Beruflich Dokumente

Kultur Dokumente

ITP Static Equipment

Hochgeladen von

aamirapi100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

2K Ansichten12 SeitenStatic Equipment itp

Copyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenStatic Equipment itp

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

2K Ansichten12 SeitenITP Static Equipment

Hochgeladen von

aamirapiStatic Equipment itp

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 12

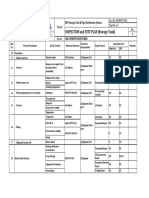

Project : IOCL Panipat , PNCP Project.

(EPCC-1) OWNER:- Indian Oil Corporation Limited

Acptd. Std. : Applicable Specs. PMC:- Engineers India Ltd.

Product : STATIC EQUIPMENT EPCC :-L&T

L&T EIL

A BEFORE ERECTION

1 Execution scheme of equipments foundation WC RW

2.A

Incoming material (Documents : Review &

Acceptance )

WC RW

2.B Incoming material (Physical verfication ) WC W

2.C Readyness for Erection

2.C.1 Centre line marking on equipment & foundation WC S

2.C.2

Level of Foundation(shims/Packing with

marking to be prepared & kept ready)

WC S

2.C.3 Correctness of no & size of foundation bolts WC W

2.C.4

Hole dia and no. of hole in base/structure of

equipment & columns

WC W

2.C.5

Matching equipments base bolt holes with

actual foundation

WC W

2.C.6 Marking orientation WC RW

2.C.7 Checking the threads of bolts & nuts WC S

2.C.6 Chipping and roughening of foundation WC S

B

ERECTION SCHEMES FOR CRITICAL

EQUIPMENTS

A Rigging procedure ( As per Annexure - 1 ) WC RW

1 Before Erection

1.A

Checking proper sequence for lifting of the

equipment

WC RW

1.B To check weight of equipment WC RW

1.C To check the center of gravity WC RW

1.D To check suspention points WC RW

1.E

To check maximum/minimum radius at which

the lifting tackle will operate

WC RW

1.F

To check the max. load to be lifted including

wt. Of slings, hook-block, lifting beams and

equipment etc.

WC RW

Format No.:LT/PNCP/ITP/STAT-EQPT/014

LARSEN & TOUBRO LIMITED Rev.0

Date 03.10.2006

INSPECTION & TEST PLAN

Sr. No. Inspection Activity

Inspection By

1.G

To identify the safe crane with requisite

capacity

WC RW

2 DURING ERECTION

2.A

To check counterweight of crane and Boom

length

WC RW

2.B To check slew limitation of crane WC RW

2.C

To check ground conditions are adequate for

supporting full/rigged crane and load

WC RW

2.D

To check the crane can be travelled in loaded

condition

WC RW

2.E

To check clearances from overhead electric

power cables

WC RW

2.F To check maintenance certificates WC RW

2.G

To check whether operators, riggers have

received proper instructions

WC RW

2.H

To verify safe load indicator on the crane is in

working condtion

WC W

2.I

To check the provision of bracing of equipment

as per Engg/ Manufacture's Requirement/

Approved drgs

RW RW

2.J

To check the guys, shoring, bracing,

interference with works

WC S

3 SAFETY TEST

3.A

Load test of cranes,lifting beams,slings and

shackles, length and dia of sling & condition of

wire rope(Broken/ damaged- strands should not

be there)

WC W/ RW

3.B

Placement of Main & tailing crane as per

approved rigging procedure

WC RW

4 DURING ERECTION

4.A Deployment of competent Rigging crew WC RW

4.B Orientation to be checked WC S

4.C Placement of packing as per marking WC S

4.D

Outside cleaning, coating/wrapping,painting for

underground equipment only

WC W

4.E Orientation of equipments as per AFC drg WC S

Prepared and Checked by Approved by

L&T L&T

5 AFTER ERECTION

5.A Tightening of bolts and providing washers WC S

5.B Levelling and alignment of equipments

5.B.1 Critical equipments/ ODC's WC HP

5.B.2 Other WC W

5.C

Corresponding requirement elevation & distance

between nozzles in special cases

WC W

5.D Cleaning of sleeves before grouting WC S

5.E Grouting

5.E.1 Availability of Specified grouting materials WC RW

5.E.2 Placement of grouting WC W

5.E.3 Curing of grout WC S

5.F Final tightening of bolts WC S

7 INSPECTION & TEST DOCUMENTS

1 Review test and inspection documents HP RW

Legend : HP - Hold Point W - Witness Point S - Surveillance inspection by OWNER/PMC

Rv - Review of documentation WC - 100% inspection by L&T

Prepared and Checked by

L&T

Approved by

L & T

OWNER:- Indian Oil Corporation Limited

PMC:- Engineers India Ltd.

EPCC :-L&T

Type of

Record

---------

clarify

LT/PNCP/PIPING-MRIR/043

LT/PNCP/PIPING-MRIR/043

may change to Rw

---------

---------

---------

---------

---------

---------

Format No.:LT/PNCP/ITP/STAT-EQPT/014

Rev.0

Date 03.10.2006

INSPECTION & TEST PLAN

---------

---------

---------

---------

---------

Reviewed & Approved

by EIL

---------

---------

---------

---------

---------

LT/PNCP/STAT-EQUIP/024

Reviewed & Approved

by EIL

L&T JACOBS

A

1 WC RW Approved Civil Format

2.A WC RW LT/MSQ/IMIR/GEN/001

2.B WC HP LT/MSQ/IMIR/GEN/001

2.C

2.C.1 WC S LT/MSQ/STAT-EQPT/029

2.C.2 WC S LT/MSQ/STAT-EQPT/029

2.C.3 WC S LT/MSQ/STAT-EQPT/029

2.C.4 WC S LT/MSQ/STAT-EQPT/029

2.C.5 WC S LT/MSQ/STAT-EQPT/029

2.C.6 WC RW LT/MSQ/STAT-EQPT/029

2.C.7 WC S LT/MSQ/STAT-EQPT/029

Signature:

Name:

Date :

Prepared by Checked by

L & T L&T

BEFORE ERECTION

Approved by

Rev.- 01

DATE:- 04.09.2008

JOB NO: 18-3177

Execution scheme of equipments foundation

Incoming material (Owner Supply)

Incoming material (Contractor Supply, including check test, if any )

Centre line marking on equipment & foundation

Level of Foundation(shims/Packing with marking to be prepared & kept ready)

OWNER : INDIAN OIL CORPORATION LIMITED

PMC :JACOBS ENGINEERING INDIA (P) LIMITED

EPCC : L&T

Correctness of no & size of foundation bolts

Readyness for Erection

Hole dia and no. of hole in base/structure of equipment & columns

Remarks Activity/Characteristics to be check Type of Record

Inspection By

LARSEN & TOUBRO LIMITED

MSQ (EPCC-1) UPGRADATION PROJECT, IOCL PANIPAT

IOCL-PANIPAT

INSPECTION AND TEST PLAN FOR STATIC EQUIPMENT

Sl. No.

ITP No. - LT/MSQ/ITP/STAT.-EQPT./008

Matching equipments base bolt holes with actual foundation

Marking orientation

Checking the threads of bolts & nuts

Reviewed & Accepted by

L&T JACOBS

PMC

Page 7 of 16

L&T JACOBS

Rev.- 01

DATE:- 04.09.2008

JOB NO: 18-3177

OWNER : INDIAN OIL CORPORATION LIMITED

PMC :JACOBS ENGINEERING INDIA (P) LIMITED

EPCC : L&T

Remarks Activity/Characteristics to be check Type of Record

Inspection By

LARSEN & TOUBRO LIMITED

MSQ (EPCC-1) UPGRADATION PROJECT, IOCL PANIPAT

IOCL-PANIPAT

INSPECTION AND TEST PLAN FOR STATIC EQUIPMENT

Sl. No.

ITP No. - LT/MSQ/ITP/STAT.-EQPT./008

PMC

2.C.6 WC S LT/MSQ/STAT-EQPT/029

2

2.A WC HP ---------

3

3.A WC W/ RW

Approved Safety Checklist

Format

3.B WC RW Erection / Rigging Scheme

4

4.A WC RW ---------

4.B WC S ---------

4.C WC S ---------

4.D WC W ---------

4.E WC S NA

5

Signature:

Name:

Date :

Prepared by Checked by

L & T L&T

AFTER ERECTION

Load test of cranes,lifting beams,slings and shackles, length and dia of sling &

condition of wire rope

Placement of Main & tailing crane as per approved rigging procedure

Deployment of competent Rigging crew

Orientation to be checked

Placement of packing as per AFC Drawing

L&T

Outside cleaning, coating/wrapping,painting for underground equipment only

Orientation of equipments as per AFC drg

Approved by Reviewed & Accepted by

JACOBS

Chipping and roughening of foundation

Approved Rigging procedure ( As per Annexure - 1 )

ERECTION SCHEMES FOR CRITICAL EQUIPMENTS

SAFETY TEST

DURING ERECTION

Page 8 of 16

L&T JACOBS

Rev.- 01

DATE:- 04.09.2008

JOB NO: 18-3177

OWNER : INDIAN OIL CORPORATION LIMITED

PMC :JACOBS ENGINEERING INDIA (P) LIMITED

EPCC : L&T

Remarks Activity/Characteristics to be check Type of Record

Inspection By

LARSEN & TOUBRO LIMITED

MSQ (EPCC-1) UPGRADATION PROJECT, IOCL PANIPAT

IOCL-PANIPAT

INSPECTION AND TEST PLAN FOR STATIC EQUIPMENT

Sl. No.

ITP No. - LT/MSQ/ITP/STAT.-EQPT./008

PMC

5.A WC S LT/MSQ/STAT-EQ./030 - 31

5.B LT/MSQ/STAT-EQ./030 - 31

5.B.1 WC HP

5.B.2 WC W ---------

5.C WC W ---------

5.D WC S LT/MSQ/STAT-EQ./030 - 31

5.E

5.E.1 WC RW LT/MSQ/STAT-EQ./030 - 31

5.E.2 WC W LT/MSQ/STAT-EQ./030 - 31

5.E.3 WC S LT/MSQ/STAT-EQ./030 - 31

5.F WC S ---------

6

1

1.A WC S ---------

Signature:

Name:

Date :

Prepared by Checked by

L & T L&T

2

Final tightening of bolts

Identify the material, check thickness, dimensions, no. and angle of fingers of

packing rings

Curing of grout

DURING INSTALLATION

L&T

Cleaning of sleeves before grouting

Availability of Specified grouting materials

Placement of grouting

Grouting

JACOBS

Approved by Reviewed & Accepted by

Levelling and alignment of equipments

Critical equipments/ ODC's

Other

Corresponding requirement elevation & distance between nozzles in special

cases

BEFORE INSTALLATION

PACKED EQUIPMENTS

Tightening of bolts and providing washers

Page 9 of 16

L&T JACOBS

Rev.- 01

DATE:- 04.09.2008

JOB NO: 18-3177

OWNER : INDIAN OIL CORPORATION LIMITED

PMC :JACOBS ENGINEERING INDIA (P) LIMITED

EPCC : L&T

Remarks Activity/Characteristics to be check Type of Record

Inspection By

LARSEN & TOUBRO LIMITED

MSQ (EPCC-1) UPGRADATION PROJECT, IOCL PANIPAT

IOCL-PANIPAT

INSPECTION AND TEST PLAN FOR STATIC EQUIPMENT

Sl. No.

ITP No. - LT/MSQ/ITP/STAT.-EQPT./008

PMC

2.A WC S ---------

2.B WC S ---------

2.C WC S ---------

2.D WC S ---------

2.E WC S ---------

7

1 HP RW LT/MSQ/STAT-EQ./030 - 31

NA - Not Applicable Dwg- Drawing

Spec - Specification Std - Standard

Signature:

Name: B MAJUMDAR

Date :

Prepared by

L & T

INSPECTION & TEST DOCUMENTS

Check for stacked or dumped packing as per specifications.

Check for nesting

Check for packings are touching bed limiter

Degrease and cleaning of packing material

Review test and inspection documents

Check packing support plate

Reviewed & Accepted by

JACOBS L&T

A K SRIVASTAVA

Checked by

HP - Hold Point W - Witness Point S - Surveillance inspection by JACOBS

Rw - Review of contractor documentation WC - 100% inspection by contractor

Page 10 of 16

L&T JACOBS

1

1.A WC RW APPROVED CIVIL FORMAT

1.B WC RW

1.C WC RW

1.D WC RW

1.E WC RW

1.F WC RW

1.G WC RW Approved Load Certificate

2 ---------

2.A WC RW Approved Load Certificate

2.B WC RW Approved Load Certificate

Signature:

Name:

Date :

Prepared by Checked by

L & T L&T

Sl. No.

JOB NO: 18-3177

Type of Record

Inspection By

LARSEN & TOUBRO LIMITED

MSQ UPGRADATION (EPCC-1) PROJECT PANIPAT

IOCL-PANIPAT

INSPECTION AND TEST PLAN FOR STATIC EQUIPMENT

Approved Rigging Procedure

Reviewed & Accepted by

L&T

To check counterweight of crane and Boom length

Checking proper sequence for lifting of the equipment

To check the center of gravity

ITP No. - LT/MSQ/ITP/STAT.-EQPT./006

Rev.- 00

11.08.2008

ANNEXURE-1

ERECTION SCHEME FOR CRITICAL EQUIPMENTS

Remarks

OWNER : INDIAN OIL CORPORATION LIMITED

PMC : JACOBS ENGINEERING INDIA (P) LTD.

EPCC : L&T

Activity / Characteristics to be check

Approved by

To check suspensition points

JACOBS

To check slew limitation of crane

DURING ERECTION

To check maximum/minimum radius at which the lifting tackle will operate

To check the max. load to be lifted including wt. Of slings, hook-block,

lifting beams and equipment etc.

To identify the safe crane with requisite capacity

Before Erection

To check weight of equipment

Page 11 of 14

L&T JACOBS

Sl. No.

JOB NO: 18-3177

Type of Record

Inspection By

LARSEN & TOUBRO LIMITED

MSQ UPGRADATION (EPCC-1) PROJECT PANIPAT

IOCL-PANIPAT

INSPECTION AND TEST PLAN FOR STATIC EQUIPMENT

ITP No. - LT/MSQ/ITP/STAT.-EQPT./006

Rev.- 00

11.08.2008

ANNEXURE-1

Remarks

OWNER : INDIAN OIL CORPORATION LIMITED

PMC : JACOBS ENGINEERING INDIA (P) LTD.

EPCC : L&T

Activity / Characteristics to be check

2.C WC RW Approved Load Certificate

2.D WC RW Approved Load Certificate

2.E WC RW ---------

2.F WC RW ---------

2.G WC RW ---------

2.H WC W ---------

2.I RW RW Approved Drawing

2.J WC S ---------

7

1 HP RW LT/PNCP/AU/STAT-EQPT/020

NA - Not Applicable Dwg- Drawing

Spec - Specification Std - Standard

Signature:

Name:

Date :

Prepared by Checked by

L & T L&T

HP - Hold Point W - Witness Point S - Surveillance inspection by JACOBS

Rw - Review of contractor documentation WC - 100% inspection by contractor

INSPECTION & TEST DOCUMENTS

L&T

Approved by Reviewed & Accepted by

JACOBS

Review test and inspection documents

To check maintenance certificates

To check whether operators, riggers have received proper instructions

To verify safe load indicator on the crane is in working condtion

To check the provision of bracing of equipment as per Engg/

Manufacture's Requirement/ Approved drgs

To check the guys, shoring, bracing, interference with works

To check ground conditions are adequate for supporting full/rigged crane

and load

To check the crane can be travelled in loaded condition

To check clearances from overhead electric power cables

Page 12 of 14

Das könnte Ihnen auch gefallen

- Architectural SymbolsDokument34 SeitenArchitectural SymbolsNiallburke100% (4)

- Installation Procedure For Pressure Vessel - EnglishDokument8 SeitenInstallation Procedure For Pressure Vessel - EnglishApri Dianto92% (13)

- ITP For Piping WorksDokument3 SeitenITP For Piping WorksOrlando1949100% (3)

- Inspection Test Plan - Piping FabricationDokument5 SeitenInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- 15 ITP Installation of Static EquipmentDokument4 Seiten15 ITP Installation of Static Equipmenta.hasan670Noch keine Bewertungen

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Dokument8 SeitenInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 MechDokument12 SeitenSaudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mechaamirapi100% (1)

- ITP Installation of Static EquipmentDokument3 SeitenITP Installation of Static EquipmentAwais Tariq90% (10)

- Equipment Erection, Static and RotaryDokument8 SeitenEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- ITP - Erection of Static EquipmentDokument4 SeitenITP - Erection of Static Equipmentbhct1987Noch keine Bewertungen

- Attachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7Dokument66 SeitenAttachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7indusampath100% (2)

- Inspection and Test Plan For Storage TankDokument7 SeitenInspection and Test Plan For Storage TankAhmed100% (5)

- ITP - PipingDokument7 SeitenITP - PipingRiaz Rasool100% (2)

- Equipment Erection PDFDokument13 SeitenEquipment Erection PDFkasturisunilkumar86% (7)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Dokument24 SeitenItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Itp For Tank Fabrication & Installation Work1 - Rev02Dokument22 SeitenItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- 003 ITP UG PipingDokument4 Seiten003 ITP UG Pipingrvsingh70100% (1)

- 02 MechanicalDokument44 Seiten02 Mechanicalmusaismail8863Noch keine Bewertungen

- Itp TankDokument4 SeitenItp TankAmber Chavez100% (2)

- ITP Heat ExchangerDokument3 SeitenITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Specification Erection Static EquipmentDokument11 SeitenSpecification Erection Static Equipmentagaricus67% (3)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Dokument28 SeitenField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNoch keine Bewertungen

- 静设备英文 Static Equipment Installation ProcedureDokument6 Seiten静设备英文 Static Equipment Installation Procedurejie100% (4)

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsDokument4 SeitenA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- Piping Release Report (Spool For Paint)Dokument2 SeitenPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Dokument44 SeitenAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Ali Hajirassouliha100% (1)

- Inspection & Test Plan TankDokument3 SeitenInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDokument18 Seiten046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNoch keine Bewertungen

- Installation Procedure For Pressure VesselDokument8 SeitenInstallation Procedure For Pressure VesselSamuel Babu100% (1)

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDokument12 SeitenField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiNoch keine Bewertungen

- FInal QAP HDPE WeldingDokument2 SeitenFInal QAP HDPE Weldingkannagi198Noch keine Bewertungen

- Pre Commisioning Check ListDokument22 SeitenPre Commisioning Check ListFardyanto, BNoch keine Bewertungen

- Itp For Installation of Pressurization UnitDokument1 SeiteItp For Installation of Pressurization UnitvictorNoch keine Bewertungen

- Itp Piping WorksDokument7 SeitenItp Piping WorksRudi EriantoNoch keine Bewertungen

- Equipment Erection Static and Rotary - METHOD OF STATEMENTDokument8 SeitenEquipment Erection Static and Rotary - METHOD OF STATEMENTNoldz SantosNoch keine Bewertungen

- ITP-PRESSURE VESSEL ExistingDokument2 SeitenITP-PRESSURE VESSEL ExistingArisNoch keine Bewertungen

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDokument2 SeitenSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNoch keine Bewertungen

- ITP For Steel Structure1Dokument3 SeitenITP For Steel Structure1吴兴泊Noch keine Bewertungen

- 033-Itp For Piping Installation Ag and Ug PDFDokument13 Seiten033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Pttchem-Sp-M-801 Equipment InstallationDokument14 SeitenPttchem-Sp-M-801 Equipment InstallationCivil Friend80% (5)

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDokument14 SeitenA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- Itp - Tanks - 01Dokument10 SeitenItp - Tanks - 01ravigurajapuNoch keine Bewertungen

- Inspection & Test Plan (Itp) : Mechanical (Machine & Equipment)Dokument2 SeitenInspection & Test Plan (Itp) : Mechanical (Machine & Equipment)ikramNoch keine Bewertungen

- Static Equipment ErectionDokument17 SeitenStatic Equipment Erectiononur gunes100% (2)

- 035-Itp For Pumps PDFDokument30 Seiten035-Itp For Pumps PDFKöksal Patan100% (3)

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Dokument4 SeitenFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- S-202A (Inspection and Testing Plan) Rev-0Dokument6 SeitenS-202A (Inspection and Testing Plan) Rev-0AliDadKhanNoch keine Bewertungen

- KP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFDokument3 SeitenKP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksDokument3 SeitenKP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksUtku Can KılıçNoch keine Bewertungen

- Itp For Switchboard, MCCDokument14 SeitenItp For Switchboard, MCCJoel AlcantaraNoch keine Bewertungen

- FQPDokument9 SeitenFQPtushar647Noch keine Bewertungen

- Docslide - Us - Itp Structural WorkDokument4 SeitenDocslide - Us - Itp Structural Workomda4wadyNoch keine Bewertungen

- KP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Dokument3 SeitenKP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Utku Can KılıçNoch keine Bewertungen

- 02 MechanicalDokument44 Seiten02 MechanicalSigit Bintan100% (1)

- Larsen & Toubro Limited: Ecc DivisionDokument4 SeitenLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- Itp Non AsmeDokument7 SeitenItp Non AsmeAkhilesh Kumar100% (1)

- TBE For UG Knock Out Drum - Draft For Rev.C1Dokument22 SeitenTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskNoch keine Bewertungen

- Repair Procedure ANNEXUREDokument16 SeitenRepair Procedure ANNEXUREShaikh AdilNoch keine Bewertungen

- Itp For SSDP Project Rev CDokument9 SeitenItp For SSDP Project Rev CRachel FloresNoch keine Bewertungen

- 025-Pro For Sewer & Drainage PDFDokument25 Seiten025-Pro For Sewer & Drainage PDFKöksal PatanNoch keine Bewertungen

- 030-QCP For UG GRP PIPING PDFDokument12 Seiten030-QCP For UG GRP PIPING PDFKöksal Patan100% (1)

- SAIC-X-3002 Rev 5Dokument3 SeitenSAIC-X-3002 Rev 5aamirapiNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistaamirapiNoch keine Bewertungen

- SATIP-X-400-01 Rev 5Dokument3 SeitenSATIP-X-400-01 Rev 5aamirapiNoch keine Bewertungen

- Saic A 1001rev 5Dokument2 SeitenSaic A 1001rev 5aamirapiNoch keine Bewertungen

- SAIC-X-3001 Rev 5Dokument3 SeitenSAIC-X-3001 Rev 5aamirapiNoch keine Bewertungen

- Saic N 2039Dokument1 SeiteSaic N 2039aamirapiNoch keine Bewertungen

- Saes N 140Dokument10 SeitenSaes N 140aamirapiNoch keine Bewertungen

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-ADokument107 SeitenRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDokument5 SeitenSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDokument5 SeitenSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNoch keine Bewertungen

- Saic N 2028Dokument4 SeitenSaic N 2028aamirapi100% (1)

- Saes N 130Dokument5 SeitenSaes N 130aamirapiNoch keine Bewertungen

- Saic N 2040Dokument4 SeitenSaic N 2040aamirapiNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2037Dokument5 SeitenSaic N 2037aamirapiNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDokument1 SeiteSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiNoch keine Bewertungen

- Saic N 2034Dokument4 SeitenSaic N 2034aamirapiNoch keine Bewertungen

- Saic N 2034Dokument4 SeitenSaic N 2034aamirapiNoch keine Bewertungen

- Saic N 2035Dokument9 SeitenSaic N 2035aamirapiNoch keine Bewertungen

- Saic N 2031Dokument4 SeitenSaic N 2031aamirapi100% (1)

- Saic N 2030Dokument6 SeitenSaic N 2030aamirapi100% (1)

- Saic N 2029Dokument6 SeitenSaic N 2029aamirapi100% (1)

- Saic N 2036Dokument6 SeitenSaic N 2036aamirapiNoch keine Bewertungen

- Saic N 2033Dokument5 SeitenSaic N 2033aamirapiNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument1 SeiteSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection Checklistaamirapi100% (1)

- Various Image Enhancement Techniques-A Critical Review: S.S. Bedi, Rati KhandelwalDokument5 SeitenVarious Image Enhancement Techniques-A Critical Review: S.S. Bedi, Rati KhandelwalArina AndriesNoch keine Bewertungen

- CCNA2 Lab 7 3 8 enDokument6 SeitenCCNA2 Lab 7 3 8 enapi-3809703100% (1)

- Relay Maintenance and Testing: BenefitsDokument2 SeitenRelay Maintenance and Testing: BenefitsojoladapoNoch keine Bewertungen

- RRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftDokument55 SeitenRRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftKuldeep SinghNoch keine Bewertungen

- Ticket Eater - User Manual 2006Dokument24 SeitenTicket Eater - User Manual 2006tokio2424Noch keine Bewertungen

- Anue 3500 Qrs - 0Dokument2 SeitenAnue 3500 Qrs - 0ullascsNoch keine Bewertungen

- Unit-3 BPDokument48 SeitenUnit-3 BPShreyas ShreyuNoch keine Bewertungen

- Dover Artificial Lift - Hydraulic Lift Jet Pump BrochureDokument8 SeitenDover Artificial Lift - Hydraulic Lift Jet Pump BrochurePedro Antonio Mejia Suarez100% (1)

- Test Bank Chapter (4) : Choose The Correct AnswerDokument2 SeitenTest Bank Chapter (4) : Choose The Correct AnswerteafNoch keine Bewertungen

- Ergonomic DesignDokument132 SeitenErgonomic DesignErin WalkerNoch keine Bewertungen

- I C Engine LabDokument3 SeitenI C Engine LabDevNoch keine Bewertungen

- RomerDokument20 SeitenRomerAkistaaNoch keine Bewertungen

- BSIT Nov Dec 2012 2nd CycleDokument59 SeitenBSIT Nov Dec 2012 2nd CyclePiyush PriyankNoch keine Bewertungen

- A Simulation-Based Process Model For Managing Complex Design ProcessDokument13 SeitenA Simulation-Based Process Model For Managing Complex Design ProcessMetehan AgacaNoch keine Bewertungen

- 16620YDokument17 Seiten16620YbalajivangaruNoch keine Bewertungen

- 02 Survey Calculations - PpsDokument96 Seiten02 Survey Calculations - PpsLeo Ivan Aviles RicaldiNoch keine Bewertungen

- Appraisal Assistant User ManualDokument55 SeitenAppraisal Assistant User ManualDamian Padilla100% (3)

- Which Is The Best Solid Modelling - Dhyan AcademyDokument3 SeitenWhich Is The Best Solid Modelling - Dhyan Academydhyanacademy engineersNoch keine Bewertungen

- Bloom QuestionsDokument270 SeitenBloom QuestionsrameshsmeNoch keine Bewertungen

- Geomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruDokument11 SeitenGeomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruVayolait BardNoch keine Bewertungen

- Translating Trig Graphs PDFDokument4 SeitenTranslating Trig Graphs PDFMark Abion ValladolidNoch keine Bewertungen

- Fractal Cities - A Geometry of Form and Function PDFDokument432 SeitenFractal Cities - A Geometry of Form and Function PDFDavid Diaz100% (1)

- 1.project FullDokument75 Seiten1.project FullKolliparaDeepakNoch keine Bewertungen

- OIML R 137-1 & 2: Nternational EcommendationDokument76 SeitenOIML R 137-1 & 2: Nternational EcommendationAMY WEINoch keine Bewertungen

- A Spectrum Analyser For The Radio AmateurDokument24 SeitenA Spectrum Analyser For The Radio AmateurRavindra MogheNoch keine Bewertungen

- Analysis and Design of Telecommunication Tower Using Different Truss System by ETab SoftwareDokument12 SeitenAnalysis and Design of Telecommunication Tower Using Different Truss System by ETab SoftwareEditor IJTSRDNoch keine Bewertungen

- Mechanism of Muscle ContractionDokument24 SeitenMechanism of Muscle Contractionfisika100% (1)

- DC Power Supply and Voltage RegulatorsDokument73 SeitenDC Power Supply and Voltage RegulatorsRalph Justine NevadoNoch keine Bewertungen

- MODULAR QUIZ - 57 - Steel DesignDokument9 SeitenMODULAR QUIZ - 57 - Steel DesignCornelio J. FernandezNoch keine Bewertungen