Beruflich Dokumente

Kultur Dokumente

Non Black Fillers in EPDM Extrusion Formulation (Peroxide Cured) PDF

Hochgeladen von

dargil660 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

136 Ansichten28 SeitenTwo classes of filler are suitable for extrusion processing, particularly when special profiles must be produced. Neuburg Siliceous Earth has a clear advantage here in terms of price to performance ratio. Surface-treated AKTISIL VM 56 wins on cost compared to untreated calcined clay.

Originalbeschreibung:

Originaltitel

Non+black+fillers+in+EPDM+Extrusion+Formulation+(peroxide+cured).pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTwo classes of filler are suitable for extrusion processing, particularly when special profiles must be produced. Neuburg Siliceous Earth has a clear advantage here in terms of price to performance ratio. Surface-treated AKTISIL VM 56 wins on cost compared to untreated calcined clay.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

136 Ansichten28 SeitenNon Black Fillers in EPDM Extrusion Formulation (Peroxide Cured) PDF

Hochgeladen von

dargil66Two classes of filler are suitable for extrusion processing, particularly when special profiles must be produced. Neuburg Siliceous Earth has a clear advantage here in terms of price to performance ratio. Surface-treated AKTISIL VM 56 wins on cost compared to untreated calcined clay.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 28

Author: Hubert Oggermller

Approval: May 2008

VM / Dr. Alexander Risch

_____________________

Non-black Fillers

in EPDM Extrusion

Formulation

(peroxide cured)

HOFFMANN MINERAL GmbH P.O. Box 14 60 D-86619 Neuburg (Donau) Phone (+49-84 31) 53-0 Fax (+49-84 31) 53-3 30

Internet: www.hoffmann-mineral.com e-Mail: info@hoffmann-mineral.com

V

M

-

4

/

0

5

.

2

0

0

8

/

A

r

t

.

-

N

r

.

0

6

1

1

0

9

8

0

Page 1

Summary

Two classes of filler are suitable for extrusion processing, particularly

when special profiles must be produced. The products based on Neuburg

Siliceous Earth and calcined clay produced the best extrusion properties

among the non-black fillers tested. Neuburg Siliceous Earth has a clear

advantage here in terms of price to performance ratio. Surface-treated

AKTISIL VM 56 wins on cost compared to untreated calcined clay, at the

same time providing better tensile strength, a higher modulus and a lower

change of elongation at break after ageing.

Where emphasis is placed on mechanical properties, combining the

active filler with carbon black or precipitated silica (or silicates in the case

of non-black applications) is a solution. Here the recipe must be adapted

to fit the specific needs involved.

Page 2

Non-black Fillers

in EPDM Extrusion Formulation

(peroxide cured)

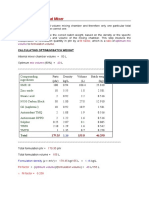

Test Compound

EPDM, 55 % Ethylene, medium diene-content

ML (1+8) 125 C, approx. 82

1

100

Zinc oxide

2

5

Stearic acid

2

Calcium oxide coated by special dispersion agents 80 %

10

Filler

250/110/75

Diethylene glycol (DEG), as indicated

0/3/5

Paraffinic oil

4

60

Triallyl-cyanurate 50 %

5

3

Bis(t-butylperoxy-isopropyl)benzene 40 %

6

8

Regarding precipitated silica and the

different types of precipitated silicate

additional compounds with 3 phr DEG were

examined. To obtain an adequate cross

linking the various hard clays need the use

of 5 phr DEG.

Curing was carried out in a press at 180 C.

The curing time was t

90

+ 10 %.

Please mind! The following figures show

trend analysis, which only can be the basis

for specific problems solving.

Filler:

Precipitated Silica

Precipitated Silicates

Carbon Black

All others

Loading:

75 phr

110 phr

110 phr

250 phr

Open Mill

Batch

Temperature

Time of mixing

150 x 300 mm

500 cm

50 C

15 to 20 min

Extruder

Temperature of barrel

Temperature of head

d = 30 mm

L/D = 15

70 C

110 C

Applied in this test compound:

(1) Vistalon 7500 , Exxon

(2) Zinkoxyd aktiv, Bayer

(3) Kezadol GR, Kettlitz

(4) Sunpar 2280, Sun Oil Company

(5) TAC 50 %, Kettlitz

(6) Perkadox 14/40, Akzo

Page 3

Contents

Index of Compound Costs Page 4

Properties of Raw Compound

Mooney Viscosity ML (1+4) at 120 C Page 5

Mooney Scorch t

5

(ML) at 120 C Page 6

Extrudability (Quality), Rating Garvey-Profile Page 7

Extrudability (Quality), Torque of Extruder Page 8

Extrudability (Quantity), Maximum of Extrusion Speed Page 9

Extrudability (Quantity), Torque of Extruder Page 10

Rotorless Cure Meter, t

5

at 180 C Page 11

Rotorless Cure Meter, t

90

at 180 C Page 12

Properties of Vulcanizate

Tensile Strength Page 13

Elongation at Break Page 14

Modulus Page 15

Hardness Page 16

Tear Resistance Page 17

Rebound Elasticity Page 18

Abrasion Page 19

Compression Set Page 20

Properties after Air Ageing

Change of Tensile Strength Page 21

Change of Elongation at Break Page 22

Change of Hardness Page 23

Change of Tear Resistance Page 24

Annex

Pictures of extrusion profiles Page 25-27

Our technical service suggestions and the information contained in this report are based on experience

and are made to the best of our knowledge and belief, but must nevertheless be regarded as non-binding

advice subject to no guarantee. Working and employment conditions over which we have no control

exclude any damage claims arising from the use of our data and recommendations. Furthermore, we

cannot assume any responsibility for any patent infringements which might result from the use of our

information.

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Annex: Extrusion Profiles

Page 26

Page 27

Das könnte Ihnen auch gefallen

- Coatings GuideDokument19 SeitenCoatings GuideUmar Muhammad100% (2)

- CBN Blade Tip AbradableDokument8 SeitenCBN Blade Tip Abradablebehtam2407Noch keine Bewertungen

- Renolin CLPDokument6 SeitenRenolin CLPjacl88Noch keine Bewertungen

- Isoflex Topas NB 52 152Dokument4 SeitenIsoflex Topas NB 52 152tapuskof1Noch keine Bewertungen

- Comparation of N990 Vs N550 in EPDM CompoundsDokument7 SeitenComparation of N990 Vs N550 in EPDM CompoundsMartha GuzmanNoch keine Bewertungen

- Sou Ficha Técnica Soudaseal 235SFDokument2 SeitenSou Ficha Técnica Soudaseal 235SFCarlos ChoqueNoch keine Bewertungen

- Simrit - Broșura Merkel PRW 1 Double WiperDokument8 SeitenSimrit - Broșura Merkel PRW 1 Double Wiperjo_rz_57Noch keine Bewertungen

- Injection Molding of RubberDokument39 SeitenInjection Molding of RubberadhityaNoch keine Bewertungen

- Deu BlinDokument58 SeitenDeu Blinraghunath.psNoch keine Bewertungen

- Design GuideDokument3 SeitenDesign GuidegvmindiaNoch keine Bewertungen

- ECN Balzers 20april10 AC Falen PresterenDokument76 SeitenECN Balzers 20april10 AC Falen PresterenMiguelNoch keine Bewertungen

- Lanxess Anderol® 5999 XEP - en - USDokument4 SeitenLanxess Anderol® 5999 XEP - en - USANoch keine Bewertungen

- Loctite 243™: Technical Data SheetDokument4 SeitenLoctite 243™: Technical Data SheetRadu_ISNoch keine Bewertungen

- Ar 2030 Kte 9 TXDokument4 SeitenAr 2030 Kte 9 TXbizhanjNoch keine Bewertungen

- LP Degalan 02141Dokument12 SeitenLP Degalan 02141La Vita E Bella100% (1)

- Carter VP-CS (08.10.02)Dokument1 SeiteCarter VP-CS (08.10.02)D Wahyu BawonoNoch keine Bewertungen

- Altuglass ManualDokument36 SeitenAltuglass Manualpislaruionut9394Noch keine Bewertungen

- Dymax GA-142 UV Curable Gasket Data SheetDokument3 SeitenDymax GA-142 UV Curable Gasket Data SheetJoshua WallesNoch keine Bewertungen

- Liquid Slilcone Rubber For Mould Making Tse 3455tDokument4 SeitenLiquid Slilcone Rubber For Mould Making Tse 3455tsumit1022Noch keine Bewertungen

- Herramientas Bombas PDFDokument172 SeitenHerramientas Bombas PDFrgb0906Noch keine Bewertungen

- Galata CFA Properties GuideDokument12 SeitenGalata CFA Properties GuideToniHospitalerNoch keine Bewertungen

- Isoflex Lds 18 Special A PDFDokument4 SeitenIsoflex Lds 18 Special A PDFNorbertoRGNoch keine Bewertungen

- Delrin100AL 500ALDokument4 SeitenDelrin100AL 500ALAEyerman100% (1)

- Asia Clearedge Ep284 TdsDokument3 SeitenAsia Clearedge Ep284 TdsDinesh KumarNoch keine Bewertungen

- Renolin CLP - enDokument7 SeitenRenolin CLP - enDANE80Noch keine Bewertungen

- Resina Uraflex EU222Dokument2 SeitenResina Uraflex EU222Emilio HipolaNoch keine Bewertungen

- RU093 EnglishDokument56 SeitenRU093 Englishbcsf01Noch keine Bewertungen

- Pif Cimperial37-280SW C29779 enDokument2 SeitenPif Cimperial37-280SW C29779 enPlamen ZapryanovNoch keine Bewertungen

- Optitemp HT 2 EP: DescriptionDokument2 SeitenOptitemp HT 2 EP: DescriptionWirawan Adi Setya RNoch keine Bewertungen

- Zytel-All in One Extrusion ProcessesDokument10 SeitenZytel-All in One Extrusion ProcessesYiğit IlgazNoch keine Bewertungen

- Klubersynth GEM 4 N SeriesDokument8 SeitenKlubersynth GEM 4 N SeriesDavid LieNoch keine Bewertungen

- Liquid Nitrogen Improves Cold Rolling 33006030glbDokument4 SeitenLiquid Nitrogen Improves Cold Rolling 33006030glbNuno TeixeiraNoch keine Bewertungen

- Af-200 Universal AngDokument4 SeitenAf-200 Universal AngGeorgi KalchevNoch keine Bewertungen

- Klübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsDokument8 SeitenKlübersynth GH 6 Oils: Synthetic Gear and High Temperature OilsFabrizzio_ValerNoch keine Bewertungen

- Clear Gear LubricantDokument2 SeitenClear Gear LubricantdhowardjNoch keine Bewertungen

- Ultem BrochureDokument41 SeitenUltem BrochureinfodrumandbassmentNoch keine Bewertungen

- Stanyl Aplicacoes Gerais - DSMDokument40 SeitenStanyl Aplicacoes Gerais - DSMRodrigo GhiroNoch keine Bewertungen

- Dupont™ Zytel 70G13Hs1L Nc010: Nylon ResinDokument6 SeitenDupont™ Zytel 70G13Hs1L Nc010: Nylon ResinZaimari FerminNoch keine Bewertungen

- Braycote 601ef - DatasheetDokument2 SeitenBraycote 601ef - Datasheetanhntran4850Noch keine Bewertungen

- ERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Dokument6 SeitenERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Sérgio GomesNoch keine Bewertungen

- 135Dokument2 Seiten135Abdullah SahlyNoch keine Bewertungen

- Investment Casting DataDokument28 SeitenInvestment Casting DataN.Palaniappan100% (1)

- Ti e Protegol 32-55 PN Juni 08Dokument4 SeitenTi e Protegol 32-55 PN Juni 08A Mahmood100% (1)

- Oli Energol GR-XPDokument2 SeitenOli Energol GR-XPakun leptopNoch keine Bewertungen

- Agip Gear Oil Pamphlet PDFDokument4 SeitenAgip Gear Oil Pamphlet PDFranjanguptNoch keine Bewertungen

- PI - Elma Korrosionsschutzzusatz (elma-KS) - ENDokument1 SeitePI - Elma Korrosionsschutzzusatz (elma-KS) - ENPham Ba Bao NgocNoch keine Bewertungen

- Klueberfluid C-F 3 ULTRADokument2 SeitenKlueberfluid C-F 3 ULTRAwajahat ali KhanNoch keine Bewertungen

- Deublin Engineering Catalog English NAmerDokument56 SeitenDeublin Engineering Catalog English NAmerOilGasManNoch keine Bewertungen

- Az 6600 Series (For HW 1)Dokument4 SeitenAz 6600 Series (For HW 1)Max LiaoNoch keine Bewertungen

- Anderol® 3057M - en - USDokument4 SeitenAnderol® 3057M - en - USFederico GomezNoch keine Bewertungen

- RTV157 and RTV159: Technical Data SheetDokument7 SeitenRTV157 and RTV159: Technical Data SheetMichael McQueenNoch keine Bewertungen

- CS1 Epoxy Curing AgentsDokument21 SeitenCS1 Epoxy Curing AgentsAlptekin100% (1)

- Statoil LoadWay EP 100Dokument2 SeitenStatoil LoadWay EP 100mstan11Noch keine Bewertungen

- Pexgol Engineering Guide Indus 2012-09 SingelDokument102 SeitenPexgol Engineering Guide Indus 2012-09 SingelFlorin StanciuNoch keine Bewertungen

- Oil DatasheetDokument2 SeitenOil DatasheetF.Nicolas LanciaultNoch keine Bewertungen

- Essential Rubber Formulary: Formulas for PractitionersVon EverandEssential Rubber Formulary: Formulas for PractitionersBewertung: 3 von 5 Sternen3/5 (1)

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyVon EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNoch keine Bewertungen

- Troubleshooting and Repair of Diesel EnginesVon EverandTroubleshooting and Repair of Diesel EnginesBewertung: 1.5 von 5 Sternen1.5/5 (2)

- HoltacDokument8 SeitenHoltacdargil66Noch keine Bewertungen

- Cargas Minerales para CauchoDokument41 SeitenCargas Minerales para Cauchodargil66Noch keine Bewertungen

- Silfit Z 91: Technical Data Sheet - Field of Application: ThermoplasticsDokument2 SeitenSilfit Z 91: Technical Data Sheet - Field of Application: Thermoplasticsdargil66Noch keine Bewertungen

- Dis Persant EsDokument5 SeitenDis Persant Esdargil66Noch keine Bewertungen

- Materials Characterization: V. Thomas Paul, S. Saroja, S.K. Albert, T. Jayakumar, E. Rajendra KumarDokument12 SeitenMaterials Characterization: V. Thomas Paul, S. Saroja, S.K. Albert, T. Jayakumar, E. Rajendra KumargardenergardenerNoch keine Bewertungen

- Multitest 50 Tablet Hardness TesterDokument8 SeitenMultitest 50 Tablet Hardness TesterNajam RafiNoch keine Bewertungen

- Aluminum 6061 Data SheetDokument2 SeitenAluminum 6061 Data SheetASHOK100% (1)

- DUH-211/211S: Dynamic Ultra Micro Hardness TestersDokument12 SeitenDUH-211/211S: Dynamic Ultra Micro Hardness TestersEstephanie GrassiNoch keine Bewertungen

- Hydrogen Embrittlement of High Strength Fasteners in Atmospheric ServiceDokument5 SeitenHydrogen Embrittlement of High Strength Fasteners in Atmospheric ServicesgarrabNoch keine Bewertungen

- To Study The Mechanical Properties of Mild Steel After Heat Treatment ProcessesDokument58 SeitenTo Study The Mechanical Properties of Mild Steel After Heat Treatment ProcessesRISHAVNoch keine Bewertungen

- Surface Vehicle Recommended Practice: Rev. FEB77Dokument4 SeitenSurface Vehicle Recommended Practice: Rev. FEB77anupthattaNoch keine Bewertungen

- International Standard: Iteh Standard Preview (Standards - Iteh.ai)Dokument9 SeitenInternational Standard: Iteh Standard Preview (Standards - Iteh.ai)Alexandra Ubaque BedoyaNoch keine Bewertungen

- Hardness Test and Mechanical PropertiesDokument15 SeitenHardness Test and Mechanical PropertiesMitzySolòrzanoNoch keine Bewertungen

- Mechanical Properties of Ion-Plated Tin Films On Aisi D2 SteelDokument9 SeitenMechanical Properties of Ion-Plated Tin Films On Aisi D2 SteelArief RachmanNoch keine Bewertungen

- Hardness Test NotesDokument5 SeitenHardness Test NotesAnonymous gFcnQ4goNoch keine Bewertungen

- Mixing in An Internal Mixer: Fill Factor RatioDokument10 SeitenMixing in An Internal Mixer: Fill Factor RatioUjjwal VigNoch keine Bewertungen

- F2730F2730MDokument7 SeitenF2730F2730MMARCELO DOS SANTOS BARRETOSNoch keine Bewertungen

- Automatic Tyre Inflation SystemDokument61 SeitenAutomatic Tyre Inflation SystemFikhriMaulanaSetiakuSatuHatiNoch keine Bewertungen

- BS en 681-1-1996Dokument24 SeitenBS en 681-1-1996Ravi Verma100% (1)

- Complete Tensile Test On MS BarDokument9 SeitenComplete Tensile Test On MS Barafzal taiNoch keine Bewertungen

- BMC1.Basic Building MaterialsDokument44 SeitenBMC1.Basic Building MaterialsMeenu Priya100% (1)

- Commande FinaleDokument58 SeitenCommande FinaleJean-Jacques OuandaogoNoch keine Bewertungen

- Shore General CatalogueDokument20 SeitenShore General Catalogueao185029Noch keine Bewertungen

- Test Results Report Rhino Wood RepairDokument10 SeitenTest Results Report Rhino Wood Repairmidzi24Noch keine Bewertungen

- Fish SausageDokument8 SeitenFish Sausagefizah_rahmanNoch keine Bewertungen

- 5 NDT Method For ConcreteDokument1 Seite5 NDT Method For ConcreteRamzi BEN AHMEDNoch keine Bewertungen

- Asme B107.8-2003Dokument14 SeitenAsme B107.8-2003noahb110Noch keine Bewertungen

- Week 1 Lecture Material - WatermarkDokument88 SeitenWeek 1 Lecture Material - Watermarkchristi SNoch keine Bewertungen

- DCC Technicals For All MachinesDokument38 SeitenDCC Technicals For All MachinesKareem TrainmanNoch keine Bewertungen

- Astm B 88 - 03Dokument7 SeitenAstm B 88 - 03carlos37Noch keine Bewertungen

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical Concrete SpecimensDokument5 SeitenUse of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical Concrete SpecimenswarsitoNoch keine Bewertungen

- 135 264 1 SMDokument9 Seiten135 264 1 SMmingNoch keine Bewertungen

- Astm B75MDokument7 SeitenAstm B75MtsliaNoch keine Bewertungen

- Astm A880Dokument5 SeitenAstm A880HenryNoch keine Bewertungen