Beruflich Dokumente

Kultur Dokumente

Sizing Conductors, PartXV IMPORTANTE

Hochgeladen von

jlcegarra0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten7 SeitenWhen sizing conductors, more is involved than just looking at table 310.15(B)(16) ampacities are based on no more than three current-carrying conductors in a raceway, cable or earth (directly buried) when there are more than three conductors and / or the ambient temperature is other than 30degC, the table ampacities must be adjusted.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWhen sizing conductors, more is involved than just looking at table 310.15(B)(16) ampacities are based on no more than three current-carrying conductors in a raceway, cable or earth (directly buried) when there are more than three conductors and / or the ambient temperature is other than 30degC, the table ampacities must be adjusted.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten7 SeitenSizing Conductors, PartXV IMPORTANTE

Hochgeladen von

jlcegarraWhen sizing conductors, more is involved than just looking at table 310.15(B)(16) ampacities are based on no more than three current-carrying conductors in a raceway, cable or earth (directly buried) when there are more than three conductors and / or the ambient temperature is other than 30degC, the table ampacities must be adjusted.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

Sizing Conductors, Part XV

Correction And Adjustment Factors

Published: August 2012

By Charles R. Miller

Table 310.15(B)(16) in the National Electrical Code (NEC) provides allowable or

maximum ampacities for insulated conductors rated up to and including 2,000 volts (V).

When sizing conductors, more is involved than just looking in Table 310.15(B)(16) and

selecting a conductor based on the ampacity shown. The ampacities in this table are

based on no more than three current-carrying conductors in a raceway, cable or earth

(directly buried). The ampacities are also based on an ambient temperature of 30C.

When there are more than three current-carrying conductors and/or the ambient

temperature is other than 30C, the table ampacities must be adjusted and/or corrected.

Therefore, factors, such as ambient temperature and the number of current-carrying

conductors, must be considered when sizing conductors. Other factors, such as the

temperature ratings of the terminations and continuous loads, also must be considered

when sizing conductors.

Last months column covered both the ambient temperature correction factor and the

adjustment factor for adjacent current-carrying conductors. This month, the discussion

continues with other factors that must be considered when sizing conductors.

This series on sizing conductors previously covered continuous loads but only when the

ambient temperature was 30C and the number of current-carrying conductors did not

exceed three. If the ambient temperature is something other than 30C and/or there are

more than three current-carrying conductors in a raceway, cable or earth (directly

buried) and the load is continuous, it will be necessary to perform separate calculations.

Perform the first calculation to meet the requirements for termination temperature

limitations; with this calculation, continuous loads shall be included at 125 percent.

Perform the second calculation to meet the requirements for ambient temperature in

310.15(B)(2); with this calculation, apply the Table 310.15(B)(3)(a) adjustment factors if

there are more than three current-carrying conductors in the raceway, cable or earth

(directly buried).

After performing both calculations, if the results are different size conductors, select the

largest conductor. The largest conductor shall be protected against overcurrent in

accordance with its ampacity specified in 310.15, unless otherwise permitted or required

in 240.4(A) through (G). For example, two three-phase, 4-wire panelboards will be

installed next to each other in an industrial facility. The loads in each panelboard will be

identical. There will be 68 amperes (A) of continuous loads and 51A of noncontinuous

loads in each panelboard. The major portion of the load in each panelboard will consist of

nonlinear loads. The feeders for these panelboards share a common raceway for

approximately 150 feet. There will also be an equipment grounding conductor in this

raceway. All terminations will be rated 75C. The maximum ambient temperature will be

35C. What size THHN copper ungrounded (hot) feeder conductors are required to supply

each panelboard?

Start by performing the calculation to meet the requirements in 110.14(C) for

termination temperature limitations. In accordance with 215.2(A)(1), feeder conductors

shall have an ampacity not less than required to supply the load. This same section also

states that the minimum feeder-circuit conductor size, before the application of any

adjustment or correction factors, shall have an allowable ampacity not less than the

noncontinuous load plus 125 percent of the continuous load. In this example, the

continuous load is 68A. After multiplying by 125 percent (or 1.25), the continuous load is

85A (68 1.25 = 85). Now add the noncontinuous loads to this number. These

ungrounded feeder conductors must have an ampacity of at least 136A (85 + 51 = 136).

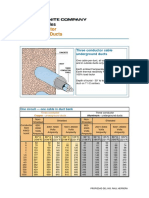

Although the THHN conductors are rated 90C, the allowable ampacity shall not exceed

the 75C column because of the terminations [see 110.14(C)(1)(b)]. The minimum size

conductors, from the 75C column, are 1/0 AWG copper conductors. Therefore, the

minimum size conductors selected to meet the requirements for termination temperature

limitations are 1/0 AWG copper conductors (see Figure 1).

Now perform a second calculation to meet the requirements for ambient temperature

correction factors and Table 310.15(B)(3)(a) adjustment factors. Ambient temperature

correction factors and Table 310.15(B)(3)(a) adjustment factors are also referred to as

the conditions of use. As previously mentioned, the minimum feeder-circuit conductor

size, before the application of any adjustment or correction factors, shall have an

allowable ampacity not less than the noncontinuous load plus 125 percent of the

continuous load [215.2(A)(1)].

This section seems to be saying to add the continuous load at 125 percent to the

noncontinuous load at 100 percent and then size the conductors in accordance with

adjustment and/or correction factors. But that is not what it is saying.

As defined in Article 100, ampacity is the maximum current, in amperes, that a

conductor can carry continuously under the conditions of use without exceeding its

temperature rating. As previously mentioned, the conditions of use are ambient

temperature and the number of current-carrying conductors in a raceway or cable. When

correcting the ampacity because of ambient temperature and/or adjusting the ampacity

because of more than three current-carrying conductors in a raceway or cable, use the

actual load: use 100 percent of the noncontinuous load and 100 percent of the

continuous load. In this example, the noncontinuous load is 51A, and the continuous load

is 68A. Therefore, after derating for ambient temperature and for more than three

current-carrying conductors in the raceway, the conductors shall have an allowable

ampacity of at least 119A (68 + 51 = 119), not 136A.

Because the major portion of the load in each panelboard will consist of nonlinear loads,

the neutral conductors shall be counted as current-carrying conductors [see

310.15(B)(5)(c)]. Since there are two three-phase, 4-wire feeders in one raceway and

the neutrals are counted, there are eight current-carrying conductors in this one

raceway. The adjustment factor from Table 310.15(B)(3)(a) for eight current-carrying

conductors is 70 percent (or 0.70). The maximum ambient temperature in this example

will be 35C. Conductors with temperature ratings higher than specified for terminations

shall be permitted to be used for ampacity adjustment, correction or both [110.14(C)].

The temperature rating for a THHN conductor is 90C. Although the terminations limit

the ampacity to the 75C column, it is permissible to use the ampacity in the 90C

column for correction and adjustment. Therefore, the Table 310.15(B)(2)(a) correction

factor, in the 90C column, for an ambient temperature of 35C is 0.96.

To find the minimum ampacity, divide the actual load by the adjustment and correction

factors. After dividing the load of 119A by the adjustment factor, the ampacity is 170A

(119 0.70 = 170). After dividing 170A by the correction factor of 0.96, the ampacity is

177A (170 0.96 = 177.08 = 177). Now select a copper conductor from the 90C

column of Table 310.15(B)(16) that has an ampacity of at least 177A. The minimum size

90C conductors selected to meet the requirements for ambient temperature correction

factors and Table 310.15(B)(3)(a) adjustment factors are 2/0 AWG copper conductors

(see Figure 2).

Because the results of the two calculations are different size conductors, compare them,

and select the largest. The minimum size selected to meet the requirements for

termination temperature limitations are 1/0 AWG copper conductors. The minimum size

selected to meet the requirements for ambient temperature correction factors and Table

310.15(B)(3)(a) adjustment factors are 2/0 AWG copper conductors. Therefore, the

minimum size ungrounded (hot) feeder conductors required to supply each panelboard

are 2/0 AWG copper conductors.

To verify that the conductor selected is the correct size, multiply the conductors

allowable ampacity by the adjustment and correction factors. After derating, the

conductors must have an allowable ampacity of at least 119A (68 + 51 = 119). Start by

finding the conductor and the listed ampacity in Table 310.15(B)(16). The allowable

ampacity for a 2/0 AWG THHN copper conductor, in the 90C column, is 195A. Multiply

195A by the Table 310.15(B)(3)(a) adjustment factor of 70 percent (195 0.70 =

136.5). Now multiply 136.5A by the Table 310.15(B)(2)(a) correction factor of 0.96

(136.5 0.96 = 131.04 = 131). After derating because of ambient temperature and the

number of current-carrying conductors, the maximum ampacity is 131A. Since the actual

load is 119A, 2/0 AWG THHN copper conductors are permitted (see Figure 3).

Next months column continues the discussion of sizing conductors.

MILLER, owner of Lighthouse Educational Services, teaches classes and seminars on the

electrical industry. He is the author of Illustrated Guide to the National Electrical Code

and The Electricians Exam Prep Manual. He can be reached at

615.333.3336, charles@charlesRmiller.com and www.charlesRmiller.com.

- See more at: http://www.ecmag.com/section/codes-standards/sizing-conductors-part-

XV#sthash.7Q7YM85K.dpuf

Image 1 of 3

Image 2 of 3

Image 3 of 3

Das könnte Ihnen auch gefallen

- Mounting: See Reverse Side For Important Safety and Warning StatementsDokument2 SeitenMounting: See Reverse Side For Important Safety and Warning StatementsjlcegarraNoch keine Bewertungen

- Type 1279 Duragauge Pressure Gauge Available With Performance OptionDokument2 SeitenType 1279 Duragauge Pressure Gauge Available With Performance OptionrohmadNoch keine Bewertungen

- CMC 256plus: High Precision Relay Test Set and Universal CalibratorDokument12 SeitenCMC 256plus: High Precision Relay Test Set and Universal CalibratorjlcegarraNoch keine Bewertungen

- Doble F6150sv - TechSpecsDokument3 SeitenDoble F6150sv - TechSpecsjlcegarraNoch keine Bewertungen

- Codigo GaugesDokument1 SeiteCodigo GaugesjlcegarraNoch keine Bewertungen

- CRFR-17: 15 KV Current TransformerDokument4 SeitenCRFR-17: 15 KV Current TransformerjlcegarraNoch keine Bewertungen

- Psg120e TDDokument1 SeitePsg120e TDjlcegarraNoch keine Bewertungen

- Hoja Regleta MagnumDokument1 SeiteHoja Regleta MagnumjlcegarraNoch keine Bewertungen

- Product:: Blue Hose®, 1 PR #20 STR TC, PE Ins Blu, CLR, Foil+TC BRD, PVC JKT, CMDokument2 SeitenProduct:: Blue Hose®, 1 PR #20 STR TC, PE Ins Blu, CLR, Foil+TC BRD, PVC JKT, CMjlcegarraNoch keine Bewertungen

- Ashcroft ThermometerDokument2 SeitenAshcroft ThermometerjlcegarraNoch keine Bewertungen

- Improve Service Continuity With Eaton's Pad-Mounted NOVA ReclosersDokument1 SeiteImprove Service Continuity With Eaton's Pad-Mounted NOVA ReclosersjlcegarraNoch keine Bewertungen

- Product:: Electronic, 2 C #16 STR SPC, TFE Ins, OA SPC BRD, TFE Tape JKT, MIL-W-16878/4 (Type E)Dokument2 SeitenProduct:: Electronic, 2 C #16 STR SPC, TFE Ins, OA SPC BRD, TFE Tape JKT, MIL-W-16878/4 (Type E)jlcegarraNoch keine Bewertungen

- 1.3 Wiring Specifications: 1.3.1 Cable SelectionDokument1 Seite1.3 Wiring Specifications: 1.3.1 Cable SelectionjlcegarraNoch keine Bewertungen

- 1vap420001-Tg Abb Utility It Ref Guide 2019Dokument137 Seiten1vap420001-Tg Abb Utility It Ref Guide 2019nikodemisNoch keine Bewertungen

- Ashcroft ThermometerDokument2 SeitenAshcroft ThermometerjlcegarraNoch keine Bewertungen

- Ashcroft ThermometerDokument2 SeitenAshcroft ThermometerjlcegarraNoch keine Bewertungen

- Selection of Neutral Grounding Reactor For Line To Ground FaultDokument4 SeitenSelection of Neutral Grounding Reactor For Line To Ground FaultjlcegarraNoch keine Bewertungen

- AMS Trex Device Communicator: Product Data Sheet Reliability SolutionsDokument9 SeitenAMS Trex Device Communicator: Product Data Sheet Reliability SolutionsjlcegarraNoch keine Bewertungen

- VEA Intercon ReqDokument41 SeitenVEA Intercon ReqjlcegarraNoch keine Bewertungen

- ESS Transformer RequirementsDokument2 SeitenESS Transformer RequirementsjlcegarraNoch keine Bewertungen

- 8 Twisted LinkDokument2 Seiten8 Twisted LinkjlcegarraNoch keine Bewertungen

- Product:: Electronic, 3 C #16 STR SPC, TFE Ins, OA SPC BRD, TFE Tape JKT, MIL-W-16878/4 (Type E)Dokument2 SeitenProduct:: Electronic, 3 C #16 STR SPC, TFE Ins, OA SPC BRD, TFE Tape JKT, MIL-W-16878/4 (Type E)jlcegarraNoch keine Bewertungen

- Nema-C84 1Dokument23 SeitenNema-C84 1Omar_35Noch keine Bewertungen

- Effective Grounding for PV Plants ExplainedDokument7 SeitenEffective Grounding for PV Plants ExplainedjlcegarraNoch keine Bewertungen

- New Methods For Detecting Unintentional IslandingDokument9 SeitenNew Methods For Detecting Unintentional IslandingjlcegarraNoch keine Bewertungen

- Great Lake Intercon ReqDokument39 SeitenGreat Lake Intercon ReqjlcegarraNoch keine Bewertungen

- Effective Grounding for PV Plants ExplainedDokument7 SeitenEffective Grounding for PV Plants ExplainedjlcegarraNoch keine Bewertungen

- Electrical Grounding Using Effective, Solid, and Low-Impedance Methods - Technical ArticlesDokument9 SeitenElectrical Grounding Using Effective, Solid, and Low-Impedance Methods - Technical ArticlesjlcegarraNoch keine Bewertungen

- Grounding Tx2Dokument54 SeitenGrounding Tx2jlcegarraNoch keine Bewertungen

- Characteristics Power Systems Neutral Grounding Techniques Fact Fiction Ap083005enDokument12 SeitenCharacteristics Power Systems Neutral Grounding Techniques Fact Fiction Ap083005enAhmedNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SCX1500 2 - Em2ce CR1 1Dokument421 SeitenSCX1500 2 - Em2ce CR1 1Tú Xuân Lương100% (1)

- ITAConfpaperDokument13 SeitenITAConfpaperjmezapNoch keine Bewertungen

- Three Conductor Underground Ducts: Ampacity TablesDokument2 SeitenThree Conductor Underground Ducts: Ampacity TablesalbertoNoch keine Bewertungen

- Animatronics Workshop ManualDokument44 SeitenAnimatronics Workshop ManualMithun P S100% (1)

- Bridge Manual: Chapter 48 - Electrical Grounding of StructuresDokument4 SeitenBridge Manual: Chapter 48 - Electrical Grounding of Structuresjoydeep_d3232Noch keine Bewertungen

- MSDB J Type Vertical 30 Way Data SheetDokument3 SeitenMSDB J Type Vertical 30 Way Data SheetMekaNo1DNoch keine Bewertungen

- Above Grade and Embedded Conduits ChecklistDokument1 SeiteAbove Grade and Embedded Conduits ChecklistsartajNoch keine Bewertungen

- DPWH Standard Specifications For Public Works Structures Vol III 1995Dokument2 SeitenDPWH Standard Specifications For Public Works Structures Vol III 1995JohnCarloTolibasNoch keine Bewertungen

- KEC - Instrumentation-Cables PDFDokument8 SeitenKEC - Instrumentation-Cables PDFbharatsehgal00Noch keine Bewertungen

- Super Slings Rigging Catalog 2020 - 1D Slings Wire Rope 1001 - WebDokument30 SeitenSuper Slings Rigging Catalog 2020 - 1D Slings Wire Rope 1001 - WebDouglasFariaNoch keine Bewertungen

- Data Sheet: Lappkabel Servo Cables LK - FNCDokument7 SeitenData Sheet: Lappkabel Servo Cables LK - FNCDiana Elena CojocariuNoch keine Bewertungen

- REYYDokument2 SeitenREYYMarioNoch keine Bewertungen

- Jun 01111Dokument1 SeiteJun 01111mishra nafalNoch keine Bewertungen

- Cable Handling Equipment Catalogue GuideDokument34 SeitenCable Handling Equipment Catalogue Guidejeb13Noch keine Bewertungen

- 228 Specificationofworks Annexure AFinalDokument19 Seiten228 Specificationofworks Annexure AFinalRoshanNoch keine Bewertungen

- Delhi Analysis of Rates 2014 Vol-1 PDFDokument696 SeitenDelhi Analysis of Rates 2014 Vol-1 PDFJaisree Balu Pydi95% (22)

- Sae J1067-2020Dokument9 SeitenSae J1067-2020يحي عامرNoch keine Bewertungen

- Silent Hill: The Arcade - Operator's ManualDokument51 SeitenSilent Hill: The Arcade - Operator's ManualRat BastardNoch keine Bewertungen

- Solar Labeling Requirements DatasheetDokument2 SeitenSolar Labeling Requirements Datasheetguillermoanaya100% (1)

- An Introduction To Wire RopeDokument13 SeitenAn Introduction To Wire Ropewindgust82Noch keine Bewertungen

- Katalog 2020 GBDokument87 SeitenKatalog 2020 GBPopp Laurentiu LiviuNoch keine Bewertungen

- Raw Material Summary SheetDokument19 SeitenRaw Material Summary SheetViswa BhuvanNoch keine Bewertungen

- 64721B510BF11337E10000000AD5062ADokument1 Seite64721B510BF11337E10000000AD5062AKailas NimbalkarNoch keine Bewertungen

- Power Cable ScheduleDokument40 SeitenPower Cable ScheduleAnupam0103Noch keine Bewertungen

- Product Information: Universal Gripper EGIDokument18 SeitenProduct Information: Universal Gripper EGImarcelo alonsoNoch keine Bewertungen

- Sampsistemi Extrusion en v012Dokument19 SeitenSampsistemi Extrusion en v012Ernesto Ivan Iniesta AlanisNoch keine Bewertungen

- Top Cable Companies in India 2022 - Wire & Cable IndiaDokument59 SeitenTop Cable Companies in India 2022 - Wire & Cable Indiaganesh kondikire100% (1)

- Important Safety Instructions: Installation Instructions For Freestanding Electric RangeDokument8 SeitenImportant Safety Instructions: Installation Instructions For Freestanding Electric RangeJohn DoeNoch keine Bewertungen

- Flame retardant halogen-free power cableDokument5 SeitenFlame retardant halogen-free power cableChand BashaNoch keine Bewertungen

- Searchline Excel Install GuideDokument2 SeitenSearchline Excel Install GuideJose JohnNoch keine Bewertungen