Beruflich Dokumente

Kultur Dokumente

PCIM2001 Stack Development

Hochgeladen von

Nishith Dhinora0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

34 Ansichten6 Seitenigbt stack

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenigbt stack

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

34 Ansichten6 SeitenPCIM2001 Stack Development

Hochgeladen von

Nishith Dhinoraigbt stack

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

PCWEk CCMVEkSlCM CCMFEkEMCE PClM200T JUME 200T MUkEMBEkC, CEkMAMY Puge T

Development of Modular High-Power IGBT Stacks

Heinz Redi

CT-Concept Technologie AG

Renferstrasse 15

2504 Biel-Bienne (Switzerland)

Tel +41 32 341 41 01

Fax +41 32 341 71 21

E-Mail Info@CT-Concept.com

Dr. Daniel Tollik

econoStack AG

Renferstrasse 15

2504 Biel-Bienne (Switzerland)

Tel +41 32 341 71 11

Fax +41 32 341 71 21

E-Mail Info@econoStack.com

Abstract

Development of a standard semiconductor stack for use in modular high-power systems

seems to be different task than the design of an application dedicated one. The paper

discusses some most significant issues influencing the component selection and outlines a

design procedure that can be employed in this case. Optimum cost-performance ratio of the

design should be achieved by optimum usage of the selected newest generation

semiconductor module and its cooling system, which constitutes the crucial part of the whole

assembly. By parallel connection of several such stacks the total output power can be scaled

up to arbitrary high level.

1. Introduction

Stacks (assemblies) are the fundamental

building blocks of any high-power system and

consist typically of semiconductor module with

its cooler, dc-link capacitors as well as the drive

and protection circuitry. Most of them are used

in the three-phase inverter or rectifier

configurations.

Today majority of stacks are designed for a

particular application according to its

specification manual. In this case the most

important technical information such as input

and output voltage and current ranges and

ambient temperature is available from the

beginning. Using calculation and simulation

tools it is then possible to calculate losses and

stresses in all components and determine their

required parameters to make the right choice.

Usually, because of many interactions between

system components, this process may need

some iterations to achieve the optimum design.

On the other hand some suppliers offer

standard stacks that are available in many

different types and classes. This variety of

forms is supposed to satisfy very broad and

very different needs of different users and

applications. Because of this majority of these

stacks are manufactured and delivered to the

customer order. Due to above diversity of

requirements and power classes the standard

stacks are built using different IGBT modules,

cooling systems, etc. Production and

distribution of such stacks requires very large

engineering and consulting expenditures and of

course extensive logistic. Obviously,

manufacturing in small series/ quantities is quite

time-consuming and expensive.

As alternative to this traditional approach it

seems to be justified to develop modular stacks

that constitute possibly optimized basic unit. By

parallel connection of several such units the

total output power of the equipment could be

scaled up to almost arbitrary high levels. This

concept offers number of advantages for the

manufacturer, distributor and also for the user.

Significantly higher production volume of only

very few stack models reduces the logistic

problems and production costs and stimulates

quality improvements both in the development

and production processes.

The objective of this paper is to discuss

essential design aspects of a optimized

standard high-power stack for the power range

above 100kVA, especially the different criteria

of selecting the most critical components. This

discussion should facilitate the development

PCWEk CCMVEkSlCM CCMFEkEMCE PClM200T JUME 200T MUkEMBEkC, CEkMAMY Puge 2

process of such products with the goal to

provide optimum cost-performance ratio.

2. The challenge

The main goal of the development project is the

optimum choice of the best-in-class

components and their combination to achieve a

state-of-the-art cost-performance ratio of the

standard stack for the broadly defined power

class between 100kVA and 200kVA per unit.

In order to achieve the cost-optimized solution

the electrical and thermal utilization of all

components should be considered very

carefully.

The next design challenge is the optimum

mechanical construction that allows for parallel

connection of any number of units as well as

enables to realize any practical topology of the

overall system. This means that the stack must

be scaleable and stackable both electrically and

mechanically.

This requirement should be achieved without

compromises in the power rating of each single

stack comprising the system. The mechanical

design should be also production friendly

especially for higher number of pieces.

The third challenge is to build a system with the

highest possible power density.

For the standard stack intended for the

universal use there are no detailed

specifications available. The design of such

stacks requires therefore different strategy in

the component choice, which will be addressed

in the proceeding sections for each component

type.

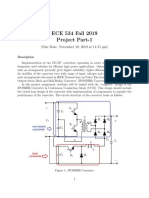

3. Choice of electrical topology

As mentioned above the majority of high-power

applications employs the very universal three-

phase bridge topology shown in Fig. 1.

Most frequently it is used in the dc-ac inverter

mode in numerous applications such as UPS

systems, ac motor drives, etc. However, it can

be also implemented in the ac-dc rectifier mode

in the active Power Factor Corrector

configuration. Two such units can be connected

to realize for example complete high-quality ac-

ac frequency converter.

Due to the progress in the IGBT chip

technology together with the developments in

the packaging techniques the IGBT modules

(containing also fast antiparallel diodes) have

become the most popular choice for this three-

phase bridge topology. The six-pack

configurations for high voltage (up to 1700V)

and high current (450A per switch) in one

package are now available on the market.

+Vdc

-Vdc

I

R

I

S

I

T

V

V

V

R

S

T

P rectifier mode

P inverter mode

Fig. 1. Selected electrical topology of the

standard high-power stack (only the key power

processing parts are shown).

4. Choice of IGBT module

The decision which module should be chosen

to do the job is the most crucial one in the

whole procedure. It seems to be very important

to select the best-in-class device, which

combines high voltage and current ratings with

low loss generation and good thermal design.

At this moment the econoPACK+ modules from

eupec with reduced conduction voltage drop

and fast turn-off characteristics (thanks to

IGBT

3

technology) appear to be the right choice

[1], [2]. Additional advantage will be the

availability of compatible devices from two other

manufacturers (Fuji and Mitsubishi).

Clearly, as the main goal of the standard stack

is to offer optimum cost-performance ratio and

the IGBT module contributes heavily to the total

cost, it is necessary to fully utilize the module

by maximizing its processed power value.

Useful help provided by the module

manufacturer is the Excel-based IPOSIM

calculation program (accessible from eupecs

internet site) that allows to calculate losses in

each IGBT and diode as a function of rms value

of the output (phase) current. As the input data,

beside the module type, one has to specify line

f

o

and switching frequency f

s

, dc voltage value

V

dc

, modulation factor m, phase shift between

phase current and voltage waveforms cos(),

PCWEk CCMVEkSlCM CCMFEkEMCE PClM200T JUME 200T MUkEMBEkC, CEkMAMY Puge 3

maximum admissible junction temperature T

jmax

as well as the case temperature T

c

.

The maximum estimated power achievable with

an assumed module type depends of course on

several parameters mentioned above, as

illustrated by the two examples in Fig. 2 and 3.

The Figs. 2 and 3 show the influence of the

switching frequency f

s

and dc voltage value V

dc

on the maximum value of the processed power

P

out

, respectively. It is important to note that

both admissible junction temperature T

jmax

and

fixed case temperature T

c

are assumed for

these calculations.

Vdc=680V

Tjmax=125

o

C, Tc=100

o

C, m=1, cos()=0.95; fo=50Hz

0

50

100

150

200

250

300

0 5 10 15 20 25

fs (kHz)

Pout (kW)

Fig. 2. Achievable value of processed power

P

out

as a function of switching frequency f

s

.

.

f

s

=3kHz

T

j max

=125

o

C, T

c

=100

o

C, m=1, cos()=0.95, f

o

=50Hz

100

120

140

160

180

200

220

240

500 550 600 650 700 750

Vdc (V)

Pout (kW)

Fig. 3. Achievable value of processed power

P

out

as a function of dc voltage V

dc

.

In reality however the T

c

value cannot be fixed

but rather the maximum ambient temperature

T

amax

is specified. Obviously, T

jmax

, T

amax

and

also assumed value of P

out

determine the

required efficiency of the cooling system (for

simplicity expressed by the thermal resistance

R

th h-a

between the heatsink body under the

module and the ambient air).

This relationship is illustrated in Fig. 4 that

shows the maximum achievable power level as

a function of the R

th h-a

value.

Tj max=125

o

C, Tamax=45

o

C, fs=3kHz, fo=50Hz, Vdc=680V,

m=1, cos()=0.95, Rth j -c=0.01K/W, Rth c-h=0.005K/W

0

50

100

150

200

250

300

0 0,01 0,02 0,03 0,04 0,05 0,06 0,07

R

th h-a

(K/W)

P

out

(kW)

Fig. 4. Achievable processed power P

out

as a

function of thermal resistance between heatsink

and ambient R

th h-a

.

5. Choice of cooling system

For high-power stacks two cooling methods

should be taken into consideration, the liquid

(usually water) cooling and the forced-air

cooling. The first one is surely more efficient

however cannot be applied in the most

standard stacks because of the potential

difficulty to integrate it in different system

environments. In some applications water

cooling is even distinctly undesirable not only

because of its high cost.

The forced-air cooling systems employ either

conventional aluminium heat-sink profiles,

including all optimized designs with hollow fins,

folded fins, cross-cutted or augmented fins, etc.

[3] or the heat-pipes combined with fin-stacks.

In either case one or more fan devices provide

the necessary air-volume to absorb the heat

from the active surfaces of heat-sink or fin-

stack.

An important limitation of the conventional

cooling systems is the bad distribution of heat

across both the heat-sink bulk material and fins.

This problem becomes aggravated when the

heat density increases above 10W/cm

2

, which

is exactly the case for the selected high-power

IGBT modules.

On the other hand the heat-pipe systems offer

very good heat transport from the source to the

fin-stack. The fin-stack structure enables then

quite efficient heat transfer to the air stream

supplied by the fan. Generally standard off-the-

PCWEk CCMVEkSlCM CCMFEkEMCE PClM200T JUME 200T MUkEMBEkC, CEkMAMY Puge 4

shelf cooling systems cannot be used in this

application as they are not designed for the

heat sources with this heat density. They are

characterized by single R

th

values, which are

defined for uniform heat distribution over the

entire mounting surface, sometimes even for

the double-side assembly. It is also assumed

that there are no temperature gradients on the

heatsink surface.

Fig. 5. Collection of cooling systems and fans

evaluated in the project.

The tests conducted on a number of standard

high-power cooling systems (refer to Fig. 5 and

6) using the selected econoPACK+ module

showed severe deviations of the results from

the R

th

values published in the data-sheets.

Fig. 6. A cooling system under test with

econoPACK+ module, radial fan, temperature

and airflow sensors.

The conclusion is that the only way to go is to

verify the efficiency of the cooler by testing it

with the real IGBT module. Simple dc current

dissipation heating should be normally sufficient

for such a test (refer to Fig. 6). In fact one is not

really interested in the R

th

value but rather in

the temperature rise above ambient for given

power dissipation. This allows extrapolation of

the measured temperatures to the maximum

ambient temperature condition and enables to

check if the admissible junction temperature will

be not exceeded.

Needless to say the temperature of the

mounting surface is never uniform so it is a

necessary to watch the temperature of the hot-

spot.

As the baseplate surface of the IGBT module is

rather small (for instant approx. 20cm

2

for

econoPACK+) and the heat distribution is pretty

bad the most part of the standard profile does

not any job except adding the weight and cost.

The heat-pipe assisted systems seem to solve

the above problem. However, comparing with

the conventional coolers the heat-pipe systems

are more expensive and exhibit also some

limitations such as operation in negative

temperatures (requires implementation of heat-

pipes filled with methanol that worsen efficiency

in the normal temperature range) and preferred

vertical orientation (otherwise more expensive

heat-pipe versions with sintered powder metal

wick structure are needed). For more

information about heat-pipes and their

application in cooling of electronic systems refer

for instant to [4].

Although the heat-pipes themselves do not

dissipate heat they are extremely efficient as a

transport medium. The heat is delivered quite

evenly to the all fins composing the stack along

the pipes (usually made of aluminium) and then

distributed across them. Sometimes the bent

heat-pipes can be preferred to improve heat

distribution across each fin by injecting it at

larger surface.

The choice of the fan device is also critical step.

One of the reasons is that its pressure drop vs

air-flow characteristic must fit the air resistance

characteristic of the heatsink structure to obtain

required R

th

value. Other considerations include

noise level, life-time, power consumption,

possibility to adjust the speed to the varying

thermal conditions, etc. Axial and diagonal fans

offer some advantages over the radial ones

such as smaller volume and weight, lower

power consumption and easier speed control,

but they are more expensive.

Generally it seems to be justified to invest

enough effort in the optimization of the cooler

design in order to fully utilize potential of the

IGBT module.

PCWEk CCMVEkSlCM CCMFEkEMCE PClM200T JUME 200T MUkEMBEkC, CEkMAMY Puge

6. Choice of capacitor bank

Because of the complexity of the current and

voltage waveforms in the multiple-phase

systems (such as the three-phase inverter) it is

not possible to express the parameters of the

capacitor bank by the closedform equations.

The various simulation programs become the

indispensable tool to find these parameters for

different topologies, voltage ranges, output

power levels, switching frequencies, load

conditions, modulation (control) strategies and

other variables.

The Fig. 7 shows just one example of the

simulated capacitor current and the resulting

rms value.

Fig. 7. Dc-link capacitor current waveform and

its rms value obtained using simulation

program.

There are different possible criteria to define

required parameters and then select the

appropriate component for this function. Both

electrical and mechanical parameters are

relevant for these considerations. Generally, the

electrical parameters to be taken into account

are required capacitance value, specified life-

time and voltage rating.

In the case of electrolytic capacitors the life-

time depends mainly on the rms current value

and its frequency spectrum, ambient

temperature and cooling conditions. The

required life-time level can be achieved using

different capacitor types and vendors

(characterized by different current capability) by

varying the count of parts connected in parallel

and changing the cooling conditions.

Usually meeting life-time requirements results

in capacitance value that is more than enough

for the most of the applications.

A reverse situation is with the foil capacitors

where it is much easier to ensure long life-times

(due to their inherent high current endurance)

however more difficult to achieve large

capacitance values.

An important practical requirement in the

standard stack application is the feasibility to

extend the capacitor bank in the sense of

voltage or current capability. This feature

should provide necessary flexibility for possible

semi-custom adaptations.

7. Choice of IGBT drivers

One of the key component of any stack is the

IGBT driver. The optimum utilization of the

IGBT module is possible only with the driver

circuit that is well designed and adjusted to the

specific IGBT module. To minimize the

switching losses of the module it is necessary

to keep the full control over the switching

transitions in the IGBT.

Small and above all symmetrical delays in all

channels of the driver are very important

conditions for smooth operation in the most

applications. This eliminates the offset

problems that are often underestimated but can

lead to difficulties with the regulation circuits.

Also in the systems with parallel connected

modules the symmetrical delays are very critical

to ensure the proper operation.

The above two aspects permit the

implementation of the short dead-time values

that in turn enables the reduction of distortions

of the output waveforms, maximization of the

output voltage and improves regulation

performance.

For the econoPACK+ modules assumed in the

above procedure there is an obvious choice of

SCALE drivers presented in [5] and [6]. These

drivers are available as complete Plug&Play

units that are electrically and mechanically

dedicated to this application. They include all

IGBT protection functions such as overcurrent,

short-circuit and overvoltage (using the Active

Clamping technique [7]) necessary in industrial

applications.

PCWEk CCMVEkSlCM CCMFEkEMCE PClM200T JUME 200T MUkEMBEkC, CEkMAMY Puge

8. Ancillary circuits and options

To provide reasonable degree of convenience

to the modular standard stack users some

additional functions can be offered:

The standard stack can be equipped with

some measurement functions to monitor

the phase currents, dc voltage and cooler

temperature.

Optionally an auxiliary power supply for fan

as well as the speed regulation and

monitoring circuits can be offered.

9. Outlook

The test methodology of high-power stacks in

particular for their parallel connection to build

Megawatt power level systems is for sure very

challenging and important task. A new concept

that enable continuous long-time testing at full

power and at the same time enable to perform

the application oriented test programs are

under development.

The existing simulation models will be further

developed to allow for simultaneous

investigations of both electrical and thermal

aspects of the stack operation under arbitrary

conditions.

As the standard stacks are intended for use in

many different applications and operating

conditions it is very important to provide the

user with their possibly full characterization on

different levels of detail as well as special

design tools to assist the further application

process by the user.

10. Conclusion

The paper discusses some essential issues

related to component selection, which must be

addressed during development process of the

standard high-power stack. The fundamental

decision to be made is the choice of the

semiconductor module (topology, technology,

package). The suitable cooling system that

permits to use full capabilities of the selected

module is the next crucial step. A special

custom cooler design seems to be unavoidable.

The choice of appropriate component for dc-

side capacitor bank matching the electrical and

mechanical is the next step.

To summarize in high-power range the modular

stack approach can be considered as an

attractive alternative to the application

dedicated approach and traditionally standard

stack series.

The described procedure has been applied to

develop new standard modular stack that will

be launched soon on the market.

References

[1] M. Hierholzer, Th. Laska, M. Mnzer, F.

Pfirsch, C. Schffer, Th. Schmidt:

3rd Generation of 1200V IGBT Modules,

PCIM Nuremberg 1999

[2] M. Mnzer, M. Hornkamp: Econo PACK+.

A new IGBT module for optimised inverter

solutions, PCIM Boston 2000

[3] C. Soule: Future trends in heat-sink

design, Electronics Cooling Magazine,

February 2001

[4] S. Garner: Heat-pipes for electronics

cooling applications, Electronics Cooling

Magazine, September 1996

[5] H. Redi: Modular SCALE Driver Solution

for EconoPACK+, PCIM Nuremberg 2001

[6] H. Redi, P. Khli: The SCALE IGBT-

Driver, A new Scaleable, Compact, All

purpose, Low Cost, Easy to use Driver for

IGBTs, PCIM Nuremberg 1998

[7] H. Redi, P. Khli: New IGBT drivers

feature active clamping, Power Electronics

Europe Magazine, January 2000

Das könnte Ihnen auch gefallen

- SmpsDokument5 SeitenSmpscalvarez_5Noch keine Bewertungen

- Isolated Full Bridge DC-DC Converter for Bidirectional Fuel Cell Energy StorageDokument10 SeitenIsolated Full Bridge DC-DC Converter for Bidirectional Fuel Cell Energy StorageAlan WalkerNoch keine Bewertungen

- Floating Production Storage and OffloadingDokument10 SeitenFloating Production Storage and OffloadingbhuvanaNoch keine Bewertungen

- Thesis Ge TFET Source OnlyDokument123 SeitenThesis Ge TFET Source OnlySumeet KalraNoch keine Bewertungen

- 06 Design Implementation Highly Efficient PDFDokument10 Seiten06 Design Implementation Highly Efficient PDFEdamEdamNoch keine Bewertungen

- Ecuaciones para Curva de Conductores y MotoresDokument6 SeitenEcuaciones para Curva de Conductores y MotoresCarlos Lovera Rodriguez100% (1)

- IGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelDokument6 SeitenIGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelculwavesNoch keine Bewertungen

- Back To Basics Vicor Power Design EbookDokument50 SeitenBack To Basics Vicor Power Design Ebookmulleraf100% (1)

- Highly Efficient Single-Phase Transformerless Inverters For Grid-Connected Photovoltaic SystemsDokument11 SeitenHighly Efficient Single-Phase Transformerless Inverters For Grid-Connected Photovoltaic SystemsKarim EfthuNoch keine Bewertungen

- Dual-Input LLCDokument11 SeitenDual-Input LLCVishal PusadkarNoch keine Bewertungen

- Technical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power SuppliesDokument4 SeitenTechnical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power Suppliesatul vijayvergiyaNoch keine Bewertungen

- REN - Using A Power Module Vs Dicrete Regulator - WHP - 20180808Dokument5 SeitenREN - Using A Power Module Vs Dicrete Regulator - WHP - 20180808أيمن السيد محمد صفوت 8560Noch keine Bewertungen

- Integrated Power DevisesDokument11 SeitenIntegrated Power DevisesmdayyubNoch keine Bewertungen

- Analysis, Design, and Implementation of The AFZ Converter Applied To Photovoltaic SystemsDokument18 SeitenAnalysis, Design, and Implementation of The AFZ Converter Applied To Photovoltaic Systemsvijaya karthegha.RNoch keine Bewertungen

- DTP ManualDokument90 SeitenDTP ManualcuamiNoch keine Bewertungen

- Lecture 24 Computer Modeling and Simulation of PWM Converter CircuitsDokument6 SeitenLecture 24 Computer Modeling and Simulation of PWM Converter Circuitslenovo1986Noch keine Bewertungen

- Design of a Full SiC Voltage Source InverterDokument10 SeitenDesign of a Full SiC Voltage Source InverterPRAJWAL MagadiNoch keine Bewertungen

- Batch 10Dokument68 SeitenBatch 10Pidikiti Surendra BabuNoch keine Bewertungen

- 3-Phase PFC KolarDokument7 Seiten3-Phase PFC KolarJayant SalianNoch keine Bewertungen

- High Side Drivers For AutomotiveDokument24 SeitenHigh Side Drivers For AutomotivesathyaeeeNoch keine Bewertungen

- Assets SENSORDokument5 SeitenAssets SENSORThomas ZhaiNoch keine Bewertungen

- Sprabw0b PDFDokument19 SeitenSprabw0b PDFAshok KumarNoch keine Bewertungen

- Adiabatic Implementation On Full Adder Circuits: R.Swapna, Shoban MudeDokument5 SeitenAdiabatic Implementation On Full Adder Circuits: R.Swapna, Shoban MudeshrivathsavsNoch keine Bewertungen

- Power Systems: State of TechnologyDokument18 SeitenPower Systems: State of TechnologyVignesh RajanNoch keine Bewertungen

- 10 1109@ITherm45881 2020 9190490Dokument5 Seiten10 1109@ITherm45881 2020 9190490womini1025Noch keine Bewertungen

- Alternate Solutions to Aged Static Exciter SystemsDokument9 SeitenAlternate Solutions to Aged Static Exciter SystemsMauricio GuanellaNoch keine Bewertungen

- Analysis and Implementation of An Improved FlybackDokument17 SeitenAnalysis and Implementation of An Improved FlybackReddyKvmNoch keine Bewertungen

- Soft-Switching Converter With HF Transformer For Grid-Connected Photovoltaic SystemsDokument9 SeitenSoft-Switching Converter With HF Transformer For Grid-Connected Photovoltaic SystemsVeeravasantharao BattulaNoch keine Bewertungen

- Gate Drive TrafoDokument4 SeitenGate Drive Trafobenygiurgiu100% (1)

- DC-DC Boost Converter ThesisDokument4 SeitenDC-DC Boost Converter Thesisdeepjonesmanchester100% (2)

- Teardown: The Power Inverter - From Sunlight To Power Grid: Steve TaranovichDokument14 SeitenTeardown: The Power Inverter - From Sunlight To Power Grid: Steve TaranovichMinh PHAN THANHNoch keine Bewertungen

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Dokument11 SeitenIjeet: International Journal of Electrical Engineering & Technology (Ijeet)IAEME PublicationNoch keine Bewertungen

- Three-Phase PWM Rectifier Based On Integrated Power Module and Fixed-Point Digital Signal Processor For Rapid Prototyping IssuesDokument13 SeitenThree-Phase PWM Rectifier Based On Integrated Power Module and Fixed-Point Digital Signal Processor For Rapid Prototyping IssuesDenise JenningsNoch keine Bewertungen

- 10 kW Inverter Design for Fuel Cell SystemDokument52 Seiten10 kW Inverter Design for Fuel Cell Systemguddu13481Noch keine Bewertungen

- An Improved DC-DC Boost Converter For Energy HarveDokument10 SeitenAn Improved DC-DC Boost Converter For Energy HarveTuấn Nguyễn VănNoch keine Bewertungen

- Switched-Capacitor Boost-Buck Ladder Converters With Extended Voltage Range in Standard CMOSDokument14 SeitenSwitched-Capacitor Boost-Buck Ladder Converters With Extended Voltage Range in Standard CMOSADITYA SHARMANoch keine Bewertungen

- Analysis, Modelling and Simulation of A Multiphase Interleaved Buck DC/DC Converter For PV ApplicationsDokument7 SeitenAnalysis, Modelling and Simulation of A Multiphase Interleaved Buck DC/DC Converter For PV ApplicationsInnovative Research PublicationsNoch keine Bewertungen

- MM2 Maximizer DatasheetDokument2 SeitenMM2 Maximizer DatasheetSUNLUX_INFONoch keine Bewertungen

- Manual de BateriasDokument32 SeitenManual de BateriasAriel Martinez N100% (1)

- Emtp Based SimultorDokument4 SeitenEmtp Based SimultorrudoljersonNoch keine Bewertungen

- Power Converters For Wind Turbines: Current and Future DevelopmentDokument13 SeitenPower Converters For Wind Turbines: Current and Future DevelopmentLullaby summerNoch keine Bewertungen

- MATLAB Simulation of 3-Level PWM Inverter Fed Motor Speed ControlDokument6 SeitenMATLAB Simulation of 3-Level PWM Inverter Fed Motor Speed Controlraviraj_kumbhar1988Noch keine Bewertungen

- Sine Wave Inverter With PICDokument50 SeitenSine Wave Inverter With PICmtrapkNoch keine Bewertungen

- Azerbaijani Experiences with Digital Substation Process BusDokument18 SeitenAzerbaijani Experiences with Digital Substation Process Buspo ghNoch keine Bewertungen

- Energies: Real-Time Control Based On A CAN-Bus of Hybrid Electrical SystemsDokument14 SeitenEnergies: Real-Time Control Based On A CAN-Bus of Hybrid Electrical SystemsHuu Vien AutoNoch keine Bewertungen

- Pvsyst Training and Solar Power Plant deDokument4 SeitenPvsyst Training and Solar Power Plant deLuis Alberto Serrano MesaNoch keine Bewertungen

- ONSemi-Developing A 25-kW SiC-Based Fast DC Charger Solution OverviewDokument8 SeitenONSemi-Developing A 25-kW SiC-Based Fast DC Charger Solution Overview133514Noch keine Bewertungen

- An 43Dokument28 SeitenAn 43Jason WilsonNoch keine Bewertungen

- ECE 534 Project 1 F19Dokument6 SeitenECE 534 Project 1 F19JAY CHHEDANoch keine Bewertungen

- Cycloconverters TopologiesDokument12 SeitenCycloconverters Topologiesjuan_fimNoch keine Bewertungen

- Weidmuller OptocouplersDokument34 SeitenWeidmuller Optocouplersspeedy65Noch keine Bewertungen

- IET Power Electronics - 2020 - Dur N - Configurations of DC DC Converters of One Input and Multiple Outputs WithoutDokument13 SeitenIET Power Electronics - 2020 - Dur N - Configurations of DC DC Converters of One Input and Multiple Outputs WithoutREYES APOLONIO CASTRO CORRALNoch keine Bewertungen

- Wind Ventillation System Final ReportDokument114 SeitenWind Ventillation System Final ReportPooja BanNoch keine Bewertungen

- Sonderdruck Refu 017KDokument8 SeitenSonderdruck Refu 017Kn_sreeNoch keine Bewertungen

- Drofenik APE07Dokument11 SeitenDrofenik APE07saravanajsrNoch keine Bewertungen

- 145Dokument8 Seiten145Стоян ТеневNoch keine Bewertungen

- Computer Modeling and Simulation of PWM Converter CircuitsDokument27 SeitenComputer Modeling and Simulation of PWM Converter CircuitsAshok KumarNoch keine Bewertungen

- ContentDokument6 SeitenContentashwingeorge101Noch keine Bewertungen

- Single Phase RectifireDokument3 SeitenSingle Phase RectifireNishith DhinoraNoch keine Bewertungen

- Balkrishna Augest 2014Dokument20 SeitenBalkrishna Augest 2014Nishith DhinoraNoch keine Bewertungen

- Patent Search & Analysis Report (PSAR) : Testing Jig of Igbt Stack For Solar PcsDokument5 SeitenPatent Search & Analysis Report (PSAR) : Testing Jig of Igbt Stack For Solar PcsNishith DhinoraNoch keine Bewertungen

- 33 DesignDokument11 Seiten33 Designtariq76Noch keine Bewertungen

- 2P4M ThyristorDokument5 Seiten2P4M ThyristorVanadia NohanNoch keine Bewertungen

- Design and Implementation of Cosine Control Firing Scheme For Single Phase Fully Controlled Bridge RectifierDokument7 SeitenDesign and Implementation of Cosine Control Firing Scheme For Single Phase Fully Controlled Bridge RectifierNishith DhinoraNoch keine Bewertungen

- APT60GF120JRDDokument9 SeitenAPT60GF120JRDNishith DhinoraNoch keine Bewertungen

- 2P4M ThyristorDokument5 Seiten2P4M ThyristorVanadia NohanNoch keine Bewertungen

- A Capacitively Based Mems Affinity Glucose SensorDokument8 SeitenA Capacitively Based Mems Affinity Glucose SensorNishith DhinoraNoch keine Bewertungen

- Laundry & Home Care: Key Financials 1Dokument1 SeiteLaundry & Home Care: Key Financials 1Catrinoiu PetreNoch keine Bewertungen

- Bernardo Corporation Statement of Financial Position As of Year 2019 AssetsDokument3 SeitenBernardo Corporation Statement of Financial Position As of Year 2019 AssetsJean Marie DelgadoNoch keine Bewertungen

- Bill of ConveyanceDokument3 SeitenBill of Conveyance:Lawiy-Zodok:Shamu:-El80% (5)

- Ayushman BharatDokument20 SeitenAyushman BharatPRAGATI RAINoch keine Bewertungen

- The Value of Repeat Biopsy in SLEDokument8 SeitenThe Value of Repeat Biopsy in SLESergio CerpaNoch keine Bewertungen

- 2020-05-14 County Times NewspaperDokument32 Seiten2020-05-14 County Times NewspaperSouthern Maryland OnlineNoch keine Bewertungen

- Notes On Lesson: Faculty Name Code Subject Name CodeDokument108 SeitenNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoNoch keine Bewertungen

- Chapter 3: Elements of Demand and SupplyDokument19 SeitenChapter 3: Elements of Demand and SupplySerrano EUNoch keine Bewertungen

- ASCE - Art Competition RulesDokument3 SeitenASCE - Art Competition Rulesswarup babalsureNoch keine Bewertungen

- Database Chapter 11 MCQs and True/FalseDokument2 SeitenDatabase Chapter 11 MCQs and True/FalseGauravNoch keine Bewertungen

- Overhead Door Closers and Hardware GuideDokument2 SeitenOverhead Door Closers and Hardware GuideAndrea Joyce AngelesNoch keine Bewertungen

- Learning HotMetal Pro 6 - 132Dokument332 SeitenLearning HotMetal Pro 6 - 132Viên Tâm LangNoch keine Bewertungen

- Circular 09/2014 (ISM) : SubjectDokument7 SeitenCircular 09/2014 (ISM) : SubjectDenise AhrendNoch keine Bewertungen

- C.C++ - Assignment - Problem ListDokument7 SeitenC.C++ - Assignment - Problem ListKaushik ChauhanNoch keine Bewertungen

- Fujitsu Spoljni Multi Inverter Aoyg45lbt8 Za 8 Unutrasnjih Jedinica KatalogDokument4 SeitenFujitsu Spoljni Multi Inverter Aoyg45lbt8 Za 8 Unutrasnjih Jedinica KatalogSasa021gNoch keine Bewertungen

- Business Case - Uganda Maize Export To South SudanDokument44 SeitenBusiness Case - Uganda Maize Export To South SudanInfiniteKnowledge33% (3)

- MSDS Summary: Discover HerbicideDokument6 SeitenMSDS Summary: Discover HerbicideMishra KewalNoch keine Bewertungen

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDokument217 Seiten13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNoch keine Bewertungen

- Take Private Profit Out of Medicine: Bethune Calls for Socialized HealthcareDokument5 SeitenTake Private Profit Out of Medicine: Bethune Calls for Socialized HealthcareDoroteo Jose Station100% (1)

- COVID-19's Impact on Business PresentationsDokument2 SeitenCOVID-19's Impact on Business PresentationsRetmo NandoNoch keine Bewertungen

- Improvements To Increase The Efficiency of The Alphazero Algorithm: A Case Study in The Game 'Connect 4'Dokument9 SeitenImprovements To Increase The Efficiency of The Alphazero Algorithm: A Case Study in The Game 'Connect 4'Lam Mai NgocNoch keine Bewertungen

- Cib DC22692Dokument16 SeitenCib DC22692Ashutosh SharmaNoch keine Bewertungen

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDokument29 SeitenMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- 3838 Chandra Dev Gurung BSBADM502 Assessment 2 ProjectDokument13 Seiten3838 Chandra Dev Gurung BSBADM502 Assessment 2 Projectxadow sahNoch keine Bewertungen

- Shoib CV Scaffold EngineerDokument3 SeitenShoib CV Scaffold EngineerMohd Shoib100% (1)

- MSBI Installation GuideDokument25 SeitenMSBI Installation GuideAmit SharmaNoch keine Bewertungen

- The SAGE Handbook of Digital JournalismDokument497 SeitenThe SAGE Handbook of Digital JournalismK JNoch keine Bewertungen

- API MidtermDokument4 SeitenAPI MidtermsimranNoch keine Bewertungen

- Royal Enfield Market PositioningDokument7 SeitenRoyal Enfield Market PositioningApoorv Agrawal67% (3)

- Sapkale Sandspit 2020Dokument5 SeitenSapkale Sandspit 2020jbs_geoNoch keine Bewertungen

- The Grid: The Fraying Wires Between Americans and Our Energy FutureVon EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureBewertung: 3.5 von 5 Sternen3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Produced Water Treatment Field ManualVon EverandProduced Water Treatment Field ManualBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyVon EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNoch keine Bewertungen

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Handbook on Battery Energy Storage SystemVon EverandHandbook on Battery Energy Storage SystemBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesVon EverandThe Rare Metals War: the dark side of clean energy and digital technologiesBewertung: 5 von 5 Sternen5/5 (2)

- Transmission Pipeline Calculations and Simulations ManualVon EverandTransmission Pipeline Calculations and Simulations ManualBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Implementing an Integrated Management System (IMS): The strategic approachVon EverandImplementing an Integrated Management System (IMS): The strategic approachBewertung: 5 von 5 Sternen5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- ISO 50001: A strategic guide to establishing an energy management systemVon EverandISO 50001: A strategic guide to establishing an energy management systemNoch keine Bewertungen

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksVon EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNoch keine Bewertungen

- Operational Amplifier Circuits: Analysis and DesignVon EverandOperational Amplifier Circuits: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeVon EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeBewertung: 4 von 5 Sternen4/5 (130)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AVon EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ABewertung: 5 von 5 Sternen5/5 (1)