Beruflich Dokumente

Kultur Dokumente

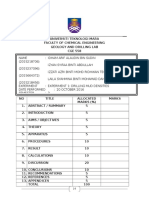

Drilling Simulator Lab Report Final

Hochgeladen von

nasreldin3Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Drilling Simulator Lab Report Final

Hochgeladen von

nasreldin3Copyright:

Verfügbare Formate

1

UNIVERSITI

TEKNOLOGI

PETRONAS

UNIVERSITI

TEKNOLOGI

PETRONAS

PAB 2024

DRILLING ENGINEERING

Experiment 1

Drilling Simulator

Amro Abd Elbadea Elsaghir 13449

Mohammed Mohammed Abderrahmane 13472

Mostafa Sharaf Eldin Hassan saad 13477

2

1) INTRODUCTION

BASIC DRILLING SYSTEM

1.1 Circulating System

The main objective of circulation system is to pump fluid through the whole active

fluid system, including the borehole and all the surface tanks that constitute the

primary system.

The complete, circuitous path that the drilling fluid travels starting at the:

- main rig pumps

- surface piping

- standpipe

- kelly hose (rotary)

- kelly

- drillpipe

- drill collars

- bit nozzles

- openhole and casing strings

- flowline

- mud-cleaning equipment

- mud tanks

- positive displacement main

rig pumps

Functions of Drilling Fluids:

- Lift-up cuttings

- To cover the underground pressure

- To restrain the well bore

- To create mud cake and prevent filtrate loss

- To lubricate drill bit and drill string

- Down hole information gathering media and well logging

- To transfer hydraulic force to downhole motor

1.2 Rotating System

The main objectives of this system is to create rotation force towards drill bit at

the bottom hole and provide helps when tightening and loosing pipe connection.

There are two types of rotating source:

1. Rotary Table

The revolving or spinning section of the drillfloor that provides power to turn

the drillstring in a clockwise direction (as viewed from above). The rotary

motion and power are transmitted through the kelly bushing and the kelly to

the drillstring. Almost all rigs today have a rotary table, either as primary or

backup system for rotating the drillstring. Top drive technology, which allows

continuous rotation of the drillstring, has replaced the rotary table in certain

operations. A few rigs are being built today with topdrive systems only, and

lack the traditional kelly system.

3

2. Top Drive

A device that turns the drillstring. It consists of one or more motors (electric or

hydraulic) connected with appropriate gearing to a short section of pipe called

a quill, that in turn may be screwed into a saver sub or the drillstring itself. The

topdrive is suspended from the hook, so the rotary mechanism is free to travel

up and down the derrick. This is radically different from the more conventional

rotary table and kelly method of turning the drillstring because it enables

drilling to be done with three joint stands instead of single joints of pipe. It also

enables the driller to quickly engage the pumps or the rotary while tripping

pipe, which cannot be done easily with the kelly system.

1.3 Hoisting System

The main objective of this system is to provide lifting and dropping force towards

drill string and any components around rig floor.

Several components of this system are:

- crown block

- travelling block

- mast

- substructure (sub)

- prime mover

1.4 Pressure Control System

The objective of this system is to prevent blowout and maintain kick during drilling

and tripping. The equipment is called Blowout Preventer (BOP).

BOP is a large valve at the top of a well that may be closed if the drilling crew

loses control of formation fluids. By closing this valve (usually operated remotely

via hydraulic actuators), the drilling crew usually regains control of the reservoir,

and procedures can then be initiated to increase the mud density until it is

possible to open the BOP and retain pressure control of the formation.

BOPs come in a variety of styles, sizes and pressure ratings. Some can

effectively close over an open wellbore, some are designed to seal around

tubular components in the well (drillpipe, casing or tubing) and others are fitted

with hardened steel shearing surfaces that can actually cut through drillpipe.

1.5 Power System

The source of power for the rig location is provided by the Power System.

On modern rigs, the prime mover consists of one to four or more diesel engines.

These engines commonly produce several thousand horsepower. Typically, the

diesel engines are connected to electric generators.

The electrical power is then distributed by a silicon-controlled-rectifier (SCR)

system around the rig site. Rigs that convert diesel power to electricity are known

4

as diesel electric rigs. Older designs transmit power from the diesel engines to

certain rig components (drawworks, pumps and rotary table) through a system of

mechanical belts, chains and clutches.

On these rigs, a smaller electric generator powers lighting and small electrical

requirements. These older rigs are referred to as mechanical rigs or more

commonly, simply power rigs.

2 KICK AND BLOW OUT

A kick is defined as any undesirable flow of formation fluids from the reservoir to the

wellbore that occurs as a result of a negative pressure differential across the

formation face. Meanwhile, Blow Out happens if the kick is reaching the surface and

uncontrollable. Wells kick because the reservoir pressure of an exposed permeable

formation is higher than the wellbore pressure at that depth.

Blow out can happen in almost every oil and gas operation such as:

- Drilling Operation

- Work over Operation

- Well Service Operation (Maintenance)

There are many situations which can produce this downhole condition. Among the

most likely and recurring are:

- Low density drilling fluid.

- Abnormal reservoir pressure.

- Swabbing.

- Not keeping the hole full on trips.

- Lost circulation

Kick indicators are classified into two groups: positive and secondary. Anytime the

well experiences a positive indicator of a kick, immediate action must be taken to

shut-in the well. When a secondary indicator of a kick is identified, steps should be

taken to verify if the well is indeed kicking.

The "Positive Indicators of a Kick" are:

- Increase in Pit Volume

- Increase in Flow rate

Immediate action should be taken to shut-in the well whenever these indicators are

experienced. It is not recommended to check for flow after a positive indicator has

been identifed.

5

The "Secondary Indicators of a Kick" are:

- Decrease in Circulating Pressure

- Gradual Increase in Drilling Rate

- Drilling Breaks

- Increase in Gas Cutting

- Increase in Water Cutting or Chlorides

The occurence of any of these indicators should alert the Drilling Representative that

the well may be kicking, or is about to kick. These indicators should never be

ignored. Instead, once realized, steps should be taken to determine the reason for

the indication.

3 SWABBING

Swabbing is a condition that arises when pipe is pulled from the well and produces a

temporary bottomhole pressure reduction.

Many downhole conditions tend to increase the likelihood that a well will be

swabbed-in when pipe is pulled. Several of these are discussed below:

- Pulling Pipe Too Fast

- Poor Mud Properties

- Heaving or Swelling Formations

- Large OD Tools

4 WELL CONTROL PROCEDURE (HARD SHUT IN * REMOTE CHOKE IS

ALWAYS CLOSE DURING DRILLING & TRIPPING)

4.1 SHUT-IN PROCEDURE WHILE DRILLING

1. When any indication is observed while drilling that the well maybe flowing,

raise the drill with pumps on until spaced out, stop rotating drill string.

2. Stop pumping and check for flow, if positive;

3. Close annular or upper pipe rams.

4. Open BOP upstream choke valve.

5. Call supervisor and commence plotting a graph of shut in drill pipe & casing

pressure. Check pit volume again.

4.2 SHUT-IN PROCEDURE WHILE TRIPPING

1. When a possible sign is observed, set top tool joint in the slips.

2. Check for flow.

3. Install a full opening Safety valve on the drill pipe. Close the valve once it is

installed.

6

4. CLOSE annular BOP.

5. Open BOP upstream choke valve.

6. Alert supervisors.

7. Read and record pressures on SICP & SIDP

8. The operators representative will have to decide whether to kill in situ, or strip

back to bottom.

9. If operator decided to strip to bottom, stab IBOP (Gray valve) & open full

opening safety valve. Ready to strip drill string to bottom.

2) OBJECTIVES

The objectives of this experiment are as follow:

1. To conduct drilling operation simulation by using DrillSim 500.

2. To identify any kick indications by using DrillSim 500.

3. To control any kick confronted during drilling operations.

3) EXPERIMENT PROCEDURES

Drilling Test

1. Take slow pump rate pump#1 20 spm / xxxx psi, 30 spm / xxxx psi

2. Take slow pump rate pump#2 20 spm / xxxx psi, 30 spm / xxxx psi.

3. Increase mud pump 1 & 2 to achieve total of 600 gpm (8-1/2 hole size)

4. Setting rotary speed to 100 rpm.

5. Use handbrake to lower the drill string until bit touches bottom.

6. Increase and maintain WOB at 35.000 lbs.

7. Continue drilling by adjusting WOB at 35.000 lbs by adjusting handbrake at

every time.

8. Identify if there is any Kick indication at all operation time.

9. Continue to kick procedure when kick is encountered.

Well Control Drillers Method

1. Monitor surface instrumentation. Once positive kick detected, follow step 2.

2. Pick up off bottom & space out (ensure tooljoint is not across ram). Stop

rotary.

3. Stop pump 1 and 2.

Close BOPs Annular or Upper Ram. Open BOP upstream choke valve.

4. Read and record final (stabilized) SIDPP and SICP. Read and record final pit

gain. Adjust the remote choke to maintain the SICP constant while bringing

the pump up to 20 or 30 strokes per minute simultaneously.

7

When the casing pressure is stabilized, read and record the new circulating

drill pipe pressure. Adjust the remote choke to maintain the initial circulating

drill pipe pressure constant until the influx (the kick) is out. Once influx out,

stop pump & close remote choke completely while maintaining the last CP

constant. ( If no further influx enter the well bore, theoretical SICP & SIDP

should be the same)

5. Increase mud weight to kill mud weight.

Kill MW = (SIDPP + 150 psi overbalance)/(0.052*vert. depth) + original MW

Open remote choke and start pump at 20 or 30 strokes per minute while

maintaining SICP constant. Once reach desired pump rate, continue to

maintain SICP constant

until kill mud reach bit.

Once kill mud reach bit, start to maintain FCP (final drill pipe circulating

pressure) constant until kill mud reach surface

6. When the kill mud reach surface, stop pump & then close remote choke.

Read and record SIDPP, SICP and pit volume. (SIDPP & SICP shoule be

zero if the well is dead)

Open the BOP Upper ram, close BOP upstream choke valve and flow check

well.

8

4) Results:

Well control Drillers method:

1. When the BOPs upper Ram is closed and the choke is opened

SIDPP= 319 psi

SICP = 305 psi

Pit deviation = 1 barrel

2. After bringing the pump to 30 strokes per minute

SIDPP = 618 psi

3. When the influx is out

SIDPP = 456 psi

SICP = 455 psi

4. Kill Mud Weight

KMW = + Original mud weight

KMW = + 12.2

KMW = 13.7 ppg

5. When the mud reach the bit

FDP = 380 psi

6. After the mud reach the surface

SIDPP = 297 psi

SICP = 298 psi

Pit deviation = 5.9 barrel

Trap pressure 5 psi

7. Check flow

Check flow =19.88 bbl

When the pump open flow =19.85 bbl

The difference is =19.88 - 19.85=0.03 bbl

9

5) Discussion

As our main objectives of this experiment are:

1. To conduct drilling operation simulation by using DrillSim 500.

2. To identify any kick indications by using DrillSim 500.

3. To control any kick confronted during drilling operations.

In this part we will discuss about the procedure of controlling a kick and interpret

the result we obtained from the experiment. The term kick is used to indicate a flow

of formation fluids into the wellbore during drilling operations. The kick is physically

caused by the pressure in the wellbore being less than that of the formation fluids,

thus causing flow. This condition of lower wellbore pressure than the formation is

caused in two ways. First, if the mud weight is too low, then the hydrostatic pressure

exerted on the formation by the fluid column may be insufficient to hold the formation

fluid in the formation. This can happen if the mud density is suddenly lightened or is

not to specification to begin with, or if a drilled formation has a higher pressure than

anticipated. This type of kick might be called an underbalanced kick. The second

way a kick can occur is if dynamic and transient fluid pressure effects, usually due to

motion of the drillstring or casing, effectively lower the pressure in the wellbore below

that of the formation. This second kick type could be called an induced kick.

When a kick occurs during drilling there are procedures that have to be followed

to control the well and prevent any further influx into the well. In this experiment

when the kick occurred we had to shut-in the well using the BOP. Then we used the

Drillers method to control and bring out the kick.

The experiment was conducted to control the kick and the results obtained are

written and mentioned above. Firstly we need to know the drillers method which is

the method used in this experiment to control the kick. The Drillers method is a two

complete circulation method; firstly the kick is circulated (brought out) by the old

mud, secondly the old mud is circulated out using kill weight mud (new mud). As

there are many other methods of controlling a kick; in this experiment we used the

Drillers method due to its simplicity and because it has less risk of stuck pipe, also

other methods like the engineers method involves a lot of complex calculation.

The kick can be detected by many ways; the firstly the addition of any fluid from

the formation will result in a change in return flow and a change in the active pit

volume which means that the flow rate of the returned drilling fluid will increase and

an increase in the pit deviation will be noticed. Other indication such as the increase

of rate of penetration happens if the differential between formation pressure and

hydrostatic pressure created by drilling mud decreases, there is possibility to

increase rate of penetration because the hold down effect is decreased. There are

more indications such as the increase of the cutting size and shape and also a

decrease in shale density. In this experiment the simulator has an automated alarm

which goes on as soon as a kick is detected so when the alarm went on we

encountered a kick with an increase of the pit volume.

After detecting the kick the first step was to shut-in the well and start with

procedure of controlling the well using the Drillers method. Our aim was to control

the well and prevent the potential blow out and also preventing further influx from

entering the wellbore. According to the Drillers method the shut-in drill pipe pressure

(SIDPP), shut-in casing pressure (SICP) and pit volume should be recorded.

10

We recorded the SIDPP pressure, SICP pressure and the pit volume. All these

reading are essential for the procedure of controlling the well for example:

SIDPP pressure is used to calculate the Kill mud weight, SICP pressure is used to

determine the controlling method and pit volume is used to specify the type of the

influx (water, gas or oil).

After taking the readings of SIDPP, SICP and pit volume, we started pumping

by bringing the pump up to 30 SPM gradually each time with a 5 SPM increment

while adjusting the choke to maintain the SICP constant between 305 and 455 psi (a

150 psi safety factor). After the SICP is stabilised the choke is adjusted to maintain

the SIDPP until the influx is out. When the influx was out we stopped the mud pump

and closed the choke. Unfortunately we closed the choke before closing the mud

pump which caused an increase in the wellbore pressure and that increase caused

the formation of the well to fracture. The reading if SIDPP and SICP after the influx

was out are nearly the same which indicated that there was no further influx into the

wellbore.

After the influx was out we increased the mud weight by the calculating the kill

mud weight using the equation:

KMW = + OMW

KMW is kill mud weight

OMW is the original mud weight =12.2 ppg

TVD true vertical depth=6000.7 ft

SIDPP the shut=in drillpipe pressure =319 psi

KMW = + 12.2

KMW = 13.7 ppg

The new mud is circulated into the well bore by gradually increasing the mud pump

to 30 SPM and maintaining the SICP constant until the kill mud reach the bit. Once

the kill mud reached the bit the FDP is maintained constant 380-530psi (a 150 psi

safety factor) until the kill mud reached the surface. After the kill mud reached the

surface the pump was stopped and choke was closed but the SIDPP and SICP were

not zero which meant that the well is not dead yet; the readings are shown above. As

thee choke was opened and closed finally the SIDPP and SICP were both zero. The

flow was checked and the difference was calculated and found to be 0.03 bbl. Finally

the well is dead and the drilling operation can be resumed. The key point here is that

during the kick control the well bore pressure is maintained slightly higher than the

formation pressure.

11

6) ANSWER TO GIVEN QUESTION

1. Explain the correlation between bottom hole temperature and hydrostatic

gradient.

-

Pressure gradient (by fluid) - The change in pressure per unit of depth,

typically in units of psi/ft or kPa/m Deviations from normal pressure are

described as high or low pressure.

-

Bottom Hole Temperature - The temperature in the borehole at total depth at

the time it is measured. In log interpretation, the bottom hole temperature

(BHT) is taken as the maximum recorded temperature during a logging run,

or preferably the last of series of runs during the same operation. BHT is the

temperature used for the interpretation of logs at total depth.

The bottom hole temperature (BHT) is basically affected by two

parameters, which is the true vertical depth (TVD) and the thermal gradient.

For hydrostatic gradient (pressure gradient of the fluid in the pore space,

normally 0.433psi/ft for fresh water and 0.465 for high salinity salt water) is a

function of TVD and types of formation.

Bottom hole Temperature, BHT = TVD x Thermal Gradient

Bottom hole Pressure, BHP = TVD x Hydrostatic Gradient

The thermal gradient will vary based on different location. The thermal

gradient will basically be reduced with depth. However, in drilling operations,

with increased depth, the BHT increment can be from the order of 15-20K

for every 1000m for low pressure and low temperature reservoir. Although

the gradient has decreased, the BHT can still be increasing as it is highly

affected by the increasing depth of TVD.

When planning or drilling a well, it is often more convenient to refer to

hydrostatic pressures in terms of pressure gradient. Pressure gradient is the

rate of increase in pressure per unit vertical depth (psi/ft). It should be noted

that fluid densities, measured in ppg or SG, are also gradients. The pressure

gradient will be increasing with depth as the cumulative overburden stress of

the formation above it is stacked.

The proper parameter to correlate the bottom hole temperature and

pressure gradient is the depth of the borehole in a vertical measure. Thus, it

can be generally concluded that the bottom hole temperature will be

increasing gradually while more rapidly for the pressure gradient with the

increment of depth. But, the contribution of the reduced thermal gradient with

depth is small compared to the rapid increment of depth.

12

2. There are a variety that can cause abnormal formation fluid pressure. List 4 of

the principal causes.

- Under-compaction of sediment

- Tectonic Activity

- Presence of salt structure

- Chemical Diagnosis

- Presence of Artesian system

3. What is MAASP stands for? When is the right time to re-calculate this

parameter?

MAASP stands for Maximum Allowable Annulus Surface Pressure. It

is an absolute upper limit for the pressure in the annulus of an oil and gas

well as measured at the wellhead.

One major threat to annulus integrity is overpressure within the annulus which

could lead to burst or collapse of a casing or damage to the formation

below. Therefore, MAASP is calculated to provide a surface pressure, which

will produce the limiting pressure at the shoe.

There are four different ways in an annulus may be over pressured which are

the right time to re-calculate MAASP:

a) Burst of the outside casing

b) Collapse of the inside casing

c) Fracturing of the formation at the shoe

d) Overpressure of the surface equipment

13

4. A well can be induced to flow by swabbing which happens due to the

reduction of bottom hole pressure when pulling pipe. List 3 conditions that

can cause swabbing.

Swabbing is the condition that happens when anything in a hole such as drill

string, logging tool, and completion sting is pulled and it brings out decreasing

hydrostatic pressure. There are 3 conditions that can cause swabbing:

a) Light density fluid in wellbore which results in decreasing hydrostatic

pressure

b) Abnormal pressure where abnormally high pressure zones are over

current mud weight in the well

c) Severe lost circulation

5. List at least 2 causes of the increase in rate of penetration during drilling.

The increment in rate of penetration during drilling happens when soft

or abnormally pressured formations are encountered.

When rotary speed increases, the rate of penetration will be enhanced.

The increment is also caused by the weight on bit. Basically, ROP is directly

proportional to weight-on-bit (WOB) till a critical point.

6. Mention at least 5 components of drill stem.

The drill stem consists of drillpipe, drill collars, drill bit, heavy-walled drillpipes

(HWDP), stabilisers and shock subs.

a. Drillpipe - It acts as a medium to transmit rotary motion to the bit and

serves as a passage for mud.

b. Drill collars - They are heavy-duty pipes with large outside diameters that

are used primarily to put weight on bit during drilling operations.

c. Drill bit - It is the main component of the drill string and is used to cut the

rock in order to make hole. Drag bits, roller cone bits and diamond bits are

the 3 main types of drill bits.

d. HWDP - It is used to ensure that the drillpipe is always kept in tension.

e. Stabiliser - Its outside diameter is close to the hole diameter. It is used to

prevent buckling or bending of drill collars and to control the drill string

direction.

14

f. Shock sub - It is included in the bottom hole assembly to absorb shocks

when the bit bounces off hard formations, hence protect the drilling string

and surface equipment from damaging effects of bit vibrations.

15

7. Shown below is a pressure versus volume plot of a leak off test

The leak off was carried out with a 10.6 ppg mud. The casing shoe is at

4000ft TVD

a. What is the maximum pressure that the exposed formations below

the shoe can support?

b. What is the Fracture Gradient?

c. What is the maximum mud weight?

d. If drilling was resumed and the mud weight was increased to 12.6

ppg. Calculate M.A.A.S.P

Solution:

Mud Weight=10.6 ppg

Casing TVD=4000 ft

Surface Pressure= 1100 psi

a) What was the maximum pressure that exposed formation below the shoe

can support?

Maximum Pressure= (casing TVD x Mud Weight x 0.052) + surface Pressure

= (4000 x 10.6 x 0.052) +1100

=3305 psi

b) What is the Fracture Gradient?

Fracture Gradient= Leak Off Pressure (psi) / Casing Shoe TVD(ft)

=3305 psi/ 4000 ft

=0.826 psi/ft

c) What is the maximum mud weight?

Maximum Mud Weight= [Leak off Pressure (psi) / 0.052 x casing Shoe TVD] +

Current mud Weight (ppg)

= [1100 / 0.052(4000)] + 10.6ppg

=15.89 ppg

16

d) If drilling was resumed and the mud weight was increased to 12.6ppg.

Calculate M.A.A.S.P

M.A.A.S.P= [Max Mud weight Mud Weight in casing][0.052 x casing TVD]

= [15.89 12.6][0.052 x 4000]

=682.24 psi

17

8. Given the following data:

Depth 10000ft TVD

Bit size 8

Shoe depth 8500ft TVD

Mud weight 12.6 ppg

Collars 600ft. Capacity = 0.0077 bbl / ft

Metal displacement = 0.03 bbl / ft

Drill-pipe 5 capacity = 0.0178 bbl / ft

Metal displacement = 0.0476 bbl / ft

Casing / pipe annular capacity = 0.0476 bbl / ft

Casing capacity = 0.0729 bbl / ft

One stand of drill-pipe = 94 ft

Assuming the 12.6 ppg mud givens an over-balances of 200 psi

a. If 10 stands of pipe are removed dry without filling the hole, what would

be the resultant reduction in bottom-hole pressure?

b. If 5 stands of pipe had been pulled wet without filling the hole, the

resultant reduction in bottom-hole pressure would be.

c. If prior to tripping a 20 barrel slug of 14.6 ppg mud was displaced to

prevent a wet trip, what would be the expected volume return due to the U-

tubing of the heavy mud?

Solution:

Depth=10000ft TVD

Shoe depth=8500 ft TVD

Bit Size=8 1/2

Mud Weight=12.6 ppg

a) 10 stands of pipe are removed dry without filling the hole. What would be the

resultant reduction in bottom hole Pressure?

Mud Weight= Mud Gradient/ 0.052

Mud Gradient=12.6(0.052)

=0.6552

Metal Displacement: from the given value from website, the metal

displacement for drill pipe of 5 capacity is 0.0075 bbl/stb

To pull the dry pipe= [Mud Gradient x metal Displacement] / [Casing Capacity

Metal Displacement]

=0.6552 x 0.0075 / 0.0729 0.0075

=0.007514 psi/ft

18

For 10 stands of pipe, the value of the depth calculated need to times 10,

which is:

94 ft x 10 x 0.007514 psi/ ft

=70.63 psi

b) 10 stands of pipe are removed wet without filling the hole. What would be

the resultant reduction in bottom hole Pressure?

To pull the wet pipe= [Mud Gradient (Metal Displacement + Drill Pipe

Capacity] / Annulus Volume (bbl/ft)

=0.6552(0.0075 = 0.0178)/ 0.0476

=0.3482 psi/ft

For 5 stands of pipe, the value of the depth calculated need to times 5, which

is:

94ft x 10 x 0.3482 psi/ft

=163.65 psi

REFERENCE

Applied drilling engineering: SPE text book vol.2 (text book).

http://www.glossary.oilfield.slb.com/Display.cfm?Term=pressure%20gradient

http://www.glossary.oilfield.slb.com/Display.cfm?Term=bottomhole%20temperature

Overview of Formation Pressure, lecture note by Mr. Saleem Q Tunio

http://doi.aapg.org/data/open/offer.do?target=/bulletns/1974-

76/data/pg/0059/0006/0950/0957.htm

http://en.wikipedia.org/wiki/MAASP

http://www.drillingahead.com/profiles/blogs/causes-of-kick-wellbore-influx

Das könnte Ihnen auch gefallen

- Lab Report GeologyDokument27 SeitenLab Report GeologySidharth Therroth88% (8)

- Lab Report Drilling Fluids LabDokument10 SeitenLab Report Drilling Fluids LabLaura Demarch100% (1)

- Lab Manual For Drilling FluidDokument13 SeitenLab Manual For Drilling FluidLemony Snickit100% (1)

- Manufacturing Egg Trays from Waste PaperDokument17 SeitenManufacturing Egg Trays from Waste Paperravibarora86% (7)

- Mud Rheology TestDokument3 SeitenMud Rheology TestAbhi Sharma100% (1)

- Jar TestDokument2 SeitenJar TestTengku Mohd KhairiNoch keine Bewertungen

- Aluminium GMAW GuideDokument32 SeitenAluminium GMAW GuideDaniel Salinas100% (2)

- Mud Lab Manual - NewDokument32 SeitenMud Lab Manual - Newfisco4ril67% (6)

- Volume Calculation Lab Report - SIti Norhananiza - 2018262666 - EH2436CDokument16 SeitenVolume Calculation Lab Report - SIti Norhananiza - 2018262666 - EH2436CNor HananizaNoch keine Bewertungen

- Jar Test ReportDokument8 SeitenJar Test ReportHeLmi Hendrix75% (4)

- Drilling Simulator: Lab ReportDokument22 SeitenDrilling Simulator: Lab ReportFizz MartinNoch keine Bewertungen

- Mud Viscocities and Other Rheological PropertiesDokument23 SeitenMud Viscocities and Other Rheological PropertiesMuhammad Naqiuddin Bin Zahid67% (3)

- Drilling Simulation LabDokument20 SeitenDrilling Simulation LabJacinto Siqueira100% (1)

- Drilling Rig Systems OverviewDokument12 SeitenDrilling Rig Systems OverviewAhmed AmirNoch keine Bewertungen

- Lab Gas Flow (Afif)Dokument17 SeitenLab Gas Flow (Afif)Nurshazwani syuhada bt al- badri100% (1)

- Understand Centrifugal CompressorDokument16 SeitenUnderstand Centrifugal Compressorramanathan72-1100% (2)

- Contoh Report Jar TestDokument12 SeitenContoh Report Jar TestIzzat75% (4)

- Drilling Simulator (16.3.2018)Dokument23 SeitenDrilling Simulator (16.3.2018)Fizz Martin100% (1)

- Che486 l7 Osbourne Reynolds ApparatusDokument23 SeitenChe486 l7 Osbourne Reynolds ApparatusEreen100% (1)

- Jar Test-1full ReportDokument6 SeitenJar Test-1full ReportSamuelNoch keine Bewertungen

- Final Drilling Fuild Lab ReportDokument19 SeitenFinal Drilling Fuild Lab ReportTaufik Zainuddin100% (2)

- Updated QuestionsDokument16 SeitenUpdated QuestionsMoNoch keine Bewertungen

- Permeability of Porous Media Using Liquid ParameterDokument18 SeitenPermeability of Porous Media Using Liquid ParameterIdham ArifNoch keine Bewertungen

- Walid Questions, 2020Dokument69 SeitenWalid Questions, 2020MoNoch keine Bewertungen

- Petroleum Technology Drilling Fluid Lab Tests ProceduresDokument50 SeitenPetroleum Technology Drilling Fluid Lab Tests ProceduresHomam MohammadNoch keine Bewertungen

- Lab 3 Solid Liquid Content Full (Electrical Stability)Dokument9 SeitenLab 3 Solid Liquid Content Full (Electrical Stability)Marouane Adam0% (1)

- Drilling Fluid Contamination TestDokument13 SeitenDrilling Fluid Contamination TestHumaira Mirza0% (2)

- Lab Drilling Exp 5 Contour MapDokument11 SeitenLab Drilling Exp 5 Contour MapIngenieur Khairuddin Ngah100% (1)

- Drilling Fluid ExperimentsDokument48 SeitenDrilling Fluid ExperimentsSamwel MmariNoch keine Bewertungen

- Experiment 3 Full Report LatestDokument17 SeitenExperiment 3 Full Report LatestChan Chun Chen100% (2)

- Fuels and Heat Power: A Guide to Fuels, Furnaces, and FiringDokument101 SeitenFuels and Heat Power: A Guide to Fuels, Furnaces, and FiringAlyssa Clarizze MalaluanNoch keine Bewertungen

- Lab Mud Solid Content DeterminationDokument10 SeitenLab Mud Solid Content DeterminationIngenieur Khairuddin Ngah33% (3)

- Pe03023 QaDokument25 SeitenPe03023 QaFariz Adriansyah100% (1)

- Drilling Lab 1 FullDokument14 SeitenDrilling Lab 1 FullIdham Arif100% (1)

- Lab Report 6Dokument12 SeitenLab Report 6Siti Nur Izzaty50% (2)

- Lab Gas FlowmeterDokument7 SeitenLab Gas Flowmeterazym94Noch keine Bewertungen

- Venturi Scrubber Pressure Drop RelationshipDokument12 SeitenVenturi Scrubber Pressure Drop Relationshipbotakmbg6035Noch keine Bewertungen

- PETE 203 Drilling Engineering Lab ManualDokument98 SeitenPETE 203 Drilling Engineering Lab ManualMarshal betaNoch keine Bewertungen

- Assignment Fluid 2 UitmDokument19 SeitenAssignment Fluid 2 UitmFirdaus AsryNoch keine Bewertungen

- EVT577 Wastewater Exp3 BODDokument6 SeitenEVT577 Wastewater Exp3 BODFadzrilNoch keine Bewertungen

- Lab 3Dokument13 SeitenLab 3ismael hashiNoch keine Bewertungen

- Lab Report Waste Water 1Dokument10 SeitenLab Report Waste Water 1eidalinNoch keine Bewertungen

- Sand Content: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab ExperimentDokument6 SeitenSand Content: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab Experimentايمن القنونيNoch keine Bewertungen

- 216 Lab ManualDokument77 Seiten216 Lab Manualniyo7Noch keine Bewertungen

- Center of PressureDokument10 SeitenCenter of PressureMuhammad Adli Amin Mohd AmzukiNoch keine Bewertungen

- Reservoir Lab SheetDokument36 SeitenReservoir Lab SheetSteve Lian Kuling100% (1)

- Exp 4 - Size Reduction Using Ball MillDokument7 SeitenExp 4 - Size Reduction Using Ball MillafifiNoch keine Bewertungen

- Lab Experiment 1 Repaired)Dokument15 SeitenLab Experiment 1 Repaired)Amirul Hakim100% (3)

- Exp 4 FlowabilityDokument4 SeitenExp 4 FlowabilityNur SyahirahNoch keine Bewertungen

- Lab 1 Cge617Dokument9 SeitenLab 1 Cge617wak syazwanNoch keine Bewertungen

- Bod ReportDokument6 SeitenBod ReportdiyanaNoch keine Bewertungen

- Exp 1-Fluid MixingDokument12 SeitenExp 1-Fluid MixingKhairulAzwanizam100% (1)

- PenetrationDokument14 SeitenPenetrationTarmidzi Mohd Zailani100% (1)

- Jar TestDokument3 SeitenJar TestUpasana BhardwajNoch keine Bewertungen

- VSS Analysis Determines Organic Contamination LevelsDokument7 SeitenVSS Analysis Determines Organic Contamination LevelsSamuelNoch keine Bewertungen

- Lab 4 BODtestDokument7 SeitenLab 4 BODtestcindyn_46100% (2)

- Aaaaaayidddddd287190871 Thermofluids Lab Fluid MixingDokument21 SeitenAaaaaayidddddd287190871 Thermofluids Lab Fluid Mixingezzat0% (1)

- Executive Summary:: Reservoir Engineering Lab SN 02 / Group F Experiment 1 27TH MARCH 2016Dokument14 SeitenExecutive Summary:: Reservoir Engineering Lab SN 02 / Group F Experiment 1 27TH MARCH 2016MelindaNoch keine Bewertungen

- Mud Densities Exp NewDokument8 SeitenMud Densities Exp NewHafizszul FeyzulNoch keine Bewertungen

- (Lab Report Operation Unit) Experiment 7Dokument4 Seiten(Lab Report Operation Unit) Experiment 7Fazsroul33% (3)

- Experiment Bag FilterDokument14 SeitenExperiment Bag FilterMuhammad Adzfar100% (2)

- Systems of Drilling OperationDokument4 SeitenSystems of Drilling Operationkurddoski28Noch keine Bewertungen

- Khartoum University drilling report summaryDokument10 SeitenKhartoum University drilling report summaryBilly WilsonNoch keine Bewertungen

- Assignment SubsurfaceDokument10 SeitenAssignment SubsurfaceLeo NgoulouNoch keine Bewertungen

- Final Report of Business VentureDokument20 SeitenFinal Report of Business Venturenasreldin3Noch keine Bewertungen

- Welded Blade Stabilizer: Flow CouplingsDokument1 SeiteWelded Blade Stabilizer: Flow Couplingsnasreldin3Noch keine Bewertungen

- Reservoir Fluid Flow FundamentalsDokument26 SeitenReservoir Fluid Flow Fundamentalsnasreldin3100% (2)

- Engineering Team Project - ETP Guide Sep 2013Dokument41 SeitenEngineering Team Project - ETP Guide Sep 2013nasreldin3Noch keine Bewertungen

- Software Hardware Tech x86 VirtDokument9 SeitenSoftware Hardware Tech x86 VirtwyfwongNoch keine Bewertungen

- AOE - FormDokument8 SeitenAOE - FormBimal GuptaNoch keine Bewertungen

- MyPower S3220&S3320-INSTALLATIONDokument83 SeitenMyPower S3220&S3320-INSTALLATIONJorge GonzalesNoch keine Bewertungen

- Brake Pedals and ValveDokument4 SeitenBrake Pedals and Valveala17Noch keine Bewertungen

- PDF Saa6d140e 2 Seriespdf CompressDokument8 SeitenPDF Saa6d140e 2 Seriespdf CompressNathawatNoch keine Bewertungen

- General Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDokument1 SeiteGeneral Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDianaShipeNoch keine Bewertungen

- Royal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale QuotationDokument3 SeitenRoyal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale Quotationmuhammad aliNoch keine Bewertungen

- D72140GC10 46777 UsDokument3 SeitenD72140GC10 46777 UsWilliam LeeNoch keine Bewertungen

- Module 8 SAHITA ConcreteDokument11 SeitenModule 8 SAHITA ConcreteHarrybfnNoch keine Bewertungen

- Fortumo Mobile Payments API GuideDokument8 SeitenFortumo Mobile Payments API GuideVladimir UtješinovićNoch keine Bewertungen

- Shivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursDokument4 SeitenShivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursSHIVAM TAYALNoch keine Bewertungen

- Disney Channel JRDokument14 SeitenDisney Channel JRJonna Parane TrongcosoNoch keine Bewertungen

- Methods of Piling ExplainedDokument3 SeitenMethods of Piling ExplainedRajesh KhadkaNoch keine Bewertungen

- 01 U3 Ws 1 Force DiagramsDokument4 Seiten01 U3 Ws 1 Force Diagramsapi-197108354Noch keine Bewertungen

- PrintedElectronics ProductOverview PDFDokument2 SeitenPrintedElectronics ProductOverview PDFanon_551622158Noch keine Bewertungen

- ARL-300 UCM Test Instructions For Hydraulic Lifts - enDokument6 SeitenARL-300 UCM Test Instructions For Hydraulic Lifts - enkizonimeisterNoch keine Bewertungen

- Types of Commercial CellDokument4 SeitenTypes of Commercial CellDaveNoch keine Bewertungen

- Testing concrete and brick strengthDokument2 SeitenTesting concrete and brick strengthlolenlennNoch keine Bewertungen

- P8B WS Memory Qualified Vendors List (QVL)Dokument3 SeitenP8B WS Memory Qualified Vendors List (QVL)bolpensmaierNoch keine Bewertungen

- DPWH Standard Specifications for ShotcreteDokument12 SeitenDPWH Standard Specifications for ShotcreteDino Garzon OcinoNoch keine Bewertungen

- How The Draganflyer Flies: So How Does It Work?Dokument5 SeitenHow The Draganflyer Flies: So How Does It Work?sav33Noch keine Bewertungen

- Human Plus Machine A New Era of Automation in ManufacturingDokument8 SeitenHuman Plus Machine A New Era of Automation in ManufacturingDuarte CRosaNoch keine Bewertungen

- ANR causes and solutionsDokument2 SeitenANR causes and solutionsPRAKHAR SRIVASTAVANoch keine Bewertungen

- Hublit Limphaire Leaflet India PDFDokument2 SeitenHublit Limphaire Leaflet India PDFAkshay RaiNoch keine Bewertungen

- 0 EDEM Applications MeDokument16 Seiten0 EDEM Applications MeRuben PurcaNoch keine Bewertungen

- KernelDokument326 SeitenKernelSkyezine Via Kit FoxNoch keine Bewertungen