Beruflich Dokumente

Kultur Dokumente

Sf-10D Series Sf-15D Series: Technical Manual

Hochgeladen von

Sunny SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sf-10D Series Sf-15D Series: Technical Manual

Hochgeladen von

Sunny SinghCopyright:

Verfügbare Formate

AUTOMATIC SHEET FEEDER

SF-10D SERIES

SF-15D SERIES

TECHNICAL MANUAL

[ EIGHTH EDITION ]

INTRODUCTION

This manual is an introduction to the Automatic Sheet Feeders as shown below.

It is intended for use as a reference for periodic inspections and maintenance procedures.

This manual is prepared for use at a technical level and not for the general user.

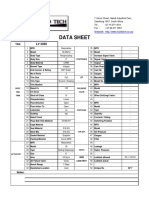

Model Name Applicable Printer

SF-10D NX-10, NX-10C, NL-10, ND-10, NR-10, NB24-10

SF-10DJ LC-10, NX-1000

SF-10DK LC24-10, NX-2400, NX24-10

SF-10DM XB-2410, XB24-10, XR-1000, FR-10, CR-3410KS

XB-2410, XB24-10, XR-1000, FR-10, CR-3410KS

XB-2420, XB24-200, XR-1020, ZA-200

SF-15D NX-15, ND-15, NR-15

NB24-15 (For asian and pacific market)

AR-2463, AR-2460HT, AR-3240, AR-2400KS

SF-15DJ NX-1500, LC-15, NX-2415, LC24-15

SF-15DM XB-2415, XB24-15, XR-1500, FR-15, CR-3415KS, CR-3200, XT-15

XB-2415, XB24-15, XR-1500, FR-15, CR-3415KS, CR-3200, XT-15

XB-2425, XB-2425HT, XB24-250, XR-1520, ZA-250

SF-10DR NX-1001, LC-20

SF-10DN NX-1020, LC-200

SF-10DQ NX-2420, LC24-200, NX-2420HT

SF-10DS NX-2430, LC24-20

SF-10DT NX-1040, LC-1010C, LC-100+, LC-100

SF-10DV NX-2440, LC24-100

SF-10DW NX-2480, LC24-300

First edition : Mar. 1987 SF-10D/15D

Second edition : Aug. 1988 Add SF-10DJ/10DK/15DE

Third edition : Feb. 1990 Add SF-10DM/15DJ/15DM

Fourth edition : Jul. 1991 Add SF-10DR/10DN/10DQ/10DMII/15DMII

Fifth edition : Dec. 1991 Add SF-10DS

Sixth edition : Aug. 1992 Add SF-10DT/10DV

Seventh edition : Mar. 1993

Eighth edition : Apr. 1996 Add SF-10DW

NOTICE

All rights reserved. Reproduction of any part of this manual in any form

whatsoever, without STARs express written permission is forbidden.

The contents of this manual are subject to change without notice.

All efforts have been made to ensure the accuracy of the contents of this

manual before printing. However, should any errors be detected, STAR

would greatly appreciate being informed of them.

The above notwithstanding, STAR can assume no responsibility for any

errors in this manual.

Copyright 1996 Star Micronics Co., Ltd.

SF-10DMII

SF-15DE

SF-15DMII

Table of Contents

Chapter 1. General Specifications ............................................................................................ 1

Chapter 2. Theory of Operation ................................................................................................ 5

1. General Flow Chart ......................................................................................................... 5

2. Path for the Paper ........................................................................................................... 9

3. Transmission of Movement ......................................................................................... 10

4. Clutch Mechanism ........................................................................................................ 11

Chapter 3. Assembly Inspection.............................................................................................. 12

Chapter 4. Parts Replacement ................................................................................................. 14

1. SF-10D/15D/15DE .......................................................................................................... 15

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV ........................................................................ 21

3. SF10DM/15DM/10DMII/15DMII ...................................................................................... 27

4. SF-10DN/10DQ/10DW.................................................................................................... 33

5. SF-10DS ......................................................................................................................... 39

Chapter 5. Maintenance and Lubrication................................................................................ 45

1. Maintenance .................................................................................................................. 45

2. Lubrication .................................................................................................................... 45

Chapter 6. Trouble Shooting.................................................................................................... 46

Chapter 7. Parts List ................................................................................................................. 48

1. SF-10D/15D/15DE .......................................................................................................... 49

1-1. Disassembly Drawing .......................................................................................... 49

1-2. Parts List ............................................................................................................... 51

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV ........................................................................ 53

2-1. Disassembly Drawing .......................................................................................... 53

2-2. Parts List ............................................................................................................... 55

3. SF-10DM/15DM/10DMII/15DMII ............................................................................................ 57

3-1. Disassembly Drawing .......................................................................................... 57

3-2. Parts List ............................................................................................................... 61

4. SF-10DN/10DQ/10DW.................................................................................................... 63

4-1. Disassembly Drawing .......................................................................................... 63

4-2. Parts List ............................................................................................................... 65

5. SF-10DS ......................................................................................................................... 67

5-1. Disassembly Drawing .......................................................................................... 67

5-2. Parts List ............................................................................................................... 69

1

CHAPTER 1

GENERAL SPECIFICATIONS

1. Number of bins 1 bin

2. Hopper capacity 120 sheets (at 64g/m

2

, A4 size) [For SF-10D/10DM/10DMII/15D/15DE/15DM/15DMII]

50 sheets (at 64g/m

2

, A4 size) [Others]

Stacker capacity 120 sheets (at 64g/m

2

, A4 size) [For SF-10D/10DM/10DMII/15D/15DE/15DM/15DMII]

50 sheets (at 64g/m

2

, A4 size) [Others]

3. Environment Temperature : operation +5 ~ +40C

storage -30 ~ +70C Humidity

: operation 30 ~ 80% (Without condensation)

storage 20 ~ 90% (Without condensation)

Vibration : 2.5G

4. Reliability MCBF : 50,000 cycles

MTTR : Max. 20 minutes

Life Time : 4 years

5. Paper feed stability Jamming : 1/500

Double feed : 1/300

Skew : 0.4 [For SF-10DM/10DMII/15DM/15DMII]

1/100mm [SF-10D/10DK/15D/15DE]

1/140 mm [Others]

Vertical tolerance : 1mm

Horizontal tolerance : 1mm

6. Paper Weight : 60 ~ 90g/m

2

Width : 182mm (7.15") ~ 216mm (8.5")

[SF-10D/10DJ/10DK/10DR/10DT/10DV]

182mm (7.15") ~ 280mm (11.0")

[SF-10DM/10DMII/10DN/10DQ/10DS/10DW]

182mm (7.15") ~ 364mm (14.3")

[SF-15D/15DE]

182mm (7.15") ~ 420 mm (16.5")

[SF-15DJ/15DM/15DMII]

Length : 182mm (7.15") ~ 356mm (14.0")

[SF-10D/10DJ/10DK/15D/15DE/15DJ/10DR/10DS/10DT/10DV]

182mm (7.15") ~ 364mm (14.3")

[SF-10DM/10DMII/15DM/15DMII/10DN/10DQ/10DW]

Type : Use fine quality paper

Note: Avoid using paper over. Paper other than smooth paper can be used in this Automatic Sheet Feeder, but it may

not be fed properly.

When using paper that does not match the above specifications, test it before actual use.

7. Others Dimensions : 355(W) 280(D) 330(H)mm [SF-10D]

355(W) 400(D) 330(H)mm [SF-10DM/10DMII]

363(W) 272(D) 270(H)mm [SF-10DN/10DQ/10DW]

361(W) 270(D) 320(H)mm [SF-10DS]

496(W) 288(D) 330(H)mm [SF-15D/15DE]

505(W) 250(D) 320(H)mm [SF-15DJ]

493(W) 400(D) 330(H)mm [SF-15DM/15DMII]

340(W) 250(D) 320(H)mm [Others]

Weight : Approx. 1.5kg [SF-10D]

Approx. 1.3kg [SF-10DM/10DMII]

Approx. 2.2kg [SF-15D/15DE]

Approx. 1.5kg [SF-15DJ]

Approx. 1.8kg [SF-15DM/15DMII]

Approx. 1.2kg [Others]

2

Fig. 1-1 External Dimension for SF-10D/15D/15DE

Fig. 1-2 External Dimension for SF-10DJ/10DK/15DJ/10DR/10DT/10DV

Unit: mm

( ): SF-15DJ

Unit: mm

( ): SF-15D/15DE

3

Fig. 1-3 External Dimension for SF-10DM/10DMII/15DM/15DMII

Fig. 1-4 External Dimension for SF-10DN/10DQ/10DW

Unit: mm

( ): SF-15DM/15DMII

Unit: mm

4

Unit: mm

Fig. 1-5 External Dimension for SF-10DS

5

CHAPTER 2

THEORY OF OPERATION

1. General Flow Chart

Fig. 2-1 is a general flow chart of the automatic sheet feeder.

Note:

(1) 1 line = 1/6 inch

(2) If there is paper, the judgment for paper

out detection is no.

<Paper Supply>

Initialize clutch

Clutch engaged

Paper feed from

hopper to platen

Clutch disengaged

To printing position

YES

NO

YES

NO

START

Home position

of ASF?

REV. n1 line

FWD. n2 line

REV. n3 line

FWD. 1 Step

Paper Out Detector ?

FWD. n4 line

REV. 4 line

FWD. n5 line

END

<Paper Ejection>

After the paper is fed the distance pro-

grammed or after the judgement for the

paper out detector changes from no to

yes.

FWD. n6 line

n1 n2 n3 n4 n5 n6 Model

15 15 7 8 12.45 35 SF-10D/15D/15DE

15 15 7.5 10 11.7 45 SF-10DJ/10DR

17 17 7.5 0 9.24 45 SF-10DT

17 17 7.5 0 9.28 45 SF-10DV

Fig. 2-1-A General Flow Chart For SF-10D/15D/15DE/10DJ/10DR/10DT/10DV

6

Note:

(1) 1 line = 1/6 inch

(2) If there is paper, the judgment for paper

out detection is no.

<Paper Supply>

Initialize clutch

Clutch engaged

Paper feed from

hopper to platen

Clutch disengaged

To printing position

YES

NO

YES

NO

<Paper Ejection>

After the paper is fed the distance programmed or

after the judgement for the paper out detector changes

from no to yes.

YES

NO

n1 n2 n3 Model

7.5 13 45 SF-10DK

7.5 9.67 35 SF-10DN

7.5 9.72 35 SF-10DQ

7.5 9.45 35 SF-10DS

START

Home position

of ASF?

REV. 15 line

FWD. 15 line

REV. n1 line

FWD. 1 Step

Paper Out Detector ?

REV. 4 line

FWD. 1 Step

Paper Out Detector ?

FWD. n2 line

END

FWD. n3 line

Fig. 2-1-B General Flow Chart For SF-10DK/10DN/10DQ/10DS

7

Note:

(1) 1 line = 1/6 inch

(2) If there is paper, the judgment for paper

out detection is no.

YES

NO

YES

NO

YES

<Paper Ejection>

After the paper is fed the distance programmed or

after the judgement for the paper out detector changes

from no to yes.

Fig. 2-1-C General Flow Chart For SF-10DM/10DMII/15DM/15DMII

NO

FWD 14.62 line

YES

NO

START

Home position

of ASF?

REV. 15 line

FWD. 15 line

REV. 8 line

FWD. 1 Step

Paper Out Detector ?

REV. 4.5 line

FWD. 1 Step

Paper Out Detector ?

To of form

is 1 inch?

FWD. 10.87 line

END

FWD. 45 line

<Paper Supply>

Initialize clutch

Clutch engaged

Paper feed from

hopper to platen

Clutch disengaged

To printing position

8

Note:

(1) 1 line = 1/6 inch

(2) If there is paper, the judgment for paper

out detection is no.

<Paper Supply>

Initialize clutch

Clutch engaged

Paper feed from

hopper to platen

Clutch disengaged

To printing position

YES

NO

YES

NO

YES

<Paper Ejection>

After the paper is fed the distance programmed or

after the judgement for the paper out detector changes

from no to yes.

Fig. 2-1-D General Flow Chart For SF-15DJ

NO

FWD 13 line

YES

NO

START

Home position

of ASF?

REV. 15 line

FWD. 15 line

REV. 7.5 line

FWD. 1 Step

Paper Out Detector ?

REV. 4 line

FWD. 1 Step

Paper Out Detector ?

To of form

is 1 inch?

FWD. 11 line

END

FWD. 45 line

9

2. Path for the Paper

Fig. 2-2 shows the path for the paper.

(1) The paper piled up in the hopper is pressed between the pressure plate unit and the roller unit.

(2) The rotation of the platen gear is transmitted to the roller unit by the gear train.

(3) The paper is guided through the hopper bottom, the stacker bottom, and the paper chute of the printer.

(4) The platen gear is fed backwards in order to disengage the clutch (to separate from the movement of the

platen gear and the roller unit).

(5) Once the clutch has been disengaged, the sheet of paper is no longer under the control of the automatic

sheet feeder. It is controlled from that point on by the printer. The paper is fed to the printing position by

the rotation of the platen.

(6) Once the sheet of paper has been printed, it is guided through the printers guide holder and the stacker

bottom and front sheet cover unit towards the stacker.

(7) Once the paper has moved away from the platen, it is ejected by the ejection roller unit and piled up in

the rear stacker.

Fig. 2-2 Path of the Paper

10

3. Transmission of Movement

The rotation of the platen gear is transmitted to the clutch by the gear train of the automatic sheet feeder. When

the clutch is engaged, the rotation of the platen gear is transmitted to the roller unit and to the ejection roller

unit to feed paper into the printer and to eject paper from the printer.

Fig. 2-3 Transmission of Movement

11

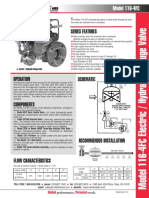

4. Clutch Mechanism

(1) Initialization of the clutch mechanism

The claw is in the home position of the clutch (B) unit.

(2) Clutch engaged

The clutch (A) unit turns the equivalent of a lines in the direction of the arrow in Fig. 2-4, i.e. reverse.

Since the claw is on the clutch (A) unit, the claw moves along the clutch (B) unit. When it has traveled

the distance equivalent to a lines, the claw falls into the hole in the clutch (B) unit, the ratchet meshes,

and the automatic sheet feeder begins to feed a sheet of paper into the printer. (See Fig. 2-5.)

(3) Clutch disengaged

With the clutch engaged, the clutch (A) unit is fed backwards the equivalent of b lines to separate the claw

and the ratchet and disengage the clutch. With the clutch disengaged, when the clutch (A) unit turns

forward, the automatic sheet feeder ejects the sheet of paper from the printer.

(4) With the clutch disengaged, when the clutch (A) unit turns forward, the claw is returned to the home

position of the clutch (B) unit (the initial position for the clutch mechanism).

The clutch mechanism repeats this 4-step cycle over and over to feed sheets of paper into the printer and

to eject them.

SF-10DM/10DMII/ SF-10DN/10DQ

15DM/15DMII 10DS/10DW/15DJ

a 8 lines 7.5 lines 7 lines

b 4.5 lines 4 lines 4 lines

Fig. 2-5 Clutch Engaged Fig. 2-6 Clutch Disengaged

Others

Fig. 2-4 Initial Position of the Clutch Mechanism

12

CHAPTER 3

ASSEMBLY INSPECTION

Check Method Item Instrument

(1) Screw tightening torque

(2) Clutch operation

(3) Transport force for the

roller unit

Tighten the screws to the torque value shown

below.

Tapping screw M3 8 6 1kgcm

Drwg. No. 57 (For SF-10D/15D/15DE)

Drwg. No. 51 (For SF-10DJ/10K/15DJ/10DT/

10DV)

Drwg. No. 47 (For SF-10DN/10DQ/10DW)

Drwg. No. 56 (For SF-10DM/10DMII/15DM/

15DMII)

Refer to chapter 7.

Other screws 8 1kgcm

Move gear by hand to move the clutch forward.

Check that the claw follows the movement of the

cam section of the clutch (B) unit normally and that

the clutch engages and disengages. Check that

when the clutch is engaged, the claw and the

ratchet mesh properly.

1 With the lever pressed back and no paper in the

hopper, check that the pressure plate unit and

the roller are touching. In other words, there

should be no gap between them.

Torque-driver

Visually inspect

Visually inspect

13

Check Method Item Instrument

2 Mount the automatic sheet feeder on the printer,

then set one sheet of 7 cm wide paper in the left

side of the roller unit and one sheet of 7 cm wide

paper in the right side of the roller unit as shown

in the figure, then press the lever to the set

position (push it back).

Engage the clutch, then check that there is no

great difference between the friction force at the

left and the right roller when the paper is pulled

in.

1 With the lever pressed back (into the set posi-

tion) and no paper in the hopper, check that the

corner separator touches the pressure plate (about

0.5 mm movement).

2 Push away the corner separator about 3 mm two

or three times with your finger and check that

the separator spring brings the corner separator

back to its original position.

Visually inspect

Visually inspect

Checking the corner separator

14

CHAPTER 4

PARTS REPLACEMENT

INTRODUCTION

(1) When a part or parts are to be removed, be sure to remove the automatic sheet feeder from the printer.

(2) In handling the parts described below, be especially careful not to scratch them or apply excess force.

Roller units

Parts of clutch mechanism

Corner separators

Separator spring, hopper spring, lever spring, claw spring

(3) After replacement is completed, carry out the designated assembly inspection. (See Chapter 3.)

(4) Installing is the reverse of removal unless otherwise specified.

(5) Grease lubrication points (marked % in the illustrations) after assembly as outlined in Chapter 5.

15

1. SF-10D/15D/15DE

1-1. Side Covers and Front Cover

1-2. Roller Unit

(1) Remove the automatic sheet feeder from the

printer.

(2) Remove

Side cover (R) [1]

Release the two hooks [2] and remove side

cover (R)[1].

Side cover (L) [3]

Release the two hooks [4] and remove side

cover (L) [3].

Front cover [5]

Cover (R) [6]

Cover (L) [7]

(1) Remove the side covers and front cover accord-

ing to the procedure described in item 1-1.

(2) Remove

Lever spring[1]

Screw [2]

Two brake levers [3]

Stop ring [4]

Roller shaft [5]

Roller (R) [6]

Roller (L) [7]

(3) Lubrication

Where roller shaft and set plates touch. (two

places)

(4) Note

When reassembling, be careful that the roll-

ers are turning in the correct direction and be

sure not to mix up the roller (R) unit and roller

(L) unit. (The roller unit with a blue mark at

the edge of the roller is the roller (R) unit.)

16

1-3. Clutch (A) Unit

1-4. Gears

(1) Remove the roller shaft according to the proce-

dure described in item 1-2.

(2) Remove

Stop ring [1]

Ratchet [2]

Clutch (B) [3]

Clutch (A) [4]

(3) Lubrication

Where clutch (A) and roller shaft touch.

(1) Remove the roller shaft according to the proce-

dure described in item 1-2.

(2) Remove

Five tapping screws [1]

Two collars [2]

Two gears G1 [3]

Gear G5 [4]

Two gears G7 [5]

Gear G10 [6]

Three stop rings [7]

Two gears G2 [8]

Gear G12 [9]

(3) Lubrication

Where gears and set plate touch. (three places)

1. SF-10D/15D/15DE (Continue)

17

(1) Remove the side covers and front cover accord-

ing to the procedure described in item 1-1.

(2) Remove

Two stop rings [1]

Gear G12 [2]

Ejection roller [3]

(3) Lubrication

Where set plate (R), (L) and ejection roller

touch. (two places)

1-5. Ejection Roller Unit

1-6. Lever

(1) Remove the side cover (L) unit according to the

procedure described in item 1-1.

(2) Remove

Lever screw [1]

Lever [2]

18

1-7. Hopper Bottom

1-8. Pressure Plate Unit

(1) Remove the lever according to the procedure

described in item 1-6.

(2) Remove

Four tapping screws [1]

Hopper bottom [2]

(1) Remove the roller shaft according to the proce-

dure described in item 1-2.

(2) Remove the hopper bottom according to the

procedure described in item 1-7.

(3) Remove

Two hopper springs [1]

(4) Remove the lever screw [2] and lever [3] accord-

ing to the procedure described in item 1-6.

(5) Remove

Stop ring SE4 [4]

Lever gear [5]

Hopper shaft [6]

Screw [7]

Shaft (A) [8]

Two O rings [9]

Hopper (L) [10]

Pressure plate (L) unit [11]

Pressure plate (R) unit [12]

1. SF-10D/15D/15DE (Continue)

19

1-9. Stacker Bottom

1-10. Set Plate (R)

(1) Remove the ejection roller according to the

procedure described in item 1-5.

(2) Remove

Stop ring SE3 [1]

Gear G2 [2]

Shaft (B) [3]

Screw [4]

Gear G1 [5]

Four screws [6]

Stacker bottom [7]

(3) Lubrication

Where set plate (R) and shaft (B) touch.

(1) Remove the clutch (A) according to the proce-

dure described in item 1-3.

(2) Remove the gears according to the procedure

described in item 1-4.

(3) Remove

Stop ring SE4 [1]

Lever gear [2]

Screw [3]

Six tapping screws [4]

Set plate (R) [5]

20

1-11. Set Plate (L)

1-12. Corner Separators

(1) Remove the lever screw [1] and lever [2]

according to the procedure described in item

1-6.

(2) Remove

Stop ring SE4 [3]

Lever gear [4]

Stop ring SE5 [5]

Stop ring SE6 [6]

(3) Remove the gear G1 and gear G2 according to

the procedure described in item 1-4.

(4) Remove

Six tapping screws [7]

Set plate (L) [8]

(1) Remove the set plate (L) [1] according to the

procedure described in item 1-11.

(2) Remove

Hopper (L) [2]

Hopper support [3]

Hopper (R) [4]

O ring [5]

Pressure plate [6]

Spring cover [7]

Separator spring [8]

Stop ring SE4 [9]

Corner separators [10]

1. SF-10D/15D/15DE (Continue)

21

2-2. Roller Unit

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV

2-1. Side Covers and Front Sheet Cover

(1) Remove the automatic sheet feeder from the

printer.

(2) Remove

Side cover (R) [1]

Press a minus driver into joints [2] of side

cover (R) and set plate (R) for separation.

Side cover (L) [3]

Press a minus driver into joints [4] of side

cover (L) and set plate (L) for separation.

Front sheet cover [5]

(1) Remove the side covers and front sheet cover

according to the procedure described in item

2-1.

(2) Remove

Screw [1]

Lever spring [2]

Stop ring [3]

Roller shaft [4]

Roller (R) [5]

Roller (L) [6]

(3) Lubrication

Where roller shaft and set plates touch. (two

places)

(4) Note

When reassembling, be careful that the roll-

ers are turning in the correct direction and be

sure not to mix up the roller (R) unit and roller

(L) unit.

(See the illustration for difference of the

rollers.)

22

2-3. Clutch (A) Unit

2-4. Gears

(1) Remove the roller shaft according to the proce-

dure described in item 2-2.

(2) Remove

Stop ring [1]

Ratchet [2]

Clutch (B) [3]

Clutch (A) [4]

Locating bushing [5]

(3) Lubrication

Where clutch (A) and roller shaft touch.

(1) Remove the roller shaft according to the proce-

dure described in item 2-2.

(2) Remove

Three tapping screws [1]

Three collars [2]

Three gears G1 [3]

Tapping screw [4]

Gear G4 [5]

Two gears G7 [6]

Gear [7]

Tapping screw [8]

Gear G8 [9]

Stop ring [10]

Gear G10 [11]

(3) Lubrication

Where gears and set plate (R) touch. (eleven

places)

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV (Continue)

23

2-5. Ejection Roller Unit

2-6. Lever

(1) Remove the side covers and front sheet cover

according to the procedure described in item

2-1.

(2) Remove

Stop ring [1]

Stop ring [2]

Gear G10 [3]

Ejection roller unit [4]

(3) Lubrication

Where set plate (R), (L) and ejection roller

touch. (two places)

(1) Remove the side cover (L) unit according to the

procedure described in item 2-1.

(2) Remove

Lever screw [1]

Lever [2]

24

2-7. Hopper Bottom

2-8. Pressure Plate Unit

(1) Remove the lever according to the procedure

described in item 2-6.

(2) Remove

Two tapping screws [1]

Hopper bottom [2]

(1) Remove the roller shaft according to the proce-

dure described in item 2-2.

(2) Remove the hopper bottom according to the

procedure described in item 2-7.

(3) Remove

Two hopper springs [1]

(4) Remove the lever screw and lever according to

the procedure described in item 2-6.

(5) Remove

Stop ring SE4 [2]

Lever gear [3]

Hopper shaft [4]

Screw [5]

Shaft (A) [6]

Two O rings [7]

Hopper (L) [8]

Pressure plate (L) unit [9]

Pressure plate (R) unit [10]

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV (Continue)

25

2-9. Stacker Bottom

2-10. Set Plate (R)

(1) Remove the ejection roller according to the

procedure described in item 2-5.

(2) Remove the clutch (A) unit according to the

procedure described in item 2-3.

(3) Remove the gears according to the procedure

described in item 2-4.

(4) Remove

Four screws [1]

Stacker bottom [2]

(1) Remove the clutch (A) according to the proce-

dure described in item 2-3.

(2) Remove the gears according to the procedure

described in item 2-4.

(3) Remove

Stop ring SE4 [1]

Lever gear [2]

Screw [3]

Three tapping screws [4]

Set plate (R) [5]

26

2-11. Set Plate (L)

2-12. Corner Separators

(1) Remove the lever screw [1] and lever [2]

according to the procedure described in item

2-6.

(2) Remove

Stop ring SE4 [3]

Lever gear [4]

Two stop rings SE5 [5]

Three tapping screws [6]

Set plate (L) [7]

(1) Remove the set plate (L) [1] according to the

procedure described in item 2-11.

(2) Remove

Hopper (L) [2]

Hopper support [3]

Hopper (R) [4]

O ring [5]

Pressure plate [6]

Spring cover [7]

Separator spring [8]

Stop ring SE4 [9]

Corner separators [10]

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV (Continue)

27

3-2. Roller Unit

3. SF-10DM/15DM/10DMII/15DMII

3-1. Side Covers and Front Stacker

(1) Remove the automatic sheet feeder from the

printer.

(2) Remove

Side cover (R) [1]

Press a minus driver into joints [2] of side

cover (R) and set plate (R) for separation.

Side cover (L) [3]

Press a minus driver into joints [4] of side

cover (L) and set plate (L) for separation.

Front stacker [5]

Push up the front stacker [5] to release the

hooks [6].

(1) Remove the side cover (R), (L) and front stacker

according to the procedure described in item

3-1.

(2) Release the brake spring [1] from the groove of

the clutch (B) [2].

(3) Remove

Stop ring [3]

Shaft (4) [4]

Roller (R) [5]

Roller (L) [6]

(4) Lubrication

Where roller shaft and set plate (L) touch.

(5) Note

When reassembling, be careful that the roll-

ers are turning in the correct direction and be

sure not to mix up the roller (R) unit and roller

(L) unit.

(See the illustration for difference of the

rollers.)

28

(1) Remove the shaft (4) according to the procedure

described in item 3-2.

(2) Remove

Two tapping screws [1]

Two gears (1) [2]

Two collars [3]

Tapping screw [4]

Gear (3) [5]

Tapping screw [6]

Parking lever unit [7]

Gear (2) [8]

Gear (5) [9]

By holding the hook with fingers

Spring [10]

Stop ring SE3 [11]

Gear (6) [12]

Bearing [13]

Two stop rings SE3 [14]

Two gears (4) [15]

Two bearings [16]

Stop ring SE5 [17]

Bearing [18]

Shaft (3) [19]

With the gear (6) [20] attached

(3) Lubrication

Where gears and plate touch.

Where bearings and plate touch.

Where gear (5) and parking lever touch.

3-3. Clutch (A) Unit

3-4. Gears

(1) Remove the shaft (4) according to the procedure

described in item 3-2.

(2) Remove

Stop ring [1]

Ratchet [2]

Clutch (B) [3]

Clutch (A) [4]

Positioning bearing [5]

(3) Lubrication

Where clutch (A) and shaft (4) touch.

3. SF-10DM/15DM/10DMII/15DMII (Continue)

29

3-5. Ejection Roller Unit

3-6. Lever

(1) Remove the side cover (R), (L) and front stacker

according to the procedure described in item

3-1.

(2) Remove

Two stop rings [1]

Two stop rings [2]

Two gears (4) [3]

Two bearings [4]

Shaft (1) [5]

Shaft (2) [6]

(3) Lubrication

Where set plate (R), (L) and shaft (1), (2)

touch. (four places)

(1) Remove the side cover (L) according to the

procedure described in item 3-1.

(2) Remove

Lever screw [1]

Lever [2]

30

3-7. Hopper Bottom

3-8. Pressure Plate Unit

(1) Remove the lever according to the procedure

described in item 3-6.

(2) Remove

Two tapping screws [1]

Hopper bottom [2]

(1) Remove the shaft (4) according to the procedure

described in item 3-2.

(2) Remove the hopper bottom according to the

procedure described in item 3-7.

(3) Remove the lever screw [1] and lever [2]

according to the procedure described in item

3-6.

(4) Remove

Two hopper springs [3]

Stop ring SE4 [4]

Lever gear [5]

Shaft (5) [6]

Screw [7]

Shaft (6) [8]

Two o rings [9]

Pressure plate (L) unit [10]

Pressure plate (R) unit [11]

3. SF-10DM/15DM/10DMII/15DMII (Continue)

31

3-9. Stacker Bottom

3-10. Set Plate (R)

(1) Remove the shaft (1) and shaft (2) according to

the procedure described in item 3-5.

(2) Remove

Four screws [1]

Stacker guide [2]

(1) Remove the clutch (A) according to the proce-

dure described in item 3-3.

(2) Remove the gears according to the procedure

described in item 3-4.

(3) Remove

Stop ring SE4 [1]

Lever gear [2]

Screw [3]

Three tapping screws [4]

Set plate (R) [5]

32

3-11. Set Plate (L)

3-12. Corner Separators

(1) Remove the lever screw [1] and Lever [2]

according to the procedure described in item

3-6.

(2) Remove

Three stop rings SE5 [3]

Stop ring SE3 [4]

Bearing [5]

Stop ring SE4 [6]

Lever gear [7]

Three tapping screws [8]

Set plate (L) [9]

(1) Remove the pressure plate (R) unit [1] and (L)

[2] according to the procedure described in item

3-8.

(2) Remove

Hopper (R) [3]

Hopper (L) [4]

Hopper separator [5]

Three bushings [6]

Two spring covers [7]

Two separator springs [8]

Two stop rings SE4 [9]

Corner separator (R) [10]

Corner separator (L) [11]

(3) Note

In assembly, first make the shaft through

hopper (R) [3] and hopper (L) [4], and next

press the bushing [6] into the shaft.

3. SF-10DM/15DM/10DMII/15DMII (Continue)

33

4-2. Roller Unit

4. SF-10DN/10DQ/10DW

4-1. Side Covers and Front Sheet Cover

(1) Remove the automatic sheet feeder from the

printer.

(2) Remove

Side cover (R) [1]

Press a minus driver into joints [2] of side

cover (R) and set plate (R) for separation.

Side cover (L) [3]

Press a minus driver into joints [4] of side

cover (L) and set plate (L) for separation.

Front sheet cover [5]

(1) Remove the side covers and front sheet cover

according to the procedure described in item

4-1.

(2) Remove

Screw [1]

Lever spring [2]

Stop ring [3]

Ejection roller shaft [4]

Roller (R) [5]

Roller (L) [6]

(3) Lubrication

Where roller shaft and set plates touch. (two

places)

(4) Note

When reassembling, be careful that the roll-

ers are turning in the correct direction and be

sure not to mix up the roller (R) unit and roller

(L) unit.

(See the illustration for difference of the

rollers.)

34

4-3. Clutch (A) Unit

4-4. Gears

(1) Remove the roller shaft according to the proce-

dure described in item 4-2.

(2) Remove

Stop ring [1]

Ratchet [2]

Clutch (B) [3]

Clutch (A) [4]

Positioning bearing [5]

(3) Lubrication

Where clutch (A) and roller shaft touch.

(1) Remove the roller shaft according to the proce-

dure described in item 4-2.

(2) Remove

Three tapping screws [1]

Three gears [2]

Two stop rings [3]

Gear [4]

Bearing [5]

Gear [6]

Two tapping screws [7]

Two gears [8]

Gear [9]

(3) Lubrication

Where gears and set plate touch. (eleven

places)

4. SF-10DN/10DQ/10DW (Continue)

35

4-5. Ejection Roller Unit

4-6. Lever

(1) Remove the side covers and front cover accord-

ing to the procedure described in item 4-1.

(2) Remove

Two stop rings [1]

Gear G4 [2]

Gear G5 [3]

Bearing [4]

Ejection roller unit [5]

(3) Lubrication

Where set plate (R), (L) and ejection roller

touch. (two places)

(1) Remove the side cover (R) unit according to the

procedure described in item 4-1.

(2) Remove

Lever screw [1]

Lever [2]

36

4-7. Hopper Bottom

4-8. Pressure Plate Unit

(1) Remove the ejection roller unit according to the

procedure described in item 4-5.

(2) Remove the lever according to the procedure

described in item 4-6.

(3) Remove

Four tapping screws [1]

Hopper bottom [2]

(1) Remove the roller shaft according to the proce-

dure described in item 4-2.

(2) Remove the hopper bottom according to the

procedure described in item 4-7.

(3) Remove the lever screw and lever according to

the procedure described in item 4-6.

(4) Remove

Two stop rings [1]

Two lever gears [2]

Hopper shaft [3]

Shaft (A) [4]

Pressure plate (R) unit [5]

Hopper support [6]

Pressure plate (L) unit [7]

4. SF-10DN/10DQ/10DW (Continue)

37

4-9. Stacker Bottom

4-10. Set Plate (R)

(1) Remove the ejection roller according to the

procedure described in item 4-5.

(2) Remove the clutch (A) unit according to the

procedure described in item 4-3.

(3) Remove

Two screws [1]

Stacker bottom [2]

(1) Remove the lever screw [1] and lever [2]

according to the procedure described in item

4-6.

(2) Remove

Three screws [3]

Stop ring [4]

Stop ring [5]

Lever gear [6]

Set plate (R) [7]

38

4-11. Set Plate (L)

4-12. Corner Separator

(1) Remove the clutch (A) according to the proce-

dure described in item 4-3.

(2) Remove the gears according to the procedure

described in item 4-4.

(3) Remove

Stop ring [1]

Gear [2]

Screw [3]

Three screws [4]

Tapping screw [5]

Set plate (L) [6]

(1) Remove the hopper unit (L) [1] according to the

procedure described in item 4-8.

(2) Remove

Hopper cover [2]

Separator spring [3]

Corner separator [4]

Pressure plate [5]

Hopper spring [6]

39

5-2. Roller Unit

5. SF-10DS

5-1. Side Cover Unit and Front Sheet Cover

(1) Remove the automatic sheet feeder from the

printer.

(2) Remove

Front cover [1]

Side cover (R) [2]

Release the two hooks [3] and remove side

cover (R) [2].

Side cover (L) [4]

Release the two hooks [5] and remove side

cover (R) [4].

(1) Remove the side covers and front sheet cover

according to the procedure described in item

5-1.

(2) Remove

Stop ring [1]

Brake spring [2]

Shaft (4) unit [3]

Roller (R) [4]

Roller (L) [5]

(3) Lubrication

Where roller shaft and set plate (R) touch.

(4) Note

When reassembling, be careful that the roll-

ers are turning in the correct direction and be

sure not to mix up the roller (R) unit and roller

(L) unit.

(See the illustration for difference of the

rollers.)

40

5-3. Clutch (A) Unit

5-4. Gears

(1) Remove the shaft (4) unit according to the

procedure described in item 5-2.

(2) Remove

Stop ring [1]

Ratchet [2]

Clutch (B) [3]

Clutch (A) unit [4]

Positioning bearing [5]

(3) Lubrication

Where clutch (A) unit and roller shaft touch.

(1) Remove the shaft (4) unit according to the

procedure described in item 5-2.

(2) Remove

Two tapping screws [1]

Stop ring [2]

Two gears G2 [3]

Gear (B) [4]

Gear G3 [5]

Gear (A) [6]

Gear (C) [7]

(3) Lubrication

Where gears and set plate touch. (five places)

5. SF-10DS (Continue)

41

5-5. Shaft assy

5-6. Lever

(1) Remove the side covers according to the proce-

dure described in item 5-1.

(2) Remove

Two stop rings [1]

Gear B [2]

Bearing [3]

Shaft assy [4]

(3) Lubrication

Where set plate (R), (L) and shaft assy touch.

(two places)

(1) Remove the side cover (R) according to the

procedure described in item 5-1.

(2) Remove

Lever screw [1]

Lever [2]

42

5-7. Hopper Bottom

5-8. Pressure Plate Unit

(1) Remove the side covers according to the proce-

dure described in item 5-1.

(2) Remove

Four screws [1]

Hopper bottom [2]

(1) Remove the shaft (4) unit according to the

procedure described in item 5-2.

(2) Remove the set plate (R) according to the proce-

dure described in item 5-10.

(3) Remove

Pressure plate (R) unit [1]

Hopper support [2]

Pressure plate (L) unit [3]

5. SF-10DS (Continue)

43

5-9. Stacker Bottom

5-10. Set Plate (R)

(1) Remove the gears according to the procedure

described in item 5-4.

(2) Remove the shaft assy according to the proce-

dure described in item 5-5.

(3) Remove

Two screws [1]

Stacker bottom [2]

(1) Remove the lever screw [1] and lever [2]

according to the procedure described in item

5-6.

(2) Remove

Stop ring [3]

Lever gear [4]

Stop ring [5]

Four screws [6]

Set plate (R) [7]

44

5-11. Set Plate (L)

5-12. Corner Separator

(1) Remove the gear according to the procedure

described in item 5-4.

(2) Remove

Stop ring [1]

Lever gear [2]

Screw [3]

Four screw [4]

Set plate (L) [5]

(1) Remove the pressure plate (R) unit and Pressure

plate (L) unit according to the procedure

described in item 5-8.

(2) Remove

Hopper cover [1]

Separator spring [2]

Corner separator [3]

Pressure plate [4]

Hopper spring [5]

5. SF-10DS (Continue)

45

CHAPTER 5

MAINTENANCE AND LUBRICATION

1. Maintenance

In order to maintain the optimum performance of this automatic sheet feeder (ASF) and to prevent troubles,

maintenance must be carried out as follows.

1-1. Cleaning

(1) Removal of dirt Wipe off dirt with a soft cloth soaked in alcohol or benzine.

* Note: Do not use paint thinner, trichlene, or ketone solvents because they may damage plastic parts.

(2) Cleaning out paper bits, and dust Wipe the roller unit and the ejection roller with a rag soaked in alcohol

and clean away any ink and any paper bits.

* Note: Make sure that there is no grease or oil on the roller unit or the ejection roller. Clean away the

paper bits in the hopper bottom, the stacker bottom and the front sheet cover.

2. Lubrication

Lubrication is very important in maintaining optimum performance of the automatic sheet feeder and in

preventing troubles.

2-1. Lubricant

The type of lubricant greatly affects the performance and durability of the automatic sheet feeder. Special care

must be taken to ensure correct low temperature characteristics. For this automatic sheet feeder, Grease

AL-#1 is recommended.

2-2. Lubricating Method

When lubrication is carried out during assembly and disassembly, wash parts well to remove dust and dirt

before lubricating them.

2-3. Lubrication Point

Here are the places to lubricate. (These locations are marked with % in the figure in Chapter 4.)

Lubrication Point Figure No.

Where roller shaft and set plates touch Roller unit of the chapter 4

Where roller shaft and clutch (A) and (B) unit touch Clutch (A) unit of the chapter 4

Where set plates and gears touch Gears of the chapter 4

Where set plates and ejection roller unit touch Ejection roller unit (Shaft assy) of the chapter 4

Where set plates and shaft (B) touch Stacker bottom of the chapter 4 (SF-10D/15D/15DE)

45

CHAPTER 6

TROUBLE SHOOTING

Possible troubles and remedies with the Automatic Sheet Feeder (ASF):

No. Symptom Cause Solution

Remount the automatic sheet feeder

and check that when you turn the

platen knob by hand the ejection roller

unit of the automatic sheet feeder turns.

Check that the protrusion at the left

rear of the automatic sheet feeder press

correctly into the automatic sheet

feeder detector (Precision snap-act-

ing switch) on the printer.

[SF-10D/15D/15DE]

Check that the DIP switch on (EDS

switch) the printer is set active posi-

tion.

[SF-10DJ/10DK/15DJ/10DT/10DV/

10DM/15DM/10DMII/15DMII/

10DR/10DN/10DQ/10DS/10DW]

Check that the printer release lever is

set to the AUTO position.

Check the movement of the gear train

and the clutch visually. If they are not

moving correctly, replace whichever

part is broken.

Set the hopper a bit wider (about 0.5

mm) than the width of the paper.

Replace the paper with paper that meets

the specifications for the automatic

sheet feeder.

Push the lever back to the set position.

Reduce the pile of paper in the hopper.

The automatic sheet feeder

is not mounted properly on

the printer.

The printer is not in auto-

matic sheet feeder mode.

The clutch is not working.

The paper is caught between

the left and the right side of

the hopper.

The paper is too thick.

The automatic sheet feeder

lever is in the reset (open)

position.

There are too many sheets of

paper in the hopper.

Automatic sheet feeder

does not work.

Paper can not be fed from

the hopper (non-feed).

1.

2.

46

No. Symptom Cause Solution

Align the hopper with the width of the

paper.

Replace the paper with paper that meets

the specifications for the automatic

sheet feeder.

Align the paper correctly.

Replace the paper with new paper.

Reduce the pile of paper in the hopper.

Set the paper correctly in the corner

separator.

Check the hopper spring, the pressure

plate, and the left and right roller units

and measure the transport force. Re-

place whichever part is broken.

Check the condition of the corner sepa-

rator and spring and fix them if neces-

sary.

Carry out the paper feed operation

exactly by hand to find out exactly

what the problem is and to eliminate

possible causes (e.g. dirt, foreign ob-

ject, or deformation or damage of the

paper guide section).

Fan the paper well before loading it

into the hopper.

Use paper that meets the specifica-

tions of the automatic sheet feeder.

Set the hopper a bit wider (about 0.5

mm) than the width of the paper.

Set the paper correctly in the corner

separator.

The hopper is set too wide or

too narrow for the paper be-

ing used.

Paper that does not meet the

specifications for the auto-

matic sheet feeder is being

used.

The paper is not lined up

correctly.

The paper is bent or folded.

There is too much paper in

the hopper.

The paper in the hopper is

outside the corner separator.

The transport force of the left

and right roller units is inad-

equate or unbalanced. (See

Item 3 in Chapter 5.)

There is something wrong

with the corner separator.

There is something wrong

along the path of the paper

through the automatic sheet

feeder and the printer.

Sheets of paper are sticking

together.

Paper that does not meet the

specifications for the auto-

matic sheet feeder is being

used.

The hopper is set too wide or

too narrow for the paper be-

ing used.

The paper in the hopper is

outside the corner separator.

Paper jams 3.

More than one sheet of

paper is pulled in at a

time. (double feed)

4.

48

CHAPTER 7

PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

The second column shows a revision number. Parts that have been added in the revised edition are

indicated with #.

Parts that have been abolished in the revised edition are indicated with *.

#1: First editionSecond edition #2: Second editionThird edition

*1: First editionSecond edition *2: Second editionThird edition

#3: Third edition Fourth edition #4: Fourth editionFifth edition

*3: Third edition Fourth edition *4: Fourth editionFifth edition

#5: Fifth edition Sixth edition #6: Sixth editionSeventh edition

*5: Fifth edition Sixth edition *6: Sixth editionSeventh edition

#7: Seventh editionEighth edition

*7: Seventh editionEighth edition

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) QTY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

When there are differences in the model, the differences are described.

(7) RANK

Parts marked S are service parts.

Service parts are recommended to be in stock.

49

1. SF-10D/15D/15DE

1-1. Disassembly Drawing

50

51

1-2. Parts List

SF-10D/15D/15DE

1 80904750 FRONT COVER SF-10D 1 FOR SF-10D S

80905100 FRONT COVER SF-15D 1 FOR SF-15D/15DE S

2 80904570 HOPPER BOTTOM SF-10D 1 FOR SF-10D

80905040 HOPPER BOTTOM SF-15D 1 FOR SF-15D/15DE

3 *6 80904310 SIDE COVER R SF-10D 1 S

#6 80903471 SIDE COVER R SF-15DEP 1 S

4 80904330 COVER R SF-10D 1

5 80904340 COVER L SF-10D 1

6 80904320 SIDE COVER L SF-10D 1 S

7 80904530 STACKER BOTTOM SF-10D 1 FOR SF-10D

80905010 STACKER BOTTOM SF-15D 1 FOR SF-15D/15DE

8 80904540 GUARD PIECE SF-10D 2 FOR SF-10D

80904540 GUARD PIECE SF-10D 4 FOR SF-15D/15DE

9 80904550 BRUSH SF-10D 1 FOR SF-10D

80905020 BRUSH SF-15D 1 FOR SF-15D/15DE

10 80904590 SHAFT B SF-10D 1 FOR SF-10D

80905060 SHAFT B SF-15D 1 FOR SF-15D/15DE

11 80904610 EJECTION ROLLER UNIT SF-10D 1 SF-10D:INCLUDE NO.60 S

80905080 EJECTION ROLLER UNIT SF-15D 1 FOR SF-15D/15DE S

12 80904560 REAR STACKER SF-10D 1 FOR SF-10D

*6 80905030 REAR STACKER SF-15D 1 FOR SF-15D/15DE

#6 80903766 REAR STACKER SF-15D 1 FOR SF-15D/15DE

13 80904730 ROLLER R UNIT SF-10D 1 S

14 80904740 ROLLER L UNIT SF-10D 1 S

15 80904600 ROLLER SHAFT SF-10D 1 FOR SF-10D

80905070 ROLLER SHAFT SF-15D 1 FOR SF-15D/15DE

16 80904620 HOPPER SHAFT SF-10D 1 FOR SF-10D

80905090 HOPPER SHAFT SF-15D 1 FOR SF-15D/15DE

17 80904580 SHAFT A SF-10D 1 FOR SF-10D

80905050 SHAFT A SF-15D 1 FOR SF-15D/15DE

18 80904780 HOPPER ATTACHMENT SF-10D 1 S

19 80904790 STACKER ATTACHMENT SF-10D 1 FOR SF-10D S

80905110 STACKER ATTACHMENT SF-15D 1 FOR SF-15D/15DE S

20 80904510 BRAKE LEVER SF-10D 1

21 80904490 RATCHET SF-10D 1

22 80904460 CLUTCH B UNIT SF-10D 1

23 80904450 CLUTCH A UNIT SF-10D 1

24 80904480 CLAW SF-10D 1

25 80904500 LEVER GEAR SF-10D 2

26 80904380 GEAR G1 SF-10D 2

27 80904390 GEAR G2 SF-10D 2 S

28 80904410 GEAR G5 SF-10D 1

29 80904420 GEAR G7 SF-10D 1

30 80904430 GEAR G10 SF-10D 2

31 80904440 GEAR G12 SF-10D 1

32 80904350 SET PLATE R SF-10D 1 S

33 80904360 SET PLATE L SF-10D 1 S

34 80904760 LEVER SF-10D 1 S

35 80904770 LEVER SCREW SF-10D 1

36 80904680 SPRING COVER SF-10D 2

37 80904660 CORNER SEPARATOR R SF-10D 1

38 80904630 HOPPER UNIT R SF-10D 1

39 80904710 O-RING SF-10D 2 S

40 80904300 BUSHING SF-10D 3

41 80904720 HOPPER SUPPORT SF-10D 1 S

42 80904690 PRESSURE PLATE R SF-10D 1

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

52

SF-10D/15D/15DE

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

43 80904700 PRESSURE PLATE L SF-10D 1

44 80904640 HOPPER UNIT L SF-10D 1

45 80904670 CORNER SEPARATOR L SF-10D 1

46 80904370 HOPPER SPRING SF-10D 2

47 80904470 CLAW SPRING SF-10D 1

48 80904520 LEVER SPRING SF-10D 1

49 80904650 SEPARATOR SPRING SF-10D 2

50 04020010 STOP RING SE2.0 1 S

51 04020015 STOP RING SE3.0 3 S

52 04020016 STOP RING SE4.0 4 S

53 04020017 STOP RING SE5.0 2 S

54 *3 04020014 STOP RING SE6.0 2 S

#3 04020022 STOP RING SE6.0-SUS 2 S

55 01903045 SCREW TR 3-8 FL 1 S

56 00630804 SCREW TR 3-8 12 S

57 01903060 SCREW TAT 3-8 PT-FL 6 S

58 80904990 COLLAR SF-10D 2

59 80905000 SUPPORTER SF-15D 1 FOR SF-15D/15DE ONLY

60 #2 80905250 RUBBER ROLLER SF-10D 3 FOR SF-10D ONLY

80904800 PRINTER COVER SF-10D 1 FOR SF-10D S

80905120 PRINTER COVER SF-15D 1 FOR SF-15D S

80905160 PRINTER COVER SF-15DE 1 FOR SF-15DE S

53

2. SF-10DJ/10DK/10DR/15DJ/10DT/10DV

2-1. Disassembly Drawing

54

55

1 80905300 FRONT SHEET COVER SF-10DJ 1 EXCEPT FOR SF-15DJ S

#2 80903498 FRONT SHEET COVER SF-15DJ 1 FOR SF-15DJ S

2 80905310 HOPPER BOTTOM SF-10DJ 1 FOR SF-10DJ/10DR

*5 80905640 HOPPER BOTTOM SF-10DK 1 FOR SF-10DK

#5 80905310 HOPPER BOTTOM SF-10DJ 1 FOR SF-10DK

#2 80903497 HOPPER BOTTOM SF-15DJ 1 FOR SF-15DJ

#5 80903741 HOPPER BOTTOM SF-10DT 1 FOR SF-10DT/10DV

3 80905320 SIDE COVER R SF-10DJ 1 FOR SF-10DJ/10DK S

*5 80903495 SIDE COVER R SF-15DJ 1 FOR SF-15DJ S

#5 80905320 SIDE COVER R SF-10DJ 1 FOR SF-15DJ S

#3 80903549 SIDE COVER R SF-10DR 1 SF-10DR/10DT/10DV S

4 80905330 SIDE COVER L SF-10DJ 1 SF-10DJ/10DK/15DJ S

#3 80903550 SIDE COVER L SF-10DR 1 SF-10DR/10DT/10DV S

5 80905340 STACKER BOTTOM SF-10DJ 1 FOR SF-10DJ

80903551 STACKER BOTTOM SF-10DR 1 FOR SF-10DR

#2 80903496 STACKER BOTTOM SF-15DJ 1 FOR SF-15DJ

*5 80905340 STACKER BOTTOM SF-10DJ 1 FOR SF-10DK

#5 80905700 STACKER BOTTOM SF-10DKP 1 SF-10DK/10DT/10DV

6 80904540 GUARD PIECE SF-10D 3 SF-10DJ/10DK S

*5 80904540 GUARD PIECE SF-10D 3 FOR SF-10DR S

#5 80903750 GUARD PIECE SF-10DT 3 SF-10DR/10DT/10DV S

80904540 GUARD PIECE SF-10D 4 FOR SF-15DJ S

7 80905350 EJECTION ROLLER UNIT SF-10DJ 1 EXCEPT FOR SF-15DJ

#2 80903493 SHAFT C SF-15DJ 1 FOR SF-15DJ

8 *5 80905360 ROLLER R SF-10DJ 1 SF-10DJ/10DK/15DJ S

#5 80903542 ROLLER R AS SF-10DR 1 SF-10DJ/10DK/15DJ S

#3 80903542 ROLLER R AS SF-10DR 1 SF-10DR/10DT/10DV S

9 *5 80905370 ROLLER L SF-10DJ 1 SF-10DJ/10DK/15DJ S

#5 80903543 ROLLER L AS SF-10DR 1 SF-10DJ/10DK/15DJ S

#3 80903543 ROLLER L AS SF-10DR 1 SF-10DR/10DT/10DV S

10 80905380 ROLLER SHAFT SF-10DJ 1 EXCEPT FOR SF-15DJ

#2 80903492 SHAFT B SF-15DJ 1 FOR SF-15DJ

11 *6 80905390 HOPPER SHAFT SF-10DJ 1 EXCEPT FOR SF-15DJ

#6 80904620 HOPPER SHAFT SF-10D 1 EXCEPT FOR SF-15DJ

#2 80903491 SHAFT A SF-15DJ 1 FOR SF-15DJ

12 *5 80905400 SHAFT A SF-10DJ 1 FOR SF-10DJ/10DK

#5 80903539 SHAFT A SF-10DR 1 FOR SF-10DJ/10DK

#3 80903539 SHAFT A SF-10DR 1 SF-10DR/10DT/10DV

#2 80903494 SHAFT D SF-15DJ 1 FOR SF-15DJ

13 80905410 HOPPER ATTACHMENT SF-10DJ 1 EXCEPT FOR SF-15DJ S

#5 80903639 HOPPER ATTACHMENT SF-15DKP 1 FOR SF-15DJ S

14 80905420 STACKER ATTACHMENT SF-10DJ 1 S

15 80905430 BRAKE SPRING SF-10DJ 1

16 80905440 RATCHET SF-10DJ 1

17 80905450 CLUTCH B SF-10DJ 1

18 80905460 CLUTCH A SF-10DJ 1

19 80905470 CLAW SF-10DJ 1

20 80904500 LEVER GEAR SF-10D 2

21 80905480 GEAR G1 SF-10DJ 3

22 80905490 GEAR G4 SF-10DJ 1

23 80904420 GEAR G7 SF-10D 1

24 80905500 GEAR G7 SF-10DJ 2

25 80905510 GEAR G8 SF-10DJ 1

26 80905520 GEAR G10 SF-10DJ 1

27 80905530 SET PLATE R SF-10DJ 1 SF-10DJ/10DK/15DJ S

#3 80903547 SET PLATE R SF-10DR 1 SF-10DR/10DT/10DV S

2-2. Parts List

SF-10DJ/10DK/10DR/15DJ/10DT/10DV

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

56

SF-10DJ/10DK/10DR/15DJ/10DT/10DV

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

28 80905540 SET PLATE L SF-10DJ 1 SF-10DJ/10DK/15DJ S

#3 80903548 SET PLATE L SF-10DR 1 SF-10DR/10DT/10DV S

29 80904760 LEVER SF-10D 1 SF-10DJ/10DK/15DJ S

#5 80903742 LEVER SF-10DT 1 SF-10DR/10DT/10DV S

30 80904770 LEVER SCREW SF-10D 1

31 80904680 SPRING COVER SF-10D 2 SF-10DJ/10DK/15DJ

#5 80903743 SPRING COVER SF-10DT 2 SF-10DR/10DT/10DV

32 80904660 CORNER SEPARATOR R SF-10D 1

33 80904630 HOPPER UNIT R SF-10D 1 SF-10DJ/10DK/15DJ

#5 80903744 HOPPER UNIT R SF-10DT 1 SF-10DR/10DT/10DV

34 80904710 O-RING SF-10D 2 S

35 80904300 BUSHING SF-10D 3

36 80904720 HOPPER SUPPORT SF-10D 1 SF-10DJ/10DK/15DJ

#5 80903745 HOPPER SUPPORT SF-10DT 1 SF-10DR/10DT/10DV

37 *5 80904690 PRESSURE PLATE R SF-10D 1 SF-10DJ/10DK/10DR

#5 80905180 PRESSURE PLATE R SF-10DP 1 SF-10DJ/10DK

80905180 PRESSURE PLATE R SF-10DP 1 FOR SF-15DJ

#5 80903746 PRESSURE PLATE R SF-10DT 1 SF-10DR/10DT/10DV

38 *5 80904700 PRESSURE PLATE L SF-10D 1 SF-10DJ/10DK/10DR

#5 80905190 PRESSURE PLATE L SF-10DP 1 SF-10DJ/10DK

80905190 PRESSURE PLATE L SF-10DP 1 FOR SF-15DJ

#5 80903747 PRESSURE PLATE L SF-10DT 1 SF-10DR/10DT/10DV

39 80904640 HOPPER UNIT L SF-10D 1 SF-10DJ/10DK/15DJ

*5 80904640 HOPPER UNIT L SF-10D 1 SF-10DR

#5 80903748 HOPPER UNIT L SF-10DT 1 SF-10DR/10DT/10DV

40 80904670 CORNER SEPARATOR L SF-10D 1

41 80905550 HOPPER SPRING SF-10DJ 2

42 80905560 CLAW SPRING SF-10DJ 1

43 80904650 SEPARATOR SPRING SF-10D 2

44 04020010 STOP RING SE2.0 1 S

45 04020015 STOP RING SE3.0 2 S

46 04020016 STOP RING SE4.0 4 S

47 04020017 STOP RING SE5.0 2 S

48 *3 04020014 STOP RING SE6.0 1 S

#3 04020022 STOP RING SE6.0-SUS 1 S

48A *3 04020014 STOP RING SE6.0 1 FOR SF-15DJ ONLY S

#3 04020022 STOP RING SE6.0-SUS 1 FOR SF-15DJ ONLY S

49 01903045 SCREW TR 3-8 FL 1 S

50 00630804 SCREW TR 3-8 6 S

51 01903060 SCREW TAT 3-8 PT-FL 6 S

52 80905570 COLLAR SF-10DJ 3 EXCEPT FOR SF-10DR

*5 80903110 COLLAR SF-10DM 3 FOR SF-10DR

#5 80905570 COLLAR SF-10DJ 3 FOR SF-10DR

53 80905580 PRINTER COVER SF-10DJ 1 FOR SF-10DJ S

80905650 PRINTER COVER SF-10DK 1 FOR SF-10DK S

#2 80903502 PRINTER COVER SF-15DJ 1 FOR SF-15DJ

#3 80903553 PRINTER COVER SF-10DR 1 FOR SF-10DR

#5 80903739 PRINTER COVER SF-10DT 1 FOR SF-10DT

#5 80903738 PRINTER COVER SF-10DV 1 FOR SF-10DV

54 80905290 POSITIONING BEARING SF-10DJ 1

55 #2 80905000 SUPPORTER SF-15D 1 FOR SF-15DJ ONLY

56 #3 80903544 RUBBER ROLLER SF-10DR 3 SF-10DJ/10DK/10DR

#5 80903544 RUBBER ROLLER SF-10DR 4 FOR SF-15DJ

#5 80903749 RUBBER ROLLER SF-10DT 3 SF-10DT/10DV

#3 80903517 REAR COVER SF-10DR 1 FOR SF-10DR

57

3. SF-10DM/15DM/10DMII/15DMII

3-1. Disassembly Drawing

A. SF-10DM/15DM

58

59

B. SF-10DMII/15DMII

60

61

3-2. Parts List

SF-10DM/10DMII/15DM/15DMII

1 80903260 FRONT STACKER SF-10DM 1 FOR SF-10DM S

#6 80903772 FRONT STACKER SF-10DMII 1 FOR SF-10DMII S

80903390 FRONT STACKER SF-15DM 1 FOR SF-15DM S

#6 80903773 FRONT STACKER SF-15DMII 1 FOR SF-15DMII S

2 80903220 STACKER GUIDE SF-10DM 1 FOR SF-10DM

*6 80903616 STACKER GUIDE SF-10DMII 1 FOR SF-10DMII

#6 80903775 STACKER GUIDE SF-10DMII 1 FOR SF-10DMII

80903350 STACKER GUIDE SF-15DM 1 FOR SF-15DM

*6 80903617 STACKER GUIDE SF-15DMII 1 FOR SF-15DMII

#6 80903774 STACKER GUIDE SF-15DMII 1 FOR SF-15DMII

3 80903210 HOPPER BOTTOM SF-10DM 1 FOR SF-10DM

*6 80903618 HOPPER BOTTOM SF-10DMII 1 FOR SF-10DMII

#6 80903778 HOPPER BOTTOM SF-10DMII 1 FOR SF-10DMII

80903370 HOPPER BOTTOM SF-15DM 1 FOR SF-15DM

*6 80903619 HOPPER BOTTOM SF-15DMII 1 FOR SF-15DMII

#6 80903777 HOPPER BOTTOM SF-15DMII 1 FOR SF-15DMII

4 80903160 SHAFT 2 SF-10DM 1 FOR SF-10DM/10DMII S

80903310 SHAFT 2 SF-15DM 1 FOR SF-15DM/15DMII S

5 80903150 SHAFT 1 SF-10DM 1 FOR SF-10DM/10DMII S

80903300 SHAFT 1 SF-15DM 1 FOR SF-15DM/15DMII S

6 80903170 SHAFT 3 SF-10DM 1 FOR SF-10DM/10DMII

80903320 SHAFT 3 SF-15DM 1 FOR SF-15DM/15DMII

7 80903200 SHAFT 6 SF-10DM 1 FOR SF-10DM/10DMII

80903380 SHAFT 6 SF-15DM 1 FOR SF-15DM/15DMII

8 80903190 SHAFT 5 SF-10DM 1 FOR SF-10DM/10DMII

80903340 SHAFT 5 SF-15DM 1 FOR SF-15DM/15DMII

9 80903180 SHAFT 4 SF-10DM 1 FOR SF-10DM/10DMII

80903330 SHAFT 4 SF-15DM 1 FOR SF-15DM/15DMII

10 *5 80905360 ROLLER R SF-10DJ 1 S

#5 80903542 ROLLER R AS SF-10DR 1 S

11 *5 80905370 ROLLER L SF-10DJ 1 S

#5 80903543 ROLLER L AS SF-10DR 1 S

12 80903030 SET PLATE R SF-10DM 1 FOR SF-10DM/15DM S

#6 80903768 SET PLATE R SF-10DMII 1 FOR SF-10DMII/15DMII S

13 80905290 POSITIONING BEARING SF-10DJ 1

14 80905460 CLUTCH A SF-10DJ 1

15 80905560 CLAW SPRING SF-10DJ 1

16 80905470 CLAW SF-10DJ 1

17 80905450 CLUTCH B SF-10DJ 1

18 80905440 RATCHET SF-10DJ 1

19 80905430 BRAKE SPRING SF-10DJ 1

20 80904500 LEVER GEAR SF-10D 2

21 80903060 GEAR 2 SF-10DM 1

22 80903130 PARKING LEVER SF-10DM 1 FOR SF-10DM/15DM S

#6 80903769 PARKING LEVER SF-10DMII 1 FOR SF-10DMII/15DMII S

23 80903090 GEAR 5 SF-10DM 1

24 80903140 SPRING SF-10DM 1

25 80903070 GEAR 3 SF-10DM 1

26 *5 80903110 COLLAR SF-10DM 2

#5 80905570 COLLAR SF-10DJ 2

27 80903050 GEAR 1 SF-10DM 2

28 80903120 BEARING SF-10DM 4

29 80903100 GEAR 6 SF-10DM 2 S

30 80903080 GEAR 4 SF-10DM 2

31 80903010 SIDE COVER R SF-10DM 1 FOR SF-10DM/15DM S

#6 80903767 SIDE COVER R SF-10DMII 1 FOR SF-10DMII/15DMII S

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

62

32 80903040 SET PLATE L SF-10DM 1 FOR SF-10DM/15DM S

#6 80903779 SET PLATE L SF-10DMII 1 FOR SF-10DMII/15DMII S

33 80903270 LEVER SF-10DM 1 FOR SF-10DM/15DM S

#6 80903781 LEVER SF-10DMII 1 FOR SF-10DMII/15DMII S

34 80903280 SCREW SF-10DM 1

35 80903020 SIDE COVER L SF-10DM 1 FOR SF-10DM/15DM S

#6 80903771 SIDE COVER L SF-10DMII 1 FOR SF-10DMII/15DMII S

36 80904630 HOPPER UNIT R SF-10D 1 FOR SF-10DM/15DM

#6 80903744 HOPPER UNIT R SF-10DT 1 FOR SF-10DMII/15DMII

37 80904660 CORNER SEPARATOR R SF-10D 1 FOR SF-10DM/15DM

#3 80903622 CORNER SEPARATOR R SF-10DMII 1 FOR SF-10DMII/15DMII

38 80904650 SEPARATOR SPRING SF-10D 2

39 80904680 SPRING COVER SF-10D 2 FOR SF-10DM/15DM

#6 80903743 SPRING COVER SF-10DT 2 FOR SF-10DMII/15DMII

40 80904710 O-RING SF-10D 2 S

41 80904300 BUSHING SF-10D 4

42 80904720 HOPPER SUPPORT SF-10D 1 FOR SF-10DM/15DM S

#6 80903745 HOPPER SUPPORT SF-10DT 1 FOR SF-10DMII/15DMII S

43 80905180 PRESSURE PLATE R SF-10DP 1 FOR SF-10DM/15DM

#3 80903624 PRESSURE PLATE R SF-10DMII 1 FOR SF-10DMII/15DMII

44 80905190 PRESSURE PLATE L SF-10DP 1 FOR SF-10DM/15DM

#3 80903625 PRESSURE PLATE L SF-10DMII 1 FOR SF-10DMII/15DMII

45 *6 80905550 HOPPER SPRING SF-10DJ 2

#6 80904370 HOPPER SPRING SF-10D 2

46 80904640 HOPPER UNIT L SF-10D 1 FOR SF-10DM/15DM

80903748 HOPPER UNIT L SF-10DT 1 FOR SF-10DMII/15DMII

47 80904670 CORNER SEPARATOR L SF-10D 1 FOR SF-10DM/15DM

#3 80903623 CORNER SEPARATOR L SF-10DMII 1 FOR SF-10DMII/15DMII

48 80903290 STACK WIRE SF-10DM 2 FOR SF-10DM/10DMII S

80903290 STACK WIRE SF-10DM 3 FOR SF-15DM/15DMII S

49 80905410 HOPPER ATTACHMENT SF-10DJ 1 FOR SF-10DM/15DM S

#3 80903629 HOPPER WIRE SF-10DMII 1 FOR SF-10DMII/15DMII S

50 04020010 STOP RING SE2.0 1 S

51 04020015 STOP RING SE3.0 5 S

52 04020016 STOP RING SE4.0 4 S

53 04020017 STOP RING SE5.0 3 S

54 00630804 SCREW TR 3-8 6 S

55 01903045 SCREW TR 3-8 FL 1 S

56 01903060 SCREW TAT 3-8 PT-FL 5 FOR SF-10DM/15DM S

#3 01903060 SCREW TAT 3-8 PT-FL 7 FOR SF-10DMII/15DMII S

57 #3 80903626 PAPER SEPARATOR R SF-10DMII 1 FOR SF-10DMII/15DMII

58 #3 80903627 PAPER SEPARATOR L SF-10DMII 1 FOR SF-10DMII/15DMII

59 #3 80903628 SUPPORTER SF-10DMII 1 FOR SF-10DMII/15DMII

SF-10DM/10DMII/15DM/15DMII

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

63

4. SF-10DN/10DQ/10DW

4-1. Disassembly Drawing

64

65

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

4-2. Parts List

SF-10DN/10DQ/10DW

1 #3 80903589 FRONT SHEET COVER SF-10DN 1 S

2 #3 80903579 EJECTION ROLLER UNIT SF-10DN 1

3 #3 80903592 SIDE COVER R SF-10DN 1 S

4 #3 80903571 SIDE COVER L SF-10DN 1 S

5 #3 80903576 STACKER BOTTOM SF-10DN 1

6 #3 80903595 REAR STACKER SF-10DN 1 S

7 #3 80903578 HOPPER BOTTOM SF-10DN 1

8 #3 80903597 ROLLER R SF-10DN 1 S

9 #3 80903598 ROLLER L SF-10DN 1 S

10 #3 80903568 ROLLER SHAFT SF-10DN 1

11 #3 80903570 HOPPER SHAFT SF-10DN 1

12 #3 80903564 SHAFT A SF-10DN 1

13 #3 80903593 HOPPER ATTACHMENT SF-10DN 1 S

14 *6 80903561 STACKER ATTACHMENT SF-10DN 1 S

#6 80904790 STACKER ATTACHMENT SF-10D 1 S

15 80905430 BRAKE SPRING SF-10DJ 1

16 80905440 RATCHET SF-10DJ 1

17 #3 80903594 CLUTCH B SF-10DN 1

18 80905460 CLUTCH A SF-10DJ 1

19 #3 80903566 POSITIONING BEARING SF-10DN 1

20 #3 80903615 LEVER GEAR SF-10DN 2

21 #3 80903596 SEPARATOR SPRING SF-10DN 1

22 #3 80903577 GEAR G4 SF-10DN 2

23 #3 80903574 GEAR G3 SF-10DN 1

24 #3 80903591 GEAR G2 SF-10DN 2

25 #3 80903575 GEAR G5 SF-10DN 1

26 #3 80903573 GEAR G6 SF-10DN 3

27 #3 80903590 SET PLATE R SF-10DN 1 S

28 #3 80903572 SET PLATE L SF-10DN 1 S

29 #3 80903588 LEVER SF-10DN 1 S

30 #3 80903565 LEVER SCREW SF-10DN 1

31 #3 80903583 HOPPER COVER R SF-10DN 1

32 #3 80903581 CORNER SEPARATOR R SF-10DN 1

33 #3 80903580 HOPPER UNIT R SF-10DN 1

34 80903120 BEARING SF-10DM 1 S

35 80904300 BUSHING SF-10D 4

36 #3 80903587 HOPPER SUPPORT SF-10DN 1

37 #3 80903585 PRESSURE PLATE R SF-10DN 1

38 #3 80903586 PRESSURE PLATE L SF-10DN 1

39 #3 80903560 HOPPER UNIT L SF-10DN 1

40 #3 80903582 CORNER SEPARATOR L SF-10DN 1

41 #3 80903599 HOPPER SPRING SF-10DN 2

42 #3 80903584 HOPPER COVER L SF-10DN 1

43 #3 80903569 STOP RING SE2.5 SF-10DN 4 S

44 #3 80903614 STOP RING SE3.0 SF-10DN 1 S

45 #3 80903562 STOP RING SE5.0 SF-10DN 1 S

46 01903045 SCREW TR 3-8 FL 1 S

47 01903060 SCREW TAT 3-8 PT-FL 3 S

48 00630804 SCREW TR 3-8 6 S

49 #3 80903567 SCREW TAD 3-10 SF-10DN 2 S

50 #3 80903563 SCREW TAT 3-6 SF-10DN 3 S

51 #3 80903515 REAR COVER R SF-10DN 1 FOR SF-10DN S

#3 80903513 REAR COVER R SF-10DQ 1 FOR SF-10DQ/10DW S

52 #3 80903516 REAR COVER L SF-10DN 1 FOR SF-10DN S

#3 80903514 REAR COVER L SF-10DQ 1 FOR SF-10DQ/10DW S

66

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

#3 80903511 PRINTER COVER SF-10DN 1 FOR SF-10DN S

#3 80903512 PRINTER COVER SF-10DQ 1 FOR SF-10DQ S

#3 80903770 PRINTER COVER SF-10DW 1 FOR SF-10DW S

SF-10DN/10DQ/10DW

67

5. SF-10DS

5-1. Disassembly Drawing

68

69

5-2. Parts List

SF-10DS

1 #4 80903672 FRONT SHEET COVER ASSY SF-10DS 1 S

2 #4 80903673 SHAFT ASSY SF-10DS 1

3 #4 80903674 SIDE COVER R SF-10DS 1 S

4 #4 80903675 SIDE COVER L SF-10DS 1 S

5 #4 80903676 STACKER BOTTOM ASSY SF-10DS 1

6 #4 80903677 REAR STACKER SF-10DS 1 S

7 #4 80903678 HOPPER BOTTOM SF-10DS 1

8 80903597 ROLLER R SF-10DN 1 S

9 80903598 ROLLER L SF-10DN 1 S

10 80903180 SHAFT 4 SF-10DM 1

11 #4 80903679 SHAFT SF-10DS 1

12 80903200 SHAFT 6 SF-10DM 1

13 #4 80903680 HOPPER PLATE SF-10DS 1 S

14 #4 80903681 REAR STACK PLATE SF-10DS 1 S

15 80905430 BRAKE SPRING SF-10DJ 1

16 80905440 RATCHET SF-10DJ 1

17 80903594 CLUTCH B SF-10DN 1

18 #4 80903682 CLUTCH A UNIT SF-10DS 1

19 80903566 POSITIONING BEARING SF-10DN 1

20 80903615 LEVER GEAR SF-10DN 2

21 80903596 SEPARATOR SPRING SF-10DN 2

22 #4 80903683 GEAR A SF-10DS 1

23 80903574 GEAR G3 SF-10DN 1

24 80903591 GEAR G2 SF-10DN 2

25 #4 80903684 GEAR B SF-10DS 1

26 #4 80903685 GEAR C SF-10DS 1

27 #4 80903686 SET PLATE R SF-10DS 1 S

28 #4 80903687 SET PLATE L SF-10DS 1 S

29 80903588 LEVER SF-10DN 1 S

30 80903565 LEVER SCREW SF-10DN 1

31 80903583 HOPPER COVER R SF-10DN 1

32 80903581 CORNER SEPARATOR R SF-10DN 1

33 80903580 HOPPER UNIT R SF-10DN 1

34 80903120 BEARING SF-10DM 1 S

35 80904300 BUSHING SF-10D 4

36 80903587 HOPPER SUPPORT SF-10DN 1

37 80903585 PRESSURE PLATE R SF-10DN 1

38 80903586 PRESSURE PLATE L SF-10DN 1

39 80903560 HOPPER UNIT L SF-10DN 1

40 80903582 CORNER SEPARATOR L SF-10DN 1

41 80903599 HOPPER SPRING SF-10DN 2

42 80903584 HOPPER COVER L SF-10DN 1

43 #4 80903688 HOOK R SF-10DS 1

44 80903569 STOP RING SE2.5 SF-10DN 4 S

45 80903614 STOP RING SE3.0 SF-10DN 1 S

46 #4 80903726 STOP RING SF-10DS 1 S

47 #4 80903727 SCREW SF-10DS 1 S

48 80903644 TAPPING SCREW SF-15DKP 3 S

49 80903563 SCREW TAT 3-6 SF-10DN 1 S

50 #4 80903689 TAPPING SCREW SF-10DS 8 S

51 #6 80903776 HOOK L SF-10DS 1

#4 80903541 PRINTER COVER SF-10DS 1 S

DRWG.NO. REV. PARTS NO PARTS NAME QTY REMARKS RANK

Printed in Japan, 80823516-A

ASF

Distributed by

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA INC.

70-D Ethel Road West.

Piscataway, NJ 08854-5950, U.S.A

Tel: 908-572-5550

Telefax: 908-572-5693

HEAD QUARTERS

STAR MICRONICS CO., LTD. JAPAN

536 Nanatsushinya, Shimizu,

Shizuoka, 424, Japan

Tel: 0543-47-0113

Telefax: 0543-48-5013

STAR MICRONICS PTY. LTD.

Unit A/107-115 Asquith Street,

Silverwater, NSW 2141

Australia

Tel: 02-748-4300

Telefax: 02-748-3527

STAR MICRONICS ASIA LTD.

18/F., Tower II, Enterprise Square

9 Sheung Yuet Road, Kowloon Bay

Hong Kong

Tel: 2796-2727

Telefax: 2799-9344

STAR MICRONICS (N.Z.) LTD.

64 Lunn Ave. Mount Wellington

P.O. Box 6255, Wellesley St.,

Auckland, New Zealand.

Tel: 570-1450

Telefax: 570-1448

STAR MICRONICS DEUTSCHLAND GMBH

Westerbachstrae 59 P.O.Box 940330

D-60489 Frankfurt/Main 90

F.R.of Germany

Tel: 069-789990

Telefax: 069-781006

Telex: 417 5825 STAR D

STAR MICRONICS U.K.LTD.

Star House, Peregrine Business

Park, Gomm Road, High Wycombe

Bucks, HP13 7DL U.K.

Tel: 01494-471111

Telefax: 01494-473333

Das könnte Ihnen auch gefallen

- Application Bus PassDokument1 SeiteApplication Bus PassSunny SinghNoch keine Bewertungen

- dc550 PDFDokument2 Seitendc550 PDFSunny SinghNoch keine Bewertungen

- Quick Use Guide: Workcentre 7132Dokument32 SeitenQuick Use Guide: Workcentre 7132Sunny SinghNoch keine Bewertungen

- Sharp Ar 5320eDokument10 SeitenSharp Ar 5320ePega SuzeNoch keine Bewertungen

- HP LaserJet 1000 Service ManualDokument134 SeitenHP LaserJet 1000 Service ManualbellobevaNoch keine Bewertungen

- ElectroDokument24 SeitenElectroTamilselvi ManuvelNoch keine Bewertungen

- Xerox Workcentre 5632/5638/5645/5655/5665/5675/5687 Multifunction Systems Security TargetDokument89 SeitenXerox Workcentre 5632/5638/5645/5655/5665/5675/5687 Multifunction Systems Security TargetSunny SinghNoch keine Bewertungen

- All Copier Error CodesDokument699 SeitenAll Copier Error Codesprejby90% (10)

- 02 ErrorCodesDokument60 Seiten02 ErrorCodesrcgeistNoch keine Bewertungen

- Summer NewsDokument5 SeitenSummer NewsSunny SinghNoch keine Bewertungen

- Compudirect, Inc.: This Document Was Provided byDokument36 SeitenCompudirect, Inc.: This Document Was Provided bySunny SinghNoch keine Bewertungen

- XEROX WorkCentre M20 4118 Final Service Manual Pages - PDF For Free - EbookBrowseeDokument17 SeitenXEROX WorkCentre M20 4118 Final Service Manual Pages - PDF For Free - EbookBrowseeFrancisco Roque0% (1)

- Toshiba BD-2060 2860 Service HandBookDokument60 SeitenToshiba BD-2060 2860 Service HandBookgiulio70100% (3)

- Basic Electronics LECTURE1Dokument13 SeitenBasic Electronics LECTURE1Nishad.K.SaleemNoch keine Bewertungen

- Fc220 Service ManualDokument197 SeitenFc220 Service ManualongkybpNoch keine Bewertungen

- Cs3035 PM ListDokument15 SeitenCs3035 PM ListSunny SinghNoch keine Bewertungen

- Canon CLC-1120, 1130, 1150 SMDokument274 SeitenCanon CLC-1120, 1130, 1150 SMkdo2nyNoch keine Bewertungen

- Compudirect, Inc.: This Document Was Provided byDokument36 SeitenCompudirect, Inc.: This Document Was Provided bySunny SinghNoch keine Bewertungen

- Spare Parts List: Figure B-1 Upper Cover AssyDokument11 SeitenSpare Parts List: Figure B-1 Upper Cover AssySunny SinghNoch keine Bewertungen

- Advanced User'S Guide: MFC-J430W MFC-J432WDokument40 SeitenAdvanced User'S Guide: MFC-J430W MFC-J432WSunny SinghNoch keine Bewertungen

- Dell Proxm PRNTG User's Guide en UsDokument40 SeitenDell Proxm PRNTG User's Guide en UsSunny SinghNoch keine Bewertungen

- Brother HL1060Dokument105 SeitenBrother HL1060Anonymous WD109UakyNoch keine Bewertungen

- DevelopD 16G SMDokument239 SeitenDevelopD 16G SMColesniuc AlinNoch keine Bewertungen

- Brother 190 SM 04Dokument19 SeitenBrother 190 SM 04Sunny SinghNoch keine Bewertungen

- Dell-Mfp1125 User's Guide En-UsDokument111 SeitenDell-Mfp1125 User's Guide En-UsSunny SinghNoch keine Bewertungen

- MFX 1930Dokument6 SeitenMFX 1930Sunny SinghNoch keine Bewertungen

- Dell Proxm PRNTG User's Guide2 en UsDokument11 SeitenDell Proxm PRNTG User's Guide2 en UsSunny SinghNoch keine Bewertungen

- Setting Passbook Ibm Wincor Pr2e NewDokument16 SeitenSetting Passbook Ibm Wincor Pr2e NewSiba PrasadNoch keine Bewertungen

- Minolta Ep1050 ServiceDokument266 SeitenMinolta Ep1050 ServiceSunny SinghNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)