Beruflich Dokumente

Kultur Dokumente

Homework 3 With Solutions

Hochgeladen von

Daniel Rodriguez0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

145 Ansichten3 SeitenHomework 3

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHomework 3

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

145 Ansichten3 SeitenHomework 3 With Solutions

Hochgeladen von

Daniel RodriguezHomework 3

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

UGKW 2008

Drexel University, Department of Materials Science and Engineering

Materials Science and Engineering II Winter 2008

Homework 3

H3.Q1 (CES Level 2) (5pts): Explore the potential of PP-SiC (polypropylene-silicon carbide) fiber

composites in the following way. Make a modulus-density (E-) chart and change the axis ranges so

that they span the range 1 <E <1000 GPa and 500 < <5000 kg/m

3

. Find and label PP and SiC,

then print it. Retrieve values for the modulus and density of PP and of SiC from the records for

these materials (use the means of the ranges). Calculate the density composite and upper and lower

bounds for the modulus E at a volume fraction f of SiC of 0.5 and plot this information on the chart.

Sketch by eye two arcs starting from (E, ) for PP, passing through each of the (E

composite

,

composite

)

points you have plotted and ending at the (E, ) point for SiC. PP-SiC composites can populate the

area between the arcs roughly up to f =0.5 because it is not possible to insert more than this.

3 3 3

composite

Density: (1 ) 0.5 3150 kg/m 0.5 900 kg/m 2030 kg/m = + = + =

f f f m

V V (1pt)

composite

Upper bound: (1 ) 0.5 420 GPa 0.5 1.2 GPa 211 GPa = + = + =

f f f m

E V E V E (1pt)

composite

(1 )

0.5 0.5

Lower bound: 1/ 1/ 2.39 GPa

420 GPa 1.2 GPa

= + = + =

f f

f m

V V

E

E E

(1pt)

Results Density

[kg/]m

3

]

Modulus

[GPa]

Polypropylene 900 1.2

Silicon carbide 3150 420

Upper bound: f = 0.5 2030 211

Lower bound: f = 0.5 2030 2.39

(2pts)

UGKW 2008

H3.Q2 (CES Level 2) (3pts): Explore the region that can be populated by making PP foams.

Expand an E- plot so that it spans the range 10

-4

<E <10 GPa and 10 < <2000 kg/m

3

. Find and

label PP, then print the chart. Construct a band starting with the PP bubble by drawing lines

corresponding to the scaling law for foam modulus E

composite

2

composite

touching the top and the

bottom of the PP bubble. The zone between these lines can be populated by PP foams.

H3.Q3 (2pts): The stiffness of an atomic bond in a particular material is 50 N/m and its center-to-

center atom spacing is 0.3 nm. What, approximately, it its elastic modulus?

0

50 N/m

166 GPa 170 GPa

3 nm

= = =

S

E

r

H3.Q4 (5pts): What is meant by:

(a) a crystalline solid

A crystalline solid is one in which the atoms or molecules are arranged in an ordered way that can be

described by a geometric lattice.

(b) an amorphous solid

An amorphous solid (or glassy solid) is one in which crystallographic order is absent.

(c) a thermoplastic

A thermoplastic is one in which the bonding along the polymer chains is covalent and strong but the

bonding between them is Van der Waals or hydrogen bonding and is weak. This causes the polymer

to melt when heated, allowing thermal molding.

(d) a thermoset

A thermosetting plastic is one in which the polymer chains are cross-linked by strong covalent bonds

that do not melt when the polymer is heated.

(e) an elastomer?

An elastomer is a slightly cross-linked polymer which, at room temperature, is above its

glasstransition temperature. The occasional cross-links give the material a memory, causing it to

return to its original shape when unloaded after stretching.

UGKW 2008

H3.Q5: Case study: Automotive headlight lens. (5pts)

Background

The lens of an automobile headlamp protects the bulb and reflector and

focuses the light where it is most needed.

What are the design requirements?

List these and use CES to select materials for the lens.

Explain advantages and disadvantages of possible solutions.

Objective

To select materials that meet the requirements for the lens.

Requirements (2pts)

Must be transparent with optical quality.

Must be able to be molded easily.

Must have very good resistance to fresh and salt water

Must have very good resistance to UV light

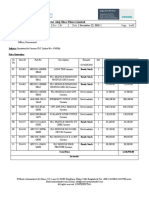

Selection (3pts)

Set the CES EduPack to Select / Level 2 / Materials. Use a Limit stage to apply the first four

requirements, selecting Optical properties to apply the first, Processability to apply the second, and

Durability to apply the third and the fourth (select both good and very good to avoid eliminating

too many materials). Then make a Graph stage with Price on the X-axis and Hardness on the Y-axis

to find the ones that are cheap and have high hardness. Remember you can grey-out materials on

the graph that do not meet the limit stage criteria by clicking the little icon like two intersecting

circles in the row of icons along the top of the graph.

Price (USD/kg)

0.1 1 10 100

H

a

r

d

n

e

s

s

-

V

i

c

k

e

r

s

(

H

V

)

1e-3

0.01

0.1

1

10

100

1000

Soda-lime glass

Borosilicate glass

Polymethyl methacrylate (Acrylic, PMMA)

The cheapest and hardest material that meets all the constraints is soda-lime glass it is used for car

head lights. If a polymer is wanted, the cheapest one is PMMA, acrylic it is used for car tail lights.

Das könnte Ihnen auch gefallen

- Group Case Study Rubric 3Dokument3 SeitenGroup Case Study Rubric 3Saraswathi Asirvatham67% (3)

- AshbyJonesV1 SolutionsDokument43 SeitenAshbyJonesV1 SolutionsSadiq Omar100% (1)

- Load Chart Crane LiftingDokument25 SeitenLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- Darkle Slideshow by SlidesgoDokument53 SeitenDarkle Slideshow by SlidesgoADITI GUPTANoch keine Bewertungen

- Composite Materials: R. Lindeke ENGR 2110Dokument41 SeitenComposite Materials: R. Lindeke ENGR 2110muthupecmec4908Noch keine Bewertungen

- BSS Troubleshooting Manual PDFDokument220 SeitenBSS Troubleshooting Manual PDFleonardomarinNoch keine Bewertungen

- Sprinkler Sizing en v1Dokument12 SeitenSprinkler Sizing en v1CristianDumitru0% (1)

- Composite MaterialsDokument38 SeitenComposite MaterialsjoyboyjayanthNoch keine Bewertungen

- Dec 2-7 Week 4 Physics DLLDokument3 SeitenDec 2-7 Week 4 Physics DLLRicardo Acosta Subad100% (1)

- Eccentric FootingDokument3 SeitenEccentric FootingVarunn VelNoch keine Bewertungen

- Interface / Interphase in Polymer NanocompositesVon EverandInterface / Interphase in Polymer NanocompositesAnil N. NetravaliNoch keine Bewertungen

- Hossain 2016Dokument4 SeitenHossain 2016Beurus SamaNoch keine Bewertungen

- Improving Power Efficiencies in Polymer-Polymer Blend PhotovoltaicsDokument9 SeitenImproving Power Efficiencies in Polymer-Polymer Blend PhotovoltaicsAde Novianti Ngesti RahayuNoch keine Bewertungen

- Ch15 CompositesDokument8 SeitenCh15 CompositesJuan RiveraNoch keine Bewertungen

- tmp174C TMPDokument8 Seitentmp174C TMPFrontiersNoch keine Bewertungen

- Problems in Compos Mater Questions PG PDFDokument15 SeitenProblems in Compos Mater Questions PG PDFJimmyFigueroaANoch keine Bewertungen

- Determination of Complex Optical Constants and Photovoltaic Device Design of All-Inorganic CSPBBR Perovskite Thin FilmsDokument12 SeitenDetermination of Complex Optical Constants and Photovoltaic Device Design of All-Inorganic CSPBBR Perovskite Thin FilmsMine ConfessionNoch keine Bewertungen

- X86910 (ST5006)Dokument2 SeitenX86910 (ST5006)Kazi Tour DépenseNoch keine Bewertungen

- ILSSDokument11 SeitenILSSyigitilgazNoch keine Bewertungen

- TE Mechanical 2019 Pattern 302052-A: Composite Materials End Sem Exam Question BankDokument5 SeitenTE Mechanical 2019 Pattern 302052-A: Composite Materials End Sem Exam Question Bankprathamesh nikamNoch keine Bewertungen

- MEMS Electrostatic Acoustic Pixel: Corresponding Author: 4700 KAUST, Kingdom of Saudi Arabia, Arpys - Arevalo@kaust - Edu.saDokument7 SeitenMEMS Electrostatic Acoustic Pixel: Corresponding Author: 4700 KAUST, Kingdom of Saudi Arabia, Arpys - Arevalo@kaust - Edu.sadiegoNoch keine Bewertungen

- Department of Aeronautical Engineering: Answer All The Questions: Part - A (10 X 2 20 MARKS)Dokument2 SeitenDepartment of Aeronautical Engineering: Answer All The Questions: Part - A (10 X 2 20 MARKS)RajakumariNoch keine Bewertungen

- Testexam AnswDokument6 SeitenTestexam AnswAnaNoch keine Bewertungen

- 21.characterization and Optimization - FullDokument12 Seiten21.characterization and Optimization - FullTJPRC PublicationsNoch keine Bewertungen

- ABD Matrix of Single-Ply Triaxial Weave Fabric Composites: A.B.H. Kueh and S. PellegrinoDokument17 SeitenABD Matrix of Single-Ply Triaxial Weave Fabric Composites: A.B.H. Kueh and S. PellegrinoVishnu Chemmanadu AravindNoch keine Bewertungen

- Failure ModeDokument9 SeitenFailure ModealfborbrNoch keine Bewertungen

- Diamond-Like Carbon Protective Anti-Reflection Coating For Si Solar CellDokument4 SeitenDiamond-Like Carbon Protective Anti-Reflection Coating For Si Solar CellnguyenthanhhopNoch keine Bewertungen

- Fiber Pull-Out Test and Single Fiber Fragmentation Test - Analysis and ModellingDokument20 SeitenFiber Pull-Out Test and Single Fiber Fragmentation Test - Analysis and ModellingFrankBravoNoch keine Bewertungen

- Effect of Buffer Layers On Performance of Organic Photovoltaic Devices Based On Copper Phthalocyanine-Perylene Dye HeterojunctionDokument6 SeitenEffect of Buffer Layers On Performance of Organic Photovoltaic Devices Based On Copper Phthalocyanine-Perylene Dye HeterojunctionAnonymous cYpEVvoNoch keine Bewertungen

- E344 2013 Summer Solution Set 3: (B) What Role Does Each Component Play in The Forming and Firing Procedures?Dokument19 SeitenE344 2013 Summer Solution Set 3: (B) What Role Does Each Component Play in The Forming and Firing Procedures?Firdhaus ZulkifleNoch keine Bewertungen

- Structural Investigation and Gas BarrierDokument7 SeitenStructural Investigation and Gas BarrierVelásquez AndradeNoch keine Bewertungen

- Composite Materials (Collection of Previous Final Exam) 110863Dokument8 SeitenComposite Materials (Collection of Previous Final Exam) 110863habba3Noch keine Bewertungen

- Effective Properties of Carbon Fiber CompositesDokument6 SeitenEffective Properties of Carbon Fiber CompositesMladenNoch keine Bewertungen

- Ae1402 CT IIDokument1 SeiteAe1402 CT IISIVANESANNoch keine Bewertungen

- Effect of SilaneDokument20 SeitenEffect of SilaneVansala GanesanNoch keine Bewertungen

- 0.3. Take Fiber OrientationDokument1 Seite0.3. Take Fiber OrientationArun Raja K KNoch keine Bewertungen

- Structural Analysis of Basalt Fiber Reinforced Plastic Wind Turbine Blade PDFDokument5 SeitenStructural Analysis of Basalt Fiber Reinforced Plastic Wind Turbine Blade PDFTohidNoch keine Bewertungen

- Polycrystalline Silicon Thin Films For MEMS ApplicationsDokument5 SeitenPolycrystalline Silicon Thin Films For MEMS Applicationsrajesh langojuNoch keine Bewertungen

- Effect of The MgO Substitution For CuO On The Properties of CaCu3Ti4O12 CeramicsDokument8 SeitenEffect of The MgO Substitution For CuO On The Properties of CaCu3Ti4O12 CeramicsAlan MartinsNoch keine Bewertungen

- Comp 12Dokument36 SeitenComp 12Tanu RdNoch keine Bewertungen

- Steeves SPIE 9151-4Dokument13 SeitenSteeves SPIE 9151-4felipe_fismed4429Noch keine Bewertungen

- Single Site Catalysts and Dual Reactor Technology Create More Freedom in Pe Rotomolding Resin and Product DesignsDokument5 SeitenSingle Site Catalysts and Dual Reactor Technology Create More Freedom in Pe Rotomolding Resin and Product Designsjsk789Noch keine Bewertungen

- Evaluation of Mode-I Inter Laminar Fracture Toughness For Fiber Reinforced Composite MaterialsDokument6 SeitenEvaluation of Mode-I Inter Laminar Fracture Toughness For Fiber Reinforced Composite Materialsn_kosmasNoch keine Bewertungen

- Chapter 5Dokument35 SeitenChapter 5Sobhy Sayed IbrahimNoch keine Bewertungen

- Numerical Study On Carbon Fibre Pullout Ising A Cohesive Zone ModelDokument6 SeitenNumerical Study On Carbon Fibre Pullout Ising A Cohesive Zone ModelRabee ShammasNoch keine Bewertungen

- 16 CmsDokument4 Seiten16 Cmsrajraj3550Noch keine Bewertungen

- M MMM M MMM MM MMMM MM MMMM M MM MM M MM MMDokument19 SeitenM MMM M MMM MM MMMM MM MMMM M MM MM M MM MMpiezodocNoch keine Bewertungen

- Studies On Behavior of Carbon and Fiberglass Epoxy Composite Laminates Under Low Velocity Impact Loading Using LS-DYNADokument12 SeitenStudies On Behavior of Carbon and Fiberglass Epoxy Composite Laminates Under Low Velocity Impact Loading Using LS-DYNAAkash VineetNoch keine Bewertungen

- Kompozit Sınav SorularıDokument13 SeitenKompozit Sınav SorularıBilim KapsülüNoch keine Bewertungen

- Comparison of Strength of 3D Printing Objects Using Short Fiber and Continuous Long FiberDokument7 SeitenComparison of Strength of 3D Printing Objects Using Short Fiber and Continuous Long FiberZhiwei ZhangNoch keine Bewertungen

- Raman - PicosDokument35 SeitenRaman - PicosCAROLINE GUIMARAESNoch keine Bewertungen

- RHenda MRS Proc RevDokument6 SeitenRHenda MRS Proc RevOmar AlshekhliNoch keine Bewertungen

- 2011-12-07 APSC278 Final ExamDokument7 Seiten2011-12-07 APSC278 Final ExamNik AgarwalNoch keine Bewertungen

- Matl Science Final 2015Dokument4 SeitenMatl Science Final 2015VirneDalisayNoch keine Bewertungen

- Eun2015Dokument30 SeitenEun2015Riston SinagaNoch keine Bewertungen

- PTFE SiO2ThinFilmsDokument7 SeitenPTFE SiO2ThinFilms陳信辰Noch keine Bewertungen

- EE130 hw1Dokument1 SeiteEE130 hw1Thomas SmithNoch keine Bewertungen

- A General Design Approach For Post Tensioned Timber SubassembliesDokument17 SeitenA General Design Approach For Post Tensioned Timber Subassemblies陈飞Noch keine Bewertungen

- Large Area 0-3 and 1-3 Piezoelectric Composites Based On Single Crystal PMN-PT For Transducer ApplicationsDokument8 SeitenLarge Area 0-3 and 1-3 Piezoelectric Composites Based On Single Crystal PMN-PT For Transducer ApplicationsAmir JoonNoch keine Bewertungen

- A Simple Design of Highly Birefringent and Nonlinear Photonic Crystal Fiber With Ultra Flattened DispersionDokument13 SeitenA Simple Design of Highly Birefringent and Nonlinear Photonic Crystal Fiber With Ultra Flattened DispersionshuvoNoch keine Bewertungen

- Nanostructured Cobalt Zinc Ferrite Thin Films For Gas Sensor ApplicationDokument10 SeitenNanostructured Cobalt Zinc Ferrite Thin Films For Gas Sensor ApplicationInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Oe 26 22 29521Dokument6 SeitenOe 26 22 29521teguhNoch keine Bewertungen

- Electron Beam Lithography (EBL) : 10. High Resolution EBL, Resolution LimitDokument36 SeitenElectron Beam Lithography (EBL) : 10. High Resolution EBL, Resolution LimitMuraleetharan BoopathiNoch keine Bewertungen

- Michels Et Al SMAR2013Dokument9 SeitenMichels Et Al SMAR2013Rodrigo LameirasNoch keine Bewertungen

- Functional and Physical Properties of Polymer NanocompositesVon EverandFunctional and Physical Properties of Polymer NanocompositesAravind DasariNoch keine Bewertungen

- Printable Solar CellsVon EverandPrintable Solar CellsNurdan Demirci SankirNoch keine Bewertungen

- Chapter 11 AssignmentDokument2 SeitenChapter 11 AssignmentsainothegamerNoch keine Bewertungen

- G.Devendiran: Career ObjectiveDokument2 SeitenG.Devendiran: Career ObjectiveSadha SivamNoch keine Bewertungen

- BECED S4 Motivational Techniques PDFDokument11 SeitenBECED S4 Motivational Techniques PDFAmeil OrindayNoch keine Bewertungen

- Anker Soundcore Mini, Super-Portable Bluetooth SpeakerDokument4 SeitenAnker Soundcore Mini, Super-Portable Bluetooth SpeakerM.SaadNoch keine Bewertungen

- CE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationDokument32 SeitenCE162P MODULE 2 LECTURE 4 Analysis & Design of Mat FoundationPROSPEROUS LUCKILYNoch keine Bewertungen

- Abilash - Subramanian CV - 003 PDFDokument4 SeitenAbilash - Subramanian CV - 003 PDFAbilash SubramanianNoch keine Bewertungen

- WWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDokument8 SeitenWWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDestiny EasonNoch keine Bewertungen

- MLX90614Dokument44 SeitenMLX90614ehsan1985Noch keine Bewertungen

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Dokument2 SeitenLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNoch keine Bewertungen

- Spanish Greeting Card Lesson PlanDokument5 SeitenSpanish Greeting Card Lesson Planrobert_gentil4528Noch keine Bewertungen

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Dokument85 SeitenME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNoch keine Bewertungen

- Vetoset CA541: Thickbed Cementitious Tile AdhesiveDokument2 SeitenVetoset CA541: Thickbed Cementitious Tile Adhesivemus3b1985Noch keine Bewertungen

- Functions of Theory in ResearchDokument2 SeitenFunctions of Theory in ResearchJomariMolejonNoch keine Bewertungen

- Installation 59TP6A 08SIDokument92 SeitenInstallation 59TP6A 08SIHenry SmithNoch keine Bewertungen

- Bring Your Gear 2010: Safely, Easily and in StyleDokument76 SeitenBring Your Gear 2010: Safely, Easily and in StyleAkoumpakoula TampaoulatoumpaNoch keine Bewertungen

- HRM Practices in NepalDokument22 SeitenHRM Practices in NepalBodhiNoch keine Bewertungen

- Chakir Sara 2019Dokument25 SeitenChakir Sara 2019hiba toubaliNoch keine Bewertungen

- Unit 2: Air Intake and Exhaust SystemsDokument10 SeitenUnit 2: Air Intake and Exhaust SystemsMahmmod Al-QawasmehNoch keine Bewertungen

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDokument9 SeitenDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaNoch keine Bewertungen

- Ficha Tecnica Bomba Inyeccion MiniFlex EDokument1 SeiteFicha Tecnica Bomba Inyeccion MiniFlex Ejohn frader arrubla50% (2)

- Digital Systems Project: IITB CPUDokument7 SeitenDigital Systems Project: IITB CPUAnoushka DeyNoch keine Bewertungen

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDokument6 SeitenSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartNoch keine Bewertungen

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Dokument7 SeitenMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimNoch keine Bewertungen