Beruflich Dokumente

Kultur Dokumente

One That Masters Everything: Sipart Ps2: Intelligent Positioner For Unlimited Flexibility

Hochgeladen von

GeraldoadriOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

One That Masters Everything: Sipart Ps2: Intelligent Positioner For Unlimited Flexibility

Hochgeladen von

GeraldoadriCopyright:

Verfügbare Formate

siemens.

com/positioner

One that masters everything:

SIPART PS2

Intelligent positioner for unlimited flexibility

Answers for industry.

2

Globally proven,

universally versatile

Convincing advantages from the start

Whether the situation only involves easy

mounting on various actuators or calls

for fast and rugged commissioning or

extensive functionality and diagnostics

capability: the flexibility of SIPART PS2

offers clear-cut advantages. Its modular-

ity and versatility make the special capa-

bilities of this universal positioner stand

out everywhere and ensure that pro-

cesses run safely, reliably and accurately.

Number one in the process industry

SIPART PS2 is the most widely used posi-

tioner for linear and part-turn actuators

in the broad range of process industries,

not least because the flexibility of this

proven all-rounder ensures fulfillment of

virtually every requirement. For reliable

control of final control elements in chem-

ical or oil and gas sectors, or for precise

control of valves in the pharmaceutical or

food industry: we can rely on SIPART PS2

to provide the right solution for every

valve namely, optimized control both

for standard uses and for sophisticated

fields of application.

With SIPART PS2, Siemens offers a positioner known for more than 20 years for

its reliable and smooth sequences in the widest range of process industries and

what impresses customers most of all for its versatility. It can control the entire

spectrum of valves both safely and dependably and also perform special tasks

with extreme precision.

The experience gained from the most diverse fields of application has been

channeled into the continuous development of the SIPART PS2. This has made

the product what it is today a multi-talent that optimally fulfills a multitude

of specific requirements.

SIPART PS2 at a glance

Comes standard with degree of protection IP66 or NEMA 4X, optionally with

Makrolon, aluminum or stainless-steel enclosure

Variants with external non-contacting travel sensors

High flexibility in the stroke range from 3 mm to 200 mm (more on request)

Communication via PROFIBUS PA, Foundation Fieldbus or HART

Intelligent diagnostic functions

Explosion-proof version

3

At home in many sectors

Chemicals/petrochemicals

Pharmaceuticals

Food and beverage

Oil and gas

Energy

Paper/cellulose

Glass

Water/wastewater

Cement

Mining and metals

Marine engineering

4

Highly flexible, always first choice

Easy mounting and initialization

SIPART PS2 can be easily mounted on a wide

range of different standardized actuators: on

rotary actuators to VDI / DDE 3845 or linear

actuators to IEC 60 534-6 (NAMUR) as well as

on non-standardized proprietary actuators.

Over 400 mounting kits are available for

this purpose. This reduces the effort

required for mounting and simplifies the

entire initialization process.

A variety of mounting possibilities for numerous actuator and valve applications in

the stroke and rotary ranges combined with a well-thought-out design concept make

SIPART PS2 one of the most flexible and versatile positioners all over the world.

Users in a wide range of different sectors benefit from the many clear advantages

that SIPART PS2 offers.

The widest range of different actuators and applications one positioner

5

consequence here. Whether it is the con-

tact or non-contacting type or uses a poten-

tiometer, current signal or voltage value:

SIPART PS2 impresses in every case. All

these variants of external sensors

whether mounted externally or installed

internally within the actuator component

(e.g. in a pneumatic cylinder) can be con-

nected to the EMC filter module quickly and

easily.

Worldwide use in hazardous areas

SIPART PS2 is well-equipped for worldwide

use in hazardous areas. In addition to

approvals for IECEx, ATEX, FM and CSA as

an intrinsically safe (Ex ia/ib) or flameproof

(Ex d) device, it has a number of other cer-

tificates of suitability for use in explosion-

protected and maritime areas.

Maximum flexibility in the stroke range

SIPART PS2 offers a wide stroke range as

the answer to the wide variety of different

actuators and the growing number of mini

valves with extremely small strokes. The

scale is adjustable from 3 mm to 200 mm.

Our proven positioner can even be inte-

grated in modern actuators pipeless with-

out any additional effort.

Vibration-resistant:

Non-Contacting Sensor (NCS)

SIPART PS2 really shows its strengths in

applications where extreme vibrations

occur. The Non-Contacting Sensor (NCS)

detects the current position of the valve

reliably and precisely based on the princi-

ple of the GMR (giant magnetoresistance)

effect using the magnetic field lines. Com-

pared to other methods that depend on

the field strength and are therefore more

adversely affected by it and by the effects

of temperature, the GMR principle offers a

further advantage: a greater distance is

possible between the sensor and mag-

nets. The compact construction and high

IP68 degree of protection of the contact-

less and wear-free NCS are also suitable

for use in applications in which conven-

tional mounting solutions reach their

limits.

Ideally suited to special

applications

SIPART PS2 is also the best choice for

applications that are not typical for posi-

tioners (e.g. with pneumatic cylinders).

It is, of course, able to sense the current

position via a mechanical interface. But,

thanks to its modular design, it can also

be connected to external distance mea-

suring systems. The principle on which

the external sensor is based is of no

6

Intelligently designed down to

the last detail

SIPART PS2 teaches itself the respective

application characteristics and sets itself

up to meet the particular requirement as

best as possible. If changes occur over

time due to environmental effects or

wear, the device automatically adjusts

itself and transmits alarm signals

depending on the communications

interface via HART, PROFIBUS PA, Foun-

dation Fieldbus or a digital output.

Optimized inventory management

SIPART PS2 also sets standards for easy

stockkeeping. Plant builders and opera-

tors profit from the fact that the stan-

dard device remains unchanged:

whether it is used for linear or rotary

actuators, for large or small strokes, for

control valves or open/close valves, for

proprietary actuators or applications with

external sensors, for firm, precise con-

trol or additional diagnostic functions

including the Partial Stroke Test.

All inclusive

SIPART PS2 already has all important func-

tions such as position feedback or limit

signaling on-board. They can be set eas-

ily via a user-friendly display with three

push buttons without the need for any

additional equipment. The positioner

knows the characteristics of all valves

inside out, so cams or further signaling

devices are unnecessary. SIPART PS2

operates without an additional electrical

power supply in accordance with the two-

wire principle. Therefore, it ensures easy

and flexible implementation and is the

ideal alternative to conventional tech-

nology.

Fast commissioning

SIPART PS2 can be commissioned easily

within just a few minutes thanks to the

possibility of direct operation of the

device by means of push buttons, a dis-

play and the adjustable slipping clutch.

The coupling ensures a smooth initializa-

tion process by eliminating costly removal

and reinstallation of the device.

It is no coincidence that countless users in a wide variety of industries rely on

SIPART PS2: The experience gained over many years in the various fields of

application has been channeled into these highly accurate and reliable

positioners.

7

Protected against hostile environments

In an optional Makrolon, aluminum or

stainless-steel enclosure, SIPART PS2 is best

equipped to withstand any conditions. With

degree of protection IP66 or NEMA 4X as

standard, it withstands even the most hos-

tile environmental conditions. Thanks to the

innovative pneumatic block, even several

days of humid compressed air will have no

effect as well as temperature variations or

pressure changes in the piping system.

Faults are almost totally excluded and the

control functions without interruption.

Explosion-proof version

SIPART PS2 is also available with an explo-

sion-proof enclosure. Protected by a flap

with a bullet-proof glass pane, the display

can be read at all times and is simple and

convenient to use even after the flap is

opened during ongoing operation.

Extremely communicative

SIPART PS2 demonstrates its communicative

side in dialog with higher-level systems. It

can be integrated into the communications

landscape via PROFIBUS PA, Foundation

Fieldbus or HART protocol. With HART and

PROFIBUS, it is also possible to use SIMATIC

PDM to clearly display and document saved

trends, histograms, as well as commission-

ing and operating data.

8

Economically and ecologically beneficial

Less compressed air, reduced cost...

Effectively reducing compressed air con-

sumption is not simply a case of turning

the usual setting screws, e.g. for optimiz-

ing compressor technology, renewing

the compressed air distribution network,

etc., because, apart from the main loads,

the auxiliary loads also consume large

quantities of compressed air in the end.

SIPART PS2 really stands out with its

extremely low internal air consumption

rate of only 0.036 m

3

/ h. Given the appro-

priate boundary conditions, the following

values can be achieved for one device

over a year: Energy consumption for

compressed air generation of only

33 kW / h, at a cost of approximately

2 euros. In comparison,the energy con-

sumption of a conventional device for

the generation of compressed air would

be 560 kW/h, amounting to costs of

around 34 euros.

... and lower emissions

The environment also benefits from the

reduced compressed air consumption

of SIPART PS2: Assuming that a plant is

equipped with 1,000 positioners, conven-

tional devices would produce around

3,500 metric tons of CO2 emissions over

a period of 10 years. This represents an

enormous potential for savings that

SIPART PS2 fully exploits. It sets the stan-

dard with CO2 emissions of only 21 kg

per device per annum. For the example

quoted above (i.e. 1,000 SIPART PS2 posi-

tioners over a period of 10 years), this

would result in only 210 metric tons of

CO2 emissions.

Current market conditions demand careful analysis of the operating costs of a device during the procurement pro-

cess. For positioners, compressed air consumption is the main consideration here. This is minimized by SIPART PS2

along with the CO2 emissions generated by the energy consumption of the compressors. Compared to conven-

tional devices, it achieves potential savings of up to 90% an economical and ecological win-win situation.

9

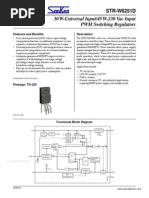

SIPART PS2: At a glance

Technical specifications

Setpoint signal 0 / 4 20 mA with/without HART signal or PROFIBUS PA / Foundation Fieldbus protocol

Stroke range 3 mm to 200 mm (larger strokes available on request)

Rotary angle range 30 to 100

Auxiliary power

Pneumatic

Electric

1.4 to 7 bar

4 to 20 mA (two-wire system) or

18 to 30 V (four-wire system) or

bus infeed 10.5 mA with PROFIBUS / Foundation Fieldbus

Load voltage 6.36 V (non-Ex without HART)

Airflow

Supply to actuator (for p = 6 bar)

Actuator to exhaust (for p = 6 bar)

9.8 m

3

n /h

19.2 m

3

n /h

Max. air bleed in settled state < 0.036 m

3

n/h

Required air quality Class 2 in accordance with ISO 8573-1

Binary inputs One digital input for floating contact

Explosion protection II 2 G Ex d IIC T6 / T4 Gb (explosion-proof enclosure d)

II 2 G Ex ia IIC T6 / T4 Gb (intrinsic safety ia)

II 2 D Ex ia IIIC 110 C Db (intrinsic safety ia)

II 3 G Ex ic IIC T6 / T4 Gc (intrinsic safety ic)

II 3 G Ex nA IIC T6 / T4 Gc (non-sparking, energy-limited nA)

II 3 D Ex tb IIIC T100 C Dc IP66 (dust, protected by enclosure t)

Additional approvals FM

CSA

SIL 2 in accordance with IEC 61508 / IEC 61551

Others on request

Ambient temperature 30 C to +80 C (other temperature ranges on request)

Accessories / Options

(can be retrofitted)

Limit module: Electrical alarm outputs including fault output and

Binary intput (floating contact or 24 V)

Slot initiators including fault output

Limit value contacts including fault output

Mounting kits

Pressure gauge block

Solenoid valve block

Position feedback, 4 20 mA

External position sensor, also non-contacting

Do you have a hostile environment?

SIPART PS2 is available in Makrolon, aluminum and stainless-

steel enclosures.

Does your control system communicate by

bus?

SIPART PS2 is available in PROFIBUS PA and Fieldbus Founda-

tion versions.

Do you need alarm signals independent of the

microprocessor?

SIPART PS2 has optional internal slot initiators or limit value

contacts also for retrofitting.

Do you have applications which require a high

degree of protection or expose the positioner

to strong vibrations?

The non-contacting sensor (NCS) has IP68 degree of protec-

tion and is extremely resistant to shocks and vibrations.

Do you want to record the valve position using

external potentiometers?

External potentiometers or the NCS can be connected to

SIPART PS2 via the EMC filter module.

Do you want to test your solenoid valve or re-

place its function (including the Partial Stroke

Test) with a positioner?

SIPART PS2 prevents the closing of valves during the solenoid

valve test, or monitors open/close valves as an intelligent

solenoid valve.

9

10

Simply safe and ideal

diagnostic interaction

The intelligent positioner SIPART PS2 is equipped with comprehensive functional-

ities and delivers reliable diagnostic data about itself, its environment, and the

valve and actuator. It reduces maintenance requirements in the plant, ensures

optimized process control and offers a high level of functional safety in emer-

gency situations.

Example of diagnostic messages in Emerson AMS Founda-

tion Fieldbus: Violation of temperature limit and stroke

number

Example of trend curve in Pactware DTM HART:

Display of actual value trend curve

Example of Partial Stroke Test in Siemens SIMATIC PDM

HART: Comparison of Partial Stroke Test curves

Example of histogram in Emerson AMS HART:

Histogram of the position

Example of diagnostic overview in Yokogawa DTM

Works HART: Diagnostic functions and information

about temperature limit violation

10

(OK, no maintenance requirement)

Maintenance necessary

Urgent maintenance request

(Impending) valve failure

Symbols on control desk:

They indicate the current maintenance status

11

Three-stage alarm concept

SIPART PS2 is equipped with comprehen-

sive diagnostic functions as standard. It

continuously checks the actuator and

valve in order to provide advanced warn-

ing of expensive failures during opera-

tion. The three-stage alarm concept,

which provides early information on

required maintenance or an imminent

failure of the valve, supports preventative

and efficient maintenance.

Partial stroke and solenoid valve test

By means of regular partial stroke testing,

SIPART PS2 ensures that ESD (emergency

shutdown) valves and other open/close

valves remain movable in case of an

emergency. SIPART PS2 is also capable of

testing the built-on solenoid valve. In the

case of solenoid valves (e.g. ESD or sole-

noid valves), the solenoid valve can also

be replaced completely by SIPART PS2.

With SIL 2 certification, the positioner

takes over the function of the valve and

can additionally control and carry out the

Partial Stroke Test.

Systematic interoperability

SIPART PS2 supports both commonly

used parameterization concepts EDD

(Enhanced Device Description) based on

EDDL (Electronic Device Description Lan-

guage) and FDT / DTM (Field Device Tool /

Device Type Manager). It also stands out

through its proven interoperability with

the Siemens process control system

SIMATIC PCS 7, with SIMATIC PDM, and

with process control systems and asset

management systems from other ven-

dors. Plant operators therefore benefit

from additional diagnostic messages that

the positioner outputs to these systems

thus creating added value for processes in

terms of preventative measures.

All standard diagnostics at a glance:

Alarm status based on NAMUR NE107

Partial Stroke Test for open/close and control valves

Pneumatic leaks

Stiffness of a valve

Stiction of the stuffing box

Wear of the valve seat or plug

Deposits or caking on the valve seat of plug

Cracking of the valve plug and blockage of a pipeline

(with continuous processes)

Trend diagrams

Histograms

Stroke counter for valve

Direction reversal counter

Operating hours counter

Deadband

Temperature measurement

For further information, see:

siemens.com/positioner

The information provided in this brochure contains merely

general descriptions or characteristics of performance which in

case of actual use do not always apply as described or which

may change as a result of further development of the prod-

ucts. An obligation to provide the respective characteristics

shall only exist if expressly agreed in the terms of contract.

All product designations may be trademarks or product names

of Siemens AG or supplier companies whose use by third par-

ties for their own purposes could violate the rights of the

owners.

Subject to change without prior notice 09/12

Order No.: E20001-A980-P710-X-7600

DISPO 27900

W/43450 MI.SC.PS.XX01.52.2.07 WS 10120.0

Printed in Germany

Siemens AG 2012

Siemens AG

Industry Sector

Sensors and Communication

76181 KARLSRUHE

GERMANY

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Robert Bosch Type VE Diesel Injection PumpDokument5 SeitenRobert Bosch Type VE Diesel Injection PumpShahrizan abdul rahman0% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- HV Cooling Fan Clutch Pinpoit Test - Ford Powertrain Control Emissions Diagnosis 2007Dokument9 SeitenHV Cooling Fan Clutch Pinpoit Test - Ford Powertrain Control Emissions Diagnosis 2007Ingrid Garcia de Jauregui100% (1)

- Growth and Yield Perpormance of Pechay FinalDokument25 SeitenGrowth and Yield Perpormance of Pechay FinalJaimeh Annabelle100% (2)

- Graphs of Polynomial FunctionsDokument38 SeitenGraphs of Polynomial FunctionsEvelyn MaligayaNoch keine Bewertungen

- Module 6 - Introduction To Hypertext PreprocessorDokument19 SeitenModule 6 - Introduction To Hypertext PreprocessorMr. EpiphanyNoch keine Bewertungen

- Piston ValveDokument28 SeitenPiston ValveDamien BouticourtNoch keine Bewertungen

- PBIPLUSMEDokument24 SeitenPBIPLUSMEGeraldoadriNoch keine Bewertungen

- Cascadas Protocol SpecificationsDokument32 SeitenCascadas Protocol SpecificationsGeraldoadriNoch keine Bewertungen

- CVS 1200 Pneumatic Positioner: Instruction ManualDokument12 SeitenCVS 1200 Pneumatic Positioner: Instruction ManualGeraldoadriNoch keine Bewertungen

- Dig 31900 Om002 HDokument85 SeitenDig 31900 Om002 HGeraldoadriNoch keine Bewertungen

- Profibus and Modbus - A ComparisonDokument5 SeitenProfibus and Modbus - A ComparisonGeraldoadriNoch keine Bewertungen

- Panel 2 - Gabriel Palma 2 - 0Dokument42 SeitenPanel 2 - Gabriel Palma 2 - 0GeraldoadriNoch keine Bewertungen

- 19 A New Approach To Portfolio Management in The Brazilian Equity Market Does The Selection of Most Efficient Assets Improve PerformanceDokument54 Seiten19 A New Approach To Portfolio Management in The Brazilian Equity Market Does The Selection of Most Efficient Assets Improve PerformanceGeraldoadriNoch keine Bewertungen

- Comp Net Amsterdam 2000Dokument284 SeitenComp Net Amsterdam 2000GeraldoadriNoch keine Bewertungen

- IGS Sever Using OPC UADokument5 SeitenIGS Sever Using OPC UAGeraldoadriNoch keine Bewertungen

- A5E00127926-ABen PS2PA OI en-US PDFDokument330 SeitenA5E00127926-ABen PS2PA OI en-US PDFGeraldoadri100% (1)

- DCL 6/10 Chute Level Transducer Data Sheet: Principle of OperationDokument1 SeiteDCL 6/10 Chute Level Transducer Data Sheet: Principle of OperationGeraldoadriNoch keine Bewertungen

- Ge Egd ManualDokument47 SeitenGe Egd ManualGeraldoadriNoch keine Bewertungen

- Driver ServerDokument10 SeitenDriver ServerGeraldoadriNoch keine Bewertungen

- Introduction To PlcsDokument27 SeitenIntroduction To PlcsGeraldoadriNoch keine Bewertungen

- Case Study Rusvinyl enDokument4 SeitenCase Study Rusvinyl enGeraldoadriNoch keine Bewertungen

- RAFT Synthesis of Poly (N-Isopropylacrylamide) and Poly (Methacrylic Acid) Homopolymers and Block Copolymers: Kinetics and CharacterizationDokument11 SeitenRAFT Synthesis of Poly (N-Isopropylacrylamide) and Poly (Methacrylic Acid) Homopolymers and Block Copolymers: Kinetics and CharacterizationClara Valverde SerranoNoch keine Bewertungen

- CNQ#1 PDFDokument32 SeitenCNQ#1 PDFareejaNoch keine Bewertungen

- Electronics Fundamentals Circuits Devices and ApplicationsDokument194 SeitenElectronics Fundamentals Circuits Devices and ApplicationsRenz Justine VillegasNoch keine Bewertungen

- Manuel Guindeau X2Dokument53 SeitenManuel Guindeau X2fr_emailleNoch keine Bewertungen

- Chapter 4 Semantic Roles - NOTESDokument8 SeitenChapter 4 Semantic Roles - NOTESWaad MajidNoch keine Bewertungen

- Datasheet PDFDokument15 SeitenDatasheet PDFperro sNoch keine Bewertungen

- 2.5.1 Feedforward Neural Networks: Products Solutions Purchase Support Community Company Our SitesDokument2 Seiten2.5.1 Feedforward Neural Networks: Products Solutions Purchase Support Community Company Our SitesAravind GaneshanNoch keine Bewertungen

- Oscillating Universe TheoryDokument1 SeiteOscillating Universe TheoryArabella BasilioNoch keine Bewertungen

- g-12 p-1 TestDokument5 Seiteng-12 p-1 TestDev SethiNoch keine Bewertungen

- Wang Heng - Active Neutral Point Clamped (ANPC)Dokument16 SeitenWang Heng - Active Neutral Point Clamped (ANPC)matias parra cuellarNoch keine Bewertungen

- KPP V1000 en Int02 0607Dokument24 SeitenKPP V1000 en Int02 0607Abanoub Badawi MasryNoch keine Bewertungen

- Business Combinations : Ifrs 3Dokument45 SeitenBusiness Combinations : Ifrs 3alemayehu100% (1)

- 3 Chiller T&C 2011Dokument9 Seiten3 Chiller T&C 2011Dtl SarozNoch keine Bewertungen

- The Effect of Sustainable Human Resource ManagemenDokument9 SeitenThe Effect of Sustainable Human Resource ManagemenFabio_WB_QueirozNoch keine Bewertungen

- Data Sheet Sylomer SR 18 ENDokument4 SeitenData Sheet Sylomer SR 18 ENlpczyfansNoch keine Bewertungen

- HFDL Specification Item-1cDokument50 SeitenHFDL Specification Item-1cBert Holtappels100% (1)

- Chains For Power TransmissionDokument11 SeitenChains For Power TransmissionQasim JavedNoch keine Bewertungen

- Nebojša Stojiljković: Work ExperienceDokument5 SeitenNebojša Stojiljković: Work Experienceastojadin1873Noch keine Bewertungen

- Parte1-Description Material and ConclusionsDokument3 SeitenParte1-Description Material and ConclusionsLisaNoch keine Bewertungen

- Strada 2001-2009 PDFDokument309 SeitenStrada 2001-2009 PDFFernando MorenoNoch keine Bewertungen

- Paper 1: Year 9 Mathematics TestDokument32 SeitenPaper 1: Year 9 Mathematics TestMa XóNoch keine Bewertungen

- LinuxDokument16 SeitenLinuxJon ExcaliburNoch keine Bewertungen

- Lipid PDFDokument17 SeitenLipid PDFAnonymous xt41ryNoch keine Bewertungen