Beruflich Dokumente

Kultur Dokumente

464OldTests Quizz Samples

Hochgeladen von

mhrdd222Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

464OldTests Quizz Samples

Hochgeladen von

mhrdd222Copyright:

Verfügbare Formate

Name:

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

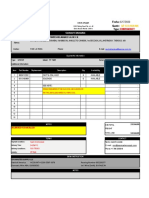

Prof. M.G. Guvench ELE 464 EXAM No.1 October 27, 2004

(Part A: Closed Books/Notes)

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

1.a. What properties of Silicon make it better suited for integrated circuit fabrication compared to

GaAs? Give a list and explain why?

1.b. Briefly describe the LOCOS process. What is Birds Beak? What materials/chemicals are

essential to do LOCOS? Why do you need a recessed structure?

1.c. Compare Ion Implantation with Diffusion for selective doping of Silicon.

2. Give the cross-sectional structures and top view patterns of junctions/layers of the following devices

which were fabricated in a standard bipolar process.

a. NPN b. Lateral PNP c. Pinch Resistor

4. CMOS Process:

a. With the help of cross sectional drawings on the left side of the page and top view drawings on the

right describe all the steps of fabrication of a CMOS inverter cell in an P-Well CMOS Process

Identify (without skipping) every masking layer up to and including METAL1

b. On the final step mark the length (L) and the width (W) of the resulting MOSFETs with arrows.

c. If NEGATIVE photoresist is being used throughout the process redraw your POLY and METAL1 mask

patterns and cross hatch the areas that need to be dark on the mask.

CROSS SECTION TOP VIEW

PMOS NMOS PMOS NMOS

PLEASE SUBMIT YOUR ANSWERS TO A1A through A4 to Prof. GUVENCH before opening your book to lookup for

formulae for Problem 5. Use the diffusion data given below

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Diffusion/Oxidation Data for Problem 5:

D @1000C D@1100C Solubility @1000 Solubility @1100

Boron 3.0E-15 cm2/s 2.0E-14 cm2/s 2.0E20 cm-3 3.0E20 cm-3

Phosphorus 4.0E-15 cm2/s 3.0E-14 cm2/s 8.0E20 cm-3 1.2 E21 cm-3

Hole mobility (average): 250 cm2/V.s Electron mobility (average): 1000 cm2/V.s

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

5. 1E17 /cm3 uniformly doped P-type Silicon substrates are being used to make P-N junction diodes. In

the process a pre-deposition step at 1000 C for 1 hour is being followed by a drive-in diffusion of

3 hours at 1100 C.

Find:

a. the surface concentration after the predep,

b. the minimum oxide thickness for masking and the color of the oxide,

c. the surface concentration after drive in, N(0),

d. the final junction depth, xj,

d. the final sheet resistance of the diffused layer, Rs.

1. Assume a square shaped wafer of 200 mm x 200 mm size undergoes an IC process which results

in 100 point defects uniformly distributed on it at the end. Determine, for each case below, how many

good die and how much die yield this wafer/process combination would produce.

Die size Total Die Good Die Die Yield (%)

a. 20 mm x 20 mm :

b. 5 mm x 5 mm :

c. 1 mm x 1 mm :

This is a collection of Quiz/Test questions/problems given in the past in ELE464.

ELE 464 QUIZ #1 7/23/96

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

1. Assume a square wafer of 10 cm x 10 cm size undergoes an IC process which results in 100 point

defects uniformly distruted on it at the end. Determine, for each case below, how many good die and how

much die yield this wafer/process combination would produce.

Die size Total Dice Good Dice Yield (%)

a. 2 cm x 2 cm :

b. 1 cm x 1 cm :

c. 0.5 cm x 0.5 cm :

d. 1 mm x 1 mm :

2. a. What properties of Silicon make it better suited for integrated circuit fabrication compared to

GaAs? Why?

b. Where does GaAs have advantage over Silicon? Why?

3. What is the meaning of segregation coefficient? Explain its effect on the Czochralski growth of

Silicon.

What happens to the crystal grown if the segregation coefficient is

a. < 1

b. = 1

c. < 1 ?

4. Draw a unit cube representing a cubic crystal. Indicate the axes on it.

a. Show (010) , 110 and (113) planes on it.

5. (10%Bonus) How would you kill the rectifying properties of Schottky barriers formed between Silicon

and Aluminum in an integrated circuit? Explain briefly the tricks used.

ELE 464 QUIZ #2 8/1/96

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

1. A boron predeposition at 1100 C gives a dopant dose Q of 1E16 cm-2. It is followed by a drive-in

diffusion of one hour at 1000 C. Find:

a. the surface concentration after the predep,

b. the time it took for the predeposition,

c. the surface concentration after drive in, N(0), and

d. the junction depth after all of these steps if the wafer was initially doped with

phosphorous at 1E15 level.

e. What if the initial doping was boron at 1E15 in (d)?

2. Briefly describe,

a. What is Solid Solubility?, Where does it apply in device/wafer fabrication?

b. What is equilibrium and non-equilibrium process? Describe what makes the two

different and give examples for an equilibrium and for a non-equilibrium doping

process.

c. It was shown in class that sheet resistance of a doped layer independent of doping

profile. What is the assumption leading to that conclusion?

Rsheet = 1/(q..Q)

3. A P-type doped wafer (1E16) and 1100 C 1Hr phosphorous diffusion is being used to

make silicon N+P diodes.

a. What is the junction depth?

b. What is the oxide thickness needed to do an effective mask?

c. If the oxide is supposed to be grown 1000 C, decide about wet or dry and calculate the

time required for the oxidation.

ELE 464 QUIZ #3 8/8/96

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

1. A boron doped 111 Silicon wafer (N=1.0E16 /cm3) is being ion implanted with phosporus at a dose

of 1.0E16 /cm2. If the implantation results in a projected range of 135 nm and a straggle of 53.5 nm and an

average mobility of 1000 cm2/V.s,

a. What kind of a junction (P+N or N+P) is formed?

b. What is the maximum implant concentration in the implanted layer?

c. What is the resulting junction depth?

d. What is the sheet resistance of the implanted layer (state approximations/assumptions used)?

e. If a beam current of 100uA was swept over a square area of 10cm by 10cm how long a time would the

process specified above take?

2. Describe the structure of an ion implanter and also answer the following:

a. What is the function of the electromagnet in an ion implanter?

b. How do you (1)generate, (2)extract and (3)accelerate the beam and make it dope (say) four wafers (4)

uniformly?

c. If the beam is made up of positive ions and the wafers held at ground potential what polarity voltage

would you apply to the source side of the accelerator?

Your Name:

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Prof. Guvench ELE 464 FINAL EXAM. 8/15/96

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

1. Assume a square wafer of 12.5 cm x 12.5 cm size undergoes an IC process which results in 100

point defects uniformly distruted on it at the end. Determine, for each case below, how many good

die and how much die yield this wafer/process combination would produce.

Die size Total Dice Good Dice Die Yield (%)

a. 2 cm x 2 cm :

b. 1 cm x 1 cm :

c. 0.5 cm x 0.5 cm :

d. 1 mm x 1 mm :

2.a. What properties of Silicon make it better suited for integrated circuit fabrication compared to

GaAs? Why?

2.b. Where does GaAs have advantage over Silicon? Why?

3.a. What is the meaning of segregation coefficient?

3.b. Explain (briefly) its effect on the Czochralski growth of Silicon.

3.c. Impurities A, B, C and D have the segregation coefficients in silicon, 0.01, 0.1, 1.0 and 10.0,

respectively. A silicon crystal, after a float zone refinement process will be purified of which one(s)?

Why?

4.1 A Czochralski grown silicon crystal shows a flower-like (daisy-like) bulging structure as

viewed from the seed end. Think of crystal symmetry to answer the following questions.

a. If pattern appears to have four petals, what is the growth direction? and why?

b. If pattern appears to have six petals, what is the growth direction? and why?

4.2 Draw a unit cube representing a cubic crystal. Label the axes and show (112) and (013) planes

on it.

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Diffusion/Oxidation Data:

(hypothetical, for use in solving the following test problems only)

D @1000C D@1100C Solubility @1000 Solubility @1100

Boron 4.0E-15 cm2/s 3.0E-14 cm2/s 2.0E20 cm-3 3.0E20 cm-3

Phosporus 4.0E-15 cm2/s 3.0E-14 cm2/s 8.0E20 cm-3 1.2 E21 cm-3

B@1000C B @1100C Phos @1000C Phos @1100C

Min.Oxide .008t (mins) .018t (mins) .015t(mins) .020t(mins)

Thickness

()

Hole mobility (average): 250 cm2/V.s

Electron mobility (average): 1000 cm2/V.s

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

5. A boron predeposition at 1000 C gives a dopant dose Q of 1E14 cm-2. It is followed by a drive-in

diffusion of one hour at 1100 C. Find:

a. the surface concentration after the predep,

b. the time it took for the predeposition,

c. the surface concentration after drive in, N(0), and

d. the junction depth and the sheet resistance after all of these steps if the wafer were

initially uniformly doped with phosphorous at 1E15 level.

e. the junction depth if the initial doping were boron at 1E15 in (d)?

6. A boron doped 111 Silicon wafer (N=1.0E16 /cm3) is being ion implanted with phosporus at a dose of

1.0E14 /cm2. If the implantation results in a projected range of 135 nm and a straggle of 53.5 nm,

a. What is the maximum implant concentration in the implanted layer?

c. What is the resulting junction depth?

d. What is the sheet resistance of the implanted layer?

e. If a beam current of 100uA was swept over a square area of 40cm by 40cm how

long a time would the process specified above take?

f. What is junction depth, peak concentration and the sheet resistance if the

implantation is followed by a deep drive-in of 1 hour @ 1100 C.

3. A P-type doped wafer (1E16) and 1100 C 1Hr phosphorous diffusion is being used to

make silicon N+P diodes.

a. What is the junction depth?

b. What is the oxide thickness needed to do an effective mask?

c. If the oxide is supposed to be grown at 1050 C dry and calculate the time required

for oxidation.

Das könnte Ihnen auch gefallen

- Introduction to Microscopy: Presentation on Light and Electron MicroscopesDokument74 SeitenIntroduction to Microscopy: Presentation on Light and Electron MicroscopesFakhri KANoch keine Bewertungen

- 3-Dimensional: Crystal StructureDokument27 Seiten3-Dimensional: Crystal StructureVesnogNoch keine Bewertungen

- Instructor's Manual for Introduction to Solid State PhysicsDokument62 SeitenInstructor's Manual for Introduction to Solid State Physicsn4meNoch keine Bewertungen

- Basics of CrystallographyDokument60 SeitenBasics of Crystallographylmanna454Noch keine Bewertungen

- How To Execute Materials StudioDokument7 SeitenHow To Execute Materials StudioHirak ChatterjeeNoch keine Bewertungen

- Journal of The European Ceramic Society: Vincenzo Buscaglia, Clive A. Randall TDokument15 SeitenJournal of The European Ceramic Society: Vincenzo Buscaglia, Clive A. Randall TAryan Singh LatherNoch keine Bewertungen

- Ceramics International: Mahamoud S. Alkathy, Rahul Gayam, K.C. James RajuDokument10 SeitenCeramics International: Mahamoud S. Alkathy, Rahul Gayam, K.C. James RajuRachna SelvamaniNoch keine Bewertungen

- Gas Kinetic TheoryDokument311 SeitenGas Kinetic Theoryrestlaim100% (1)

- Tem Workshop Electron Diffraction PDFDokument190 SeitenTem Workshop Electron Diffraction PDFxiao zhangNoch keine Bewertungen

- FEMTOSECOND MULTIPASS TI:SAPPHIRE AMPLIFIER USER'S GUIDEDokument23 SeitenFEMTOSECOND MULTIPASS TI:SAPPHIRE AMPLIFIER USER'S GUIDEss626Noch keine Bewertungen

- Charge Transport in Disordered Organic Field Effect TransistorsDokument144 SeitenCharge Transport in Disordered Organic Field Effect Transistorsajayiitm05Noch keine Bewertungen

- A Critical Review On The Fabrication Processes and Applications of Microwave Dielectric Ceramics Ba6-3Xnd8+2Xti18O54Dokument24 SeitenA Critical Review On The Fabrication Processes and Applications of Microwave Dielectric Ceramics Ba6-3Xnd8+2Xti18O54TJPRC Publications100% (1)

- 1.5.0.potentials and EquilibriumDokument8 Seiten1.5.0.potentials and EquilibriumAnonymous G3DRjDMkNoch keine Bewertungen

- Scaling Laws and Multiscale ManufacturingDokument32 SeitenScaling Laws and Multiscale ManufacturingVikas Lakhmani100% (1)

- Nano Electro Mechanical System NemsDokument26 SeitenNano Electro Mechanical System NemsAnaMilerNoch keine Bewertungen

- Microfluidics 1Dokument7 SeitenMicrofluidics 1amar hattimareNoch keine Bewertungen

- B 2000 (Ovsyannikov) Plasma DiagnosticsDokument590 SeitenB 2000 (Ovsyannikov) Plasma Diagnosticsutente489133Noch keine Bewertungen

- Lecture 2 7 Atomic - Force - MicrosDokument51 SeitenLecture 2 7 Atomic - Force - MicrosMudzakkir DioktyantoNoch keine Bewertungen

- Surface Energy and Surface TensionDokument46 SeitenSurface Energy and Surface TensionSanjeev SahuNoch keine Bewertungen

- Introduction To Convective Heat Transfer Analysis Chapter 8 PDFDokument84 SeitenIntroduction To Convective Heat Transfer Analysis Chapter 8 PDFhenrengNoch keine Bewertungen

- Lecture Notes On SuperconductivityDokument122 SeitenLecture Notes On Superconductivityapi-26870484Noch keine Bewertungen

- Microfluidics Fluid Physics at The Nanoliter Scale PDFDokument50 SeitenMicrofluidics Fluid Physics at The Nanoliter Scale PDFDavid CoralNoch keine Bewertungen

- Photomultiplier Tubes: Photon Is Our BusinessDokument323 SeitenPhotomultiplier Tubes: Photon Is Our Businessico haydNoch keine Bewertungen

- The Child-Langmuir Law and AnalyticalDokument14 SeitenThe Child-Langmuir Law and AnalyticalVadimJabotinskiNoch keine Bewertungen

- Paper-Based Microfluidic Point-Of-care Diagnostic DevicesDokument42 SeitenPaper-Based Microfluidic Point-Of-care Diagnostic DevicesMani SandhuNoch keine Bewertungen

- 377674main Black Hole MathDokument127 Seiten377674main Black Hole MathAnonymous BPFIMnCdNoch keine Bewertungen

- 11 Ohmic ContactsDokument19 Seiten11 Ohmic ContactsThee TeeNoch keine Bewertungen

- Basic Principle of Cyclotron: V. S. PanditDokument9 SeitenBasic Principle of Cyclotron: V. S. PanditAkshat Kumar AgarwalNoch keine Bewertungen

- Fundamentals of Ultrasonic Phased Arrays - 311-320Dokument10 SeitenFundamentals of Ultrasonic Phased Arrays - 311-320Kevin HuangNoch keine Bewertungen

- How Dilute Are Dilute Solutions in Extensional Flows?: C. Clasen, J. P. Plog, and W.-M. KulickeDokument33 SeitenHow Dilute Are Dilute Solutions in Extensional Flows?: C. Clasen, J. P. Plog, and W.-M. Kulickemexicanu99Noch keine Bewertungen

- Ab Initio Methods ExplainedDokument8 SeitenAb Initio Methods ExplainedKiran ChowdaryNoch keine Bewertungen

- Optimal Designs of Staggered Dean Vortex Micromixers: Molecular SciencesDokument25 SeitenOptimal Designs of Staggered Dean Vortex Micromixers: Molecular SciencesGoji SabaNoch keine Bewertungen

- Fiber-Optic Chemical Sensors and BiosensorsDokument15 SeitenFiber-Optic Chemical Sensors and BiosensorsSabiran GibranNoch keine Bewertungen

- Modern Aspects of Electrochemistry Volume 36 (Modern Aspects of Electrochemistry) (PDFDrive)Dokument325 SeitenModern Aspects of Electrochemistry Volume 36 (Modern Aspects of Electrochemistry) (PDFDrive)Javier RiveraNoch keine Bewertungen

- Generalized Quantum Fourier Transforms in Phase EstimationDokument94 SeitenGeneralized Quantum Fourier Transforms in Phase EstimationPandora SpotifyNoch keine Bewertungen

- Orderly Structure in Jet TurbulenceDokument99 SeitenOrderly Structure in Jet TurbulenceAryce_Noch keine Bewertungen

- Development of A Solver For The Heat Equation Using MATLABDokument14 SeitenDevelopment of A Solver For The Heat Equation Using MATLABManan Academy100% (2)

- Translational Symmetry and the Laws of CrystallographyDokument4 SeitenTranslational Symmetry and the Laws of Crystallographyhp2020Noch keine Bewertungen

- Anisotropic Plasticity and ViscoplasticityDokument107 SeitenAnisotropic Plasticity and Viscoplasticityking sunNoch keine Bewertungen

- ThesisDokument127 SeitenThesisSri SaiNoch keine Bewertungen

- Introduction To Molecular Dynamics Simulations. Prabal MaitiDokument42 SeitenIntroduction To Molecular Dynamics Simulations. Prabal MaitiCornersouthNoch keine Bewertungen

- Mass Spectrometry 1Dokument33 SeitenMass Spectrometry 1PhiPhiNoch keine Bewertungen

- Matrix Mathematics Chemical Problems: ApplicationsDokument9 SeitenMatrix Mathematics Chemical Problems: ApplicationsCarlosNoch keine Bewertungen

- Electron Scattering and Nuclear Structure PDFDokument44 SeitenElectron Scattering and Nuclear Structure PDFFernanda RibeiroNoch keine Bewertungen

- Biophysical Techniques in Photosynthesis PDFDokument424 SeitenBiophysical Techniques in Photosynthesis PDFAbdelhakim HarchaouiNoch keine Bewertungen

- Maskless LithographyDokument8 SeitenMaskless Lithographymarci_elgNoch keine Bewertungen

- Lithography GuideDokument29 SeitenLithography GuidezanibtahiraNoch keine Bewertungen

- Introduction and Bravais LatticesDokument17 SeitenIntroduction and Bravais LatticesBilal BarutNoch keine Bewertungen

- Discharge ModelDokument186 SeitenDischarge ModelSigit KurniawanNoch keine Bewertungen

- Nanoengineered Nanofibrous Materials PDFDokument534 SeitenNanoengineered Nanofibrous Materials PDFRaj Narayan100% (1)

- MicrofluidicsDokument64 SeitenMicrofluidicsFrancesco CarrozzoNoch keine Bewertungen

- Plasma Diagnostics Techniques for Measuring Electron PropertiesDokument25 SeitenPlasma Diagnostics Techniques for Measuring Electron PropertiestrynextNoch keine Bewertungen

- Lecture Notes On Discrete-Time Signal ProcessingDokument155 SeitenLecture Notes On Discrete-Time Signal ProcessingŞöhret Görkem Karamuk100% (3)

- Shohet J. Leon Encyclopedia of Plasma Technology II Microplasma Wool 2017Dokument880 SeitenShohet J. Leon Encyclopedia of Plasma Technology II Microplasma Wool 2017Seren Elif KızışarNoch keine Bewertungen

- DetectorsDokument282 SeitenDetectorsMoch. Syamsul AlamsyahNoch keine Bewertungen

- Formal Report ZeemanDokument10 SeitenFormal Report ZeemanW-d DomNoch keine Bewertungen

- Structure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsVon EverandStructure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsNoch keine Bewertungen

- Current Topics in Amorphous Materials: Physics & TechnologyVon EverandCurrent Topics in Amorphous Materials: Physics & TechnologyY. SakuraiBewertung: 5 von 5 Sternen5/5 (1)

- Surface Physics of Materials: Materials Science and TechnologyVon EverandSurface Physics of Materials: Materials Science and TechnologyNoch keine Bewertungen

- Lenntech APP 11-13 data sheet provides specs for corrosion-resistant pumpsDokument12 SeitenLenntech APP 11-13 data sheet provides specs for corrosion-resistant pumpsmhrdd222Noch keine Bewertungen

- Goulds Rev PSG33Dokument40 SeitenGoulds Rev PSG33mhrdd222Noch keine Bewertungen

- Lenntech APP 11-13 data sheet provides specs for corrosion-resistant pumpsDokument12 SeitenLenntech APP 11-13 data sheet provides specs for corrosion-resistant pumpsmhrdd222Noch keine Bewertungen

- Walden Park Apartments: Here's What Residents Are Saying..Dokument3 SeitenWalden Park Apartments: Here's What Residents Are Saying..mhrdd222Noch keine Bewertungen

- Lenntech APP Pump Data SheetDokument12 SeitenLenntech APP Pump Data SheetilieoniciucNoch keine Bewertungen

- Easy PDF CreatorDokument450 SeitenEasy PDF CreatorEdson Costa83% (6)

- Machine A PDF Writer That Produces Quality PDF Files With Ease!Dokument3 SeitenMachine A PDF Writer That Produces Quality PDF Files With Ease!mhrdd222Noch keine Bewertungen

- Walden Park Apartments: Here's What Residents Are Saying..Dokument3 SeitenWalden Park Apartments: Here's What Residents Are Saying..mhrdd222Noch keine Bewertungen

- Machine A PDF Writer That Produces Quality PDF Files With Ease!Dokument3 SeitenMachine A PDF Writer That Produces Quality PDF Files With Ease!mhrdd222Noch keine Bewertungen

- Machine A PDF Writer That Produces Quality PDF Files With Ease!Dokument3 SeitenMachine A PDF Writer That Produces Quality PDF Files With Ease!mhrdd222Noch keine Bewertungen

- Machine A PDF Writer That Produces Quality PDF Files With Ease!Dokument3 SeitenMachine A PDF Writer That Produces Quality PDF Files With Ease!mhrdd222Noch keine Bewertungen

- Flowserve Pompe PDFDokument76 SeitenFlowserve Pompe PDFrossifrancescoNoch keine Bewertungen

- Lenntech APP Pump Data SheetDokument12 SeitenLenntech APP Pump Data SheetilieoniciucNoch keine Bewertungen

- Centrifugal pump data sheet detailsDokument1 SeiteCentrifugal pump data sheet detailsdiksha surekaNoch keine Bewertungen

- Goulds Rev PSGDokument40 SeitenGoulds Rev PSGBruno GerbasiNoch keine Bewertungen

- E1Uht: E1Uht High Temperature, Double Seal Industrial Cable Gland For All Types of Armoured CablesDokument1 SeiteE1Uht: E1Uht High Temperature, Double Seal Industrial Cable Gland For All Types of Armoured Cablesmhrdd222Noch keine Bewertungen

- Lenntech APP Pump Data SheetDokument12 SeitenLenntech APP Pump Data SheetilieoniciucNoch keine Bewertungen

- Pump Specification Data SheetDokument3 SeitenPump Specification Data SheetMelvin MagbanuaNoch keine Bewertungen

- Supreme 121AO: Key FeaturesDokument3 SeitenSupreme 121AO: Key Featuresmhrdd222Noch keine Bewertungen

- Goulds Rev PSGDokument40 SeitenGoulds Rev PSGBruno GerbasiNoch keine Bewertungen

- Lenntech APP Pump Data SheetDokument12 SeitenLenntech APP Pump Data SheetilieoniciucNoch keine Bewertungen

- Flowserve Pompe PDFDokument76 SeitenFlowserve Pompe PDFrossifrancescoNoch keine Bewertungen

- Centrifugal pump data sheet detailsDokument1 SeiteCentrifugal pump data sheet detailsdiksha surekaNoch keine Bewertungen

- 1 Identification: Acc. To OSHA HCSDokument16 Seiten1 Identification: Acc. To OSHA HCSmhrdd222Noch keine Bewertungen

- Pump Specification Data SheetDokument3 SeitenPump Specification Data SheetMelvin MagbanuaNoch keine Bewertungen

- ErrorsDokument3 SeitenErrorsmhrdd222Noch keine Bewertungen

- Trelleborg Applied Technologies Syntac 450Dokument2 SeitenTrelleborg Applied Technologies Syntac 450mhrdd222Noch keine Bewertungen

- Latex IntroDokument171 SeitenLatex Intromhrdd222Noch keine Bewertungen

- C2Kht: C2Kht Internationally Approved, Ex E, Explosive Atmosphere Cable Gland For All Types of Armoured CablesDokument1 SeiteC2Kht: C2Kht Internationally Approved, Ex E, Explosive Atmosphere Cable Gland For All Types of Armoured Cablesmhrdd222Noch keine Bewertungen

- Thermo HW2 SolutionsDokument8 SeitenThermo HW2 Solutionsmhrdd222Noch keine Bewertungen

- Communication LetterDokument4 SeitenCommunication LetterEj FerrerNoch keine Bewertungen

- The Essential Entrelec - Cat - enDokument76 SeitenThe Essential Entrelec - Cat - engeekboxcaruaruNoch keine Bewertungen

- Software Engineering Course OverviewDokument2 SeitenSoftware Engineering Course OverviewRajatKumarNoch keine Bewertungen

- BS WaterDokument0 SeitenBS WaterAfrica OdaraNoch keine Bewertungen

- Experiment 3Dokument18 SeitenExperiment 3Simyeen LeongNoch keine Bewertungen

- ELER v3 Technical ManualDokument141 SeitenELER v3 Technical ManualAlla Eddine G CNoch keine Bewertungen

- Terrible Old Games You Have Probably Never Heard ofDokument274 SeitenTerrible Old Games You Have Probably Never Heard ofNagyKristóf100% (2)

- Emebbedd Question BankDokument25 SeitenEmebbedd Question Banksujith100% (3)

- PDFDokument76 SeitenPDFRavishankarNoch keine Bewertungen

- Solar Panel 200 WPDokument1 SeiteSolar Panel 200 WPNos GoteNoch keine Bewertungen

- Emergency Replacement Parts for Grove RT 760E CraneDokument1 SeiteEmergency Replacement Parts for Grove RT 760E CraneraulNoch keine Bewertungen

- ACM+System+ (Active+Control+Engine+Mount) Odisey 2016Dokument2 SeitenACM+System+ (Active+Control+Engine+Mount) Odisey 2016Wilder M. LopezNoch keine Bewertungen

- Documents - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsDokument80 SeitenDocuments - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsAnonymous ItzBhUGoi100% (1)

- Process Analysis.2018Dokument30 SeitenProcess Analysis.2018Geena boengaiNoch keine Bewertungen

- Fiber Internet ONU AgreementDokument2 SeitenFiber Internet ONU AgreementShazama Abdul WajidNoch keine Bewertungen

- Gigabyte Sandy Bridge Overclocking GuideDokument27 SeitenGigabyte Sandy Bridge Overclocking GuideGIGABYTE UK100% (2)

- Summarized ResumeDokument2 SeitenSummarized Resumeapi-310320755Noch keine Bewertungen

- List of Classical Music Composers by Era - Wikipedia, The Free EncyclopediaDokument12 SeitenList of Classical Music Composers by Era - Wikipedia, The Free Encyclopediasercast99Noch keine Bewertungen

- Pipe Material Specs (MCP)Dokument106 SeitenPipe Material Specs (MCP)BoulHich BoulHichNoch keine Bewertungen

- Atp CucmDokument26 SeitenAtp CucmnoumanNoch keine Bewertungen

- List Nama ATKDokument26 SeitenList Nama ATKRiyandi RozikinNoch keine Bewertungen

- Configure Dynamic NAT and PATDokument20 SeitenConfigure Dynamic NAT and PATMary Amirtha Sagayee. GNoch keine Bewertungen

- Groovy 9 – capturing RawRequest & ResponseDokument4 SeitenGroovy 9 – capturing RawRequest & ResponseSirisha ChigurupatiNoch keine Bewertungen

- Locking and Unlocking of Automobile Engine Using RFID1Dokument19 SeitenLocking and Unlocking of Automobile Engine Using RFID1Ravi AkkiNoch keine Bewertungen

- SST CrossguideDokument39 SeitenSST Crossguideardacho1968Noch keine Bewertungen

- Clean BotDokument26 SeitenClean BotCrystal FrostNoch keine Bewertungen

- Sullair AWFDokument4 SeitenSullair AWFOscar BedregalNoch keine Bewertungen

- Form KalibrasiDokument7 SeitenForm KalibrasiDhika PradanaNoch keine Bewertungen

- Electric Loco Moti 00 NewtDokument232 SeitenElectric Loco Moti 00 NewtNanu KaruniaNoch keine Bewertungen