Beruflich Dokumente

Kultur Dokumente

Stainless Steel - Torque Guidelines A2 & A4 - Grampian Fasteners

Hochgeladen von

chandravadiyaketanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stainless Steel - Torque Guidelines A2 & A4 - Grampian Fasteners

Hochgeladen von

chandravadiyaketanCopyright:

Verfügbare Formate

For more information, contact us:

Grampian Fasteners, Grampian House, Pitmedden Road, Dyce, AB21 0DP, Aberdeen

Tel: +44 (0) 1224 772 777 | Fax: +44 (0) 1224 772 778 | Email: sales@grampianfasteners.com

www.grampianfasteners.com

Stainless Steel

Torque applicable to material grades A2 and A4

There are theoretical methods in which tightening torque can be calculated but the coefficient of

friction is required not only for the mating threads but the head of the bolt and/or nut etc.

The problem with tightening torque for black self colour bolts in various grades (not Stainless Steel) is

that up to 90% of the applied torque is employed in overcoming friction; 50% at the bearing face of the

nut, and 40% between the mating threads. Their final comments on the figures they published were

"torque figures are approximate".

It therefore follows seen that only 10% effort is employed in indicating axial load in the bolt. If this is

correct then by applying a lubricant to overcome friction (especially for Stainless Steel when a

lubricant is used to help prevent galling / cold welding) the fasteners may be over torqued and may fail

in tensile because of the increase in pre-axial load.

There are practical methods in which tightening torque can be measured only under near laboratory

conditions to establish the yield point of the thread, this is achieved by applying torque and taking the

work shop theory of tighten to 70 - 80 - 85 or even 90% of yield load.

As indicated all these methods are very inaccurate and at best can only offer a guide to the user.

However there are tables available and by kind permission of the Fastener Engineering and

Research Association they have been reproduced below.

Tightening Torque and Load Applicable to Material Grade A2 and A4

Bolt or

screw

diameter

Property

Class

M3 M4 M5 M6 M8 M10 M12 M14 M16 M20

100 1.7 4.1 8.1 13.9 33.5 66.0 115.0 182.0 280.0 545.0

80 1.2 2.7 5.4 9.3 22.0 44.0 76.0 121.0 187.0 364.0

Tightening

Torque

(Nm) 70 0.9 2.0 4.1 7.0 17.0 33.0 57.0 91.0 140.0 273.0

100 2.9

2

5.1

3

8.32 11.7 21.4 33.9 49.3 67.3 91.8 143.3

80 2.0 3.4 5.5 7.8 14.3 22.6 32.8 44.8 61.2 95.5

Applied

Preload

70 1.5 2.6 4.2 5.9 10.7 17.0 24.7 33.7 46.9 71.7

100 5.0 8.7 14.2 20.1 36.6 58.0 84.3 115.0 157.0 245.0

80 4.0 7.0 11.3 16.1 29.2 46.6 67.4 92.0 125.6 196.0

Failure

Load

70 3.5 6.1 9.9 14.0 25.6 40.6 59.0 80.5 109.9 171.5

100 4.5 7.9 12.8 18.0 33.0 52.2 75.9 103.5 141.3 220.5

80 3.0 5.3 8.5 12.0 21.9 34.8 50.5 69.0 94.2 147.0

Yield

Load

70 2.2 3.9 6.4 9.0 16.4 26.1 37.9 51.8 70.6 110.4

NB: The above tightening torque values have not been verified by Grampian Fasteners, therefore we

can take no responsibility for their use. Due to variations in the coefficient of friction between mating

threads and the bearing face of the nut, seeking the advice of an expert would be prudent for

assembly applications.

Das könnte Ihnen auch gefallen

- Rawlbolt: Shield Anchor Loose BoltDokument2 SeitenRawlbolt: Shield Anchor Loose BoltBappy IslamNoch keine Bewertungen

- Stainless Steel Pre-Load and Tightening TorquesDokument4 SeitenStainless Steel Pre-Load and Tightening TorquesPrasetyaHutamaNoch keine Bewertungen

- Manual Técnico de Parafusos - BOSSARDDokument85 SeitenManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- Iec60273 (Ed3 0) B ImgDokument56 SeitenIec60273 (Ed3 0) B ImgThi Huyen Trang Vu100% (1)

- S.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMDokument12 SeitenS.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMRajiv DamodarNoch keine Bewertungen

- Is 15560 - 2005Dokument12 SeitenIs 15560 - 2005kalpanaadhiNoch keine Bewertungen

- Iso 13920 (1996) PDFDokument13 SeitenIso 13920 (1996) PDFFakrul Hasan100% (1)

- Erection Manual of ERS (Disaster Management)Dokument155 SeitenErection Manual of ERS (Disaster Management)Krishna Murthy100% (2)

- 080M40 (EN8) Specification Chemical CompositionDokument1 Seite080M40 (EN8) Specification Chemical CompositionAmar ThakurNoch keine Bewertungen

- Steel TablesDokument2 SeitenSteel TablesAnonymous mcHqIfbnV1Noch keine Bewertungen

- Metric screw thread parameters and gaugesDokument5 SeitenMetric screw thread parameters and gaugesnoe juarezNoch keine Bewertungen

- 2Dokument345 Seiten2Brijesh MishraNoch keine Bewertungen

- Metric Bolt Torque TableDokument1 SeiteMetric Bolt Torque TableChittaranjan PradhanNoch keine Bewertungen

- Din 580-Lifting Eye Bolts PDFDokument1 SeiteDin 580-Lifting Eye Bolts PDFAntohi CatalinNoch keine Bewertungen

- Universal Beams To BS4 Part 1 - 2005Dokument2 SeitenUniversal Beams To BS4 Part 1 - 2005Jeebers CrrebersNoch keine Bewertungen

- ABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14Dokument14 SeitenABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14cupidkhhNoch keine Bewertungen

- ISO Tolerances For Holes ShaftsDokument4 SeitenISO Tolerances For Holes ShaftsFeeza ZukepeliNoch keine Bewertungen

- 15CVL77-Computer Aided Detailing of StructuresDokument23 Seiten15CVL77-Computer Aided Detailing of StructuresRaghavNoch keine Bewertungen

- BUET Calibration ReportDokument15 SeitenBUET Calibration ReportjamilNoch keine Bewertungen

- Fillet Weld Strength Calculation Example For Welded Connection Subjected To BendingDokument6 SeitenFillet Weld Strength Calculation Example For Welded Connection Subjected To Bendingchetanmale0% (1)

- EN ISO 11542-2 PropertiesDokument17 SeitenEN ISO 11542-2 Propertieschaminda nayanajithNoch keine Bewertungen

- LTS 6 TableOfContents PDFDokument29 SeitenLTS 6 TableOfContents PDFTAHANoch keine Bewertungen

- TurnbuckleDokument6 SeitenTurnbuckleAbi Latiful HakimNoch keine Bewertungen

- 1.4313 enDokument2 Seiten1.4313 envesselNoch keine Bewertungen

- Upn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesDokument3 SeitenUpn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesshankerNoch keine Bewertungen

- Alloy Master LinksDokument1 SeiteAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Strengthening s80m RatioDokument1 SeiteStrengthening s80m RatioJemi TowerNoch keine Bewertungen

- StainlessSteelData (GERPAAS)Dokument4 SeitenStainlessSteelData (GERPAAS)ilovemould100% (1)

- Design of fillet weld as per BS EN 1993 1 8 CL 4.5.3Dokument2 SeitenDesign of fillet weld as per BS EN 1993 1 8 CL 4.5.3Giri DharanNoch keine Bewertungen

- Calculate Bolt StrengthsDokument14 SeitenCalculate Bolt Strengthsgeorge sanchesNoch keine Bewertungen

- BS 6166-2Dokument4 SeitenBS 6166-2FEKINoch keine Bewertungen

- UPA Channel SizesDokument2 SeitenUPA Channel SizesSatish Kumar100% (1)

- Doubler Plate CheckDokument3 SeitenDoubler Plate CheckkarthickNoch keine Bewertungen

- TorqueDokument2 SeitenTorquestaedtlerpNoch keine Bewertungen

- Na2xy-O/ (J) : Din Vde 0276-603 (5G-2)Dokument3 SeitenNa2xy-O/ (J) : Din Vde 0276-603 (5G-2)Asad Ali100% (1)

- Topographic Wind Factor KZT - ASCE 7-10Dokument2 SeitenTopographic Wind Factor KZT - ASCE 7-10zubairmeerNoch keine Bewertungen

- IS 802 Part-2:1978Dokument13 SeitenIS 802 Part-2:1978Sardar. Vikramjit Singh RandhawaNoch keine Bewertungen

- FRP Lighting PolesDokument16 SeitenFRP Lighting PolesManish VaghelaNoch keine Bewertungen

- Structural Steel Fabrication Tolerances GuideDokument6 SeitenStructural Steel Fabrication Tolerances GuideRene Alfonso BeltranNoch keine Bewertungen

- Bolt TighteningDokument6 SeitenBolt TighteningahmedbeaetNoch keine Bewertungen

- Design KN/M.: 388 RelnforcedDokument6 SeitenDesign KN/M.: 388 RelnforcedSubhajyoti DasNoch keine Bewertungen

- Improving Gear Train Performance Through Nonstandard Tooth Proportions and Center DistanceDokument9 SeitenImproving Gear Train Performance Through Nonstandard Tooth Proportions and Center Distanceluis_dominguezeNoch keine Bewertungen

- Bakelite PropertiesDokument6 SeitenBakelite PropertiesAlexander PrasetyaNoch keine Bewertungen

- Standard Bolt Tightening TorqueDokument1 SeiteStandard Bolt Tightening Torquefixer86Noch keine Bewertungen

- Weld SymbolDokument5 SeitenWeld Symbolkayakeras3335Noch keine Bewertungen

- Offshore Testing Services Lab ReportDokument3 SeitenOffshore Testing Services Lab ReportKandula RajuNoch keine Bewertungen

- SABS SANSrenumberinglistFINALDokument92 SeitenSABS SANSrenumberinglistFINALMauridi KaminyuNoch keine Bewertungen

- DEWA Infrastructure GuidelineDokument819 SeitenDEWA Infrastructure Guidelinenirmal mohanNoch keine Bewertungen

- Iso 4866 2010 PDFDokument11 SeitenIso 4866 2010 PDFSj OnNoch keine Bewertungen

- Color Code Chart Qfm-qc-03 Rev. 17Dokument1 SeiteColor Code Chart Qfm-qc-03 Rev. 17Balram Ji100% (1)

- ISO Tolerances for Holes and Shafts Chart (ISO 286-2Dokument12 SeitenISO Tolerances for Holes and Shafts Chart (ISO 286-2rlnjay2003Noch keine Bewertungen

- Screw ForcesDokument10 SeitenScrew ForceskasreedharNoch keine Bewertungen

- Appendix 6.2-G - Fire Pump Engine SpecsDokument9 SeitenAppendix 6.2-G - Fire Pump Engine Specs050678Noch keine Bewertungen

- ANALYSIS OF RATE FOR PROVIDING SINGLE LIGHTSDokument2 SeitenANALYSIS OF RATE FOR PROVIDING SINGLE LIGHTSmuhammad iqbalNoch keine Bewertungen

- Weld Deposition DataDokument5 SeitenWeld Deposition Datachetan85100% (4)

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincDokument15 SeitenHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysNoch keine Bewertungen

- Quality Standards Manual Tightening Loads and Torques For Standard Metric Bolts and Foundation BoltsDokument6 SeitenQuality Standards Manual Tightening Loads and Torques For Standard Metric Bolts and Foundation Boltsgabriel_517180914Noch keine Bewertungen

- FITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDokument9 SeitenFITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDênis DáyolNoch keine Bewertungen

- Seal Friction Parker SealsDokument6 SeitenSeal Friction Parker SealsChristian MavarezNoch keine Bewertungen

- SA RawlboltDokument2 SeitenSA Rawlboltpower_generator133850% (2)

- Production of Microcrystalline Cellulose by Reactive Extrusion - 2 PDFDokument6 SeitenProduction of Microcrystalline Cellulose by Reactive Extrusion - 2 PDFchandravadiyaketanNoch keine Bewertungen

- Q&ADokument3 SeitenQ&ANathamuni NarasimhanNoch keine Bewertungen

- APB Profile PDFDokument4 SeitenAPB Profile PDFchandravadiyaketanNoch keine Bewertungen

- Air Handling Units - Equipment GuideDokument84 SeitenAir Handling Units - Equipment Guideesteban_f1100% (1)

- Hotel Maha Shiv Ankleshwar - Google Search PDFDokument1 SeiteHotel Maha Shiv Ankleshwar - Google Search PDFchandravadiyaketanNoch keine Bewertungen

- Address SlipDokument1 SeiteAddress SlipchandravadiyaketanNoch keine Bewertungen

- Answer:: A Basic DefinitionDokument3 SeitenAnswer:: A Basic DefinitionchandravadiyaketanNoch keine Bewertungen

- Mec Main List MainteDokument3 SeitenMec Main List MaintechandravadiyaketanNoch keine Bewertungen

- VacuumDokument7 SeitenVacuumMassimilianø Erricø100% (1)

- Part1 CATPart PDFDokument1 SeitePart1 CATPart PDFchandravadiyaketanNoch keine Bewertungen

- ResinDokument2 SeitenResinchandravadiyaketanNoch keine Bewertungen

- WHOPIR Macleods 25-26may06Dokument6 SeitenWHOPIR Macleods 25-26may06chandravadiyaketanNoch keine Bewertungen

- History About Us: Home Careers Media Contact UsDokument1 SeiteHistory About Us: Home Careers Media Contact UschandravadiyaketanNoch keine Bewertungen

- Alumni Information Form - Doc111Dokument1 SeiteAlumni Information Form - Doc111chandravadiyaketanNoch keine Bewertungen

- Kashyap CV PDFDokument3 SeitenKashyap CV PDFchandravadiyaketanNoch keine Bewertungen

- 8 7 Homework Progress Q1Dokument1 Seite8 7 Homework Progress Q1chandravadiyaketanNoch keine Bewertungen

- Maintenance CostDokument2 SeitenMaintenance CostTrunoNoch keine Bewertungen

- Fda Site Inspection Preparation Checklist Task Items Done NA NotesDokument2 SeitenFda Site Inspection Preparation Checklist Task Items Done NA NoteschandravadiyaketanNoch keine Bewertungen

- MIT Preventive MaintenanceDokument20 SeitenMIT Preventive MaintenanceDexron3Noch keine Bewertungen

- Subject Code: 141903 Subject Name: Engineering ThermodynamicsDokument2 SeitenSubject Code: 141903 Subject Name: Engineering ThermodynamicschandravadiyaketanNoch keine Bewertungen

- Best Practice Guide CFD 1Dokument46 SeitenBest Practice Guide CFD 1sandiphirade100% (3)

- History About Us: Home Careers Media Contact UsDokument1 SeiteHistory About Us: Home Careers Media Contact UschandravadiyaketanNoch keine Bewertungen

- MechanicalDokument2 SeitenMechanicaljvc_84Noch keine Bewertungen

- Kashyap Application PDFDokument1 SeiteKashyap Application PDFchandravadiyaketanNoch keine Bewertungen

- IUTS ANS LNTITMockSample1 PDFDokument1 SeiteIUTS ANS LNTITMockSample1 PDFchandravadiyaketanNoch keine Bewertungen

- Fda Site Inspection Preparation Checklist Task Items Done NA NotesDokument2 SeitenFda Site Inspection Preparation Checklist Task Items Done NA NoteschandravadiyaketanNoch keine Bewertungen

- 718 CFDDokument8 Seiten718 CFDchandravadiyaketanNoch keine Bewertungen

- Best Practice Guide CFD 2Dokument18 SeitenBest Practice Guide CFD 2sandiphirade100% (2)

- Hand Tools List Of G/S And M/A Excel SheetDokument2 SeitenHand Tools List Of G/S And M/A Excel SheetchandravadiyaketanNoch keine Bewertungen

- 02-Welding Procedure SpecificationDokument4 Seiten02-Welding Procedure Specificationveera Satya saiNoch keine Bewertungen

- API 1104 Interpretations July 2022Dokument45 SeitenAPI 1104 Interpretations July 2022FrancoNoch keine Bewertungen

- TVS Bolt PricelistDokument32 SeitenTVS Bolt PricelistDhanus Kodi0% (1)

- Welders QualificationDokument47 SeitenWelders Qualificationidealparrot100% (3)

- Execution Schedule for TR1 & TR2 ShutdownDokument3 SeitenExecution Schedule for TR1 & TR2 ShutdownSaqlain MalikNoch keine Bewertungen

- Dod-Std-1866 Notice 1 1988Dokument33 SeitenDod-Std-1866 Notice 1 1988liuyx866Noch keine Bewertungen

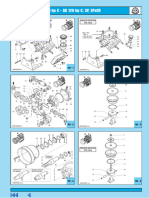

- Pl100 Pl200 Pl300 Pl400 SparepartDokument9 SeitenPl100 Pl200 Pl300 Pl400 Sparepartphantomboyz_aip100% (1)

- Table QW-253 Welding Variables Procedure Specifications (WPS) - Shielded Metal-Arc Welding (SMAW)Dokument2 SeitenTable QW-253 Welding Variables Procedure Specifications (WPS) - Shielded Metal-Arc Welding (SMAW)BabarNoch keine Bewertungen

- AWS D8.8M-2007 Specification For AutomotiveWeld Quality-Arc Welding of Steel PDFDokument28 SeitenAWS D8.8M-2007 Specification For AutomotiveWeld Quality-Arc Welding of Steel PDFcesardario90100% (1)

- Aramco Hot Tap Welding Procedure Rev 1Dokument3 SeitenAramco Hot Tap Welding Procedure Rev 1BWQNoch keine Bewertungen

- Payload Safety and Mission Success Conference 2004Dokument26 SeitenPayload Safety and Mission Success Conference 2004ilham faqihNoch keine Bewertungen

- Welding Questions PDFDokument42 SeitenWelding Questions PDFA. ΒρατσισταNoch keine Bewertungen

- Macro - Latest Answer PDFDokument12 SeitenMacro - Latest Answer PDFMc. DorisNoch keine Bewertungen

- CuproBraze 34Dokument2 SeitenCuproBraze 34Vinod SaleNoch keine Bewertungen

- Electrical ConnectorsDokument132 SeitenElectrical ConnectorsRonald Perlaza NarvaezNoch keine Bewertungen

- Asme Ix Welder Qualification InterpretationDokument95 SeitenAsme Ix Welder Qualification Interpretationvangie3339515100% (3)

- Sas670 KatalogDokument8 SeitenSas670 KatalogKrusovice15Noch keine Bewertungen

- Welding Defect PhotoDokument14 SeitenWelding Defect Photo0502raviNoch keine Bewertungen

- Work Immersion TarpDokument23 SeitenWork Immersion TarpFiya CalmaNoch keine Bewertungen

- AC April 2014 WebsiteDokument358 SeitenAC April 2014 WebsiteBrunoBragadoNoch keine Bewertungen

- CGFVHDokument6 SeitenCGFVHvijayakumarNoch keine Bewertungen

- Visual Weld InspectionDokument53 SeitenVisual Weld InspectionThiru RajaNoch keine Bewertungen

- Wood Glue Price List from Denlaks CompanyDokument1 SeiteWood Glue Price List from Denlaks CompanyminervadeaNoch keine Bewertungen

- Aws d143 1994 Specification For Welding Earthmoving and Con Struction Equipment1Dokument89 SeitenAws d143 1994 Specification For Welding Earthmoving and Con Struction Equipment134ravisinghNoch keine Bewertungen

- WPQRDokument1 SeiteWPQRJBStringerNoch keine Bewertungen

- Calculate Stick Electrode Requirement for 851kg WeldDokument2 SeitenCalculate Stick Electrode Requirement for 851kg WeldMOHAN0% (1)

- Sample Welder Qualification Blank Form (Multi-Process) Welder, Welding Operator, or Tack Welder Performance Qualification Test RecordDokument1 SeiteSample Welder Qualification Blank Form (Multi-Process) Welder, Welding Operator, or Tack Welder Performance Qualification Test RecordtuanNoch keine Bewertungen

- Ar100 Ar120Dokument2 SeitenAr100 Ar120Nicoleta CosteaNoch keine Bewertungen

- Spesifikasi Tiang Pancang by Pt. Tripalindo PersadaDokument8 SeitenSpesifikasi Tiang Pancang by Pt. Tripalindo Persadasugiarto budiNoch keine Bewertungen