Beruflich Dokumente

Kultur Dokumente

ME401 Part 8

Hochgeladen von

odvut0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten25 Seitenengine parts

Originaltitel

ME401_part_8

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenengine parts

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten25 SeitenME401 Part 8

Hochgeladen von

odvutengine parts

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 25

Internal Combustion Engines Dr. Md.

Ehsan 2009 ME 401

Emission from IC engines

Expected Products : CO

2

and H

2

O

Undesirable Products :

CO Unburned HC NOx PM SOx Pb

Major Emission Concerns :

SI Engines : CO, Unburned HC, NOx, Pb

CI Engines : PM, NOx, Unburned HC, SOx

Unburned HC :

Major Concern for SI engines.

Could be as high as 6000 ppm, 1.5% of fuel

Constitutes of fuel itself and partially reacted components.

Causes of Formation : Non-Stoichiometric AF ratios of combustion

Incomplete combustion, EGR

Crevice volumes

Valve Overlap

Oil or deposition on combustion chamber wall

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Carbon Monoxide (CO) :

Major Concern for SI engines.

Could be as high as 5% of exhaust volume.

Causes of Formation : Non-Stoichiometric AF ratios of combustion

Incomplete combustion, EGR

Nitrogen Oxides :

Major Concern for both SI and CI engines.

Could be as high as 2000 ppm

Constitutes of No and NO

2

Causes of Formation : High temperature of combustion

Availability of excess Oxygen at high temp

Highest rate at slightly lean mixture (=0.95)

Photo-Chemical Smog :

NO

2

+Energy from Sunlight NO +O O +O

2

O

3

(Ground level)

Particulate Matter (PM) :

Major Concern for CI engines, may be in SI engines at high loads.

High concentration effects the opacity of exhaust (smoke)

Constitutes of Carbon Soot Particle, coated with SO3 and Soluble

Organic Fractions (SOF) of fuel.

Average mean diameter 10 m (PM 10), 2.5 m (PM 2.5)

Causes of Formation : Near-Stoichiometric AF ratios of combustion

Presence of heavy components in the fuel

Richer burning at high loads

At higher temperatures : PM but NO

X

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Sulfur Oxides (SOx) :

Major Concern for CI engines.

Formation : Sulfur in fuel SI (150-600 ppm), CI (5000 ppm-1%)

LSD (low sulfur diesel), ULSD (Ultra low sulfur diesel <50ppm)

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Emission Standards :

Emission Standards may vary in different countries. The standards are

getting stringent day by day.

EURO stand. CARB stand. FTP stand. EPA stand. Mode stand.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Vehicle Emission test on Chassis Dynamometer

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Driving Cycles

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Measurement of Engine Emissions

ORSAT APPARATUS

In the Orsat apparatus the analysis is

determined volumetrically appears on a

dry basis. It is convenient for

measurement of CO

2

, CO and O

2

. The

exhaust sample is exposed to a number

of chemicals which absorb one of the

constituent components.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Gas Analyzers

3-Gas Analyzers : CO

2

, CO and HC

4-Gas Analyzers : CO

2

, CO, HC and remaining Oxygen

5-Gas Analyzers : CO

2

, CO, HC, remaining Oxygen and NOx

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

NDIRA : Mostly used for measuring gases like CO, CO

2

and Total HC

CO

2

absorbs radiation 4-4.5 m, CO absorbs radiation 4.5-5 m

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

FID is mainly used for unburned HC measurement. Pure Ar-H

2

flames use

very little ionization but this changes with the presence of HC in exhaust.

NO

x

and O

2

measurement is generally done using electro-chemical cells.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Smoke Meters :

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Emission Control Techniques

Pre-Engine System : Hot Air Intake System

In-Engine System : MPFI, EGR, -sensor

Post-Engine System : Thermal reactor, Catalytic Converter, DPF

Manufacture needs to attain the tail pipe emission as per the standard, which

may be done involving one or more of the systems.

Typical Sources of Emission from an Automobile

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Emission as a function of Equivalence ratio In a SI engine

Emission as a function of Equivalence ratio In a CI engine

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Thermal Reactors :

They provide more time for the exhaust at about 600C, allowing more

complete combustion of some exhaust components. Mainly involves

oxidation of HC and CO.

Exhaust gas Recirculation (EGR)

EGR % ={m

EGR

/(m

f

+m

a

)} x 100

EGR ensures lower temperature and lower NOx formation, at the cost of

lower volumetric efficiency, thermal efficiency and higher HC formation.

EGR is typically done at the rate of 10-15% of the intake, not exceeding

30%.

EGR is done on top of the normal residual fraction of exhaust gas.

EGR is not done at idling, EGR is not done at WOT.

In CI engines EGR is less common as abrasive soot particles may re-enter

the engine.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

CATALYTIC CONVERTERS (CC)

Typically used for SI engine emission control.

2-WAY Catalytic Converter : Removes CO and HC

3-WAY Catalytic Converter : Removes NOx, CO and HC

Catalytic Converter Efficiency ={1 (m

exhaust out

/ m

exhaust in

)} x 100 %

A CC may have different removal efficiencies for different components.

The Alumina wash coat ( about 20 m) containing the noble materials is

used to enhance the surface area ( 100-200 m

2

/g) of chemical reaction.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Catalysts (Noble metals) :

Platinum(Pt), Rhodium (Rd), Palladium(Pd); About 4-5 g/cat converter.

CC could be either Monolith(Honey-comb) or Pellet(Bead) type.

2-Way Catalytic Converter : Catalysts - Pt, Pd

Oxidation reaction : CO +O

2

CO

2

HC +O

2

CO

2

+H

2

O

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

3-Way Catalytic Converter : Catalysts - Pt, Rd, (Pd)

Reducing reaction :

NO +CO N

2

+CO

2

2 NO +5H

2

2NH

3

+2H

2

O

NO +H

2

N

2

+H

2

O 2NO +5CO +3H

2

O 2NH

3

+5CO

2

Oxidation reaction : CO +O

2

CO

2

HC +O

2

CO

2

+H

2

O

3-way catalytic converters work best with engines having precise

control of air-fuel ratio. Many of them use O2 sensors incorporated at

the exhaust, communicating with the engine management system.

Specially the NOx reduction reaction requires very accurate air-fuel

ratio, regular carburetors and simple fuel-injection are simply too

inaccurate to keep up to the requirement.

Catalytic converters stars working effectively as they get warm above

250-300C. The reactions taking place are exothermic. Converter

material should be able to with stand up to 1000C. Generally heat

shields are used to protect other parts of the vehicle body.

Extra oxygen is needed to support the reactions, that might be

provided by lean air-fuel ratio or pump-type air injection.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Unleaded (Pb free) fuel is essential to prevent Fouling of Catalytic

converters.

Most common cause of failure is an engine that pumps too much

unburned fuel, which can overheat or carbon-clog the catalyst.

Fuel specification like Sulpher content should be maintained to

prevent catalyst poisoning detoriating performance.

Fouling, clogging, meltdown, breakage of ceramic substance may

cause a converter to stop doing its job, and/or plug it and raise back

pressure.

In most automobiles you need to use a silencer in addition the

catalytic converter to achieve desired low noise level.

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

DIESEL PARTICULATE FILTER (DPF)

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Mitsubishi DPF System

Internal Combustion Engines Dr. Md. Ehsan 2009 ME 401

Selective Catal ytic Reduction (SCR) is the process whereby a reductant such

as ammonia or urea is mixed with NOx emissions then passed through a special

flow-through catalyst to create a reduction process. During the process, the

ammonia-NOx mixture is converted into harmless nitrogen and water.

Comparative performance of various emission control systems

for diesel engines

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Sop For Spill KitDokument1 SeiteSop For Spill KitodvutNoch keine Bewertungen

- Gas Engine Emissions Technology 4th EditionDokument16 SeitenGas Engine Emissions Technology 4th EditionLenin Marcel Fajardo AlmeidaNoch keine Bewertungen

- Examples of Community Nursing DiagnosisDokument5 SeitenExamples of Community Nursing Diagnosiskitsilc72% (18)

- 54 IMS ManualDokument41 Seiten54 IMS ManualodvutNoch keine Bewertungen

- DebentureDokument34 SeitenDebentureSOHEL BANGINoch keine Bewertungen

- TDC-15-S-07-1 Special Laws V92021Dokument113 SeitenTDC-15-S-07-1 Special Laws V92021Reynald Apostol100% (1)

- Save Earth Essay 1 (100 Words)Dokument3 SeitenSave Earth Essay 1 (100 Words)Manastirea ContNoch keine Bewertungen

- Science9 q1 Mod5 Biodiversity-And-Evolution v3Dokument41 SeitenScience9 q1 Mod5 Biodiversity-And-Evolution v3aymee8yerro8paminian80% (5)

- EIA GUIDELINES FOR INDUSTRIES - Farid DoneDokument129 SeitenEIA GUIDELINES FOR INDUSTRIES - Farid DoneodvutNoch keine Bewertungen

- Parameter Unit Bangladesh India Pakistan Myanmar Bhutan Bgmea RecommendedDokument2 SeitenParameter Unit Bangladesh India Pakistan Myanmar Bhutan Bgmea RecommendedodvutNoch keine Bewertungen

- Full Model Name:: Camera FormatDokument1 SeiteFull Model Name:: Camera FormatodvutNoch keine Bewertungen

- MGT Asinment Case Study 03 - 1Dokument13 SeitenMGT Asinment Case Study 03 - 1odvutNoch keine Bewertungen

- Risk Aversion and Utility ValueDokument1 SeiteRisk Aversion and Utility ValueodvutNoch keine Bewertungen

- Feed Tank and Pressure SizingDokument4 SeitenFeed Tank and Pressure SizingodvutNoch keine Bewertungen

- BGMEA Trade InfoDokument13 SeitenBGMEA Trade InfoodvutNoch keine Bewertungen

- Light T5 T8Dokument6 SeitenLight T5 T8odvutNoch keine Bewertungen

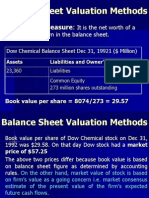

- Balance Sheet Valuation Methods: Book Value MeasureDokument43 SeitenBalance Sheet Valuation Methods: Book Value MeasureodvutNoch keine Bewertungen

- IM Keya CottonDokument70 SeitenIM Keya CottonodvutNoch keine Bewertungen

- Listing RegulationDokument38 SeitenListing RegulationodvutNoch keine Bewertungen

- Brac Research Solar BDDokument15 SeitenBrac Research Solar BDodvutNoch keine Bewertungen

- Grant ProposalDokument9 SeitenGrant ProposalNicci SperczakNoch keine Bewertungen

- Evs CiaDokument8 SeitenEvs CiaShravan Subramanian BNoch keine Bewertungen

- MEM Micro-ProjectDokument16 SeitenMEM Micro-ProjectGanesh GoreNoch keine Bewertungen

- Lab Report Air ParticleDokument11 SeitenLab Report Air ParticleSalmah AbasNoch keine Bewertungen

- Shipping Solutions:: Technological and Operational Methods Available To Reduce CoDokument28 SeitenShipping Solutions:: Technological and Operational Methods Available To Reduce CoCvitaCvitić100% (1)

- Assignment#1 1Dokument5 SeitenAssignment#1 1Marial JavierNoch keine Bewertungen

- Dictionar DizertatieDokument19 SeitenDictionar DizertatieDiana DeedeeNoch keine Bewertungen

- Pollution in UKDokument13 SeitenPollution in UKHassan TariqNoch keine Bewertungen

- Air Quality Index: Ashly Naysha Soto Vargas Pd. 7 Mrs. I. Sierra Env. ScienceDokument5 SeitenAir Quality Index: Ashly Naysha Soto Vargas Pd. 7 Mrs. I. Sierra Env. Scienceanaysha06Noch keine Bewertungen

- Enviornmental PollutionDokument6 SeitenEnviornmental PollutionSanya RamzanNoch keine Bewertungen

- Q A Traffic ManagementDokument26 SeitenQ A Traffic ManagementChester Cuarentas100% (1)

- PHEngg Handouts and Workbook 4Dokument175 SeitenPHEngg Handouts and Workbook 4AMmarNoch keine Bewertungen

- A Raqeeb Thabit CV IIIDokument7 SeitenA Raqeeb Thabit CV IIIMohammed Ahmed NasherNoch keine Bewertungen

- Student Health and Performance: The Impact of School Buildings OnDokument36 SeitenStudent Health and Performance: The Impact of School Buildings OnAlisher SadykovNoch keine Bewertungen

- Module 3 - Save The Holocene, Save ManDokument20 SeitenModule 3 - Save The Holocene, Save ManPaolo Nicolo OpeñaNoch keine Bewertungen

- Phillips SMR Rail Project Public Draft EIRDokument889 SeitenPhillips SMR Rail Project Public Draft EIRKevin SmithNoch keine Bewertungen

- 2003 0900 Building Healthy CommunitiesDokument40 Seiten2003 0900 Building Healthy CommunitiesDavid FerrerNoch keine Bewertungen

- SSRN Id3697395Dokument5 SeitenSSRN Id3697395akttripathiNoch keine Bewertungen

- Arab Times - Ma 4 Abr 2017Dokument44 SeitenArab Times - Ma 4 Abr 2017Anonymous AE1w0EaPNoch keine Bewertungen

- Vype Made in UK E-LiquidDokument12 SeitenVype Made in UK E-Liquidvapemeisters2Noch keine Bewertungen

- Contaminacion y FN Pulmonar en NiñosDokument14 SeitenContaminacion y FN Pulmonar en NiñosLaura del pinoNoch keine Bewertungen

- EC For Induction Furnaces by East India Holdings PVTDokument4 SeitenEC For Induction Furnaces by East India Holdings PVTChetan MaheshwariNoch keine Bewertungen

- Pre-Lab PM10 Sampling in FoodCourtDokument8 SeitenPre-Lab PM10 Sampling in FoodCourtAjlaa RahimNoch keine Bewertungen

- Brick and Structural Clay ManufacturingDokument20 SeitenBrick and Structural Clay ManufacturingsabrahimaNoch keine Bewertungen