Beruflich Dokumente

Kultur Dokumente

Controling The Addition of Chlorine Into Process

Hochgeladen von

Leon Sanchez0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

33 Ansichten4 SeitenThere are several methods for controlling the addition of chlorine into a process. These methods include flow proportional injection, ORP or residual chlorine analyzer. Each method measures a different process characteristic.

Originalbeschreibung:

Originaltitel

Controling the Addition of Chlorine Into Process

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThere are several methods for controlling the addition of chlorine into a process. These methods include flow proportional injection, ORP or residual chlorine analyzer. Each method measures a different process characteristic.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

33 Ansichten4 SeitenControling The Addition of Chlorine Into Process

Hochgeladen von

Leon SanchezThere are several methods for controlling the addition of chlorine into a process. These methods include flow proportional injection, ORP or residual chlorine analyzer. Each method measures a different process characteristic.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

1

Controlling the addition of Chlorine into a Process

By Lori McPherson

Lori McPherson is a regional sales manager for Walchem Corporation. She is based in Florida and covers Texas

and the Southeastern United States. She may be reached at Walchem: tel 321-453-2525, fax 321-453-2925, e-mail

lmcpherson@walchem.com .

There are several methods for controlling the addition of chlorine into a process. These

methods include flow proportional injection, ORP (oxidation reduction potential) or a

residual chlorine analyzer. Each method measures a different process characteristic.

Depending on the specific type of process being controlled, there generally is a best choice

for controlling the injection of either chlorine gas or sodium hypochlorite (liquid bleach,

NaOCl).

In order to better understand why one method is preferred over another, it is best to define

exactly what the measurement is for each method, what the desired control situation is, the

limitations of each system and what routine maintenance is required.

Flow Proportional Injection

In flow proportional control, a volume of chlorine is injected relative to the flow rate (of

water) through the system. In most applications, there is a desired resultant concentration of

chlorine (i.e., five ppm), and the system is configured to enable the dosing of the chlorine

(generally bleach through a metering pump) to achieve this value. Table 1 lists the volumes

required per gallon to achieve a one-ppm level of chlorine. To achieve a concentration of five

ppm, simply multiply these values by five.

The flow proportional control system uses a flow sensor to determine the flow rate of the

carrier solution (generally water). Many types of flow sensors are designed to produce a

pulse output (per volume of flow) directly from the sensor. These include multi-jet meters,

paddlewheel, turbine, magnetic, vortex and others. The signal may be taken through an

intermediate flow controller (normally required when the pulse rate off the sensor is not

adjustable) or directly into a metering pump. The function of the intermediate meter is to

ratio a pulse output to that received from the flow sensor. Other functionality such as flow

rate monitoring and flow totalization also may be achieved.

Many metering pumps feature an on-board microprocessor-based controller and are capable

of multiplying or dividing the pulse signal directly. This eliminates the need for an

intermediate controller for flow sensors with non-adjustable pulse outputs and can simplify

the overall situation.

The pulse rate required for the application is determined by the amount of bleach required per

gallon (generally in ml) and output per stroke of the selected metering pump. Adjustment of

the stroke length on the pump can enable the pump output (per stroke) to be trimmed to

exactly the dose per stroke needed. For example, if five ml of sodium hypochlorite is

required for each gallon of water, a pump with an output of six ml per stroke can be set at an

80-percent stroke length and programmed to stroke once for each pulse received from a

flowmeter generating one pulse per gallon. As the flow rate increases, the pulse output from

the flowmeter increases proportionally, achieving a consistent dosing per volume of flow

through the system. When selecting a metering pump, using a smaller pump (in ml/stroke)

pulsing at a higher rate (i.e., ten strokes per gallon vs. one stroke per gallon) can reduce

2

"slugging" of the chemical into the flow stream. Metering pumps on the market today can

stroke at 300 to 360 strokes per minute, virtually eliminating slug feed of the hypochlorite.

Selection of the flowmeter/sensor (pulse generating device) can affect the overall reliability

and consistency of the chlorine injection. Hall-effect sensors are generally preferred over

mechanical reed switches. The mechanical reed switch should never be used at pulse rates

greater than 100 pulses per minute and offers shorter overall life than a hall-effect sensor.

The disadvantage of the hall-effect sensor is that it requires external power, generally in the

range of 6 to 24 VDC. Installation of the sensor should follow manufacturer's guidelines for

an upstream straight run to ensure linearity across the flow range.

The flow proportional system for controlling chlorine injection is best used for in-line (one-

pass) applications only such as municipal water treatment. In other systems where

chlorinated water is recirculated, it is not safe to assume that all chlorine added previously

was consumed and requires replacement. For these applications, either an ORP or residual

chlorine system should be used. The advantage of the flow proportional system is that it has

the lowest maintenance, and lowest cost of all three options. Once installed and configured

correctly, minimal attention is necessary.

Table 1: Chlorination Chart

Approximate chemical solution required for chlorination based on 5.25 percent sodium

hypochlorite (bleach) at 1ppm dosage

WATER FLOW BLEACH (Sodium Hypochlorite) Required

GPM GPH m3/h ml/min l/hr GPD

20

30

40

1200

1800

2400

4.542

6.813

9.084

1.51

2.27

3.02

0.09

0.136

0.181

0.57

0.86

1.15

50

60

70

3000

3600

4200

11.355

13.626

15.897

3.78

4.54

5.30

0.227

0.272

0.318

1.44

1.73

2.01

80

90

100

4800

5400

6000

18.168

20.439

22.71

6.06

6.81

7.57

0.364

0.409

0.454

2.30

2.60

2.88

200

300

400

12000

18000

24000

45.42

68.13

90.84

15.14

22.71

30.28

0.908

1.363

1.817

5.76

8.64

11.52

500

750

1000

30000

45000

60000

113.55

170.33

227.10

37.65

56.77

75.71

2.271

3.41

4.54

14.4

21.6

28.8

ORP (Oxidation Reduction Potential)

ORP measures the oxidizing (or reducing) potential or activity of a solution. Chlorine gas and

sodium hypochlorite (bleach) are strong oxidizers that are effectively monitored with an ORP

system. In many applications, the control system is intended specifically to control the

oxidation of a species such as cyanide or hydrogen sulflide (H

2

S). In other cases the

oxidation is the disinfection of bacteria, such as E. Coli. ORP is generally the best

measurement for processes of oxidation or disinfection, because it measures the true

oxidizing activity of the solution.

3

The primary limitation of an ORP system is that it does not provide a direct, repeatable

correlation to an exact concentration of chlorine. Two key factors affect this correlation: the

pH of the solution and the chloride (salt) concentration. Changes in pH cause a shift in the

form of the chlorine in water. With increasing pH, chlorine in water changes from

hypochlorous acid (HOCl) to hypochlorite ion (OCl-). The hypochlorous acid is much more

active as an oxidizer (80 to 300 times stronger) than the hypochlorite ion. The result is that as

pH increases, the overall oxidizing activity (ORP) of the solution decreases.

To understand the affect of chloride concentration requires evaluation of the Nernst equation.

This equation defines the output from the ORP electrode with any oxidizing system:

E = E

0

+ (RT/nF) log (a

ox

/a

red

)

This shows that the ORP measurement is made up of the ratio of two concentrations: the

concentration of the oxidizing agent and its reduced form. In the case of chlorine, the reduced

form is the unreactive chloride ion. Since the ORP is proportional to the ratio of these

concentrations (affecting the equilibrium state of the reaction), a greater concentration of

chlorides in the solution will also cause the ORP to decrease.

The advantage of using an ORP system is that it measures the true oxidation potential

(capability) that a solution has. If the chlorine (or hypochlorite) is being added for the

specific purpose to oxidize or disinfect, ORP is the best method for control because it

measures the variable that is most important - the solution's actual ability to perform the

oxidation. In disinfecting applications for the Pool and Spa Industry, the World Health

Organization in Europe has conclusively stated that ORP is preferred over measurements of

PPM Chlorine. A minimum ORP value of 650 to 700 mV can guarantee immediate

destruction of E. Coli bacteria. However, a given concentration of chlorine may have reduced

activity because of high pH or high chloride concentration, and therefore be ineffective at

destroying the E. Coli.

ORP is a good choice for recirculated systems. It maintains an oxidizing activity by replacing

the oxidizer that has been consumed. Water that is used for spraying foods is often

recirculated, and must maintain an oxidation capability to ensure against bacteria in the

system or on the food. Cooling towers and air scrubbers will also utilize oxidizers to prevent

bacteria in the system. The ORP measurement is able to monitor a drop in oxidation activity

(oxidizer that has been consumed), and control the addition of replacement chlorine

(hypochlorite).

ORP systems require regular maintenance. Generally, the system must be calibrated on a

monthly basis using standard solutions, and the electrode must be replaced every 1 to 2 years.

With proper maintenance, ORP can provide rapid, on-line measurement of a process, and

reliable oxidizing/disinfecting control.

4

Residual Chlorine

There are several technologies available for monitoring residual chlorine. These include

polarographic, amperometric, and colorimetric. In general, each system may be set up to

monitor/control either free residual chlorine (generally in the form of HOCl or OCl-), or

total chlorine, consisting of both the free residual chlorine and any "combined" chlorine

that may be present. Combined chlorine generally is in the form of chloramines that are

very weak oxidizers, and ineffective for oxidation.

The advantage of a Residual Chlorine system is that it can provide an exact readout of the

actual chlorine present in a solution. If actual chlorine concentration is the key variable

for the process and not its oxidizing capability, or if the presence of chlorine can be

damaging to a process, than a residual chlorine analyzer should be used. Unfortunately,

no one method is accepted as a standard. All systems are higher in cost than a flow or

ORP system and require significantly higher maintenance. Depending on the system

selected, maintenance may involve membrane replacement on the sensor (every 4 to 8

weeks), or membrane and electrolyte solution on the sensor (every 4 to 8 weeks), or

reagent replacement (every 7 days).

Determining the Best Method for Control

There are many options available for monitoring and controlling chlorine. It is essential

to review the application, determine the desired result, and understand the advantages and

limitations for each type of control available. A simplified summary is listed below.

Application Best Method Result

One-pass/In-line Flow Proportional Injection Consistent volumetric addition

Recirculated oxidation/disinfection ORP Consistent oxidation rate

PPM chlorine monitoring PPM Chlorine Actual Chlorine concentration

Example of

ORP Control

pH/ ORPCONTROLLER

CTRL1 AUX1 CTRL2 AUX2

NEXT PREV.

EXIT ENTER

ORP

SUBMERSION

ELECTRODE

pH

PROBE

METERING

PUMP

ORP

CONTROLLER

METERING

PUMP

Example of Flow

Proportional Control

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Ansi - Ahri Standard 575-2008Dokument18 SeitenAnsi - Ahri Standard 575-2008swapnadiphNoch keine Bewertungen

- Calculation of Section Modulus PDFDokument4 SeitenCalculation of Section Modulus PDFAnthony Gravagne40% (5)

- Infinera 7100 Series: Compact and Flexible Packet Optical Transport For The MetroDokument2 SeitenInfinera 7100 Series: Compact and Flexible Packet Optical Transport For The MetroTaha AlhatmiNoch keine Bewertungen

- Donk in Turbo CompressorsDokument16 SeitenDonk in Turbo CompressorsLeon SanchezNoch keine Bewertungen

- AIChE-Condenser Performance Monitoring - 020340Dokument4 SeitenAIChE-Condenser Performance Monitoring - 020340Leon SanchezNoch keine Bewertungen

- HSS English User Manual 06ADokument29 SeitenHSS English User Manual 06ALeon SanchezNoch keine Bewertungen

- ASTM A537 Standard SpecificationDokument4 SeitenASTM A537 Standard SpecificationLeon SanchezNoch keine Bewertungen

- Best Practices For The Control of Fuel GasDokument4 SeitenBest Practices For The Control of Fuel GasLeon SanchezNoch keine Bewertungen

- GE Roots Compressors BrochureDokument11 SeitenGE Roots Compressors BrochureLeon Sanchez100% (1)

- API 611 ScopeDokument1 SeiteAPI 611 ScopeLeon Sanchez67% (3)

- GE Roots Blowers Product Catalog - 11 12 - FDokument12 SeitenGE Roots Blowers Product Catalog - 11 12 - FLeon Sanchez0% (2)

- Ejector Process Vacuum SystemsDokument13 SeitenEjector Process Vacuum SystemsLeon SanchezNoch keine Bewertungen

- Compressor Magazine March 2014Dokument97 SeitenCompressor Magazine March 2014Leon SanchezNoch keine Bewertungen

- The Crane ComponentsDokument24 SeitenThe Crane ComponentsLeon SanchezNoch keine Bewertungen

- Chemical Engineering, March 2014Dokument92 SeitenChemical Engineering, March 2014Leon Sanchez100% (1)

- Power Magazine March 2014Dokument82 SeitenPower Magazine March 2014Leon SanchezNoch keine Bewertungen

- Fluid Handling ColfaxDokument12 SeitenFluid Handling ColfaxLeon SanchezNoch keine Bewertungen

- Ce 370 - Centrifugal Pump CharacteristicsDokument29 SeitenCe 370 - Centrifugal Pump CharacteristicsLeon SanchezNoch keine Bewertungen

- Flu or Delayed Coking ExperienceDokument5 SeitenFlu or Delayed Coking ExperienceLeon SanchezNoch keine Bewertungen

- CT2 Compressor Magazine May-2010Dokument85 SeitenCT2 Compressor Magazine May-2010Leon Sanchez100% (1)

- Exercises Conditional SentencesDokument2 SeitenExercises Conditional SentencesDivine GuancoNoch keine Bewertungen

- Project Robot ArmDokument62 SeitenProject Robot ArmTechs Solutions RobotsNoch keine Bewertungen

- Module 4. Heat TransferDokument28 SeitenModule 4. Heat TransferBry RamosNoch keine Bewertungen

- Chapter 9 Deflections of Beams: X Axis and The Tangent To The DeflectionDokument5 SeitenChapter 9 Deflections of Beams: X Axis and The Tangent To The DeflectionRimon GawandeNoch keine Bewertungen

- Change ManDokument17 SeitenChange Mansrikanth9gannuNoch keine Bewertungen

- Construction Cost EstimatesDokument25 SeitenConstruction Cost EstimatesAnonymous zwnFXURJNoch keine Bewertungen

- Introduction To Computer Networks: NetworkDokument61 SeitenIntroduction To Computer Networks: NetworkSaihari NarayanNoch keine Bewertungen

- Maintenance Component Main Function Level Activity Frequency Line DepartmentDokument7 SeitenMaintenance Component Main Function Level Activity Frequency Line DepartmentBarathNoch keine Bewertungen

- Class 10 Science Chapter 2 Revision NotesDokument16 SeitenClass 10 Science Chapter 2 Revision NotesKriish RatnaniNoch keine Bewertungen

- Relayoperationprinciples 141126065914 Conversion Gate01Dokument43 SeitenRelayoperationprinciples 141126065914 Conversion Gate01kenlavie2Noch keine Bewertungen

- Chemistry Note Form 5Dokument9 SeitenChemistry Note Form 5SofiyyahOpieNoch keine Bewertungen

- Calculate Quantities of Materials For Concrete - Cement, Sand, AggregatesDokument7 SeitenCalculate Quantities of Materials For Concrete - Cement, Sand, Aggregatesvenkateswara rao pothinaNoch keine Bewertungen

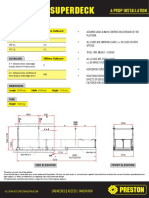

- SuperDeck All ModelsDokument12 SeitenSuperDeck All Modelsarthur chungNoch keine Bewertungen

- Mozart Symphony 6 TimpaniDokument2 SeitenMozart Symphony 6 Timpaniגיל עברוןNoch keine Bewertungen

- New ScriptDokument2 SeitenNew ScriptDeveloper 4Noch keine Bewertungen

- RS 385SHDokument3 SeitenRS 385SHshahpinkalNoch keine Bewertungen

- LSMW To Update Customer Master Records With Standard ObjectDokument9 SeitenLSMW To Update Customer Master Records With Standard ObjectShahid_ONNoch keine Bewertungen

- Assignment 1 - Spring2006: SolutionDokument31 SeitenAssignment 1 - Spring2006: SolutionMuhammad UmairNoch keine Bewertungen

- Unit 7: Brittel Coating MethodsDokument12 SeitenUnit 7: Brittel Coating Methodsmaya singhNoch keine Bewertungen

- Concept Note For The Conversion of 75 TPHDokument2 SeitenConcept Note For The Conversion of 75 TPHMeera MishraNoch keine Bewertungen

- AIR IOS ReadmeDokument2 SeitenAIR IOS ReadmeHeir TatamiNoch keine Bewertungen

- Bituminus Material PDFDokument196 SeitenBituminus Material PDFSubramanian BalakrishnanNoch keine Bewertungen

- 2007 Paper - Water Injection Effects On Compressor Stage OperationDokument30 Seiten2007 Paper - Water Injection Effects On Compressor Stage OperationBassam ElsayedNoch keine Bewertungen

- Buchholz Relay OperationDokument71 SeitenBuchholz Relay Operationlinus abrahamNoch keine Bewertungen

- Exm Notes PMPDokument29 SeitenExm Notes PMPjay2kay5793100% (1)

- Estimation of Microbial GrowthDokument25 SeitenEstimation of Microbial GrowthziaiitdNoch keine Bewertungen

- Astm C97/C97M-09Dokument3 SeitenAstm C97/C97M-09Azuriak150% (2)

- Shape and Volume: A Presentation On AcousticsDokument35 SeitenShape and Volume: A Presentation On AcousticsSiddharth BhandariNoch keine Bewertungen