Beruflich Dokumente

Kultur Dokumente

Global Food Safety Brochure

Hochgeladen von

Septiana SariCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Global Food Safety Brochure

Hochgeladen von

Septiana SariCopyright:

Verfügbare Formate

The sterilisation of spices, herbs and

vegetable seasonings:

Understanding the options

The spice of life

Spices, herbs, seeds and dehydrated vegetable substances bring a world of

flavours, aromas and colours to food.

Harvested in the rural reaches of places such as India, China and Indonesia, spices

and herbs develop their flavors and fragrances by fermenting in the sun, drying in

the open air, and through processing techniques such as roasting and grinding.

Once the appropriate flavours and aromas have been attained, the flavouring

agents are shipped to brokers around the world using methods of transportation

ranging from open barges to refrigerated trucks.

Unfortunately, during their long journey to the table, spices and herbs become

contaminated with bacteria and molds. Bacterial contamination may come from

soil, insects, bird or rodent droppings or from the water used in processing. Fungal

growth may occur before or during drying, or during storage or shipping.

In any event, the consequences can be significant.

Salmonella has occasionally been

found in spices (such as pepper)

and herbal teas. Though normally

destroyed by thorough cooking,

the Salmonella in spices can cause

illness when the spices are added

to food toward the end of the

cooking process, when foods are

improperly refrigerated or when

leftovers are improperly stored for

several days.

Molds and fungal growths

Left untreated, mold can produce

aatoxins, which destroy the

avour and colour of the ingredients

and make them unsuitable for use.

The risk

of

contamination

Bacterial contamination

Bacteria such as Bacillus cereus

and Clostridium perfringens can cause

a variety of foodborne illnesses.

Fortunately, most foodborne

pathogens cannot survive modern

sanitation measures. Even in case

of extreme contamination, bacteria

that remain after processing are

unlikely to tolerate further cooking

or heating.

The additional threat of pests

Pests such as beetles and lesser

grain borers are also commonly

found in spices, seeds, herbs and

prepared seasonings. Fortunately,

since infectious pests are more

susceptible to decontamination

measures than bacteria or molds,

technology used to control

microbial contamination will also

kill pests.

Two effective

solutions

The world leader in microbial

reduction services, Sterigenics

offers the spice and food processing

industries a choice of two

sanitation options: ethylene

oxide (EO) fumigation and

irradiation processing.

While both effectively kill

organisms, the challenges

presented by the bulk packaging

of spices and herbs have made

ethylene oxide fumigation

and gamma processing the

methodologies of choice

due to their efcient, high-

density penetration.

Often, the nal destination

of the spice and herb product plays

a dominant role in the technology

selection. Although EO fumigation

is widely utilised in the US, it

is not currently accepted in the

European Union.

Irradiation: todays

most effective and most

preferred choice

Irradiation is achieved either

by gamma rays, pure energy rays

emitted from Cobalt-60 and

similar in many ways to microwaves,

or by accelerated electrons,

commonly known as electron

beam (E-beam) irradiation.

Approved by the FDA in 1988,

gamma processing is the preferred

method of food sterilisation in

the US and on a global basis.

Less harsh and intrusive than EO,

irradiation uses ionising energy

to kill bacteria, mold and insects

while retaining the avours,

colours, aromas and antioxidant

properties of the avouring

ingredients.

While it is true that gamma

processing can affect the sensory

characteristics of some avouring

agents, the extent of the effect

and the dose level required to

cause a perceptible change varies

by product. Ingredients that

have been stored for a long time

or those whose quality, avour or

aroma are not up to usual

standards may be more affected

than better quality spices.

A penetrating sterilant, gamma

irradiation leaves no area of

the product or packaging

untreated. Even high-density

products such as 250-liter ber

drums can be readily processed

without the need for breathable

packaging. Furthermore,

gamma rays create no residues,

so aeration is not required.

EO fumigation:

the original standard

of excellence

A trusted means of spice sterilisation

for more than 60 years, ethylene

oxide fumigation uses alkylation

as its mechanism of action.

Usage of EO for food sanitation

accelerated dramatically in the

1960s with the discovery that EO

fumigation could signicantly

reduce spoilage organisms in spices

and spice blends. From that point

until the approval of gamma

radiation in 1988, EO was the

tool of choice for herb and spice

decontamination in the US.

In 2001, the US Food and Drug

Administration (FDA) approved

EO as a reconditioning technology

for detained raw spices. Today,

EO is also approved for spice blends,

but only those that do not include

salt (10CFR 185).

In order to ensure an effective result,

the EO gas must be able to diffuse

freely throughout the product being

treated, making breathable

packaging a necessity. In addition,

because a non-volatile residue

remains after processing, an aeration

period is required to allow the

residue to dissipate. Typically,

the aeration process is complete

within 24 hours.

Since ethylene oxide processing

does not require labeling in the US,

it remains a favoured sanitation

agent for a signicant number of the

countrys food processors.

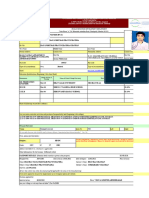

The table above summarizes the work of several researchers and provides a general indication of

the likely microbiological effects of processing at various dose levels for a range of spices grown in

various countries. The actual dose used depends on factors such as the format of product, initial

contamination level, type of microorganisms involved and packaging configuration.

Data compiled from Irradiation of Dry Ingredients, Farkas, 1988.

Test Dose

Ingredients Tested Results

(in kGy)

4-10 Black pepper, white pepper, turmeric, Coliforms eliminated

rosemary, basil

5 Coriander, cumin, turmeric, chili, Starting fungal counts of 10

2

-10

6

rosemary, basil eliminated; coliforms eliminated

Garlic powder Coliforms not detected

White pepper 3.0 log reduction total plate count

Nutmeg 4.0 log reduction total plate count

Ginger 2.0 reduction total plate count

6.5 Paprika, crushed red pepper Standard plate counts<3x10

3

;

molds and coliforms eliminated

7 Cinnamon, cloves, coriander, 2.5 to 4.0 log reduction total plate

nutmeg, white pepper, black pepper count

Garlic powder Starting from 5x10

4

total plate

count=below detectable level

7.5-10 Pepper, cardamom, mace, cinnamon, Virtual sterility

marjoram, cloves, caraway, coriander,

charlock, juniper, paprika, black

pepper, pimento, commercial spice blends

10 Cinnamon, cloves, coriander, nutmeg, 1.7 log CFU/g

white pepper, black pepper

Chili Total plate counts below detectable level

Herbs, garlic powder, onion powder Standard plate counts<3x10

3

;

molds and coliforms negligible

Black pepper, white pepper, turmeric, Spore forming bacteria<10

3

rosemary, basil

Paprika, caraway seeds Standard plate counts<3x10

3

12-15 Black pepper, white pepper, turmeric, Total aerobic bacteria reduced to

rosemary, basil below detectable level

Likely effects of irradiation

processing at various dose levels

Irradiation in combination

with other food processing

Since spices are used in foods that

undergo other processes, it is

important to know how irradiation

works in combination with these

other treatments. As a rule,

irradiation improves the ability

of subsequent processes to further

lower microbial contamination.

Microbial contamination levels

in irradiated spices continue

to decline during storage

because radiation-damaged

microorganisms cannot

reproduce. This has been found

to be true even when storage

occurs at elevated temperatures

and relative high humidity for

several months.

Microorganisms that survive

irradiation are much more

sensitive to heat. As a result,

food groups that are heated and

held at constant temperatures

(such as soups from mixes

used in food service operations)

can have a longer storage life.

Surviving microora have

been found to be less resistant

to sodium and more sensitive

to pH changes, moisture

and growth temperatures.

These sensitivities further

reduce their ability to

survive and grow in

processed food products.

A look at labeling

Federal labeling requirements

may be a key factor for some US

manufacturers when making

decisions regarding irradiation

methodology (21 CFR 179.26).

While labeling is not required

for food products containing EO-

processed ingredients, products

that have been decontaminated

using gamma processing must

prominently display the

international symbol signifying

irradiationknown as the

Raduraand a statement that

the products have been processed

with irradiation. In the EU, every

irradiated product must be labeled

as ionised.

Not surprisingly, labeling

requirements vary from country

to country:

In the U.S., wholesale or bulk

package labels, invoices or

bills of lading must include

a statement along the lines of

treated with radiationdo not

irradiate again if the product

is shipped to a food

manufacturer or processor

for further processing, labeling

or packaging.

Irradiated spice and herb

products that are merely

cleaned, chopped, graded and/or

repackaged must retain the

irradiation label. However, an

irradiated product that is roasted,

heat treated or blended with

other irradiated or non-irradiated

spices or ingredients does not

have to be labeled as irradiated.

Labeling requirements vary from

country to country.

Worldwide, the Radura symbol is the consumers assurance of food safety. Research has confirmed

that, when provided with factual information about food irradiation, consumers will choose

irradiated products with confidence.

Ensuring the highest

quality and safety

No matter which sanitation technology

is selected, in order to prevent

the contamination of nished food

products it is important for dry

ingredients to enter the processing area

with very low bacterial and fungal

counts. In most cases, only sterilised

spices can meet the low plate counts

specied by food processors

manufacturing under HACCP

1

or

ISO

2

standards.

Whenever products present a greater

than average risk of foodborne illness

or economic loss from spoilage,

processors should use spices with

the lowest possible microbial

contamination. Such at risk products

include:

ready-to-eat foods that are

minimally processed and do not

require further cooking

refrigerated foods sold at the retail

level and those

refrigerated foods used in food

service operations

snack foods, deli meats and cheeses,

cooked poultry, meat products, salad

dressings and refrigerated salads

sold at retail.

1

Hazardous Analysis of Critical Control Points

(HACCP): Irradiation and HACCP are

complementary weapons in the battle to ensure

the safety of our food supply. HACCP is a plan

that identies the hazards associated with

each food item and determines how each hazard

can be reduced or eliminated. The microbial

contamination of spices, herbs, and seasonings

is a critical control point in many food-processing

operations.

2

International Organization for Standardization

(ISO): A network of national standards institutes

from 146 countries.

Sterigenics International,

the sterilisation expert

The worlds leading supplier of microbial reduction

services for food products and food packaging,

Sterigenics offers more technologies and more

locations than any other provider.

With 40 processing centres across North America,

Europe and Asia, and the widest range of technology

choices, you can be sure Sterigenics is able to

provide technology for every product and every

processing requirement.

To learn more about how Sterigenics expertise

and technology can help your company extend

product shelf life and prevent foodborne illness,

call 800.472.4508 or visit www.sterigenics.com.

Related applications

Botanicals and health supplements

Many suppliers of botanical ingredients and

manufacturers of natural health products rely

on irradiation to ensure the cleanliness of their

productswith little or no effect on active

ingredients. As reported in 1998, tests of irradiation

effects on active components of 36 traditional

Chinese medicines showed less than a 3% loss

of active ingredients at doses up to 10.0 kGy.

Pet feeds and chews

When the feed is destined for domestic pets,

resident bacteria could affect the health of the

pets human family. Additionally, there have been

multiple cases of children contracting Salmonellosis

from handling dog chew treats such as pigs ears,

bullwinkles, rawhide and similar items. Irradiation

has been shown to effectively eliminate these

microorganisms.

2015 Spring Road

Suite 650

Oak Brook, IL 60523

USA

Tel 800.472.4508

Fax 630.928.1701

Remylaan

4c box 4

3018 Leuven

Belgium

Tel +32 (0)16 525220

Fax +32 (0)16 525230

www.sterigenics.com

S

t

e

r

i

g

e

n

i

c

s

a

n

d

t

h

e

S

t

e

r

i

g

e

n

i

c

s

l

o

g

o

a

r

e

r

e

g

i

s

t

e

r

e

d

t

r

a

d

e

m

a

r

k

s

o

f

S

t

e

r

i

g

e

n

i

c

s

I

n

t

e

r

n

a

t

i

o

n

a

l

.

2

0

0

7

S

t

e

r

i

g

e

n

i

c

s

I

n

t

e

r

n

a

t

i

o

n

a

l

R

e

v

F

S

0

7

P

r

i

n

t

e

d

i

n

t

h

e

U

S

A

.

References

1. Farkas J. Irradiation of Dry Ingredients. Boca Raton, Florida: CRC Press, 1988

2. Federal Register. April 18, 1986. 21 CFR 179. Irradiation in the

Production, Processing, and Handling of Food. Final Rule. pp 13376-13399.

3. International Consultative Group on Food Irradiation. Irradiation of spices,

herbs, and other vegetable seasoningsA compilation of technical data for its

authorization and control. International Atomic Energy Agency. February 1992.

4. Federal Register. August 4, 1994. 10 CFR 21, Ch.1. Development

of Hazard Analysis Critical Control Points For The Food Industry:

Proposed Rule; Vol. 59, No 149, pp 39888-39896.

5. U.S. Food and Drug Administration, 1995. Irradiation in the Production,

Processing and Handling of Food. Code of Federal Regulations, Title 21:

pp 388-390.

6. Bruhn C.M. 1995 Consumer Attitudes and Market Response to

Irradiated Foods. Journal of Food Protection 58: pp 175-181.

7. Council of Agricultural Science and Technology, 1995 Food Borne

Illnesses: Risks and Consequences. CAST Report No. 122.

8. Diehl, J.F. Safety of Irradiated Food, 2nd ed. 1995, M. Dekker, Inc. New York.

9. Monk, J.D., Beuchat, L.R., and Doyle, M.P. 1995. Irradiation

Inactivation of Food-Borne Microorganisms. Journal of Food Protection 58:

pp197-208.

10. Radomyski, T., Murano, E.A., Olson, D.G. and Murano, P.S. 1994.

Elimination of Pathogens of Signicance in Food by Low-dose Irradiation:

A Review. Journal of Food Protection. 57: pp 73-86.

11. Thayer, D.W., Josephson, E.S., Brynjolfsson, A. and Giddings, G.G.

1996. Radiation Pasteurization of Food. Council For Agricultural Science and

Technology Issue Paper. No. 7.

12. Urbain, W.M. Food Irradiation. 1986. Academic Press, Inc.

Orlando Florida.

13. Marcotte, M., Tibelius, C., Effect of Irradiation on Microbiology,

Chemistry and Active Components of Botanicals, Traditional Medicines

and Herbal Products, 1998.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Maternal Health: Ekta Modi 2 MPT in RehabDokument368 SeitenMaternal Health: Ekta Modi 2 MPT in RehabMihir_Mehta_5497100% (1)

- Dark Souls 5eDokument17 SeitenDark Souls 5ebite_clown_437074191Noch keine Bewertungen

- Accupressure EyeDokument7 SeitenAccupressure Eyemayxanh1234100% (3)

- Final Coaching NP4 Set 1Dokument13 SeitenFinal Coaching NP4 Set 1STEFFI GABRIELLE GOLEZNoch keine Bewertungen

- Timed Up and Go Test RalanDokument1 SeiteTimed Up and Go Test RalanBagus Andi PramonoNoch keine Bewertungen

- OME Video DurationsDokument7 SeitenOME Video DurationsLucas RiosNoch keine Bewertungen

- Nature and Characteristics of Services in HospitalsDokument7 SeitenNature and Characteristics of Services in HospitalsOun MuhammadNoch keine Bewertungen

- Model Pembelajaran Berbasis Masalah Dengan Langkah Penyelesaian Berdasarkan Polya Dan Krulik-Rudnick Ditinjau Dari Kreativitas SiswaDokument17 SeitenModel Pembelajaran Berbasis Masalah Dengan Langkah Penyelesaian Berdasarkan Polya Dan Krulik-Rudnick Ditinjau Dari Kreativitas SiswaSeptiana SariNoch keine Bewertungen

- Problem Solving, Critical Thinking, and Case AnalysisDokument4 SeitenProblem Solving, Critical Thinking, and Case AnalysisSeptiana SariNoch keine Bewertungen

- Gamma Irradiation and Autoclave Sterilization Peat and Compost As The Carrier For Rhizobial Inoculant ProductionDokument9 SeitenGamma Irradiation and Autoclave Sterilization Peat and Compost As The Carrier For Rhizobial Inoculant ProductionSeptiana SariNoch keine Bewertungen

- Water: Water Radiolysis: Influence of Oxide Surfaces On H Production Under Ionizing RadiationDokument19 SeitenWater: Water Radiolysis: Influence of Oxide Surfaces On H Production Under Ionizing RadiationSeptiana SariNoch keine Bewertungen

- Convergent Validity: Concept Maps and Competence Test For Students' Diagnosis in PhysicsDokument7 SeitenConvergent Validity: Concept Maps and Competence Test For Students' Diagnosis in PhysicsSeptiana SariNoch keine Bewertungen

- EURASIA v8n4 OzgelenDokument10 SeitenEURASIA v8n4 OzgelenSeptiana SariNoch keine Bewertungen

- Development of Scientific Skills and Values in Physics EducationDokument10 SeitenDevelopment of Scientific Skills and Values in Physics EducationSeptiana SariNoch keine Bewertungen

- Assessment of Testing Practical Skills in Senior Secondary Certificate Examination - Ssce - in Physics Subject in Nigeria by Moses AtadogaDokument10 SeitenAssessment of Testing Practical Skills in Senior Secondary Certificate Examination - Ssce - in Physics Subject in Nigeria by Moses AtadogaSeptiana SariNoch keine Bewertungen

- Game-Based Remedial Instruction in Mastery Learning For Upper-Primary School StudentsDokument11 SeitenGame-Based Remedial Instruction in Mastery Learning For Upper-Primary School StudentsSeptiana SariNoch keine Bewertungen

- Non - Food Meher Final Report (2023)Dokument87 SeitenNon - Food Meher Final Report (2023)atakltigebertsadikNoch keine Bewertungen

- Cystic Hygroma - Symptoms - Diagnosis - Treatment of Cystic Hygroma - NY Times Health InformationDokument3 SeitenCystic Hygroma - Symptoms - Diagnosis - Treatment of Cystic Hygroma - NY Times Health InformationRenno AdiNoch keine Bewertungen

- Lesson Plan in Science Perpetuation of Life I. Learning ObjectivesDokument3 SeitenLesson Plan in Science Perpetuation of Life I. Learning ObjectivesRachel Lorenzo SaldoNoch keine Bewertungen

- Global Manual On Surveillance of AEFIDokument128 SeitenGlobal Manual On Surveillance of AEFIHarold JeffersonNoch keine Bewertungen

- Yoga Poses For Acid RefluxDokument6 SeitenYoga Poses For Acid RefluxKirit JhaNoch keine Bewertungen

- HTTP Oyc - Yale.edu Yale Psychology Introduction-To-psychology Content Transcripts Transcript 11Dokument7 SeitenHTTP Oyc - Yale.edu Yale Psychology Introduction-To-psychology Content Transcripts Transcript 11Amol ShashiNoch keine Bewertungen

- RN Physiological Integrity GIDokument14 SeitenRN Physiological Integrity GIAaLona RobinsonNoch keine Bewertungen

- Breast Cancer Staging SystemDokument4 SeitenBreast Cancer Staging SystemGabriella PatriciaNoch keine Bewertungen

- John Doe Mpa SampleDokument56 SeitenJohn Doe Mpa SampleSameer SamouaNoch keine Bewertungen

- Applied Bryology BryotechnologyDokument12 SeitenApplied Bryology Bryotechnology-Noch keine Bewertungen

- 1 PPT Bioethics Lecture N1Dokument44 Seiten1 PPT Bioethics Lecture N1h.a.r.ade.v.ierNoch keine Bewertungen

- Health Teaching PlanDokument4 SeitenHealth Teaching Plani & vNoch keine Bewertungen

- Ghidul de Prevenire A Miopiei - de Dr. Kaisu VIIKARI - Cu Coperta in RomanaDokument104 SeitenGhidul de Prevenire A Miopiei - de Dr. Kaisu VIIKARI - Cu Coperta in Romanadlucian82Noch keine Bewertungen

- Mci Mbbs SyllabusDokument110 SeitenMci Mbbs Syllabusmetabolicmedicine100% (1)

- Maret 18 PDFDokument178 SeitenMaret 18 PDFAnonymous vLgCd0U7Noch keine Bewertungen

- Group 4 Environmental Pollution and Impacts On Public HealthDokument10 SeitenGroup 4 Environmental Pollution and Impacts On Public HealthBen KuNoch keine Bewertungen

- MTL CHAPTER 9 2020 ClickUpDokument11 SeitenMTL CHAPTER 9 2020 ClickUpcharlieNoch keine Bewertungen

- Gold Awards: Organization Name Title of InnovationDokument10 SeitenGold Awards: Organization Name Title of Innovationchek86351Noch keine Bewertungen

- Multiple Dengue Virus Types Harbored by Individual MosquitoesDokument7 SeitenMultiple Dengue Virus Types Harbored by Individual MosquitoesYL Slalu BahagieaNoch keine Bewertungen

- HR 2 FormDokument8 SeitenHR 2 Formrkpatel40Noch keine Bewertungen

- Bite Force and Occlusion-Merete Bakke 2006Dokument7 SeitenBite Force and Occlusion-Merete Bakke 2006Dan MPNoch keine Bewertungen

- AllRefer Health - PerichondritisDokument2 SeitenAllRefer Health - PerichondritisandosaputraNoch keine Bewertungen

- WelcomeDokument74 SeitenWelcomeSagarRathodNoch keine Bewertungen