantages of the

electrical conductivity method. Present author has used the

electrical conductivity technique due to the above advantages.

The principle of the electrical conductivity method is that, the

effective conductivity of a suspension depends on the fraction

of conducting phase in the suspension. Though different

theoretical expressions exist for the effective electrical

conductivity of a solid-liquid suspension [2], it is preferable to

calibrate the electrodes for the particular geometry that is

being used. The calibration procedure adopted here is the

same as that following authors [3],[4],[5],[6],[7].

The electrodes were calibrated using the liquid holdup data

(calculated using bed height) of 2-phase fluidized bed

obtained for different particle characteristics over wide range

of liquid velocity. The 2-phase conductance measured at each

electrode covered by the bed was normalized by the

conductance measured by the corresponding electrode for pure

water. The normalized conductance was averaged over the

length of the bed for uniform holdups else the local

An Electrical Conductivity Method for Axial Gas

and Solid Holdup Determination in Three Phase

Fluidized Beds

B.S.V.S.R. Krishna

T

Bonfring International Journal of Industrial Engineering and Management Science, Vol. 2, No. 2, June 2012 6

ISSN 2277 - 5056 | 2012 Bonfring

conductance was used for local holdups as shown below

equations.

=

H

loc

loc

dz

H

0

0

1

---(4)

0

cs ,

loc

loc

l

= ---(5)

Similarly, data were taken for different liquid flow rates

(different void fractions), static bed heights and particles of

different diameters and densities. The entire data was fitted

using a power law relation as mentioned in the literature

m

cs l cs l , ,

= ----(6)

Here the parameter m depends on particle size at constant

temperature. The value of m lies within the range (0.67 to 1)

as reported in literature [2].

The conductivity of a liquid-solid suspension is expected

to be dependent only on the solid fraction and temperature of

the system. Nevertheless, due to the finite size of electrodes

used, the size of the particles has an effect on the conductivity

and the liquid conductivity also depends on temperature.

Hence the present study focused on measuring the local

holdups by conductivity method and to find the effect of

temperature on conductivity.

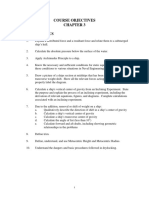

III. EXPERIMENTAL

The schematic diagram of experimental setup is shown in

Fig 1. The column is made up of acrylic material with an

internal diameter of 8.9 cm and a height of 2.75 m.A one inch

hole was provided at middle of the column for loading and

unloading of particles.The liquid was pumped through

rotametersfrom the bottom of the column where it is

distributed in heat exchanger type distributor[8].

Figure 1: The Schematic Diagram of Experimental Setup

Calibrated rotameters are used for measuring gas flow rate

and it is dispersed at the bottom of the section. Perforated

plate with 1.5 mm holes of triangular pitch is used as gas

distributor. In test section a mesh was provided at the bottom

for providing support to particles another mesh also provided

at the top to prevent particlecarryover. Water, air and spherical

polypropylene solid particles were used as liquid, gas and

solid phases respectively. Here the liquid or water is

conducting material and gas and solid particles are non-

conducting materials.

Equally spaced pressure tapings were mounted on the

column wall from bottom gas distributor to top particles

retaining mesh. The pressure taps are connected to vertical

manometer. Eighteen electrodes (stainless steel 2 cm x 1 cm x

1 cm) centered between the pressure taps were fixed to the

column for measuring the cross sectional phase holdups

[4],[5]. The electrode sectional view was shown in Fig 2. A

sequential switching circuit connects the conductivity meter

sequentially to the electrodes and the DC output of the meter

given to the data acquisition system

Bonfring International Journal of Industrial Engineering and Management Science, Vol. 2, No. 2, June 2012 7

ISSN 2277 - 5056 | 2012 Bonfring

Figure 2: The Schematic Arrangement of Electrode

In the present work, the electrodes were calibrated in the 2-

phase to convert the conductance (proportional voltage) data

to void fraction. For a chosen particle and bed height, the

liquid-solid system was allowed to reach steady state for a

particular liquid flowrate and the expanded bed height was

noted. The void fraction is calculated using the formula

H

H

0 0

) 1 (

1

= --- (7)

The liquid holdup by conductivity method and bed height

method was obtained for various flow rates and data was

correlated successfully in the form of power law equation as

discussed in the above section.

IV. RESULTS AND DISCUSSION

The effect of temperature on liquid conductivity was shown in

Fig 3a. A sample of 10 data points for each electrode has

shown in the Fig 3a out of 150 data points for each electrode.

The averaged data (average of 150 data for each electrode) is

also shown in Fig 3b.

Figure 3a: Effect of temperature on conductivity of tap water

(sample raw data)

It is clearly evident that from the figure 3a and 3b that the

conductivity is increasing with increase in temperature. This is

probably due to the increase in the activity of ions or salts

present in the water. Same trend is observed for a wide range

of temperatures (25

0

C to 41

0

C).

The change of conductance is approximately 2% for each 1

0

C change in the liquid temperature. The probability of error

may be high if the estimation can be done for high range of

temperatures.

Once the effect of temperature is identified and correlated,

the conductivity data collected various liquid flow rates as

explained in experimental section along with non-

conducting(particles and/or gas bubbles) material.

Figure 3b: Effect of Temperature on Conductivity of Tap

Water

Figure 4: Variation of Conductivity with Particles and Without

Particles

The variation of conductivity of the pure liquid and in the

presence of non-conducting material (particles or gas bubbles)

is shown in Fig 4. It is evident that the presence of particles

decreases the conductivity till the 5

th

electrode, 6

th

electrode

was covered partially with non-conducting material (particles)

and a steep increase from 7

th

electrode shows single phase of

liquid presence alone. Figure 5 is compared the data of

conductivity and the transformed data as the liquid holdup

present in that each electrode. The liquid holdup was

calculated with help of equation 6 by using the relative

conductivity. The constant m in the equation (6) depends

on non-conducting material size (size of particles/ size of air

bubble).

Electrode

Wire

Column

Bonfring International Journal of Industrial Engineering and Management Science, Vol. 2, No. 2, June 2012 8

ISSN 2277 - 5056 | 2012 Bonfring

Figure 5: Comparison of Conductivity with Liquid Holdup for

Two Phase Liquid and Solid Fluidized

Present study found that the m = 0.727 for particles of

diameter between 0.180 mm and 2.89 mm and m = 0.877 for

particles of diameter between 5 mm and 8 mm.The above

values are with-in the range [2].Above procedure was adopted

for obtainingthe liquid holdup for various flow rates of

liquid/gas.

.

Figure 6: Comparison of Predicted and Estimated Liquid

Holdup for 3 Phase

Figure 7: Variation of Gas-Liquid- Solid Holdup in Three

Phase Fluidized Bed

The liquid holdup calculated based on conductivity from

equation (6) and bed height measurement of equation (7) is

compared in Fig 6 for two phase flow of liquid and solid. The

data was well correlated with an RMS error of 2.3%.

Figure 7 shows the axial variation of Gas-Liquid-Solid

holdup. One can observe a clear axial variation of solid-liquid

holdup change from the fluidized bed region to free board

region. Similar observations are made in literature[3],[4],[5].

V. CONCLUSIONS

The following conclusions can be drawn from the study

1. Conductivity technique is successfully used for

identifying the axial variation of gas-liquid-solid holdup

2. Effect of temperature on liquid conductivity showed 2%

change in conductivity for one degree change in

temperature for the present case.

3. A power law relation was established between the relative

conductivity and liquid holdup

4. The constant m depends on non-conducting material.

For small particles the m may be small and for bigger

radius particles this can be high but the range of m is 0.67

to 1.

VI. NOMENCLATURE

A -cross-sectional area

dP/dz-pressure gradient

g-acceleration due to gravity

H-Height of the bed

M -mass of solids

m -constant in equation (6)

Greek letters

-holdup

-density (kg/m

3

)

-Liquid conductivity with particles

0

-Liquid conductivity without particles

-relative conductivity

Subscripts

0 -static bed conditions

cs-cross sectional

g -gas

l-liquid

loc- local

s-solid

ACKNOWLEDGEMENT

The author would like to acknowledge the help and

guidance of Prof. K. Krishnaiah, Dean, Academic Research,

and Dr Renganathan, Assistant professor, Dept. Chemical

Engineering. IIT Madras, Chennai, India

REFERENCES

[1] Razzak, S.A., Barghi, S., Zhu J. X. and Mi, Y., Phase holdup

measurement in a Gas-Liquid-Solid circulating Fluidized bed riser using

electrical resistance tomography and optical fiber probe Chem. Eng.

Jr.147, 210-218 (2009).

[2] Tang, W. T. and L. S. Fan, Hydrodynamics of a Three-Phase Fluidized

Bed Containing Low-Density Particles, AIChE J. 35(3), 355-364

(1989).

[3] Begovich, J. M. and J. S. Watson, An Electroconductivity Technique

for the Measurement of Axial Variation of Holdups in Three-Phase

Fluidized Beds, AIChE J. 24(2), 351-354 (1978).

Bonfring International Journal of Industrial Engineering and Management Science, Vol. 2, No. 2, June 2012 9

ISSN 2277 - 5056 | 2012 Bonfring

[4] Ibrahim, Y. A. A., C. L. Briens, A. Margaritis and M. A. Bergongnou,

Hydrodynamic Characteristics of a Three-Phase Inverse Fluidized-Bed

Column, AIChE J. 42(7), 1889-1900 (1996).

[5] Renganathan, T. and K. Krishnaiah, Voidage Characteristics and

Prediction of Bed Expansion in Liquidsolid Inverse Fluidized Bed,

Chem. Eng. Sci. 60, 2545-2555 (2005).

[6] Krishna, B.S.V.S.R., Hydrodynamics of 2- and 3-phase Inverse

Fluidized bed with mono and binary particles, Ph.D. Thesis, IIT

Madras, Chennai, India (2006).

[7] Krishna, B.S.V.S.R and K. Krishnaiah, The Minimum and Uniform

Fluidization velocity of Inverse Fluidized bed, Int. J. Chem. Sci., 5(4),

p1733 (2007).

[8] Fan, L.-S.,K. Muroyama and S.-H. Chern, Hydrodynamic

Characteristics of Inverse Fluidization in Liquid-Solid and Gas-Liquid-

Solid Systems, Chem. Eng. J. 24, 143-150 (1982).

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Review On MRI Brain Tumor Segmentation ApproachesDokument5 SeitenReview On MRI Brain Tumor Segmentation ApproachesBONFRINGNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- A Study On Time ManagementDokument5 SeitenA Study On Time ManagementBONFRINGNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- An Overview of Organizational Commitment Among The IT Employees in Chennai CityDokument3 SeitenAn Overview of Organizational Commitment Among The IT Employees in Chennai CityBONFRINGNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Smart Home Implementing IOT Technology With Multilingual Speech Recognition SystemDokument6 SeitenSmart Home Implementing IOT Technology With Multilingual Speech Recognition SystemBONFRINGNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Effective Online Discussion Data For Teachers Reflective Thinking Using Feature Base ModelDokument5 SeitenEffective Online Discussion Data For Teachers Reflective Thinking Using Feature Base ModelBONFRINGNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Detection of Polycystic Ovary Syndrome From Ultrasound Images Using SIFT DescriptorsDokument5 SeitenDetection of Polycystic Ovary Syndrome From Ultrasound Images Using SIFT DescriptorsBONFRINGNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Block Chain Technology For Privacy Protection For Cloudlet-Based Medical Data SharingDokument4 SeitenBlock Chain Technology For Privacy Protection For Cloudlet-Based Medical Data SharingBONFRINGNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Power Quality Improvement Using Dynamic Voltage RestorerDokument4 SeitenPower Quality Improvement Using Dynamic Voltage RestorerBONFRINGNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Review of Data Mining Classification TechniquesDokument4 SeitenReview of Data Mining Classification TechniquesBONFRINGNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Different Traffic Profiles For Wireless NetworkDokument3 SeitenDifferent Traffic Profiles For Wireless NetworkBONFRING100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Android Application Development For Textile IndustryDokument4 SeitenAndroid Application Development For Textile IndustryBONFRINGNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Security Enhancement and Time Delay Consumption For Cloud Computing Using AES and RC6 AlgorithmDokument6 SeitenSecurity Enhancement and Time Delay Consumption For Cloud Computing Using AES and RC6 AlgorithmBONFRINGNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Automated Switching Solar Power Grid Tie Inverter Using Embedded SystemDokument5 SeitenAutomated Switching Solar Power Grid Tie Inverter Using Embedded SystemBONFRINGNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Preventing The Breach of Sniffers in TCP/IP Layer Using Nagles AlgorithmDokument5 SeitenPreventing The Breach of Sniffers in TCP/IP Layer Using Nagles AlgorithmBONFRINGNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Awareness Among The Consumers About Instant Food ProductsDokument3 SeitenAwareness Among The Consumers About Instant Food ProductsBONFRINGNoch keine Bewertungen

- Investigation of CO2 Capturing Capacity of Solid Adsorbents (PEIs) Polyethylenimines From Automotive Vehicle Exhausts System For 4-Stroke SI EngineDokument5 SeitenInvestigation of CO2 Capturing Capacity of Solid Adsorbents (PEIs) Polyethylenimines From Automotive Vehicle Exhausts System For 4-Stroke SI EngineBONFRINGNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Topic Categorization Based On User Behaviour in Random Social Networks Using Firefly AlgorithmDokument5 SeitenTopic Categorization Based On User Behaviour in Random Social Networks Using Firefly AlgorithmBONFRINGNoch keine Bewertungen

- Copia de Tabla O2 (VT TW TM DM 3000 250)Dokument112 SeitenCopia de Tabla O2 (VT TW TM DM 3000 250)felipeNoch keine Bewertungen

- PHY VIII P2 BEFORE MID 2nd SemsDokument10 SeitenPHY VIII P2 BEFORE MID 2nd SemsShahidul Hassan MontiNoch keine Bewertungen

- Answer For Tutorial 5Dokument7 SeitenAnswer For Tutorial 5Pedro DegrandiNoch keine Bewertungen

- Cambridge O Level: Physics 5054/11Dokument16 SeitenCambridge O Level: Physics 5054/11Jack KowmanNoch keine Bewertungen

- Presmod User GuideDokument90 SeitenPresmod User GuidehkaqlqNoch keine Bewertungen

- 2018 The Study of Effect of Blast Load On Multi-Storey Building by Using Time History MethodDokument8 Seiten2018 The Study of Effect of Blast Load On Multi-Storey Building by Using Time History MethodMadhav PurohitNoch keine Bewertungen

- Experiment: To Verify Boyle's LawDokument3 SeitenExperiment: To Verify Boyle's Lawheheh100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Astm E96.9061 PDFDokument8 SeitenAstm E96.9061 PDFgaso99Noch keine Bewertungen

- Pall HSPA Hydraulic Fluid Purifier For Aircraft Maintenance: DescriptionDokument2 SeitenPall HSPA Hydraulic Fluid Purifier For Aircraft Maintenance: DescriptionridwansadelyNoch keine Bewertungen

- Journal of Natural Gas Science and Engineering 26 (2015) 587-594 PDFDokument8 SeitenJournal of Natural Gas Science and Engineering 26 (2015) 587-594 PDFRafael CeccattoNoch keine Bewertungen

- Annulus Communications Eliminated Using Pressure-Activated Sealant April 2005Dokument12 SeitenAnnulus Communications Eliminated Using Pressure-Activated Sealant April 2005fudvariNoch keine Bewertungen

- Air Duct Sizing - SI & Imperial UnitsDokument4 SeitenAir Duct Sizing - SI & Imperial UnitsDarshan Patel100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Astm D2104Dokument7 SeitenAstm D2104JUAN DAVID GOMEZ PATIÑONoch keine Bewertungen

- Blastmaster Tornado Internal Pipe Blasting Tool Operators Manual 1090614Dokument28 SeitenBlastmaster Tornado Internal Pipe Blasting Tool Operators Manual 1090614Sahab DeenNoch keine Bewertungen

- Hydraulic Gradient Line Bob FMMDokument2 SeitenHydraulic Gradient Line Bob FMMHARSH SHAHNoch keine Bewertungen

- AGA Report 7 Turbine Gas MeterDokument42 SeitenAGA Report 7 Turbine Gas MeterO100% (12)

- 02.03 Chapter 3Dokument41 Seiten02.03 Chapter 3jotiram baban ghadgeNoch keine Bewertungen

- Gas Dynamics: Lab ManualDokument31 SeitenGas Dynamics: Lab ManualAreebNoch keine Bewertungen

- Sheet 4Dokument2 SeitenSheet 4Mo 16Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Pump CalculationDokument20 SeitenPump Calculationcoolsummer1112143100% (1)

- Pascal LawDokument4 SeitenPascal LawpratishgnairNoch keine Bewertungen

- Expt 140 Comsol TutorialDokument50 SeitenExpt 140 Comsol TutorialBashar Al ZoobaidiNoch keine Bewertungen

- Druck PTX-PMP 3000 Series Amplified Aerospace Pressure Transducers Datasheet - ENDokument4 SeitenDruck PTX-PMP 3000 Series Amplified Aerospace Pressure Transducers Datasheet - ENmoreauNoch keine Bewertungen

- Diagram PsychrometricDokument4 SeitenDiagram PsychrometricJanry EfriyantoNoch keine Bewertungen

- Yuken Pressure Control ValvesDokument5 SeitenYuken Pressure Control ValvesDANIEL LNoch keine Bewertungen

- API2000 Tank Venting CalcsDokument5 SeitenAPI2000 Tank Venting CalcsfajaraminwahyullahNoch keine Bewertungen

- Easyline El3000 Series: Continuous Gas AnalyzersDokument40 SeitenEasyline El3000 Series: Continuous Gas AnalyzersRajesh KumarNoch keine Bewertungen

- DB 01.01.26.04 Pump S200 SSDokument2 SeitenDB 01.01.26.04 Pump S200 SSPRAMOD KUMARNoch keine Bewertungen

- Class 7-Physics-Worksheet-PressureDokument3 SeitenClass 7-Physics-Worksheet-Pressureenosh.sinhaNoch keine Bewertungen

- Worksheet 5.1: Kinetic Theory and The General Gas EquationDokument4 SeitenWorksheet 5.1: Kinetic Theory and The General Gas EquationfdjjNoch keine Bewertungen

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)