Beruflich Dokumente

Kultur Dokumente

Acid Tunneling Technology

Hochgeladen von

Ramanamurthy Palli0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten6 Seitenacid frac

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenacid frac

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten6 SeitenAcid Tunneling Technology

Hochgeladen von

Ramanamurthy Palliacid frac

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

SPE 135989

Acid Tunneling Technology: Application Potential in Timan-Pechora

Carbonates

A. E. Akhkubekov, Rosneft, and V. N. Vasilyev, TNK-BP

Copyright 2010, Society of Petroleum Engineers

This paper was prepared for presentation at the 2010 SPE Russian Oil & Gas Technical Conference and Exhibition held in Moscow, Russia, 2628 October 2010.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Petroleum industry needs low-cost and efficient hydrocarbon production enhancement techniques. Oil and gas reserves

production need to be economic; therefore high-technology stimulation methods should be used.

The considerable part of hydrocarbon world reserves is associated with carbonate reservoirs. To enhance production in

carbonate reservoirs, the conventional and special techniques are applied. Sidetracking includes heavy expenses in both money

and time, since it requires rig installation and drilling crew gathering. The carbonate natural property of dissolution with acid is

used in acidizing and acid fracs. Acid treatment is inefficient in thick reservoirs, thus the treatment design becomes quite

complex to achieve efficient acid placement. The acid frac efficiency in carbonate reservoirs is controlled by matrix to fracture

porosity ratio, whereas acid fracs in fractured reservoir with zero matrix porosity will be unefficient.

This paper describes the possibility to apply a relatively new enhancement technique acid-tunneling in Timan-

Pechora oil province carbonate reservoirs in Russia.

In this paper the evaluation methods of vertical and multilateral well potential are specified; the productivity ratios of

various multilateral well designs in dual porosity reservoirs vs. permeability anisotropy are shown; the pseudoradial skin-

factor calculation procedures of multilateral well are described.

The well candidate technologic and economic selection criteria are also considered. As a result, the matrix of

production enhancement technology application in Timan-Pechora oil and gas province has been developed.

Introduction

The acid-tunneling technique is low-cost and efficient alternative compared to acid treatment and acid frac used for production

enhancement in carbonates. This technique is applicable in openhole completions in limestone or dolomite reservoirs, uses

coiled tubing and does not require drilling rig placement, has no fluid returns to the surface, resulting in very low

environmental impact. In cased holes, the incremental cost is related to the removal of casing section by mill or drill bit.

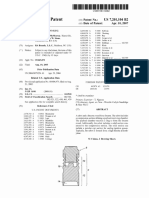

In acid-tunneling technology, acid is jetted under pressure from the special nozzle at the end of coiled tubing (Fig. 1),

thus dissolving the reservoir rock ahead, a wide tunnel with multiple wormholes is created.

The assembly is equipped with one or two knuckle joints, the deviation angle is controlled by coiled tubing pressure.

The orienting and logging tools can be added to the assembly. The reservoir contact area to the well improves significantly; the

bottom-hole porosity and permeability also increase. The tunnels are kept uncased which also provides reservoir to well

connection improvement. The tunnel length is 4 to 10 m depending on mineralogy and fluid type, but there are also cases of

tunnels of 30m in length (Mazerov, 2009). For tunnel initiation, strong acid (15-30% HCl) is used; for further circulation,

weaker acid (7-15% HCl) is used. The average acid rate to create 1 m of tunnel is about 5 m

3

. The penetration rate is 0.1-

1 m/min.

This technology is used worldwide to stimulate well productivity (Portman et al., 2008). The initial field trials of the

technology were in the massive Mara carbonate Field near Lake Maracaibo, Venezuela, where typical permeability is in the

range of 1 to 5 millidarcies. In the first five wells treated, 38 tunnels were constructed for a total length of over 350 m, at half

the cost of standard acid treatments and with at least twofold increases in production index.

The next series of operations was in Indonesia, Sumatran carbonate field (Portman and Royce, 2008), where despite of

high matrix permeability (220-4150 millidarcies), the acid treatment and acid frac had poor response. The reservoir thickness

of 5-7 m and proximity to oil-water contact were complicating factors. Two wells were acidized, in one well two tunnels were

created, in the second one six tunnels were created. Tunnels lengths were 3 to 8 m, total acid rate was 100 m

3

. The dramatic

results were achieved. The rate of the first well increased from 8 to 20 m

3

per day; the increase of the second well was from 8

2 SPE 135989

to 36 m

3

per day. Both saw reductions in water cut. This shows that even relatively short acid tunnels in a thin reservoir can

give significant production benefits. Before acid-tunneling, the series of acidizing operations were performed, without any

production increase.

After the acid-tunneling technique proved to be a success in Indonesia, it was applied in Kuwait. Two wells were

selected for treatment, the first well was vertical and the second well was horizontal. In the first well, two tunnels were created

of 4 and 12 m long, in the second well, twelve tunnels of 3 m each were created, spaced about 30 m apart. Production

improvement was 75%.

Classification of fractured reservoirs in Timan-Pechora oil province

Selection of fractured reservoirs development strategy is more efficient when the reservoir-analogue results analysis is

available. After determining the reservoir properties, fracture system parameters, connectivity, interaction between fractures

and matrix blocks, the reservoir type can be defined depending on fracture impact on reservoir quality and its further

development.

One of the most common is Nelsons classification (Nelson, 2001). The main classification advantage is the description

of the fracture systems having the major impact on development and potential challenges occur during production.

The fields, developed by Rosneft Company in Timan-Pechora oil/gas province, are mainly carbonate oil reservoirs

which differ in geology, depth of occurrence and petrophysical properties. One of the paper objectives was to classify

reservoirs under development and exploration in compliance with fracture impact on development and hydrocarbon

production.

The classification task is complicated by various fields maturity, absence of available data unification acquired from

1970s till now, different reservoir development stages (from green to brown field). In this paper we applied Nelsons approach

based on allocation of production data by well. The more the impact of fractures on the development is, the more anisotropic

the allocation of parameters by well will be.

The modified Lorenz plots were the basis of the reservoir type analysis. The percentage of the wells drilled at the field

is plotted on the x-axis, the percentage of cumulative production and maximum well rate is plotted on the y-axis. To plot the

graph, wells are ranked from minimum cumulative production (rate) to maximum cumulative production (rate). The criterion

of reservoir heterogeneity and reservoir type defined by fractured reservoir classification was the degree of graph deviation

from diagonal line at the origin. Fig. 2 shows the final graphs of producing reservoirs in Timan-Pechora oil/gas province. The

analysis allows classifying reservoirs, developed by Rosneft in Timan-Pechora (Fig. 3). It must be noted that upper Ordovician

oil saturated reservoirs are penetrated only in Srednemakarikhinskoye Field, no production. This reservoir is allocated to the

first type due to its low porosity (0.6%) and relatively impermeable matrix based on core analysis.

Technology application matrix

The next step was an attempt of looking through opportunities of using the acid tunneling technique from the reservoir

engineers point of view, its comparison to the existing well completion technologies as applied to various types of fractured

reservoirs. A large number of papers describe this technology application experience (Aguilera, 1995; Nelson, 2001; Reiss,

1980), here we will only highlight the key features of the most common methods.

The acid-tunneling technique in carbonate reservoirs will allow avoiding many disadvantages of conventional

techniques, and using its benefits.

Thus, compared to horizontal and multilateral well drilling, acid-tunneling requires less investment, has more potential

to be applied in massive reservoirs, and has less impact on well productivity by using natural acid dissolubility properties of

the reservoir, compared to conventional overbalanced drilling. The drilling efficiency in reservoir of first and second type,

where the objective is to cross maximum number of fractures, will depend on fracture density. For example, regional fracture

system (or fracture corridors) having the fracture density less then 1 fracture by 50 m will have low possibility of junction with

individual dendrite.

The acid-tunneling technology application as an alternative to acid frac enable to solve the artificial fracture

development issue in the maximum horizontal stress direction, optimize the working agent rate and operation cost, using

pointwise impact to productive layers of massive carbonate reservoirs.

Based on the above, the technology application success matrix was formed depending on reservoir type (Table 1).

Well Candidates for Acid Tunnelling

Selected well candidates should meet several technical and economic criteria. The main technical criterion is the openhole

section in the wellbore, this window is used for initial wash-out and further washing up of channels. For a cased hole, a special

mill is required to remove the casing in the selected interval, or a whipstock and a milling bit to open a window in the casing

wall. The other criterion is the rock solubility by acid. Reservoir rock solubility should be at least 80%.

Other technical criteria are well curvature, diameter and measured depth. Those parameters of a well candidate can

influence potential complications during the operation but not the operation itself.

Economic criteria include a wide range of reservoir properties related to well productivity and oil reserves. OWC

proximity can lead to higher post-acid tunneling watercut because tunnels normally deviate downwards from the vertical due

to natural reasons. It is also important to evaluate the well potential, specifically the remaining recoverable reserves,

SPE 135989 3

productive capabilities rate and watercut. If the fields (wells) active history-matched model is available, the effect from all

those economic parameters is accounted for in simulations.

Post-Acid Tunneling Well Productivity

After acid tunneling there are several factors that impact well productivity. The key factor is the completion geometry,

specifically the number of created tunnels, their length, diameter, and lateral position. Reservoir properties result in dual

porosity skin and PI reduction ratio due to fracture permeability anisotropy.

The effect of multilateral horizontal completion geometry on productivity has been reviewed in many sources (Larsen,

1996; Ozkan and Raghavan, 1991). Larsens analytical solution is applicable to thin reservoirs and long wellbore, the error is

3% at L/h>1.5. When the tunnel length is comparable to the reservoir thickness, Ozkan and Raghavans exact solution shall be

used to evaluate pseudoradial skin. The value of pseudoradial skin depends much on the number of branches and their length,

skin is a negative value and can reach -6. More tunnels N>6 lead to little change in productivity index.

The influence of natural fractures on productivity is accounted for by dual porosity skin (Hagoort, 2008). Dual porosity

skin evolves when calculating the productivity index for pseudo steady state from Warren-Root model, and has a positive

value. Dual porosity skin does not exceed 1 for standard interporosity flow coefficient ranging from 10

-6

to 10

-7

and

storativity ratio ranging from 0.001 to 0.5.

The effect of fracture permeability anisotropy on well productivity was evaluated through hydrodynamic modeling. In

dual porosity model, there was a sensitivity analysis performed to permeability variation in a horizontal direction for various

well configurations and geometries. The plot of productivity index reduction ratio versus anisotropy coefficient is almost linear

(Fig. 4). Because the anisotropy coefficient estimate normally has little reliability, it is agreed to apply the resultant linear

relation as a correction factor to productivity index for any configuration. A case with two symmetrical wellbores in

anisotropic reservoir is considered separately, since the effect of reservoir permeability anisotropy in this case is most

significant. The influence of well orientation is most prominent in the range of low anisotropy coefficients, fold of productivity

index reduction ratio can be as high as 3.

Post-acid tunneling well productivity growth is related not only to well effective radius increase, but also to bypassing

the near-wellbore skin-zone with poor permeability. In order to evaluate the efficiency of acid tunneling job correctly, it is

necessary to account for current skin in a pre-treatment vertical well.

Conclusion

This paper describes the possibility to apply the relatively new production enhancement technique acid-tunneling in oil/gas

basin of Timan-Pechora carbonate reservoirs in Russia. Carbonate reservoirs are classified by Nelsons technique for all

reservoirs in Timan-Pechora oil province, the evaluation methods of vertical and multilateral well potential are specified, the

productivity ratios of various multilateral well designs in dual porosity reservoirs vs. permeability anisotropy are shown,

pseudoradial skin calculation procedures for multilateral wells are described. The candidate well technological and economic

selection criteria are also considered. As a result, the matrix of production enhancement technologies application in Timan-

Pechora oil province has been developed.

Reference

Aguilera, R. 1995. Naturally Fractuerd Reservoirs. PennWell Publishig Company. 2

nd

edition. Tulsa. 521 p.

Hagoort, J. 2008. Stabilized Well Productivity in Dual-Porosity Reservoirs. SPERE 10 (1), October 2008: 940-947. SPE

110984-PA-P.

Larsen, L. 1996. Productivity Computations for Multilateral, Branched and Other Generalized and Extended Well Concepts.

SPE 36754, presented at SPE Annular Technical Conference & Exhibition, Denver, USA, 3-6 October, 1996: 739-751.

Mazerov, K. 2009. New technologies make well intervention faster, more accurate, cost-efficient, more reliable. Drilling

contractor, March/April: 62-69.

Nelson, R. 2001. Geologic Analysis of Naturally Fractured Reservoirs. 2

nd

edition. Gulf Professional Publishing. 332 p.

Ozkan, E., and Raghavan, R. 1991. New Solutions for Well-Test-Analysis Problems: Part 1 Analytical considerations. SPE

18615, SPEFE September 1991: 365-368.

Portman, L., Royce, T. 2008. Acid tunnels open oil pathways in Indonesia. BJ TechLine, Volume 7: 4.

Portman, L., et al. 2008. Acid-Tunneling Technique Shows Success in Carbonates. JPT November: 28-31.

Reiss, L.H. 1980. Reservoir Engineering Aspects of Fractured Formations. Editions technip. Paris. 1980. 108 p.

Strasburg, J., Clark, J. 2009. Acid Tunneling Stimulation in Oklahoma Limestone Using Coiled Tubing. SPE 120772,

presented at 2009 SPE Production and Operation Symposium, Oklahoma, USA, 4-8 April 2009

4 SPE 135989

Figure 1 Acid-tunneling tool, patent pending, comprises two kickoff joints that simplify tunnel extension

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

% drilled wells

%

c

u

m

u

l

a

t

i

v

e

p

r

o

d

u

c

t

i

o

n

'South-Baganskoye P1-C3' 'Cherpayukskoye D1lh'

'Hasyreiskoye D1lh' S2gr' Hasyreiskoye

'Nadeyukskoye D1lh' 'Srednemakarihinskoye S1vk'

'North-Baganskoye P1as' S1vk' North-Baganskoye

'Sandiveyskoye C3' P1as+s' Sandiveyskoye

'Veyakoshorskoye C2m-C3'

'Baganskoye P1-C3' 'Baganskoye D3dm'

S1vk' Baganskoye

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

% drilled wells

%

m

a

x

i

m

u

m

o

i

l

r

a

t

e

'South-Baganskoye P1-C3' 'Cherpayukskoye D1lh'

'Hasyreiskoye D1lh' S2gr' Hasyreiskoye

'Nadeyukskoye D1lh' 'Srednemakarihinskoye S1vk'

'North-Baganskoye P1as' S1vk' North-Baganskoye

'Sandiveyskoye C3' P1as+s' Sandiveyskoye

'Veyakoshorskoye C2m-C3'

'Baganskoye P1-C3' 'Baganskoye D3dm'

S1vk' Baganskoye

Figure 2 Lorentz plots for Nelsons classification of the Timano-Pechora reservoirs

SPE 135989 5

IIb

III

IIa

I

?????????? ???????

?????????? ??????? ??????

100% Kf

100% Km

100% f m 100% f f

East-Bagan

D3dm

- P1as

C3

S1vk

D3dm

O3

P1k

P1as+s

C2m-C3

C2b

P1as

C3

D3fm

D1lh

D1lh

S2gr

D1lh

S2gr

D1lh

S2gr

P1as+s

C2-C3

S1vk

P1- 3

D3fr

IV

IIb IIb

III III

IIa

I

Matrix impact decreases

100% Kf

100% Km

100% f m 100% f f

D3dm

S1vk

- as

C3

D3dm

S1vk

P1k

P1as+s

C2m-C3

P1a

P1as

C3

D3fm

D1lh

D1lh

Nadeyukskoye D1lh

S2gr

D1lh

C2-C3

P1as+s

C3

1-

South-Bagan D3fr

C3

IV

Fractures impact increases

Cherpayukskoye

Hasyreyskoye

Vostochno-Veyakskoye

Verhnemakarihinskoye

P1as+s

P1

C3

Osoveyskoye

Osoveyskoye

Usino-Kushor

Nadeyukskoye

North-Bagan

Srednemakarihinskoye

Srednemakarihinskoye

Bagan

Vostochno-Veyakskoye

3 C South-Bagan

Srednemakarihinskoye

Vostochno-Veyakskoye

Sandiveyskoye

Vostochno-Veyakskoye Sandiveyskoye

Veyakoshorskoye

Veyakoshorskoye

Veyakoshorskoye

Veyakoshorskoye

Hasyreyskoye

Cherpayukskoye

East-Bagan

Salyukinskoye

North-Bagan

Salyukinskoye

North-Bagan

Figure 3 Timano-Pechora carbonates positioning in Nelsons classification

0

0.2

0.4

0.6

0.8

1

1.2

0.00 0.20 0.40 0.60 0.80 1.00 1.20

(kx/ky)^0.5

J

/

J

0

Well || ky

Well || k

Figure 4 Productivity index decrease with horizontal anisotropy, the case of two equal symmetrical tunnels, parallel

and perpendicular to anisotropy axis

6 SPE 135989

Table 1 Technology efficiency matrix

Reservoir type

Technology

I II III IV

Horizontal/Multilateral

wells

+

Intersection of large

number of fractures

(increase productivity)

Large drainage area

+

Intersection of large

number of fractures

(increase productivity,

increase areal sweep

efficiency)

Large drainage area

+

High productivity

Large drainage area

Uniform displacement in presence of OWC

(GWC)

-

Expensive

Technical risks in geosteering, drilling problems (mud losses, stuck pipe)

Little effect in massive layers

Hydraulic/Acid

fracturing

+

Reactivation of

natural fractures

Bypass the skin zone

+

Reactivation of

natural fractures

Increase well effective

radius

+

Reactivation of

natural fractures

Increase well effective

radius

Creates additional

flow channels in matrix

+

Increase well effective

radius

Creates additional

flow channels in matrix

-

Expensive

Ineffective when major fracture networks are oriented in maximum horizontal stress direction

Little effect in massive layers

Acidizing

+

Low-cost

+

Improve conductivity of matrix near wellbore area

Low-cost

-

Ineffective due to short radius of penetration

Technical problems in massive layers

-

Technical problems

in massive layers

Acid tunneling

+

Low-cost

Significant increase of wellbore effective radius

Intersection of large number of fractures (increase productivity)

Bypass the near wellbore area with low permeability

+

Low-cost

Remove positive skin

Increase of wellbore

effective radius

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Unlocking The Secrets of Gann PDFDokument11 SeitenUnlocking The Secrets of Gann PDFfsolomon100% (1)

- The Colonization of Tiamat V (Phoenix III, Daniel) PDFDokument44 SeitenThe Colonization of Tiamat V (Phoenix III, Daniel) PDFKonstantina GlezakouNoch keine Bewertungen

- Section 2 - CalculationsDokument34 SeitenSection 2 - CalculationsIllimination Illuminated Minisatan100% (1)

- SC-2 GP PackerDokument12 SeitenSC-2 GP PackerRamanamurthy Palli100% (1)

- Physics 2 Mechancs ReviewDokument6 SeitenPhysics 2 Mechancs ReviewNaraindas MatiasNoch keine Bewertungen

- Quick Panel BrochureDokument11 SeitenQuick Panel BrochuretantanNoch keine Bewertungen

- Solids-Free Invert Gravel Pack (US-English)Dokument2 SeitenSolids-Free Invert Gravel Pack (US-English)Ramanamurthy PalliNoch keine Bewertungen

- Us4587423 PDFDokument12 SeitenUs4587423 PDFRamanamurthy PalliNoch keine Bewertungen

- Us4587423 PDFDokument12 SeitenUs4587423 PDFRamanamurthy PalliNoch keine Bewertungen

- Us4587423 PDFDokument12 SeitenUs4587423 PDFRamanamurthy PalliNoch keine Bewertungen

- GP in Depleted ReservoirsDokument14 SeitenGP in Depleted ReservoirsRamanamurthy PalliNoch keine Bewertungen

- Us4587423 PDFDokument12 SeitenUs4587423 PDFRamanamurthy PalliNoch keine Bewertungen

- Application of Tip Screen-Out Fracturing TechniqueDokument11 SeitenApplication of Tip Screen-Out Fracturing TechniqueZhiyong Huang100% (1)

- Us4587423 PDFDokument12 SeitenUs4587423 PDFRamanamurthy PalliNoch keine Bewertungen

- Help Frac Pack 01Dokument9 SeitenHelp Frac Pack 01Ramanamurthy PalliNoch keine Bewertungen

- Us4587423 PDFDokument12 SeitenUs4587423 PDFRamanamurthy PalliNoch keine Bewertungen

- OTC 7891 New Tool Designs For High Rate Gravel Pack OperationsDokument12 SeitenOTC 7891 New Tool Designs For High Rate Gravel Pack OperationsRamanamurthy PalliNoch keine Bewertungen

- Lessons Learned From Using VESDokument8 SeitenLessons Learned From Using VESRamanamurthy PalliNoch keine Bewertungen

- New Fracpack Design - Accurate Tip ScreenoutDokument11 SeitenNew Fracpack Design - Accurate Tip ScreenoutRamanamurthy PalliNoch keine Bewertungen

- Spe 103184 MSDokument7 SeitenSpe 103184 MSRamanamurthy PalliNoch keine Bewertungen

- SPE-171001-MS Frictional Pressure Losses of Slurries in Straight and Coiled Tubing - Part I: Model Statistical AnalysisDokument9 SeitenSPE-171001-MS Frictional Pressure Losses of Slurries in Straight and Coiled Tubing - Part I: Model Statistical AnalysisRamanamurthy PalliNoch keine Bewertungen

- Gravel Pack LitDokument1 SeiteGravel Pack LitRamanamurthy PalliNoch keine Bewertungen

- SPE 84218 Modeling Fracture Tip Screenout and Application For Fracture Height Growth ControlDokument6 SeitenSPE 84218 Modeling Fracture Tip Screenout and Application For Fracture Height Growth ControlRamanamurthy PalliNoch keine Bewertungen

- Spe 68639 MSDokument8 SeitenSpe 68639 MSRamanamurthy PalliNoch keine Bewertungen

- Spe 11012 PaDokument10 SeitenSpe 11012 PaRamanamurthy PalliNoch keine Bewertungen

- Fracpack Tool Erosion Qualifiaction TestingDokument11 SeitenFracpack Tool Erosion Qualifiaction TestingRamanamurthy PalliNoch keine Bewertungen

- Spe 37735 MSDokument7 SeitenSpe 37735 MSRamanamurthy PalliNoch keine Bewertungen

- Spe 0802 0049 JPTDokument2 SeitenSpe 0802 0049 JPTRamanamurthy PalliNoch keine Bewertungen

- Spe 56589 MSDokument10 SeitenSpe 56589 MSRamanamurthy PalliNoch keine Bewertungen

- Crosslinked and Linear Gel CompositionDokument11 SeitenCrosslinked and Linear Gel CompositionrodrigoayresNoch keine Bewertungen

- TechTips Mini Frac DFITDokument1 SeiteTechTips Mini Frac DFITRamanamurthy PalliNoch keine Bewertungen

- 7 Inch GP Packer DetailsDokument1 Seite7 Inch GP Packer DetailsRamanamurthy PalliNoch keine Bewertungen

- Aldehyde C 16Dokument4 SeitenAldehyde C 16Ramanamurthy PalliNoch keine Bewertungen

- Mechanical-Engineering Gate2016.InfoDokument3 SeitenMechanical-Engineering Gate2016.InfoHenryNoch keine Bewertungen

- Flame Photometer: Models PFP7 and PFP7/C Operating and Service ManualDokument45 SeitenFlame Photometer: Models PFP7 and PFP7/C Operating and Service ManualSree Nivas ReddyNoch keine Bewertungen

- A Tutorial in Logistic RegressionDokument14 SeitenA Tutorial in Logistic RegressionOmar MsawelNoch keine Bewertungen

- AME101 LectureNotesDokument142 SeitenAME101 LectureNotesNagarjunavarma GannaNoch keine Bewertungen

- L16 Complex Number and Representation of ACDokument14 SeitenL16 Complex Number and Representation of ACsanyam KanungaNoch keine Bewertungen

- Engineering Aplication SDokument371 SeitenEngineering Aplication SLon CarlNoch keine Bewertungen

- On Bridgman's Stress Solution For A Tensile Neck Applied To Axisymmetrical Blunt Notched Tension BarsDokument8 SeitenOn Bridgman's Stress Solution For A Tensile Neck Applied To Axisymmetrical Blunt Notched Tension BarsDiogo GaiaNoch keine Bewertungen

- Silicon CarbideDokument10 SeitenSilicon CarbideTushar AneyraoNoch keine Bewertungen

- New Oscillation Criteria For Second Order Nonlinear Differential EquationsDokument6 SeitenNew Oscillation Criteria For Second Order Nonlinear Differential EquationsresearchinventyNoch keine Bewertungen

- List of Institutes Engineering (Gujcet)Dokument20 SeitenList of Institutes Engineering (Gujcet)Kumar ManglamNoch keine Bewertungen

- Blast Resistant Design With Structural Steel PDFDokument6 SeitenBlast Resistant Design With Structural Steel PDFMatthieuNoch keine Bewertungen

- Us7201104 PDFDokument7 SeitenUs7201104 PDFThamuze UlfrssonNoch keine Bewertungen

- Turbine GoverningDokument44 SeitenTurbine Governingcoleiro100% (2)

- Analysis On Conversion Efficiency of Homojunction and Heterojunction Solar Cell Using Semiconductor MaterialsDokument4 SeitenAnalysis On Conversion Efficiency of Homojunction and Heterojunction Solar Cell Using Semiconductor MaterialsAnonymous izrFWiQNoch keine Bewertungen

- Fluent ManDokument876 SeitenFluent ManAryan KumarNoch keine Bewertungen

- 1 (CCE.M) 1: Total No. of Printed Pages: 8 Roll No. ...........................Dokument4 Seiten1 (CCE.M) 1: Total No. of Printed Pages: 8 Roll No. ...........................TarunNoch keine Bewertungen

- Science Chapter 12 Solar SystemDokument23 SeitenScience Chapter 12 Solar Systemg-32347797Noch keine Bewertungen

- Lab Report Strength Tensile TestDokument3 SeitenLab Report Strength Tensile TestAbdul KarimNoch keine Bewertungen

- Measuring Voltage, Current & ResistanceDokument5 SeitenMeasuring Voltage, Current & ResistancedilsharakaviNoch keine Bewertungen

- What Is Solvatochromism?: Alberto Marini, Aurora Mun Oz-Losa, Alessandro Biancardi, and Benedetta MennucciDokument8 SeitenWhat Is Solvatochromism?: Alberto Marini, Aurora Mun Oz-Losa, Alessandro Biancardi, and Benedetta MennucciJadaNoch keine Bewertungen

- Exothermic and Endothermic ReactionsDokument5 SeitenExothermic and Endothermic ReactionsSehyun OhNoch keine Bewertungen

- Applied Clay Science: Research PaperDokument8 SeitenApplied Clay Science: Research PaperDaniela NarvaezNoch keine Bewertungen

- Physics Paper 2 TZ0 HLDokument21 SeitenPhysics Paper 2 TZ0 HLwakoaisha2Noch keine Bewertungen

- GR 9 Eng BaselineDokument12 SeitenGR 9 Eng BaselineMalie SibisiNoch keine Bewertungen

- Honeycomb PDFDokument40 SeitenHoneycomb PDFstaedtlerpNoch keine Bewertungen

- Cengage Magnetism and Electromagnetic InductionDokument2 SeitenCengage Magnetism and Electromagnetic InductionShruthi reddy0% (1)

- Tulsion A 23SMDokument2 SeitenTulsion A 23SMMuhammad FikriansyahNoch keine Bewertungen