Beruflich Dokumente

Kultur Dokumente

PHA Presentation

Hochgeladen von

safaldCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PHA Presentation

Hochgeladen von

safaldCopyright:

Verfügbare Formate

Process Hazard Analysis

Fundamentals

Walt Frank, P.E.

Frank Risk Solutions

R I SK SOL U T I ON S

2

Walt Frank, PE

B.S. CheE, Rose-Hulman Institute of Technology

24 years with DuPont

10+ years with ABS Consulting

President, Frank Risk Solutions, Inc.

Emeritus member of American Institute of

Chemical Engineers (AIChE) Center for Chemical

Process Safety (CCPS)

AIChE and CCPS Fellow

NFPA member and chair of the Technical

Committee on Handling and Conveying of Dusts,

Vapors, and Gases

3

Focus Of This Presentation

Provide basic understanding of:

Requirements for PHAs in NFPA 654

How to conduct, document, and follow up on a

Process Hazard Analysis (PHA)

4

What is a PHA?

An organized effort to identify and evaluate

hazards associated with chemical processes and

operations to enable their control. This review

normally involves the use of qualitative techniques

to identify and assess the significance of hazards.

Conclusions and appropriate recommendations are

developed. Occasionally, quantitative methods are

used to help prioritized risk reduction.

AIChE, Center for Chemical Process Safety

(CCPS)

5

What is a Hazard?

An inherent chemical or physical characteristic that

has the potential for causing damage to people,

property, or the environment. it is the

combination of a hazardous material, an operating

environment, and certain unplanned events that

could result in an accident.

CCPS

6

Why Do A PHA?

It is required by NFPA 654

Hazard/risk controls are expensive

We seek confidence that:

We understand the hazards in the process

We can identify the most appropriate means of

controlling those hazards

The controls we apply will be effective in addressing

the hazard

We know how to maintain the effectiveness of those

controls over time

We are not wasting resources on unneeded or

ineffective controls

7

NFPA 654 Requirements

4.2 Process Hazard Analysis.

4.2.1* The design of the fire and explosion safety

provisions shall be based on a process hazard

analysis of the facility, the process, and the

associated fire or explosion hazards.

4.2.2 The results of the process hazard analysis shall be

documented and maintained for the life of the

process.

4.2.3 The process hazard analysis shall be reviewed and

updated at least every 5 years.

A.4.2.1One method by which this requirement can be

satisfied is with a process hazard analysis

conducted in accordance with the methods outlined

by the AIChE Center for Chemical Process Safety in

Guidelines for Hazard Evaluation Procedures.

8

Goals of PHA

Identify the hazards inherent with an activity

We cannot evaluate the hazards we are not aware of

Identify process upsets, human errors, and

equipment failures that could manifest these

hazards in the form of incident scenarios leading

to undesired consequence (e.g., injuries,

equipment damage, environmental damage,

etc.)

9

Hazard Identification

Hazards that are not identified cannot be

analyzed

Yes our process materials are combustible

But how about:

Health hazards?

Chemical reactivity?

Conductivity (high or low)?

Propensity to electrostatic charging?

10

Goals of PHA

Identify and evaluate existing protections

against such scenarios and consequences

Determine whether additional protections are

necessary, and propose such protections as

warranted

11

Some Important PHA Concepts

Preparation for the PHA

Proper team make-up

Correct and up-to-date information to support

PHA

Selection of appropriate PHA technique(s)

Effective conduct of the meetings

Clear documentation of PHA results

Timely, effective implementation of PHA

recommendations

12

Some Common PHA Techniques

Hazard and Operability Analysis (HAZOP)

Checklist Analysis

What If Analysis

What If/ Checklist Analysis

Failure Modes and Effects Analysis (FMEA)

Layers of Protection Analysis (LOPA)

13

HAZOP Overview

Detailed/rigorous technique developed in the

chemical industry

Looks at the design intent of the process and

assesses what might happen if operations

deviate from that intent

Analysis proceeds step-wise through the process

Each relevant process parameter is assessed

(flow, temperature, pressure, composition, etc.)

14

HAZOP Overview

Guidewords are applied to process parameters

to construct deviations from process intent

More flow, less flow, no flow, reverse flow

More pressure, less pressure

More (Higher) temperature, less (lower) temperature

Deviations from intent are assessed for safety

significance

15

HAZOP Overview

Where concerns are identified

Potential consequences are estimated

Likelihood may be estimated

Existing protections are identified and evaluated for

effectiveness

Additional protections are proposed, as warranted

16

HAZOP Step-By-Step

Identify the process/activity to be assessed

Section the process into discrete nodes for which

a succinct design intent can be described

Describe the design intent for each node,

documenting relevant process parameters, e.g.:

Unload the contents of the tank truck into the silo in

45 minutes or less.

Feed 500 lbs/hr to the spray dryer, maintaining a

product exit temperature of no more than 175

o

F.

17

HAZOP Step-By-Step

Select a process parameter and apply a guide

word to create the first deviation; e.g., Higher

temperature

Determine if there are any undesired safety

consequences for this deviation

Note: it is conventional to assume any existing

protection fail when estimating consequences to

ensure a conservative estimate

If so, identify the potential causes for the

deviation

18

HAZOP Step-By-Step

Identify existing protections (engineered,

administrative, etc.)

Note: protections may be specific to a particular

cause or a particular consequence

Optional: risk rank the accident scenario being

studied (more on this later)

Determine if additional protections are

warranted, and propose as appropriate

19

HAZOP Step-By-Step

Select the next guide word, apply to same

process parameter, and repeat above process

Repeat for all relevant guidewords

Repeat for all relevant process parameters

Repeat for all process nodes

20

HAZOP Summary

HAZOP is clearly a detailed analytical technique

Designed to ensure comprehensive analysis of

complex process situations

HAZOP may not be appropriate for your

situation

May be too big a tool

21

HAZOP Summary

HAZOP exemplifies the underlying thought

processes that are inherent in all PHAs

What is supposed to happen when things are

normal?

What can go wrong... and how?

How bad can it be?

How likely is this to happen?

How are we currently protected?

Do we need more protection?

The other PHA techniques (discussed later) all

seek to answer these same questions

22

Preparing for the PHA

Some basic considerations:

Define analytical scope of PHA (not unusual for a site

to require multiple PHAs)

Assemble/compile required supporting information

Identify the PHA team

Get agreement/endorsement of all involved

individuals/groups

Agree on the schedule

Arrange meeting room and logistical issues

On-site or off-site?

23

Assemble Supporting Information

Required information may include:

Process flow diagrams (or piping and instrumentation

diagrams)

MSDSs and other sources of hazard information for

the process chemicals

Process descriptions

Operating procedures

Information on safety systems

Incident investigation reports

Etc.

Information should be accurate and up-to-date

24

PHA Team Make-Up

The PHA Team should be led/facilitated by

someone with experience in the conduct of PHAs

and familiarity with the technique(s) selected

The PHA Team should, at a minimum provide

knowledge on the following topics:

The process and procedures

The equipment and maintenance practices

Process materials and their hazards

Safety systems and their functions

Emergency response systems and procedures

(Possibly) building construction and fire resistance

25

PHA Team Make-Up

PHA Teams typically contain the following

membership:

Team leader/facilitator

Scribe

Operator and/or operations supervisor

Mechanic and/or maintenance supervisor

Process engineer

Health and Safety representative

Other specialized expertise as needed

One person may represent several functions

Avoid tag team participation

26

Preparing the PHA Team

Depending upon the team members past

experience, the PHA leader may need to provide

some training on the PHA process and the

technique(s) selected

A tour of the process to be studied may help the

team focus in its thinking

27

Conducting the Meetings

The success of the PHA is highly dependent

upon having a skilled, experienced team leader

Keeps team focused, keeps energy level up

Identify and evaluate problems, but do not

engineer solutions

Maintain focus on worst credible events

Seek outside expertise when needed

Avoid bogging down, identify stuck issues for

later resolution

Accurately document the team deliberations

28

Other PHA Techniques

Checklist Analysis

What If Analysis

What If/Checklist Analysis

Failure Modes and Effects Analysis

Layers of Protection Analysis (LOPA)

29

Checklist Analysis

Uses a prepared list of questions or topics to

prompt the hazard assessment

Is the question/topic applicable to the system being

assessed?

If the question/topic proposes a particular protective

feature, is this present in the system?

What other concerns do the question/topic prompt?

What additional protections may be warranted?

Checklists must prepared before the PHA

Companies with similar processes/equipment may

develop checklists specific to their needs/experience

Some may find NFPA 654 to be a useful checklist

30

What If Analysis

The least-structured of the techniques

PHA team brainstorms potential safety problems,

assessing significance, existing protections, need

for additional protections

Highly dependent upon knowledge/experience of

team members and effective team leadership

Useful when relevant checklists are not available

31

What If/ Checklist Analysis

Conduct brainstorming What If first, followed by

the more structured Checklist to fill in the gaps

Analysis process is not constrained by the content of

the prepared checklist

Combined approach is not solely reliant on team

experience

32

Failure Modes and Effects Analysis

FMEA focuses on equipment systems

Mechanical processing equipment

Control systems, such as dryer temperature control

Protective systems, such as interlocks

Assesses:

How can each major component in the system fail?

What would the resulting effects (consequences) be?

What protections currently exist to mitigate the

failure?

What additional protections may be warranted?

33

Technique Selection

Each technique has its niche

For example, FMEA can be effective in assessing

complex equipment systems, while HAZOP

addresses complex process operations

Often, a PHA may use a combination of

techniques; e.g.:

HAZOP supplemented by one or more checklists

FMEA to evaluate one particularly important safety

system identified in a checklist analysis

A skilled PHA leader should be familiar with all

techniques and know when to draw upon each

34

Risk Ranking

Risk expresses the likelihood of experiencing a

certain consequence

For example, fatalities/year

Risk ranking is commonly used in HAZOP, can be

expanded to other techniques

Each scenario is assessed for

Consequences (assuming protections fail)

Likelihood of occurrence (allowing credit for

protections)

Estimates can be on a qualitative or semi-

quantitative basis

35

Risk Ranking

Consequence and likelihood are combined to

estimated the likelihood of loss (risk)

Usually using a risk matrix

Risk ranking can allow rational prioritization of

recommendations

Higher risk scenarios warrant higher priority

36

Risk Ranking

37

Risk Ranking

Example Consequence Categories Qualitative Risk Matrix

Category Description

1 No injury or health effects

2 Minor to moderate injury or health effects

3 Moderate to severe injury or health effects

4 Permanently disabling injury or fatality

38

Example Frequency Categories Qualitative Risk Matrix

Category Description

1

Not expected to occur during life of

process/facility

2 May occur once during life of process/facility

3 May occur several times during life of

process/facility

4 Expected to occur more than once in a year

Risk Ranking

39

Risk Ranking

40

Risk Ranking

Example Risk Ranking/Response

Categories Qualitative Risk Matrix

Risk

Level

Description Required Response

I

Unacceptable

Immediate mitigation or termination

of activity

II High Mitigation within 6 months

III Moderate Mitigation within 12 months

IV Acceptable As Is No mitigation required

41

Layers of Protection Analysis

Technique for assessing the number of safety

layers required to achieve a tolerable level of

risk for a particular scenario

7.1.2 Explosion Protection for Equipment

(a) Where oxygen monitoring is used, it shall be

installed in accordance with ISA 84.00.01,

Functional Safety: Application of Safety

Instrumented Systems for the Process Industry

Sector.

More detailed discussion of LOPA is beyond

todays scope

42

Documentation

PHA must be clearly, effectively documented

Documentation should address:

Scope of analysis

Team members and qualifications

Information used in support of analysis (with revision

number or date, where appropriate)

Results of the analysis (typically in tabular form)

Recommendations

PHA documentation must be kept for the life of

the process

43

Recommendation Follow-up

Properly follow-up on recommendations protects

the investment in time and resources that went

into the PHA

Many organization trip up by not following up

Legal liabilities, in addition to safety concerns, in

failing to address recommendations in timely fashion

Document, for each recommendation:

Responsible party

Due date

Track each recommendation to resolution

Enforcing expectations that due dates will be met

Implement formal extension process for rare

exceptions

44

Recommendation Follow-up

Include in PHA documentation:

Date recommendation closed out

How it was closed out (what actually was done)

Close out recommendations only after required

actions have been implemented

Do not close out recommendations based upon a

future intent to do something

45

Recommendation Follow-up

Recommendations may be rejected for cause

Further analysis shows the recommendation was

based upon erroneous conclusions, will not enhance

safety

Changing circumstances remove need for

recommendation

Recommendation is not feasible (but look for

alternate means of satisfying underlying intent of

recommendation)

J ustification for rejection should be clearly

documented

46

PHA Revalidation

NFPA 654 requires that the PHA be reviewed

and updated at least every 5 years

Guidance for determining the appropriate

approach to doing so can be found in CCPS

publication Revalidating Process Hazard Analyses

47

Questions?

For follow-up:

Walt Frank

Frank Risk Solutions, Inc.

302-521-7588

WLF@FrankRisk.com

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Steam Tracing CalculationDokument44 SeitenSteam Tracing CalculationsafaldNoch keine Bewertungen

- 4 GEN 8602 DOC - Vendor's Documentation RequirementsDokument7 Seiten4 GEN 8602 DOC - Vendor's Documentation RequirementssafaldNoch keine Bewertungen

- Steam TracingDokument18 SeitenSteam TracingSyed Mujtaba Ali Bukhari100% (2)

- Receipt - Nusatrip Online TravelDokument1 SeiteReceipt - Nusatrip Online TravelsafaldNoch keine Bewertungen

- List of Tender PackagesDokument25 SeitenList of Tender PackagessafaldNoch keine Bewertungen

- Vendors Info (2015!04!09) SsssssDokument49 SeitenVendors Info (2015!04!09) SssssssafaldNoch keine Bewertungen

- Restrictive Orifice Calc For Tube FinalDokument12 SeitenRestrictive Orifice Calc For Tube FinalsafaldNoch keine Bewertungen

- Piping PDFDokument46 SeitenPiping PDFGORO43100% (1)

- 3182xxx - PDS For Rupture DiskDokument2 Seiten3182xxx - PDS For Rupture DisksafaldNoch keine Bewertungen

- Pressure Control Valve (PV) : Process Data Sheet ForDokument1 SeitePressure Control Valve (PV) : Process Data Sheet ForsafaldNoch keine Bewertungen

- 3182xxx - Restriction OrificeDokument2 Seiten3182xxx - Restriction OrificesafaldNoch keine Bewertungen

- Process Data Sheet For Temperature Gauge: XXX XXX XXX XXX XX of XXDokument2 SeitenProcess Data Sheet For Temperature Gauge: XXX XXX XXX XXX XX of XXsafaldNoch keine Bewertungen

- 3182xxx - Flow Instruments - FT, FC, FIDokument5 Seiten3182xxx - Flow Instruments - FT, FC, FIsafaldNoch keine Bewertungen

- 3182xxx - Level Switch, Transmitter, IndicatorDokument4 Seiten3182xxx - Level Switch, Transmitter, IndicatorsafaldNoch keine Bewertungen

- Process Data Sheet For Tank / Vessel: XXX XXX XXX XXX XXX XXXDokument2 SeitenProcess Data Sheet For Tank / Vessel: XXX XXX XXX XXX XXX XXXsafaldNoch keine Bewertungen

- New Microsoft Excel WorksheetDokument6 SeitenNew Microsoft Excel WorksheetsafaldNoch keine Bewertungen

- 3181xxx - PDS For FilterDokument1 Seite3181xxx - PDS For FiltersafaldNoch keine Bewertungen

- 3181xxx - PDS For PumpDokument1 Seite3181xxx - PDS For PumpsafaldNoch keine Bewertungen

- 3181xxx - PDS For Mixer - AgitatorDokument1 Seite3181xxx - PDS For Mixer - AgitatorsafaldNoch keine Bewertungen

- Design of AgitatorDokument3 SeitenDesign of AgitatorManish PatelNoch keine Bewertungen

- Agitator DesignDokument7 SeitenAgitator DesignTint Tiger100% (4)

- 2011-08 Newsletter TNBVDokument3 Seiten2011-08 Newsletter TNBVsafaldNoch keine Bewertungen

- EDS DisciplineDokument7 SeitenEDS DisciplinesafaldNoch keine Bewertungen

- Pressure Vessel Nozzle Calc - ASME VIII Div 1Dokument20 SeitenPressure Vessel Nozzle Calc - ASME VIII Div 1aauppal100% (1)

- Ex Reactor DesignDokument10 SeitenEx Reactor DesignsafaldNoch keine Bewertungen

- Heat Transfer Coeficient in ReactorDokument2 SeitenHeat Transfer Coeficient in ReactorDavid LambertNoch keine Bewertungen

- Gas Linesizing Rev1Dokument9 SeitenGas Linesizing Rev1safaldNoch keine Bewertungen

- 8.62 Bars 45.6 C 8.62 Bars: Condenser Expansion CompressorDokument16 Seiten8.62 Bars 45.6 C 8.62 Bars: Condenser Expansion Compressorduazo2009100% (1)

- Styrene Acrylic LatexDokument4 SeitenStyrene Acrylic LatexsafaldNoch keine Bewertungen

- Styrene Acrylic LatexDokument4 SeitenStyrene Acrylic LatexsafaldNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Air Compressor: TopicDokument17 SeitenAir Compressor: TopicManuel GuerreroNoch keine Bewertungen

- 2021 H2 Chemistry Prelim Paper 1Dokument15 Seiten2021 H2 Chemistry Prelim Paper 1clarissa yeoNoch keine Bewertungen

- Kim Lighting Landscape Lighting Catalog 1988Dokument28 SeitenKim Lighting Landscape Lighting Catalog 1988Alan MastersNoch keine Bewertungen

- Synergic Antiobesity Effects of Bitter Melon Water Extract and Platycodin-D in Genetically Obese MiceDokument9 SeitenSynergic Antiobesity Effects of Bitter Melon Water Extract and Platycodin-D in Genetically Obese Micegege wpNoch keine Bewertungen

- Shutdown Jobs List C & IDokument12 SeitenShutdown Jobs List C & Imanohar kumar0% (1)

- Mount Kenya University: Department: School of Social SciencesDokument4 SeitenMount Kenya University: Department: School of Social SciencesLETISIA FATUMANoch keine Bewertungen

- BCRSPDokument2 SeitenBCRSPDastan YermegaliyevNoch keine Bewertungen

- Design of Marina Structures and FacilitiesDokument23 SeitenDesign of Marina Structures and FacilitiesAhmed Balah0% (1)

- Brook Health Care Center Inc Has Three Clinics Servicing TheDokument1 SeiteBrook Health Care Center Inc Has Three Clinics Servicing Thetrilocksp SinghNoch keine Bewertungen

- Tinda Tomato PachadiDokument1 SeiteTinda Tomato PachadijyosriNoch keine Bewertungen

- Resume PLPDokument2 SeitenResume PLPapi-302180779Noch keine Bewertungen

- 1st English Lesson 6-7 - CompressedDokument21 Seiten1st English Lesson 6-7 - Compressedharonac588Noch keine Bewertungen

- Geared Motor Device 100/130V E1/6-T8Dokument2 SeitenGeared Motor Device 100/130V E1/6-T8seetharaman K SNoch keine Bewertungen

- Recipes For Ceviche, Pebre and Pisco SourDokument4 SeitenRecipes For Ceviche, Pebre and Pisco SourJoaquín Rolón CarrerasNoch keine Bewertungen

- Unit Weight of Materials Used at Construction Site - Online Civil PDFDokument2 SeitenUnit Weight of Materials Used at Construction Site - Online Civil PDFKeshav VarpeNoch keine Bewertungen

- Effect of Different Immediate Dentin Sealing Techniques On The Microtensile Bond Strength PDFDokument6 SeitenEffect of Different Immediate Dentin Sealing Techniques On The Microtensile Bond Strength PDFclaudiaNoch keine Bewertungen

- Icu2 Vol22 Sepsisincriticalcare 29marchDokument52 SeitenIcu2 Vol22 Sepsisincriticalcare 29marchricardoatejassNoch keine Bewertungen

- Exercises: (A) Read The Following PassageDokument2 SeitenExercises: (A) Read The Following PassageNur Nezanna0% (1)

- 4 Strength and Durability of Concrete With LC3Dokument41 Seiten4 Strength and Durability of Concrete With LC3Mirza BasitNoch keine Bewertungen

- Kevin Coleman's Sentencing MemoDokument26 SeitenKevin Coleman's Sentencing MemoThe Valley IndyNoch keine Bewertungen

- Primary Health Care: Mr. John Michael M. Pitoy, B.S.N., R.NDokument44 SeitenPrimary Health Care: Mr. John Michael M. Pitoy, B.S.N., R.NJohn Michael Manlupig Pitoy100% (9)

- The Company - MicroDokument2 SeitenThe Company - MicroMai Hương QuỳnhNoch keine Bewertungen

- Hilti AnchorsDokument202 SeitenHilti AnchorsmwendaNoch keine Bewertungen

- AASHTO Digital Publications: Instructions Located HereDokument2 SeitenAASHTO Digital Publications: Instructions Located HereMinn LwinNoch keine Bewertungen

- Eaton 092394 T5B 3 7 E en - GBDokument6 SeitenEaton 092394 T5B 3 7 E en - GBJorge AmayaNoch keine Bewertungen

- 1 s2.0 S0378517311000226 MainDokument9 Seiten1 s2.0 S0378517311000226 MainFIRMAN MUHARAMNoch keine Bewertungen

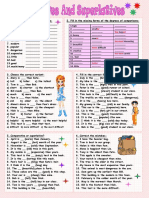

- Comparatives and SuperlativesDokument2 SeitenComparatives and Superlativesjcarlosgf60% (5)

- Morgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Dokument386 SeitenMorgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Tsiory RanaivosonNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument3 SeitenNew Microsoft Office Word DocumentSunija SelvamNoch keine Bewertungen

- The Safe Motherhood InitiativeDokument3 SeitenThe Safe Motherhood InitiativeAnonymous g6L7jJWNoch keine Bewertungen