Beruflich Dokumente

Kultur Dokumente

Hydraulics of Water Distribution Systems

Hochgeladen von

meshahanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydraulics of Water Distribution Systems

Hochgeladen von

meshahanCopyright:

Verfügbare Formate

Lecture 7: Basic hydraulics of water transport

The Islamic University of Gaza- Environmental Engineering Department

Networks Design and Pumping Stations

EENV 5315

The cornerstone of any healthy population is access to safe drinking water.

The population growth in developing countries almost entirely wiped out the

gains. In fact, nearly as many people lack those services.

INTRODUCTION

Developing Country Needs for Urban and Rural Water Supply,1990 and 2000

Population not served

(millions) in 1990

Expected Population

Increase 1990-2000

(millions)

Total Additional

Population

Requiring

Service 2000

(millions)

Urban

243 570 813

Rural

989 312 1301

Total

1232 882 2114

Shaft of water holder at the Acropolis at Athens, Greece. (Photograph by L. W. Mays).

Water distribution pipe in Ephesus, Turkey. (Photographs by L. W. Mays).

Reference

Z

2

Z

1

g

P

1

g

P

2

g

V

2

2

2

g

V

2

2

1

E o

Energy, Piezometric and pressure Head

E E E o + = 2 1

E

g

V

g

P

Z

g

V

g

P

Z + + + = + + o

2 2

2

2

2

2

1

2 1 1

Bernoulli equation states that for constant flow, an energy balance between two

pipes cross section can be written as: or expressed in developed

form, per unit weight (in MWC):

Elevation Head: this is an amount of flow potential energy in one cross section

defined by the elevation. This correspond to Z in cross section

Pressure Head :this is an amount of the flow potential energy in one cross

section defined by the water pressure.

Piezometric Head : this is the sum of elevation and pressure head in

one cross section.

Velocity Head : this is an amount of flow kinetic energy in one cross section

defined by the water velocity.

g

P

g

P

Z

+

g

V

2

2

Energy Losses

(Head losses)

Major Losses Minor losses

The roughness

of the pipe

The properties

of the fluid

The mean

velocity, V

The pipe

diameter, D

The pipe

length, L

Head (Energy) Losses

When a fluid is flowing through a pipe, the fluid experiences some resistance

due to which some of energy (head) of fluid is lost.

Compound Pipe flow

The system is called compound pipe flow: When two or more pipes with

different diameters are connected together head to tail (in series) or connected

to two common nodes (in parallel)

A. Flow Through Pipes in Series

pipes of different lengths and different diameters connected end to end

(in series) to form a pipeline

Discharge: The discharge through each pipe is the same

Head loss: The difference in liquid surface levels is equal to the sum of the

total head loss in the pipes:

3 3 2 2 1 1

V A V A V A Q = = =

H

L

total = H

L1

+ H

L2

+ H

L3

B. Flow Through Parallel Pipes:

If a main pipe divides into two or more

branches and again join together

downstream to form a single pipe,

then the branched pipes are said

to be connected in parallel

(compound pipes).

Points A and B are called nodes.

Q

1

, L

1

, D

1

, f

1

Q

2

, L

2

, D

2

, f

2

Q

3

, L

3

, D

3

, f

3

=

= + + =

3

1

3 2 1

i

i

Q Q Q Q Q

g

V

D

L

f

g

V

D

L

f

g

V

D

L

f

2 2 2

2

3

3

3

3

2

2

2

2

2

2

1

1

1

1

= =

3 2 1 f f f L

h h h h = = =

Discharge:

Head loss: the head loss for each branch is the same

Example

Four pipes connected in parallel as shown. The following details are given:

Pipe L (m) D (mm) f

1 200 200 0.020

2 300 250 0.018

3 150 300 0.015

4 100 200 0.020

If Z

A

= 150 m , Z

B

= 144m,

determine the discharge in each

pipe ( assume P

A

=P

B

= P

atm

)

Q1

Q4

Q3

Q2

Q Q

A

B

Solution

Z

A

- Z

B

= h

f

= h

f1

= h

f2

= h

f3

=h

f4

(neglect minor losses)

150 -144 = 6 h

fi

=

But Vi = =

g

V

D

L

f

i

i

i

i

2

2

i

i

A

Q

2

4

i D

Qi

t

2 2

2

8

6

i gD

Q L f i i

t

=

Substitute for Pipe 1, 2, 3 and 4

Q = 0.0762 + 0.1146+ 0.28 + 0.1078 = 0.579 m

3

/s

MODERN WATER DISTRIBUTION SYSTEMS

All water transport and distribution system and devices have to satisfy the following

criteria:

a) To be constructed and/or manufactured of materials that are not harmful for

human being life.

b) To be resistant to mechanical; and chemical attacks possible in distribution

system

c) To be constructed and manufactured of durable materials.

Urban water distribution is composed of three major components:

distribution piping

distribution storage

pumping stations

These components can be further divided into subcomponents, which can in

turn be divided into sub-subcomponents.

The pumping station component consists of structural, electrical, piping, and

pumping unit subcomponents.

The pumping unit can be further divided into sub-subcomponents:

pump, driver, controls, power transmission, piping and valves.

The exact definition of components, subcomponents, and sub-

subcomponents is somewhat fluid and depends on the level of detail of the

required analysis and, to a somewhat greater extent, the level of detail of

available data.

Water Distribution System

Pumping Station

Distribution Piping Distribution Storage

Electrical Structural Pumping Piping Tanks Pipes Valve Pipes Valve

pump driver Power transmission controls

Hierarchical relationship of Components, Subcomponent, and sub-subcomponent.

(Cullinane, 1989)

Pipes

Pipe sections or links are the most abundant elements in the network.

These sections are constant in diameter and may contain fittings and other

appurtenances, such as valves, storage facilities, and pumps.

Pipes are the largest capital investment in a distribution system.

Pipes used in water supply are made of various materials. They can be

categorized in three large groups:

Rigid (iron, prestressed concrete, asbestos cement)

Semi-rigid (steel, ductile iron)

Flexible (PVC, PE, HDPE, glass reinforced plastic)

System Components

Transmission: This is the basic part of water transport and distribution system

that represents a large proportion of investment.

It consists of various types of pipes, joints, fittings and connections, that

operate together with miscellaneous control equipment.

Trunk main: To transport water from the source to the distribution area. (usually

above 400mm to few meters).

Secondary main: To link main distribution pipes with the service reservoir or

/and with the trunk distribution mains.

Distribution Main: carry water from the secondary main to the smaller

consumers. These are in particular pipes laid in the roads and streets of urban

areas with diameters in principal 100-200mm.

Service pipe: To bring water from distribution main directly to a public dwelling.

In case of domestic supplies service pipes are generally less than 25mm

diameter.

Water distribution network pipelines classification

Design Criteria

Are the design limitations required to get the most efficient and

economical water-distribution network.

Velocity Pressure

Pipe Sizes

Head Losses Design Period

Average Water Consumption

The design criteria for water distribution system can be divided in non-

hydraulic and hydraulic design consideration.

One of the non-hydraulic criteria can be the ability to isolate part of the

system especially during emergency operation.

Hydraulic design criteria are primarily related to the flow and pressure in the

network. Moreover, criteria for minimum and maximum pipe capacities, flow

velocities, pressure fluctuations and pressure gradients are relevant factors.

Velocity

Not be lower than 0.6 m/s to prevent sedimentation

Not be more than 2 m/s to prevent erosion and high head losses.

Commonly used values are 1 - 1.5 m/sec.

Diameter (mm) Velocity ( m/sec )

100 0.9

150 1.21

250 1.52

400 1.82

Design Criteria ( Velocity )

Source: Standards Handbook

Diameter (mm) Head losses ( m/km )

100 7.7

150 4.8

200 3.4

250 2.6

300 2.1

350 1.7

400 1.7

Design Criteria ( Head Losses )

Source: Water Supply ( 4th Edition )

Instead of pressure gradient, the velocity can also be used as a design criterion

(both parameters are correlated by friction loss calculations).

Pressure in municipal distribution systems ranges from 150-300

kPa in residential districts with structures of four stories or less

and 400-500 kPa in commercial districts.

Also, for fire hydrants the pressure should not be less than 150

kPa (15 m of water).

In general for any node in the network the pressure should not be

less than 25 m of water.

Moreover, the maximum pressure should be limited to 70 m of

water

Pressure

The pressure criterion can be formulated as a min. /max. In general 5 mwc above

the highest tap is sufficient. For urban areas this means min. 20-25 mwc above

street level. In case of high building, internal posting system has to be installed.

As mentioned in the Standard Handbook, in multi-storied structures the following

pressures are satisfactory.

No. of Floors Pressure Required ( kg / cm

2

= 0.98 bar)

Up to and below 3 stories 2

3 - 6 2.1 - 4.2

6 - 10 4.2 - 5.27

Above 10 5.27 - 7

Design Criteria ( Pressure )

Source : Standards Handbook

Maximum pressure limitations are required to reduce the additional

cost of the pipe, strengthening necessary due to the high pressure.

Pipe sizes

Lines which provide only domestic flow may be as small as 100 mm (4 in) but

should not exceed 400 m in length (if dead-ended) or 600 m if connected to

the system at both ends.

Lines as small as 50-75 mm (2-3 in) are sometimes used in small

communities with length not to exceed 100 m (if dead-ended) or 200 m if

connected at both ends.

The size of the small distribution mains is seldom less than 150 mm (6 in) with

cross mains located at intervals not more than 180 m.

In high-value districts the minimum size is 200 mm (8 in) with cross-mains at

the same maximum spacing. Major streets are provided with lines not less

than 305 mm (12 in) in diameter.

General requirement for pipe network

1. Mains should be divided into sections and valves should be provided so that

any section may be taken out of operation for repair.

2. Dead ends are to be avoided. If a dead-end is must, a hydrant should be

provided for cleaning.

3. Air valves at summits and drains at the lowest point between summits should

be installed.

4. Mains should follow the general contour of the ground.

5. The minimum cover under roadway should be 90cm and under paths 75 cm.

6. Proper installation and operation of water supply system requires that a number

of appurtenances be provided in the pipeline;

a. Gate valve: they are used at summits and to isolate a particular section.

b. Sluice gate: They are used in pipelines laid at steep grades or in openings into

wells

c. Check valves: (non return valve): to allow flow in one direction only.

7. Pipes constructed of steel and other flexible material must have valves that

automatically allow air to enter when the pipeline is emptied in order to prevent

a vacuum, which will cause the pipe to collapse.

General requirement for pipe network (continue)

Network Layout

Estimate pipe sizes on the basis of water demand and local code requirements.

The pipes are then drawn on a digital map (using AutoCAD, for example) starting

from the water source.

All the components (pipes, valves, fire hydrants) of the water network should be

shown on the lines.

Hydraulic Analysis

After completing all preliminary studies and layout drawing of the network, one of

the methods of hydraulic analysis is used to

Size the pipes and

Assign the pressures and velocities required.

Hydraulic Analysis of Water Networks

The solution to the problem is based on the same basic hydraulic principles that

govern simple and compound pipes that were discussed previously.

The following are the most common methods used to analyze the Grid-system

networks:

1. Hardy Cross method.

2. Sections method.

3. Circle method.

Hardy Cross Method

This method is applicable to closed-loop pipe networks

(a complex set of pipes in parallel).

It depends on the idea of head balance method

Was originally devised by professor Hardy Cross.

Assumptions / Steps of this method:

1. Assume that the water is withdrawn from nodes only; not directly from pipes.

2. The discharge, Q , entering the system will have (+) value, and the discharge, Q ,

leaving the system will have (-) value.

3. Usually neglect minor losses since these will be small with respect to those in

long pipes, i.e.; or could be included as equivalent lengths in each pipe.

4. Assume flows for each individual pipe in the network.

5. At any junction (node), as done for pipes in parallel,

=

out in

Q Q Q =

0

or

6. Around any loop in the grid, the sum of head losses must equal to zero:

Conventionally, clockwise flows in a loop are considered (+) and

produce positive head losses; counterclockwise flows are then (-) and

produce negative head losses.

This fact is called the head balance of each loop, and this can be valid

only if the assumed Q for each pipe, within the loop, is correct.

h

f

loop

=

0

The probability of initially guessing all flow rates correctly is virtually null.

Therefore, to balance the head around each loop, a flow rate correction ( )

for each loop in the network should be computed, and hence some iteration

scheme is needed.

A

7. After finding the discharge correction, (one for each loop) , the

assumed discharges Q

0

are adjusted and another iteration is

carried out until all corrections (values of ) become zero or

negligible. At this point the condition of :

is satisfied.

A

A

h

f

loop

~

00 .

How to find the correction value ( )

A

h k Q

f

x

=

Q Q = +

0

A

h k Q k Q k Q x Q

x x

Q

f

x x x

x x

= = + = + +

+

(

( )

( )

( ) ( )

0 0 0

1

0

2

2

1

2

A A A

| |

h k Q k Q x Q

f

x x

x

= = +

0 0

1 ( )

A

Since for each loop in the grid

= =

loop loop

x

f

Q k h 0

k Q k Q x k Q

x x

x

= + =

0 0

1

0

( )

A

therefore we have (for each loop in the network)

A =

k Q

x k Q

h

x

h

Q

x

x

f

f

0

0

1 ( )

Note that if Hazen Williams (which is generally used in this

method) is used to find the head losses, then

h k Q

f

=

185 .

A =

h

h

Q

f

f

185 .

If Darcy-Wiesbach is used to find the head losses, then

h k Q

f

=

2

A =

h

h

Q

f

f

2

85 . 1

87 . 4

7 . 10

|

|

.

|

\

|

=

HW

f

C

Q

D

L

h

g

V

D

L

f h

f

2

) (

2

=

Hardy Cross Method

The figure below represents a simplified pipe network.

Flows for the area have been disaggregated to the nodes, and a

major fire flow has been added at node G.

The water enters the system at node A.

Pipe diameters and lengths are shown on the figure.

Find the flow rate of water in each pipe using the Hazen-

Williams equation with C

HW

= 100.

Carry out calculations until the corrections are less then 0.2

m

3

/min.

Das könnte Ihnen auch gefallen

- Collection and Distribution of Water 4.1 Types of IntakeDokument71 SeitenCollection and Distribution of Water 4.1 Types of IntakenimcanNoch keine Bewertungen

- 1.explain The Following Types of Distribution Systems : (A) Dead EndDokument15 Seiten1.explain The Following Types of Distribution Systems : (A) Dead EndMichael LangatNoch keine Bewertungen

- Design of Water Distribution System Environmental EngineeringDokument48 SeitenDesign of Water Distribution System Environmental EngineeringJithendar ReddyNoch keine Bewertungen

- Determination of Viscosity Using The Falling Ball Viscometer 2Dokument17 SeitenDetermination of Viscosity Using The Falling Ball Viscometer 2Gayantha Induwara RanasinghaNoch keine Bewertungen

- Water Resources and EngineeringDokument6 SeitenWater Resources and EngineeringJoery Jr EsperonNoch keine Bewertungen

- Importance of Soil Study in Civil EngineeringDokument6 SeitenImportance of Soil Study in Civil EngineeringJack FosterNoch keine Bewertungen

- Experiment 1Dokument6 SeitenExperiment 1Nor Farah AlwaniNoch keine Bewertungen

- Lab Report 2Dokument13 SeitenLab Report 2Unique GuyNoch keine Bewertungen

- Expt 4b.flexure TestDokument5 SeitenExpt 4b.flexure TestVishwasVerma100% (1)

- Fluid Mechanics Lab Report 1 20Dokument18 SeitenFluid Mechanics Lab Report 1 20manthan100% (1)

- Department of Civil Engineering: Reticulation DesignDokument30 SeitenDepartment of Civil Engineering: Reticulation Designanon_307271108100% (1)

- Chapter 1 - Quantity of WaterDokument13 SeitenChapter 1 - Quantity of WaterAzhar farooqueNoch keine Bewertungen

- Final Report - 2008 - 10 - 27Dokument81 SeitenFinal Report - 2008 - 10 - 27jarrydNoch keine Bewertungen

- Three-Point Flexural TestDokument3 SeitenThree-Point Flexural TestBassey Okon100% (1)

- Archimedes' Principle: Density of WaterDokument2 SeitenArchimedes' Principle: Density of WaterNg Mei EngNoch keine Bewertungen

- Tension TestDokument27 SeitenTension TestBurhan AhmadNoch keine Bewertungen

- Viscosity of Fluids Lab Ball Drop MethodDokument4 SeitenViscosity of Fluids Lab Ball Drop MethodNOKIANoch keine Bewertungen

- Vinaza ViscosidadDokument8 SeitenVinaza ViscosidadPatricia J ÁngelesNoch keine Bewertungen

- Faculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetDokument18 SeitenFaculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetPanadol PanadolNoch keine Bewertungen

- Project RepresentionDokument13 SeitenProject RepresentionDeema sultanNoch keine Bewertungen

- BOQ-of FoundationDokument8 SeitenBOQ-of FoundationJohn Carlo AbalaNoch keine Bewertungen

- Stage MeasurementDokument20 SeitenStage MeasurementMadan Mohan ReddyNoch keine Bewertungen

- Lab #10: Dissolved Oxygen Levels in Natural Waters: Date: Name: Student Id: Co-WorkerDokument5 SeitenLab #10: Dissolved Oxygen Levels in Natural Waters: Date: Name: Student Id: Co-WorkerCuong NguyenNoch keine Bewertungen

- Experimental Mechanics Laboratory ManualDokument76 SeitenExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- 04-01 Water ResourcesDokument74 Seiten04-01 Water ResourcesAindrila Ganguly100% (1)

- (Water Distribution System) PDFDokument83 Seiten(Water Distribution System) PDFAljeena BukhariNoch keine Bewertungen

- Work ReportDokument6 SeitenWork ReportAmit Karmakar100% (1)

- BTS Layout and Site Selection ISSUE1.0 - 3Dokument62 SeitenBTS Layout and Site Selection ISSUE1.0 - 3iAZHTONNoch keine Bewertungen

- Semnar ReportDokument32 SeitenSemnar ReportRishabh Parihar0% (1)

- Water SupplyDokument36 SeitenWater Supplyjuliyet strucNoch keine Bewertungen

- Statics: Course Instructor: Course TA (Section-A) : Course TA (Section-B)Dokument23 SeitenStatics: Course Instructor: Course TA (Section-A) : Course TA (Section-B)Farjad ShahidNoch keine Bewertungen

- Module - 3 Design of Storm SewerDokument18 SeitenModule - 3 Design of Storm SewerFaran Masood FASTNUNoch keine Bewertungen

- Rational Method Hydologic Calculations With Excel CourseDokument20 SeitenRational Method Hydologic Calculations With Excel Coursesyammc100% (1)

- Construction Practice 1 For TechnicianDokument24 SeitenConstruction Practice 1 For TechnicianMichael_Mensah_2238Noch keine Bewertungen

- Hydrologic CycleDokument4 SeitenHydrologic CycleDEXTURENoch keine Bewertungen

- Consumptive Use of WaterDokument16 SeitenConsumptive Use of WaterMonde NuylanNoch keine Bewertungen

- Viscosity Lee Eakin Gonzales PG 55Dokument140 SeitenViscosity Lee Eakin Gonzales PG 55Paul Renzo Miranda ZuritaNoch keine Bewertungen

- Viscosity ReportDokument12 SeitenViscosity ReportBF3nobelNoch keine Bewertungen

- Chapter-1 & 2Dokument35 SeitenChapter-1 & 2nimcan100% (2)

- Envisci Lesson 8water Use and ManagementDokument30 SeitenEnvisci Lesson 8water Use and ManagementMaria100% (1)

- Assignment QuestionsDokument5 SeitenAssignment QuestionsKinson Prabu100% (2)

- Final Project CivilDokument26 SeitenFinal Project CivilVishnu Kulkarni100% (1)

- Losses in Pipes: This Page Provides A Quick Review of Piping Losses, Starting With Bernoulli's EquationDokument4 SeitenLosses in Pipes: This Page Provides A Quick Review of Piping Losses, Starting With Bernoulli's EquationLucky GuyNoch keine Bewertungen

- Al Falaj (Autosaved)Dokument18 SeitenAl Falaj (Autosaved)Cacai GariandoNoch keine Bewertungen

- Mechanical PropertiesDokument57 SeitenMechanical PropertiesElmedin Gluhic100% (1)

- Introduction ArshadDokument20 SeitenIntroduction ArshadShahrukh ansariNoch keine Bewertungen

- Water Distribution System: Mubashir Saleem Lecturer Department of Environmental EngineeringDokument28 SeitenWater Distribution System: Mubashir Saleem Lecturer Department of Environmental EngineeringKhushbakht Khushi100% (1)

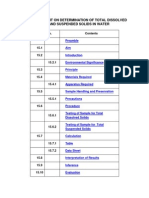

- 15.0 Experiment On Determination of Total Dissolved and Suspended Solids in WaterDokument15 Seiten15.0 Experiment On Determination of Total Dissolved and Suspended Solids in Waterhero100% (2)

- Analysis of RCC Structure Using Staad ProDokument28 SeitenAnalysis of RCC Structure Using Staad ProVaibhav VaishNoch keine Bewertungen

- Chapter 1 - Water Resources Quality+Dokument15 SeitenChapter 1 - Water Resources Quality+Nazrina RinaNoch keine Bewertungen

- Department of Civil Engineering M.Tech Seminar Report 2021Dokument22 SeitenDepartment of Civil Engineering M.Tech Seminar Report 2021Classic PrintersNoch keine Bewertungen

- Engineering Mechanics 1 LabDokument4 SeitenEngineering Mechanics 1 LabZiyad RazaliNoch keine Bewertungen

- Chapter 1 TIMBER IntroductionDokument23 SeitenChapter 1 TIMBER IntroductionResearcher BrianNoch keine Bewertungen

- Tension ReportDokument14 SeitenTension ReportDevruwan Wijetilleke100% (1)

- Water Supply DesignDokument13 SeitenWater Supply DesignF Fahim KhanNoch keine Bewertungen

- Pipeline Hydraulic Design Lec5Dokument25 SeitenPipeline Hydraulic Design Lec5Kokab AzazNoch keine Bewertungen

- Lecture 14 Water NetworksDokument11 SeitenLecture 14 Water NetworksZahid BasharNoch keine Bewertungen

- Water Distribution System PDFDokument12 SeitenWater Distribution System PDFakhilchibberNoch keine Bewertungen

- Water Transmission and Distribution SystemsDokument71 SeitenWater Transmission and Distribution SystemsDr. Akepati Sivarami Reddy100% (6)

- What Is SAP S/4HANA?Dokument7 SeitenWhat Is SAP S/4HANA?Haitham Wahdan100% (1)

- What Is SAP S/4HANA?Dokument7 SeitenWhat Is SAP S/4HANA?Haitham Wahdan100% (1)

- ABAPon HANADokument46 SeitenABAPon HANAvishalmahajan89Noch keine Bewertungen

- Custom Code Within SAP S4HANA OnPremise PDFDokument20 SeitenCustom Code Within SAP S4HANA OnPremise PDFHaitham WahdanNoch keine Bewertungen