Beruflich Dokumente

Kultur Dokumente

Lesson Components Construction and Design

Hochgeladen von

mister pogiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lesson Components Construction and Design

Hochgeladen von

mister pogiCopyright:

Verfügbare Formate

LESSON

2

LECTURE

COMPONENTS CONSTRUCTION AND

DESIGN

SUB-OBJECTIVE

At the end of the Lesson the Tranees !"" #e a#"e to des$r#e !tho%t error

$o&'onents $onstr%$ton and des(n)

*)+ EVAPORATOR

The evaporator shell is a rectangular vessel and consists of 19 flash stages

with a partition plate between each successive stage. The first 16 stages form

the heat recovery section and the last 3, stages form the heat rejection

section. For !"1 desal units ## stages for !"1 desal units. The first 19

stages form the heat recovery section and the last 3 stages form the heat

rejection section. $ee %"#"#.

&ach stage contains a single bundle of condensing tubes with a water bo' at

each end.

(nside each stage there is a flashing device, a demister, a distillate tray and a

distillate trough. The flashing device has a series of mechanically adjustable

orifices to allow regulation of the brine level at each stage.

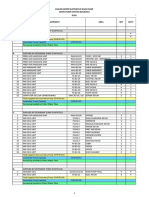

See ,() --2-*) Te$hn$a" data of the e.a'orator)

,() --2-*)

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 1 DESALINATION

(tem )o. (*F+1,1 " -*F+1,1

)ame &vaporator

Type ross tube type, multi"stage flash evaporator with brine recirculating

system.

)o. of $tages!eat recovery section 16 stages

!eat rejection section 3 stages

Total 19 stages

.esign Temp. Flash chamber side

" recovery 1#/ 0

" rejection 1#/ 0

"Tube side

" recovery 1#/ 0

" rejection 1+ 0

.esign ressure Flash chamber side 1 bar 2 and full vacuum

"Tube side

" recovery 9./6 bar 2 and full vacuum

" rejection +./ bar 2

!eat transfer 3rea " !eat recovery section 46,%%/ m5

" !eat rejection section 9,#%% m5

)o. of Tubes " !eat recovery section 63,31#

" !eat rejection section 4,+%1

Tube length " !eat recovery section 1+,1// mm

" !eat rejection section 1+,/// mm

Tube $ide " !eat recovery section #+.6 mm 6-..7 ' 1./ mm

thic8ness.

!eat rejection section #6./ mm 6-..7 ' 1.# mm

6Thic8ness7

!ydrostatic test Flash chamber side 1.+ bar 2 at the top pressure

tube side.

" recovery 13.+9 bar 2

" rejection 4.+ bar 2

.imensions 3,%// mm 6!eight7 '

11,1// mm 6*idth7 '

+%,/1/ mm 69ength7

*eight &mpty 1,41/ ton

.uring operation #,%#/ ton

Flooded +,13/ ton

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 2

,() --2-2) / --2-0) E.a'orator 1Sta(e No) *2 *-3 / *4)5

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 3 DESALINATION

*)* MATERIALS

$ea water and brine are corrosive. Therefore, special consideration for

prevention of corrosion is necessary in selecting construction materials

for the evaporator.

The bottom plate of the shell is of 3149 stainless steel clad. Front, rear,

and side plates are of 3169 stainless steel clad. the ceiling plate is of

3/19 stainless steel clad.

!ot brine is highly corrosive. Therefore, tubes and tube sheets are of

copper"nic8el, but tube sheets of the heat rejection section are made of

aluminum"bron:e.

Flashing devices, distillate troughs and demisters are of 3169 stainless

steel.

2)+ BRINE 6EATER

The low pressure e'haust steam enters the shell side of the brine heater and

is condensed on the outside surface of the tubes. The recycle brine is heated

to the re;uired ma'imum for entry to stage 1 of the evaporator. 3 small

amount of steam condensate is used for the desuperheater, the remainder

pumped bac8 to the power plant.

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 4

,() --2-7) Brne 6eater)

2)* MATERIALS

$team is supplied to the shell side and condensate is used for high pressure

boiler feed water. The shell is made or carbon steel.

!ot brine flows through the tubes. 3s hot brine is highly corrosive, the tube

surface must be made of special anti"corrosive materials.

Tube and tube sheets are of 4/<3/ copper"nic8el alloy. Tube supports,

impingement baffles and vent baffles are of 3/19 stainless steel. The water

bo' is of alloy clad steel 6carbon steel base and 9/<1/ copper"nic8el alloy

clad7.

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 5 DESALINATION

0)+ DE AERATOR

3s you have learnt from lesson 1 the deaerator removes non"condensable

gases from the sea water ma8e up.

The o'ygen content of the sea water is further reduced by injecting sodium

sulphite after passing through the deaerator.

The structure of the deaerator is shown in Fig. %"#"6.

,() --2-8 Deaerator)

0)* MATERIALS

The shell is made of carbon steel and the inside surface of the shell plate is

lined with neoprene rubber to prevent the shell plate from corrosion by hot sea

water. *ate distributor pipes, stripping steam pipes and gratings for pac8ings

layer are made of F= 6Fiber =einforced lastics7 to prevent corrosion.

ac8ings and spray no::les are made of polypropylene.

7)+ VACUUM S9STEM

The vacuum system consists of a pre"condenser and three stages ejectors

and condensers, arranged in series. The detailed structure of the ejector is

shown in Fig. %"#"4.

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 6

,() --2-:) E;e$tor)

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 7 DESALINATION

,() --2-2) IPre Condenser)

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 8

,() --2--) Ist) Inter Condenser

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 9 DESALINATION

,() --2-4)

7)* MATERIALS

&jectors are made of stainless steel to prevent corrosion by steam with sea

water mist. The air chamber, the steam no::le and the spray no::le are of

3169 stainless steel. The diffuser is of 3169 and F3169 stainless steel. The

steam chest is of 3169T stainless steel.

3lmost all p>arts of condensers are made of F= to prevent corrosion by hot

sea water.

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 10

8)+ BRINE BLO< DO<N PUMP

-ne only per unit, and is used to discharge part of the concentrated brine from

the last stage to the out fall canal. 3s in the previous pump, the bearing sea

water system supplies the lubricating and sealing water.

0apacity

#,3%/m

3

<hr

=?

41/

motor output

1++ 8*

,() --2-*+) Brne P%&'s)

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 11 DESALINATION

:)+ PRODUCT <ATER PUMP

Two per plant, one standby duty. 9ubricating and sealing water are supplied

from the pump bearing water system, but using .($T(99&. *3T&=. (t is also

electrically driven, and is a vertical pit barrel type.

0apacity

1,#1%m

3

<hr

=?

1,19/

motor output

#1/ 8*

,() --2-**) Condensate Ret%rn P%&')

-)+ MA=E-UP>TEMPERING PUMP

There are three per unit with two stand by. They supply ma8e"up sea water

which also serves other functions besides ma8e"up water. They are of

hori:ontal split casing, centrifugal, double suction type, driven by electric

motor.

0apacity

3,143m

3

<hr

=?

%9/

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 12

motor output

#// 8*

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 13 DESALINATION

,() --2-*2) Ma?e-%'>Te&'ern( P%&')

4)+ EJECTOR CONDENSER <ATER PUMP

Two per unit, one stand"by duty. This pump is used to pump up the sea water

from the sea water supply header to the heat rejection system, and to supply

sea water cooling for the barometric condensers of the vacuum jet system. 3

smaller version of the ma8e"up<tempering pump.

0apacity

1,36+m

3

<hr

=?

1,19/

motor output

6+ 8*

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 14

,() --2-*0) Do%#"e s%$ton '%&')

*+)+ DE SUPER 6EATER

The steam de super heater reduces the temperature of the 9 steam supplied

to the brine heater from the power plant. (t is a spray no::le type.

MECHANICAL MAINTENANCE COURSE MODULE 8

LESSON 2 PAGE 15 DESALINATION

,() --2-*7) Des%'erheater)

@UESTIONS

1. *here e'actly does the steam come from that supplies the brine heater@

#. *hy are parts of the evaporator made from alloys@

3. !ow is air pumped out of the evaporator@

1. *hat 8ind or bearings can be sea water cooled and lubricated@

+. *hy are the bearings on the product water pump cooled by distillate@

6. *hich other pump also re;uires distillate cooling<lubrication@

4. *hat is the advantage of a double suction pump@

MODULE 8 MECHANICAL MAINTENANCE COURSE

DESALINATION LESSON 2 PAGE 16

Das könnte Ihnen auch gefallen

- Room Integrity Testing, Room Integrity Test, Enclosure Integrity Testing, Blower Door Test PDFDokument6 SeitenRoom Integrity Testing, Room Integrity Test, Enclosure Integrity Testing, Blower Door Test PDFJomyJose100% (1)

- Expansion, Conctraction and Construction Joint On Concrete For Civil Works PDFDokument10 SeitenExpansion, Conctraction and Construction Joint On Concrete For Civil Works PDFSushil DhunganaNoch keine Bewertungen

- SCDF Fire Engineering Assessment For Waiver ApplicationDokument7 SeitenSCDF Fire Engineering Assessment For Waiver Applicationya hanNoch keine Bewertungen

- 20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZDokument12 Seiten20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZmister pogi100% (1)

- Life Cycle Cost Analysis of Water-cooled ChillersDokument24 SeitenLife Cycle Cost Analysis of Water-cooled ChillersGaruda GarudaNoch keine Bewertungen

- Chilled Water Supply and Pressure DropDokument10 SeitenChilled Water Supply and Pressure DropgothdaddeeNoch keine Bewertungen

- STAINLESS GRADES - Full PDFDokument204 SeitenSTAINLESS GRADES - Full PDFgogger100% (2)

- Plumbing Design for a 4-Storey Mixed-Use BuildingDokument65 SeitenPlumbing Design for a 4-Storey Mixed-Use BuildingCharles Kaven Dela Cruz100% (1)

- Flue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1Dokument56 SeitenFlue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1ASHIL PRABHAKARNoch keine Bewertungen

- Turbine:: Working PrincipleDokument11 SeitenTurbine:: Working PrincipleAzan khanNoch keine Bewertungen

- Use of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and ColumnsDokument34 SeitenUse of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and Columnszakaria200811060Noch keine Bewertungen

- Vapour Compression Refrigeration SlidesDokument41 SeitenVapour Compression Refrigeration SlidesLesegoNoch keine Bewertungen

- 05.40.00 Cold-Formed Metal Framing Specification Updated June 2015Dokument26 Seiten05.40.00 Cold-Formed Metal Framing Specification Updated June 2015mishikhanNoch keine Bewertungen

- BOILER WATER TREATMENT GUIDEDokument36 SeitenBOILER WATER TREATMENT GUIDERajendran SrnNoch keine Bewertungen

- Ak Mühendislik Taahhüt San. Ve Tic. Ltd. ŞtiDokument75 SeitenAk Mühendislik Taahhüt San. Ve Tic. Ltd. ŞtiVictorNoch keine Bewertungen

- ASME Training PRESSURE VESSELSDokument45 SeitenASME Training PRESSURE VESSELSMohamed Karim MohamedNoch keine Bewertungen

- Water Treatment & MethodsDokument39 SeitenWater Treatment & MethodsHaydar TaşNoch keine Bewertungen

- The Epocast Marine HandbookDokument43 SeitenThe Epocast Marine Handbookswapneel_kulkarni100% (2)

- Ecolutia - Proteus Fact Sheet PDFDokument2 SeitenEcolutia - Proteus Fact Sheet PDFJoselito CortesNoch keine Bewertungen

- SWRO Desalination Plant Construction and Pipe InstallationDokument8 SeitenSWRO Desalination Plant Construction and Pipe Installationdugma100% (2)

- Lesson Main Stop Valve & Servomotor, Governing Valves and ServomotorDokument41 SeitenLesson Main Stop Valve & Servomotor, Governing Valves and Servomotormister pogiNoch keine Bewertungen

- Series 900 BrochureDokument40 SeitenSeries 900 BrochureLungisaniNoch keine Bewertungen

- Water Treatment Guide for Palm Oil MillsDokument46 SeitenWater Treatment Guide for Palm Oil Millsmuhammad85100% (1)

- 1000LPH RO System HinadaDokument5 Seiten1000LPH RO System HinadaBrenda HaroNoch keine Bewertungen

- Project Standards and Specifications Precommissioning Piping Cleaning Rev01Dokument5 SeitenProject Standards and Specifications Precommissioning Piping Cleaning Rev01Tiago HenriquesNoch keine Bewertungen

- Allborg BoilersDokument2 SeitenAllborg BoilersHIPAP100% (1)

- Boiler Water ChemistryDokument48 SeitenBoiler Water ChemistryR.S.Sankarasubramanian100% (1)

- Data Sheet Indirect Fired Heater NapkjsDokument12 SeitenData Sheet Indirect Fired Heater Napkjsahmad santosoNoch keine Bewertungen

- MS 213 Method Statement For The Chlorination of Drinking Water Network Area 01 Package 5Dokument7 SeitenMS 213 Method Statement For The Chlorination of Drinking Water Network Area 01 Package 5Dipak VaghelaNoch keine Bewertungen

- Effluent Treatment Plant (ETP) - Process Flow DiagramDokument4 SeitenEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthNoch keine Bewertungen

- 2 - Package Boilers ProfileDokument3 Seiten2 - Package Boilers ProfileBayu Pramana PutraNoch keine Bewertungen

- Chapter 14 Boiler System Failures: Deaerator CrackingDokument22 SeitenChapter 14 Boiler System Failures: Deaerator CrackingVijay RajaindranNoch keine Bewertungen

- Technical Aspects of Desalination PlantDokument12 SeitenTechnical Aspects of Desalination PlantMonica UrbietaNoch keine Bewertungen

- O&M Scope of Turbine & Boiler at Kamalanga Power PlantDokument35 SeitenO&M Scope of Turbine & Boiler at Kamalanga Power PlantAbzad HussainNoch keine Bewertungen

- Membrane TechnologyDokument47 SeitenMembrane TechnologyDwiMariaUlfahNoch keine Bewertungen

- Lesson Chemical Injection and ChlorinationDokument3 SeitenLesson Chemical Injection and Chlorinationmister pogiNoch keine Bewertungen

- Closed SystemsDokument3 SeitenClosed SystemsMohamed IrfanNoch keine Bewertungen

- Consolis Asia - Presentation Bonna Pipes - MeralcoDokument62 SeitenConsolis Asia - Presentation Bonna Pipes - MeralcoFerdie TolosaNoch keine Bewertungen

- SCR AlstomDokument6 SeitenSCR Alstomcristi_molinsNoch keine Bewertungen

- Electrofusion Jointing The European WayDokument2 SeitenElectrofusion Jointing The European WayMahesh MalaiChamyNoch keine Bewertungen

- The Analysis of CarbonDioxide in Natural GasDokument4 SeitenThe Analysis of CarbonDioxide in Natural GasBimo Gunners RespatiNoch keine Bewertungen

- GE Generator Protection SystemDokument25 SeitenGE Generator Protection SystemEmmanuel A. ClaveriaNoch keine Bewertungen

- Detail A: Shuqaiq 3 Independent Water ProjectDokument1 SeiteDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNoch keine Bewertungen

- Boiler Types and Classifications - WikiDokument21 SeitenBoiler Types and Classifications - WikiKarthik ChillaNoch keine Bewertungen

- Punch List-Electrochlorination Plant-1 (ENVITECH) PDFDokument3 SeitenPunch List-Electrochlorination Plant-1 (ENVITECH) PDFJoni EfwanNoch keine Bewertungen

- 11) Manufacturing Processes II Welding III - 2Dokument23 Seiten11) Manufacturing Processes II Welding III - 2mkkNoch keine Bewertungen

- Weld CalculationDokument5 SeitenWeld CalculationTAUFIKNoch keine Bewertungen

- SWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and SystemsDokument8 SeitenSWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and Systemsmister pogiNoch keine Bewertungen

- Equipment and ToolsDokument15 SeitenEquipment and ToolsMathias OnosemuodeNoch keine Bewertungen

- Waste and Wastewater Trip ReportDokument15 SeitenWaste and Wastewater Trip ReportAira Ariana100% (4)

- Sample - Resume-IOCL FormatDokument5 SeitenSample - Resume-IOCL FormatRajasekaran PrakasamNoch keine Bewertungen

- FloGard MS6208Dokument1 SeiteFloGard MS6208engr.shahid041Noch keine Bewertungen

- Turbo MachineryDokument35 SeitenTurbo MachineryAbenezer ZebeneNoch keine Bewertungen

- Catalogo Industrias Ing0420Dokument16 SeitenCatalogo Industrias Ing0420SameerKhanNoch keine Bewertungen

- HYDROTESTDokument144 SeitenHYDROTESTJean GheorgheNoch keine Bewertungen

- Condensate Considerations in High Pressure Cogen PlantsDokument8 SeitenCondensate Considerations in High Pressure Cogen Plantsaliscribd46Noch keine Bewertungen

- Lesson Piping Anciliaries: Sub-ObjectiveDokument23 SeitenLesson Piping Anciliaries: Sub-Objectivemister pogiNoch keine Bewertungen

- AgitatorDokument8 SeitenAgitatorMugesh KannaNoch keine Bewertungen

- Alstom NID PräsentationDokument41 SeitenAlstom NID Präsentation41176711411100% (1)

- Sa04c2-Ms-Met-Aag-00012 - MS - Pickling & PassivationDokument7 SeitenSa04c2-Ms-Met-Aag-00012 - MS - Pickling & PassivationABAID ULLAHNoch keine Bewertungen

- Heatshrink Cable Terminations for Power UtilitiesDokument63 SeitenHeatshrink Cable Terminations for Power UtilitiesBasman GeorgeNoch keine Bewertungen

- Cathotic ProtectionDokument5 SeitenCathotic Protectionkrishna_swaroop99Noch keine Bewertungen

- Travelling Band ScreensDokument2 SeitenTravelling Band ScreensIngénérie traitement des eauxNoch keine Bewertungen

- Impact Sprinkler Troubleshooting GuideDokument11 SeitenImpact Sprinkler Troubleshooting GuidemuthuvelaaNoch keine Bewertungen

- Water Demineralization BasicsDokument16 SeitenWater Demineralization BasicsvenkeekuNoch keine Bewertungen

- Drum Filter PDFDokument8 SeitenDrum Filter PDFleroniusNoch keine Bewertungen

- Deionized For Cooling Tower PDFDokument8 SeitenDeionized For Cooling Tower PDFThipsuree KornboonraksaNoch keine Bewertungen

- AWT Standards For Corrosion Rates PDFDokument2 SeitenAWT Standards For Corrosion Rates PDFdalton2004Noch keine Bewertungen

- Types of Refrigeration Compressors: OCT. 2006 D.RavindraDokument31 SeitenTypes of Refrigeration Compressors: OCT. 2006 D.RavindraDnyanesh BodreNoch keine Bewertungen

- Lime Neutralization Wastewater TreatmentDokument15 SeitenLime Neutralization Wastewater TreatmentMehrdad AminkazemiNoch keine Bewertungen

- In Line BrazingDokument13 SeitenIn Line Brazingaries26marchNoch keine Bewertungen

- How To Acclimate Strawberry Plants - Stark Bro'sDokument5 SeitenHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNoch keine Bewertungen

- How To Acclimate Strawberry Plants - Stark Bro'sDokument5 SeitenHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNoch keine Bewertungen

- Stub End LengthDokument1 SeiteStub End Lengthmister pogi100% (1)

- Manual For Welding InspectorDokument308 SeitenManual For Welding Inspectormister pogi100% (1)

- Growing Catfish in The PhilippinesDokument4 SeitenGrowing Catfish in The Philippinesmister pogiNoch keine Bewertungen

- Atty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC ProceedingsDokument15 SeitenAtty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC Proceedingsmister pogiNoch keine Bewertungen

- SWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and SystemsDokument8 SeitenSWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and Systemsmister pogiNoch keine Bewertungen

- Lesson Introduction To CompressorsDokument12 SeitenLesson Introduction To Compressorsmister pogiNoch keine Bewertungen

- Air Con 02 OverDokument50 SeitenAir Con 02 Overmister pogiNoch keine Bewertungen

- Msfpt2 LesDokument9 SeitenMsfpt2 Lesmister pogiNoch keine Bewertungen

- 4air Con02Dokument9 Seiten4air Con02mister pogiNoch keine Bewertungen

- Air Con 01overDokument19 SeitenAir Con 01overmister pogiNoch keine Bewertungen

- Air Con 03 OverDokument30 SeitenAir Con 03 Overmister pogiNoch keine Bewertungen

- 4air Con05Dokument6 Seiten4air Con05mister pogiNoch keine Bewertungen

- 10air Con04Dokument7 Seiten10air Con04mister pogiNoch keine Bewertungen

- 4air Con04Dokument24 Seiten4air Con04mister pogiNoch keine Bewertungen

- 3air Con03Dokument10 Seiten3air Con03mister pogiNoch keine Bewertungen

- Turbine 3Dokument11 SeitenTurbine 3mister pogiNoch keine Bewertungen

- 3air Con02Dokument12 Seiten3air Con02mister pogiNoch keine Bewertungen

- Lesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration SystemsDokument4 SeitenLesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration Systemsmister pogiNoch keine Bewertungen

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDokument26 SeitenLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNoch keine Bewertungen

- Lesson Basic Air Conditioner SystemsDokument7 SeitenLesson Basic Air Conditioner Systemsmister pogiNoch keine Bewertungen

- Lesson Heat Pumps and Complete Air Conditioning SystemDokument14 SeitenLesson Heat Pumps and Complete Air Conditioning Systemmister pogiNoch keine Bewertungen

- 10air Con03Dokument10 Seiten10air Con03mister pogiNoch keine Bewertungen

- Lesson Heating and CoolingDokument8 SeitenLesson Heating and Coolingmister pogiNoch keine Bewertungen

- Lesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet ValvesDokument15 SeitenLesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet Valvesmister pogiNoch keine Bewertungen

- Lesson Rigging SafetyDokument14 SeitenLesson Rigging Safetymister pogiNoch keine Bewertungen

- Turbine 2Dokument32 SeitenTurbine 2mister pogiNoch keine Bewertungen

- Lesson Basic RiggingDokument15 SeitenLesson Basic Riggingmister pogiNoch keine Bewertungen

- I. Storage Guidelines and Redrying: Storing Stic ElectrodesDokument2 SeitenI. Storage Guidelines and Redrying: Storing Stic ElectrodesMohammad ganiNoch keine Bewertungen

- EVCO O RingeDokument24 SeitenEVCO O RingeteresamcabralNoch keine Bewertungen

- Unit IV - Limit State Design of ColumnsDokument7 SeitenUnit IV - Limit State Design of ColumnsManikandanNoch keine Bewertungen

- Ahu Hatcher Room 3Dokument7 SeitenAhu Hatcher Room 3CITACOM UTAMANoch keine Bewertungen

- Applied Thermo - 1st ClassDokument10 SeitenApplied Thermo - 1st ClassNur Hanim Abd GhaniNoch keine Bewertungen

- Rapid Freezing Prototyping With Water (4PS09MCM02)Dokument20 SeitenRapid Freezing Prototyping With Water (4PS09MCM02)Chetan MaskiNoch keine Bewertungen

- Triad Series: 3 Piece Ball ValvesDokument8 SeitenTriad Series: 3 Piece Ball Valvesevilnemesis133Noch keine Bewertungen

- Vortex CNC Cooler System HBWDokument7 SeitenVortex CNC Cooler System HBWHannan RizqiNoch keine Bewertungen

- Trox Webconfiguration: VDW-Q-Z-H-M-L/600x24Dokument1 SeiteTrox Webconfiguration: VDW-Q-Z-H-M-L/600x24amenokoeNoch keine Bewertungen

- Rock Mechanics in Wellbore ConstructionDokument65 SeitenRock Mechanics in Wellbore ConstructionAnonymous rey6aU3ZNoch keine Bewertungen

- General Requirements For Steel Plates For Pressure VesselsDokument34 SeitenGeneral Requirements For Steel Plates For Pressure VesselsIndira BanerjeeNoch keine Bewertungen

- Micropile Design 2021-07-14Dokument1 SeiteMicropile Design 2021-07-14BinSayeedNoch keine Bewertungen

- Ball ValvesDokument28 SeitenBall ValvesRAVINDR.KNoch keine Bewertungen

- Arenadora MaxusDokument3 SeitenArenadora MaxusrobinNoch keine Bewertungen

- Vertical glandless pump installation guideDokument22 SeitenVertical glandless pump installation guideYoutube For EducationNoch keine Bewertungen

- Design Guidelines For The Use of HM Strips - Strengthening of Steel Concrete Composite Bridge With High Modulus Carbon Fibrer Reinforced Polymer (CFRP) StripsDokument40 SeitenDesign Guidelines For The Use of HM Strips - Strengthening of Steel Concrete Composite Bridge With High Modulus Carbon Fibrer Reinforced Polymer (CFRP) Stripsvlad lupasteanuNoch keine Bewertungen

- Process Piping Products GuideDokument17 SeitenProcess Piping Products GuidekicsnerNoch keine Bewertungen

- ROADBED CONSTRUCTION (HIGHWAY ENGINEERINGDokument42 SeitenROADBED CONSTRUCTION (HIGHWAY ENGINEERINGGrace Ann CabanbanNoch keine Bewertungen

- Non-Destructive Testing of Masonry StructuresDokument5 SeitenNon-Destructive Testing of Masonry StructuresRajesh KhadkaNoch keine Bewertungen

- IT - Flammability RatingsDokument5 SeitenIT - Flammability RatingsRa HulNoch keine Bewertungen