Beruflich Dokumente

Kultur Dokumente

Ceramic Blanket

Hochgeladen von

abasak0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

26 Ansichten2 SeitenCeramic Blanket

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCeramic Blanket

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

26 Ansichten2 SeitenCeramic Blanket

Hochgeladen von

abasakCeramic Blanket

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Kaowool Blanket, Kaowool RT Blanket,

Cerablanket

, Cerachem

Blanket and

Cerachrome

Blanket are air laid into a continuous

mat and mechanically needled for added strength

and surface integrity. Blanket products do not contain

organic binders. Thermal Ceramic Blankets provide

excellent resistance to chemical attack. Exceptions

include hydrofluoric acid, phosphoric acid, and strong

alkalies (ie. Na

2

O, K

2

O). Thermal Ceramic blankets

are unaffected by oil or water. Thermal and physical

properties are restored after drying.

Kaowool Blanket

Kaowool blanket is produced from kaolin, a naturally

occurring alumina-silica fire clay. Kaowool, the

worlds most recognizable name in ceramic fiber

blanket, is available in a wide variety of densities and

sizes. Kaowool blanket offers excellent handleability

and high temperature stability. This allows it to meet

a wide range of hot face and backup insulation appli-

cations in furnaces, kilns and other equipment requir-

ing high temperature heat containment.

Kaowool RT Blanket

Kaowool RT Blanket is produced from a blend of high

quality alumina, silica and kaolin using the spinning

process. It is available in a wide variety of densities

and sizes, and offers a highly cost effective alterna-

tive to Cerablanket with its 2300F (1260C) maxi-

mum temperature rating.

Cerablanket

Cerablanket is produced from exceptionally pure

oxides of alumina and silica using the spinning

process. The resultant quality spun fibers have been

optimized for high handling strength, with on average

the highest tensile strength of any Thermal Ceramics

ceramic fiber blanket. Cerablanket is available in a

wide variety of densities and sizes. Cerablanket

offers excellent handleability and high temperature

stability which allows it to meet a wide range of hot

face and back up insulation applications in furnaces,

kilns and other equipment requiring high temperature

heat containment.

Cerachem Blanket

Cerachem Blanket is a 2600F (1427C) maximum

temperature rated refractory blanket formed from a

unique, patented, spun alumina-silica-zirconia fiber. It

is specially designed for applications where high fiber

tensile strength, low thermal conductivity and low

shrinkage are required. Cerachem Blanket is used

extensively in high temperature units in the ceramic,

chemical processing, and ferrous metal industries.

Thermal Ceramics Cerachem refractory blankets are

ideal for a wide range of hot face lining and backup

insulation applications in furnaces, kilns and other

high temperature equipment.

Cerachrome Blanket

Made from spun alumina-silica-chromia fiber,

Cerachrome Blanket is well suited for hot face lining

applications where higher temperatures are encoun-

tered, such as soaking pit covers, reheat and forging

furnaces. Cerachrome Blanket with its chromia-sta-

bilized chemistry offers improved long term shrinkage

characteristics over zirconia containing blankets

such as Cerachem. Cerachrome Blanket effectively

fills the gap between zirconia blankets and high

alumina products.

Blanket Products

Product Information

01.07/5 14-205

Blanket Products

Product Information

www.thermalceramics.com

Physical Properties Kaowool Kaowool RT Cerablanket Cerachem Cerachrome

Color white white white white blue/green

Density, pcf 3, 4, 6, 8, 10, 12 4, 6, 8 3, 4, 6, 8 4, 6, 8 4, 6, 8

(kg/m

3

) (48, 64, 96, 128, 192) (64, 96, 128) (48, 64, 96, 128) (64, 96, 128) (64, 96, 128)

Thickness, in. (mm)

1

/8 - 1 (3.125-50) 1 - 2 (25-50) - 2 (6.25-50) - 2 (12.5-50) - 2 (12.5-50)

Continuous use limit, F (C) 2000 (1093) 2000 (1093) 2150 (1177) 2400 (1315) 2500 (1371)

Classification temp. rating, F (C) 2300 (1260) 2300 (1260) 2400 (1315) 2600 (1426) 2600 (1426)

Melting point, F(C) 3200 (1760) 3200 (1760) 3200 (1760) 3200 (1760) 3200 (1760)

Chemical Analysis, Nominal %

Alumina, Al

2

O

3

45 35 - 47 46 35 43

Silica, SiO

2

50 - 55 49 - 54 54 50 54

Ferric oxide, Fe

2

O

3

1.0 0.05 - 1.5 0.05 0.05

Titanium oxide, TiO

2

1.7 0.05 - 1.9

Calcium oxide , CaO 0.1 0.05 0.05 0.05

Magnesium oxide, MgO trace 0.05 0.05 0.05

Alkalies as, Na

2

O 0.2 0.2 0.2 0.2

Boron Oxide, B

2

O

3

0.08

Chromium Oxide, Cr

2

O

3

3

Zirconia 0 - 15 15

Other 0 - 3 trace trace trace

Leachable chlorides 1 - 2 0 - 3 trace traces trace

Thermal Conductivity, BTUin./hrft

2

F (w/mK) (ASTM C 201)

Mean temperature, 8pcf

@ 500F (260C) 0.44 (0.06) 0.44 (0.06) 0.44 (0.06) 0.44 (0.06) 0.44 (0.06)

@ 1000F (538C) 0.87 (0.12) 0.93 (0.13) 0.93 (0.13) 0.93 (0.13) 0.93 (0.13)

@ 1500F (816C) 1.45 (0.21) 1.60 (0.23) 1.60 (0.23) 1.60 (0.23) 1.60 (0.23)

@ 1800F (982C) 1.83 (0.26) 2.05 (0.30) 2.05 (0.30) 2.05 (0.30) 2.05 (0.30)

@ 2000F (1093C) 2.09 (0.30) 2.34 (0.34) 2.34 (0.34) 2.34 (0.34

Mean temperature, 6pcf

@ 500F (260C) 0.47 (0.07) 0.47 (0.07) 0.47 (0.07) 0.47 (0.07) 0.47 (0.07)

@ 1000F (538C) 1.01 (0.15) 1.05 (0.15) 1.06 (0.15) 1.06 (0.15) 1.06 (0.15)

@ 1500F (816C) 1.73 (0.25) 1.90 (0.27) 1.90 (0.27) 1.90 (0.27) 1.90 (0.27)

@ 1800F (982C) 2.19 (0.32) 2.45 (0.35) 2.45 (0.35) 2.45 (0.35) 2.45 (0.35)

@ 2000F (1093C) 2.83 (0.41) 2.83 (0.41) 2.83 (0.41) 2.83 (0.41)

Mean temperature, 4 pcf

@ 500F (260C) 0.54 (0.08) 0.54 (0.08) 0.54 (0.08) 0.54 (0.08) 0.54 (0.08)

@ 1000F (538C) 1.29 (0.19) 1.34 (0.19) 1.34 (0.19) 1.34 (0.19) 1.34 (0.19)

@ 1500F (816C) 2.30 (0.33) 2.48 (0.36) 2.48 (0.36) 2.48 (0.36) 2.48 (0.36)

@ 1800F (982C) 2.96 (0.43) 3.23 (0.47) 3.23 (0.47) 3.23 (0.47) 3.23 (0.47)

@ 2000F (1093C) 3.74 (0.54) 3.74 (0.54) 3.74 (0.54)

Military Specifications and Approvals Water Leachable Elements on Surface of Fiber, typical quantities, PPM

Mil-I-23128A 3, 6 pcf blanket Boron 40 Sulphur 10

Mil-I-24244 All blankets Chlorine <10 Sodium 40

Mil-I-23128B 6, 8 pcf blanket Fluorine <5 Silicate 125

Acoustical performance per ASTM C-423 A and E-795, Sound Absorption Coefficient

Kaowool Blanket 250Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz NRC

1- 4 pcf 0.29 1.00 1.04 0.99 0.98 0.85

1- 8 pcf 0.50 0.92 0.91 0.91 0.94 0.80

2- 4 pcf 0.92 1.01 1.01 1.03 1.10 1.00

2- 8 pcf 0.80 0.72 0.86 0.92 1.02 0.85

The values given herein are typical average values obtained in accordance with accepted test methods and are sub-

ject to normal manufacturing variations. They are supplied as a technical service and are subject to change with-

out notice. Therefore, the data contained herein should not be used for specification purposes. Check with your

Thermal Ceramics office to obtain current information.

Thermal Ceramics, Cerachrome, and Cerablanket are trademarks

of The Morgan Crucible Company plc. Kaowool is a trademark of

Thermal Ceramics Inc.

Marketing Communications Offices

Thermal Ceramics Americas

T: (706) 796 4200

F: (706) 560 5841

Thermal Ceramics Asia Pacific

T: +65 6733 6068

F: +65 6733 3498

Thermal Ceramics Europe

T: +44 (0) 151 334 4030

F: +44 (0) 151 334 1684

North America - Sales Offices

Canada

T: +1 (905) 335 3414

F: +1 (905) 335 5145

Mexico

T: +52 (555) 576 6622

F: +52 (555) 576 3060

United States of America

Eastern Region

T: +1 (800) 338 9284

F: +1 (866) 785 2764

Western Region

T: +1 (866) 785 2738

F: +1 (866) 785 2760

South America - Sales Offices

Argentina

T: +54 (11) 4373 4439

F: +54 (11) 4372 3331

Brazil

T: +55 (21) 2418 1366

F: +55 (21) 2418 1205

Chile

T: +56 (2) 854 1064

F: +56 (2) 854 1952

Colombia

T: +57 (2) 2282935/2282803/2282799

F: +57 (2) 2282935/2282803/23722085

Guatemala

T: +50 (2) 4733 295/6

F: +50 (2) 4730 601

Venezuela

T: +58 (241) 878 3164

F: +58 (241) 878 6712

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Jsa Jis K 0101 1998 PDFDokument481 SeitenJsa Jis K 0101 1998 PDFRiris Trinartika50% (2)

- Fathi HabashiDokument63 SeitenFathi HabashiJavier Antahuara Lazo0% (2)

- HVAC Cooling Load Procedure Guideline Lo0Dokument62 SeitenHVAC Cooling Load Procedure Guideline Lo0api-385802594% (36)

- Mat Chem Comp GB en PDFDokument48 SeitenMat Chem Comp GB en PDFvzimak2355Noch keine Bewertungen

- Open Flow ChannelDokument27 SeitenOpen Flow ChannelNitish RamdaworNoch keine Bewertungen

- Viskozimetri PDFDokument9 SeitenViskozimetri PDFabasakNoch keine Bewertungen

- Bubble Column Reactor - RPDS PDFDokument11 SeitenBubble Column Reactor - RPDS PDFabasakNoch keine Bewertungen

- Online Payment ReceiptDokument1 SeiteOnline Payment ReceiptabasakNoch keine Bewertungen

- Hastelloy N Alloy: Principle FeaturesDokument14 SeitenHastelloy N Alloy: Principle FeaturesabasakNoch keine Bewertungen

- Air Entrainment by Water Jet Impacting Free SurfaceDokument19 SeitenAir Entrainment by Water Jet Impacting Free SurfaceabasakNoch keine Bewertungen

- Microsoft PowerPoint - Open-Channel 1Dokument63 SeitenMicrosoft PowerPoint - Open-Channel 1Eng Bagaragaza RomualdNoch keine Bewertungen

- Ceramic Refractory HeatersDokument12 SeitenCeramic Refractory HeatersabasakNoch keine Bewertungen

- NDE and inspection of sodium to air heat exchangers during fabricationDokument9 SeitenNDE and inspection of sodium to air heat exchangers during fabricationabasakNoch keine Bewertungen

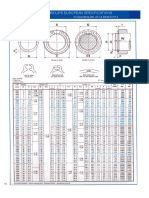

- Circlip SpecDokument4 SeitenCirclip SpecabasakNoch keine Bewertungen

- Eurotherm 3500 Data Sheet HA029045 8 PDFDokument8 SeitenEurotherm 3500 Data Sheet HA029045 8 PDFabasakNoch keine Bewertungen

- Bubble Column Reactor - RPDSDokument11 SeitenBubble Column Reactor - RPDSabasakNoch keine Bewertungen

- Distribution of This Document Is Unlimi"Dokument25 SeitenDistribution of This Document Is Unlimi"abasakNoch keine Bewertungen

- Challenges in Manufacture of PFBR Steam GeneratorsDokument6 SeitenChallenges in Manufacture of PFBR Steam GeneratorsabasakNoch keine Bewertungen

- Chandigarh SPDDokument4 SeitenChandigarh SPDabasakNoch keine Bewertungen

- Series 4000Dokument36 SeitenSeries 4000abasakNoch keine Bewertungen

- Us 5112190Dokument13 SeitenUs 5112190abasakNoch keine Bewertungen

- LMTD Correction Factor Chart for Cross Flow Heat ExchangerDokument1 SeiteLMTD Correction Factor Chart for Cross Flow Heat ExchangerabasakNoch keine Bewertungen

- Fermilab d0 en 173Dokument4 SeitenFermilab d0 en 173abasakNoch keine Bewertungen

- Lec 17Dokument18 SeitenLec 17abasakNoch keine Bewertungen

- Lok Sabha Starred Question No. 2: (A) To (E)Dokument4 SeitenLok Sabha Starred Question No. 2: (A) To (E)abasakNoch keine Bewertungen

- 5 Vitreous Carbon Mersen 04Dokument6 Seiten5 Vitreous Carbon Mersen 04abasakNoch keine Bewertungen

- Radiation View FactorsDokument30 SeitenRadiation View FactorsabasakNoch keine Bewertungen

- Messphysik Materials Testing Machine Product InformationDokument2 SeitenMessphysik Materials Testing Machine Product InformationabasakNoch keine Bewertungen

- Orifice Calculation PDFDokument6 SeitenOrifice Calculation PDFasdoliopNoch keine Bewertungen

- Walkin HoodDokument8 SeitenWalkin HoodabasakNoch keine Bewertungen

- A. Electrolysis of Acidified Water (Dilute Sulphuric Acid) : Notes Myp 5 ChemistryDokument10 SeitenA. Electrolysis of Acidified Water (Dilute Sulphuric Acid) : Notes Myp 5 Chemistrywama ojhaNoch keine Bewertungen

- The Australian Welding Guide PDFDokument220 SeitenThe Australian Welding Guide PDFThành Nguyễn XuânNoch keine Bewertungen

- Dilutions Worksheet SolutionsDokument4 SeitenDilutions Worksheet SolutionsAtulya BharadwajNoch keine Bewertungen

- 2022 - Skema Bab3 - Konsep Mol, Formula Dan Persamaan KimiaDokument17 Seiten2022 - Skema Bab3 - Konsep Mol, Formula Dan Persamaan Kimiasyed ahmad ansarNoch keine Bewertungen

- Science Form 1 Chapter 4Dokument26 SeitenScience Form 1 Chapter 4Beevy GB73% (11)

- 1.4435 - C Stainless Steel DetailsDokument3 Seiten1.4435 - C Stainless Steel DetailsmeenakshiNoch keine Bewertungen

- VSEPRDokument20 SeitenVSEPRHải NguyễnNoch keine Bewertungen

- Analyze organic compounds mass spec fragmentsDokument6 SeitenAnalyze organic compounds mass spec fragmentssureshthevanNoch keine Bewertungen

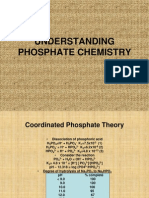

- PhosphateDokument18 SeitenPhosphatejaykotak12345100% (8)

- Science P2 April 2019 PDFDokument16 SeitenScience P2 April 2019 PDFLee Jia Bao BerniceNoch keine Bewertungen

- Selina Concise Chemistry Class 9 ICSE Solutions For Chapter 1 - Language of ChemistryDokument24 SeitenSelina Concise Chemistry Class 9 ICSE Solutions For Chapter 1 - Language of ChemistryfelixNoch keine Bewertungen

- Lab Formal - Chemistry of CopperDokument3 SeitenLab Formal - Chemistry of CopperAimee Capinpuyan67% (3)

- Analisis+jurnal+2 Komplekso Complexometric+Determination+of+MagnesiumDokument4 SeitenAnalisis+jurnal+2 Komplekso Complexometric+Determination+of+Magnesiumferdina wahyuNoch keine Bewertungen

- (c96d68d8 3419 42e8 b7c6 689afc850d61) TS Ebook XRF Technology in The FieldDokument32 Seiten(c96d68d8 3419 42e8 b7c6 689afc850d61) TS Ebook XRF Technology in The FieldLewy HandleNoch keine Bewertungen

- Leaching Kinetics of Bastnaesite Concentrate in HCL SolutionDokument5 SeitenLeaching Kinetics of Bastnaesite Concentrate in HCL Solutionmtanaydin100% (1)

- Recovery of Tellurium from Anode Slime Containing High CopperDokument21 SeitenRecovery of Tellurium from Anode Slime Containing High Copperbarsha2sweetNoch keine Bewertungen

- Aws 5.1Dokument57 SeitenAws 5.1saranperiyan1100% (1)

- Sources of Oxygen Contamination in SAW - EagerDokument5 SeitenSources of Oxygen Contamination in SAW - EagerAndres CasteloNoch keine Bewertungen

- Physical Science Powerpoint 1Dokument40 SeitenPhysical Science Powerpoint 1Jenezarie TarraNoch keine Bewertungen

- Airblast Abrasives: Brown Fused AluminaDokument2 SeitenAirblast Abrasives: Brown Fused Aluminamekhman mekhtyNoch keine Bewertungen

- 0708 F3 Chem Notes 3Dokument8 Seiten0708 F3 Chem Notes 3Lee MeltyNoch keine Bewertungen

- 8 PDFDokument2 Seiten8 PDFAlodia VaniaNoch keine Bewertungen

- Chapter 12 - Surface Water TreatmentDokument36 SeitenChapter 12 - Surface Water TreatmentDwi Yerlis RahmiNoch keine Bewertungen

- 5: Chemical Trends - Topic Questions: Year Series Paper NumberDokument10 Seiten5: Chemical Trends - Topic Questions: Year Series Paper NumberSumaira AliNoch keine Bewertungen

- Co CR Mo AlloyDokument7 SeitenCo CR Mo AlloyRe ZanoNoch keine Bewertungen

- HidroDokument16 SeitenHidroLasandi Affan NurNoch keine Bewertungen

- Chemistry Paper AITSDokument8 SeitenChemistry Paper AITSRishabh AgrawalNoch keine Bewertungen