Beruflich Dokumente

Kultur Dokumente

Shaper

Hochgeladen von

santhanam920 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

91 Ansichten5 Seitenintroduction of shaper machine

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenintroduction of shaper machine

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

91 Ansichten5 SeitenShaper

Hochgeladen von

santhanam92introduction of shaper machine

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

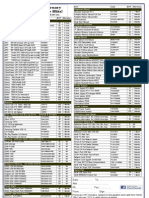

Sie sind auf Seite 1von 5

The Shaper

The shaper is a relatively simple machine. It is a

reciprocating type of machine tool used for producing

small flat surfaces with the help of a single point tool

reciprocating over the stationary work piece. I t is used

fairly often in the tool room or for machining one or two

pieces for prototype work. Tooling is simple, and shapers

do not always require operator attention while cutting.

Typical cuts made by both shapers and planers. (On

the basis of position and travel of Ram)

1. The horizontal shaper: The horizontal shaper is

the most common type, and its principal components are shown below, and described as

follows:

Ram: Ram is the main moving part of a shaper. It holds and drives a cutting tool back

and forward across the work in dovetail or square ways to transmit power to the cutter. It

is attached to the rocker arm which gives an oscillating motion by the turning of large

driving gear. An adjustable pin attached to the driving gear acts as a crank which

determines the length of the stroke of ram. The starting point and the length of the stroke

can be adjusted. It caries a tool-slide on its head.

Tool-head: The tool holds a cutting tool. Its head is attached to the front portion of the

ram and it may be swiveled to a required angle to the left or the right and locked in place.

It may also adjust vertically and locked in position. So it can also rotate for making

angular cuts. It is used to hold the tool rigidity. The tool head can also be moved up or

down by its hand crank for precise depth adjustments. The tool-post is fastened to a

clapper block, which is hinged at the top to permit the tool to ride over the work on return

stork.

(Attached to the tool-head is the tool-holding section. This has a tool post very similar to

that used on the engine lathe. The block holding the tool post can be rotated a few

degrees so that the cutter may be properly positioned in the cut.)

Clapper Box: The clapper box is needed because the cutter drags over the work on the

return stroke. The clapper box is hinged so that the cutting tool will not dig in. Often this

clapper box is automatically raised by mechanical, air, or hydraulic action.

Table: The table is a metal box attached to the frame of shaper. It has T slots on the top

& sides which are used for clamping the work or a vise to table. It is moved left and right,

usually by hand, to position the work under the cutter when setting up. Then, either by

hand or more often automatically, the table is moved sideways to feed the work under the

cutter at the end or beginning of each stroke.

1

Apron: It supports the table on the cross rail and moves across it from left to right.

Saddle: The saddle moves up and down (Y axis), usually manually, to set the rough

position of the depth of cut. Final depth can be set by the hand crank on the tool head.

Column: The column supports the ram and the rails. The

mechanism for moving the ram and table is housed inside

the column.

Base: It is the heavy structure of cast iron which supports

other part of the shaper. It is also a reservoir for oil supply

to different part of shaper.

The horizontal shaper is the most common type.

Tool holders: Tool holders are the same as the ones used on an engine lathe, though

often larger in size. The cutter is sharpened with rake and clearance angles similar to

lathe tools, though the angles are smaller because the work surface is usually flat. These

cutters are fastened into the tool holder, just as in the lathe, but in a vertical plane.

Work holding: Work holding is frequently done in a vise. The vise is specially designed

for use in shapers and has long ways which allow the jaws to open up to 14 or more,

therefore quite large workpieces can be held. The vise may also have a swivel base so

that cuts may be made at an angle. Work that cannot be held in the vise (due to size or

shape) is clamped directly to the shaper table in much the same way as parts are secured

on milling machine tables.

Shaper Size: The size of a shaper is the maximum length of stroke which it can take.

Horizontal shapers are most often made with strokes from 16 to 24 long, though some

smaller and larger sizes are available. These shapers use from 2- to 5-hp motors to drive

the head and the automatic feed.

Shaper Width: The maximum width which can be cut depends on the available

movement of the table. Most shapers have a width capacity equal to or greater than the

length of the stroke. The maximum vertical height available is about 12 to 15.

Drive Mechanisms: Shapers are available with either mechanical or hydraulic drive

mechanisms. Figures below show diagrams of both shaper

drive mechanisms.

Mechanical Drive: The less expensive shaper, the one most

often purchased, uses a mechanical drive. This drive uses a

crank mechanism. The bull gear is driven by a pinion which

is connected to the motor shaft through a gear box with

four, eight or more speeds available. The RPM of the bull

2

gear becomes the strokes per minute (sometimes abbreviated SPM) of the shaper.

Shapers are available with either (a) mechanical drive mechanisms or (b) hydraulic

drive mechanisms.

Cutting Speed: The cutting speed of the tool across the work will vary during the stroke

as shown by the velocity diagram. The maximum is at the center of the stroke. However,

if the cutting speed chosen is somewhat on the slow side, the average speed may be used,

and computations are greatly simplified.

Although the ratio varies somewhat, several shapers have a linkage using 220 degrees of

the cycle for the cutting stroke and 140 degrees for the return stroke. This is close to a

3:2 ratio.

In setting up a mechanically operated shaper, the length of cut (in inches) is known, and

the cutting speed (in feet per minute) is selected according to the kind of metal being cut.

It is then necessary to compute the strokes per minute since that is how the shaper speed

is controlled. Such calculations are beyond the scope of this text.

The stroke per minute available on a shaper will vary according to the size of the shaper.

The larger shapers will have lower speeds. A 16 shaper may have speeds of 27 to 150

strokes per minute, while a 24 shaper will have 10 to 90 strokes per minute speeds

available.

Cutting Feed: Feed per stroke on a shaper is comparable to the feed per revolution on a

lathe. Coarse feeds for roughing range up to 0.100 per stroke (sometimes abbreviated as

IPS), and finish cuts from 0.005 to 0.015 per stroke. Finish would also depend on the

nose radius of the cutting tool.

Hydraulic Drive

The hydraulic shaper has the same major parts as the mechanical one; however, the ram

is driven by a hydraulic cylinder as shown in the simplified sketch. These shapers use 5-

to 10-hp motors.

Cutting Speed and Feed: The cutting speed of the hydraulic

shaper is infinitely variable by means of hydraulic controls, as

is the cross feed. The reverse stroke is made faster than the

power stroke because of the smaller area in the return side of

the cylinder, if a constant volume pump is used. Another

method is to have the rate of fluid flow increased to speed up

the return stroke.

Speed and feed on a hydraulic shaper are often controlled by

directly in feet per minute and feed is read directly in decimal

inches. The cutting speed remains nearly constant through the full stroke.

simple dials. Speed is read

3

2 Vertical Shapers

The vertical shaper, sometimes called a slotter, has a vertical ram, with table and saddle

similar to the horizontal shaper. If a rotary table is mounted on the regular table, a number of slots

can be made at quite accurately spaced intervals. This machine can work either outside or inside a

part, provided that the interior opening is larger than the tool head. It is similar to a horizontal

shaper except that the ram reciprocates vertically rather than horizontally. A slide, into which the

ram is mounted, can be adjusted to an angle with respect to the vertical position so that the ram

can reciprocate at this angle. The table can be moved in 2 perpendicular directions as well as can

rotate.

Such a combination of table movement enables the vertical shaper to cut vertical

plane surfaces, round or partially round surfaces, and surface with an irregular profile.

Its principal components are shown below, and described

as follows:

Bed: The bed of the planer must be a weldment or

casting twice as long as the table. Thus a 12-foot table

requires a 24-foot bed. The gearing of hydraulic

cylinders for driving the table is housed under the bed.

Tool holders: Planers use high-speed steel or carbide tipped

cutting tools similar to those used on shapers. Since planers

make heavy cuts, their tools are much larger. Rake relief

lathes for cutting cast iron or steel, although relief angles are

often only 3 to 5 degrees, because all cuts are on flat surfaces.

angles are similar to those used on

Work holding: Holding the work while machining such heavy cuts at 60 to 100 feet per minute

requires considerable force; therefore, the work pieces must be solidly fastened to the table.

Because the reversal of direction occurs quite rapidly, the work must be especially well braced at

the ends. The table has T-slots, both lengthwise and across, in which heavy bolts and clamps may

be used. Sometimes holes are drilled in the table so that large pins can be used to prevent the

work piece from going off the table when the machine reverses.

Planer Size: The size of planers is often referred to as a 30 planer or a 60 planer. This

specifies the approximate width of the table which ranges from 30 to 72. A more

complete specification is:

Width of table x height under rail x length of table (For

example: 48 x 48 x 14 feet)

The width and height are usually, but not always, the

same. Table length is often made to order and may be as

short as 8 feet, or as long as 20 feet or more. The drive

4

may be 15 hp on the smaller planers, and 100 hp or more on the larger models.

A double-housing planer.

Mechanical and hydraulic power can be used for planers. Uniform cutting speed is

attained throughout the cutting stroke. Acceleration and deceleration of the table takes

place in a short distance of travel and does not influence the time to machine.

Double-housing Planers: Double-housing planers consist of a long heavy base on which

the table reciprocates. The upright housing near the center on the side of the base,

supports the cross rail on which the tools are fed across the work. The earlier illustration

shows how the tools are supported both above and on the sides, and their adjustment for

angle cuts. They are fed by power in either a vertical or a crosswise direction.

Open-sided Planers: Open-sided planers have the housing on one side only. The open

side permits machining wider work pieces. Most planers have one flat and one double V-

way, which allows for unequal bed and platen expansions. Adjustable dogs at the side of

the bed control the stroke length of the platen.

Planers are often converted to planer-mills, for more efficient machining.

3 Comparison of Shapers and Planers

Although both the planer and the shaper are able to machine flat surfaces, there is little

overlapping in their application. They differ greatly in construction and in the method of

operation. The planer is especially adapted to large work: the shaper can do only small

work. On the planer the work is moved against a stationary tool: on the shaper the tool

moves across the work, which is stationary. On the planer the tool is fed into the work; on

the shaper the work is usually fed across the tool. The drive on the planer table is either

by gears or by hydraulic means. The shaper ram also can be driven in this manner, but

many times a quick-return link mechanism is used.

Most planers differ from shapers in that they approach more constant-velocity cutting

speeds. Tools used in shaper and planer work are single point as used on a lathe, but are

heavier in construction. The holder is designed to secure the tool bit near the centerline of

the holder or the pivot point rather than at an angle as is customary with lathe tool

holders.

Cutting tools for the planer operation are usually tipped with high-speed steel, cast alloy,

or carbide inserts. High-speed steel or cast alloys are commonly used in heavy roughing

cuts and carbides for secondary roughing and finishing.

Cutting angles for tools depend on the tool used and the work piece material. They are

similar to angles used on other single-point tools, but the end clearance does not exceed 4

degrees. Cutting speeds are affected by the rigidity of the machine, how the work is held,

tool, material, and the number of tools in operation. Worktables on planers and shapers

are constructed with T-slots to hold and clamp parts that are to be machined.

5

Das könnte Ihnen auch gefallen

- Advanced Machining ProcessesDokument26 SeitenAdvanced Machining Processessanthanam92Noch keine Bewertungen

- Microstructural and Fracture Analysis of Aged Cast Gx2Crnimocu25-6-3-3 Duplex Stainless SteelDokument6 SeitenMicrostructural and Fracture Analysis of Aged Cast Gx2Crnimocu25-6-3-3 Duplex Stainless Steelsanthanam92Noch keine Bewertungen

- Bhagat Singh Yean Naan NathiganDokument21 SeitenBhagat Singh Yean Naan Nathiganஇளம்பருதி தமிழன்75% (4)

- Failure in BambooDokument11 SeitenFailure in Bamboosanthanam92Noch keine Bewertungen

- IstecatDokument166 SeitenIstecather hue VitoNoch keine Bewertungen

- Forming (NPTEL Web Course)Dokument621 SeitenForming (NPTEL Web Course)abhisheks5987100% (5)

- Pesquisa Operacional Usando GLPKDokument201 SeitenPesquisa Operacional Usando GLPKFabricio BarrosNoch keine Bewertungen

- Reactive Processing of Polymers Begishev VP Malkin AY ChemTec 1999Dokument260 SeitenReactive Processing of Polymers Begishev VP Malkin AY ChemTec 1999santhanam92Noch keine Bewertungen

- Introduction To Carbon NanotubesDokument72 SeitenIntroduction To Carbon Nanotubessanthanam92100% (1)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lecture 1: Introduction To Network SecurityDokument40 SeitenLecture 1: Introduction To Network SecurityPinnamaneni_Dh_1228Noch keine Bewertungen

- Ontario Driving Licence PDFDokument161 SeitenOntario Driving Licence PDFsalimrejaNoch keine Bewertungen

- Is 2986Dokument9 SeitenIs 2986sreenathaNoch keine Bewertungen

- The Building and Other Construction WorkersDokument2 SeitenThe Building and Other Construction WorkersShreejith100% (1)

- PCS-902 - X - Instruction Manual - EN - Overseas General - X - R2.01 PDFDokument556 SeitenPCS-902 - X - Instruction Manual - EN - Overseas General - X - R2.01 PDFAyub HasersNoch keine Bewertungen

- RADIUS Setup: Figure 2. Configuring The RADIUS SettingsDokument30 SeitenRADIUS Setup: Figure 2. Configuring The RADIUS SettingsvenkataNoch keine Bewertungen

- Total Containment Trap Brochure 0216Dokument7 SeitenTotal Containment Trap Brochure 0216alsexeNoch keine Bewertungen

- Cisco Model Epc3940 and Epc3940L Eurodocsis 3.0 16X4 W Ireless Residential Gateway With Embedded Digital Voice Adapter User GuideDokument54 SeitenCisco Model Epc3940 and Epc3940L Eurodocsis 3.0 16X4 W Ireless Residential Gateway With Embedded Digital Voice Adapter User Guidemanuolo27Noch keine Bewertungen

- PretestingPRV PDFDokument5 SeitenPretestingPRV PDFIvan RocoNoch keine Bewertungen

- LTE Radio Parameters RL60 Idle Mode Mobility-NokiaDokument37 SeitenLTE Radio Parameters RL60 Idle Mode Mobility-Nokiavishalkavi18Noch keine Bewertungen

- BSC6900V900R012 UO System Structure-20101218-B-V1.0Dokument99 SeitenBSC6900V900R012 UO System Structure-20101218-B-V1.0Dinesh Raja MNoch keine Bewertungen

- Led Daylight 4 Installation Guide.1-6Dokument6 SeitenLed Daylight 4 Installation Guide.1-6petricabogdanNoch keine Bewertungen

- As 60044.1-2007 Instrument Transformers Current Transformers (IEC 60044-1 Ed.1.2 (2003) MOD)Dokument10 SeitenAs 60044.1-2007 Instrument Transformers Current Transformers (IEC 60044-1 Ed.1.2 (2003) MOD)SAI Global - APACNoch keine Bewertungen

- 580 SM Service 3 PDFDokument1.467 Seiten580 SM Service 3 PDFcruz Tobilla75% (4)

- D800 BrochureDokument4 SeitenD800 BrochurefrankNoch keine Bewertungen

- Cryptography PDFDokument270 SeitenCryptography PDFVishnu Das KNoch keine Bewertungen

- DPoE SP OAMv2.0 I14 190213Dokument115 SeitenDPoE SP OAMv2.0 I14 190213Testgame GameonlyNoch keine Bewertungen

- Bondwell Specials Combo SpecDokument1 SeiteBondwell Specials Combo SpecMaxFijiNoch keine Bewertungen

- Catalogue - LS-Titan Position SwitchesDokument33 SeitenCatalogue - LS-Titan Position SwitchesRicardo CalmonNoch keine Bewertungen

- New Degree Program Proposal GuidelinesDokument9 SeitenNew Degree Program Proposal GuidelinesS22Noch keine Bewertungen

- ZTE LTE FDD Clock Synchronization Feature GuideDokument103 SeitenZTE LTE FDD Clock Synchronization Feature Guidem2adeelNoch keine Bewertungen

- Digital SingatureDokument1 SeiteDigital SingatureFilipe LouroNoch keine Bewertungen

- ReportDokument172 SeitenReportAnonymous MBsUH11tNoch keine Bewertungen

- Whitepaper Kerio Control Vs Other UTMsDokument2 SeitenWhitepaper Kerio Control Vs Other UTMsadi wibowo yudo pranotoNoch keine Bewertungen

- Excel Tool Prozessaudit VDA 6.3 2010 enDokument37 SeitenExcel Tool Prozessaudit VDA 6.3 2010 enrodolfo barbosa0% (1)

- Ocb 283 - General Description-Bsnl TrainingDokument55 SeitenOcb 283 - General Description-Bsnl Trainingsihabek83% (6)

- Everest CAD CAM System en 1 004 7802Dokument5 SeitenEverest CAD CAM System en 1 004 7802Mohamed ElsharawyNoch keine Bewertungen

- Is 1897Dokument9 SeitenIs 1897Yuvaraj SathishNoch keine Bewertungen

- Extraction Steam System Design DescriptionDokument14 SeitenExtraction Steam System Design DescriptionKarthik Rampa100% (1)