Beruflich Dokumente

Kultur Dokumente

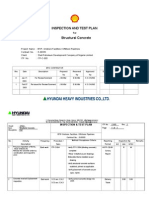

S-202A (Inspection and Testing Plan) Rev-0

Hochgeladen von

AliDadKhanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

S-202A (Inspection and Testing Plan) Rev-0

Hochgeladen von

AliDadKhanCopyright:

Verfügbare Formate

Asia Eng SGS Pak BP Pak

1

1.1 H R M Drawings Isssued for Construction

1.2 H R M Sketch

2

2.1 H R M WPS Refer to the approved PQR

2.2 H R M PQR

2.3 H R M WQTR

3

3.1 SW W M

3.2 SW W M

3.3 SW W M

3.4 W R M X

QA/QC# Form-

09/010

4

4.1 SW W M

4.2 SW W M

4.3 W R M X

QA/QC# Form-

09/010

5

5.1 H SW M

QA/QC# Form-

012

5.2 SW W M

QA/QC# Form-

01

5.3 SW W M

5.4 SW W M

5.5 SW W M

5.6 SW W M

5.7 SW SW M

QA/QC# Form-

05

5.8 W R M X

QA/QC# Form-

09/010

Acceptable Criteria ASME Sec V

QA/QC# form-

04

(DPT or MPI) of Arc gouges

Visual Inspection

Air Leak Test For Reinforcement Pad

(MT or PT) of Re-Built Area

Dismentling of the damage Nozzles do

do

do

do

do

do

Orientation Check

Inclination check

Straddle Check of Bolt Hole do

MT or PT of nozzles fit up & after final weld

Roof Nozzles and Manhole

do

do

Material Identification

do

Projection Check

As Built Drawing for NDE Weld map

Sr

No

Sketch Drawing for Repairing

Drawing

Inspected By

Description of Inspection

Applicable Code /

Standard / Spec

Refer to the repair scope & layout

Roof

ASIA ENGINEERS

Original Drawings IFC Drawing

Welder's Qualification Test Record

ASME Sec IX

Refer to the approved WPS

Refer to the approvel for WPS

Remarks

As Per SOW, API-653

do

Re-Build of marked pitted areas on Roof

Surface

Welding Procedure Specification

Welding Procedure Qualification Record

Dismentling of Existing Bottom Plates and Nozzles

Dismentling of the existing bottom As Per SOW, API-653

Cutting of shell at bottom edge do

PROJECT:

LOCATION:

Welding Qualification

NDT

Inspecto

QA/QC

Forms

Repair of S - 202A

AE Karachi Work Shop / Mazari Facility

CLIENT:

CONTRACTOR:

BP PAKISTAN

do Fit-UP Inspection

QA/QC# form-

08

bp

Repair of S - 202A at Mazari Facility

Inspection and Testing plan

QA/QC# form-

04

As Per SOW, API-653

Page 1 of 6

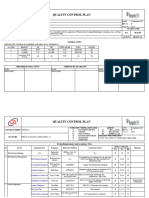

Asia Eng SGS Pak BP Pak

Sr

No

Inspected By

Description of Inspection

Applicable Code /

Standard / Spec

ASIA ENGINEERS

Remarks

PROJECT:

LOCATION:

NDT

Inspecto

QA/QC

Forms

Repair of S - 202A

AE Karachi Work Shop / Mazari Facility

CLIENT:

CONTRACTOR:

BP PAKISTAN

bp

Repair of S - 202A at Mazari Facility

Inspection and Testing plan

5.10 W R M X

QA/QC# Form-

011

6

6.1 SW W M

QA/QC# Form-

04

6.2 W R M X

QA/QC# Form-

09/010

7

7.1 H SW M

QA/QC# Form-

012

7.2 SW W M

QA/QC# Form-

06

7.3 SW SW M

QA/QC# Form-

01

7.4 SW W M

QA/QC# Form-

04

7.5 SW SW M

QA/QC# Form-

01

7.6 W R M X

QA/QC# Form-

09/010

7.7 SW SW M

QA/QC# Form-

07

8

8.1 H SW M

QA/QC# Form-

012

8.2 SW W M

QA/QC# Form-

01

8.3 SW W M

8.4 SW W M

8.5 SW W M

8.6 SW W M

8.7 SW SW M

QA/QC# Form-

05

Acceptable Criteria ASME Sec V

do

Fit-UP Inspection

Orientation Check

do

do

do

do

Roof Appurtenances

As Per SOW, API-650

Visual & Dimension Inspection

Radiography of nozzles

do

do

do

do

As Per SOW, API-653

Vacuum box testing for bottom lap welds

Joint Fit Up Shell to Bottom

MT or PT for Shell to Bottom

MT or PT (as Required SOW)

Projection Check

do

do

Inclination check

Straddle Check of Bolt Hole

Air Leak Test For Reinforcement Pad

Material Identification As Per SOW, API-653

Bottom

Shell Nozzles and Manhole

Dimension Inspection of Bottom Diagonal and

Sketch Plates

Arrangement of Lapping Condition Check

after Welding

Material Identification

do

Arrangement of Lapping Condition Check

before Welding

As Per SOW, API-653

do

QA/QC# form-

08

Acceptable Criteria ASME Sec V

Acceptable Criteria ASME Sec V

Acceptable Criteria ASME Sec V

Page 2 of 6

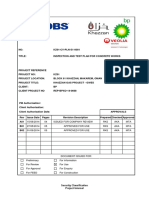

Asia Eng SGS Pak BP Pak

Sr

No

Inspected By

Description of Inspection

Applicable Code /

Standard / Spec

ASIA ENGINEERS

Remarks

PROJECT:

LOCATION:

NDT

Inspecto

QA/QC

Forms

Repair of S - 202A

AE Karachi Work Shop / Mazari Facility

CLIENT:

CONTRACTOR:

BP PAKISTAN

bp

Repair of S - 202A at Mazari Facility

Inspection and Testing plan

8.8 W R M X

QA/QC# Form-

09/010

8.9 W R M X

QA/QC# Form-

011

9

9.1 SW W M

QA/QC# Form-

04

9.2 W R M X

QA/QC# Form-

09/010

10

10.1 SW SW M

QA/QC# Form-

04

11

11.1 SW SW M

QA/QC# Form-

02

12

12.1 SW W M

12.2 SW W M

13 SW R M

QA/QC# Form-

013

14 SW SW M

QA/QC# Form-

04

15 H R M Dossier

Abbreviation:

1) R 6) M

2) H`

3) W

4) SW

5) X

Final Visual Inspection of Internal and

External Tank befor commencing the job of

hydrotest

do

do

As Per SOW, API-653

As Per SOW, API-653 &

BPP Specifications

Sand Blasting and Painting

Completed Tank

MT or PT (as Required SOW)

Monitoring

Painting Inspection

As Per SOW, API-653

Hydrotest

Hydrostatic Test for Tank

Surface Preparation Checking for Painting

Verify and Review Documents

Radio Graphy of nozzles (butt weld) As Per SOW, API-650

Hold Point

MT or PT of nozzles fit up & after final weld

Visual & Dimension Inspection

Final Inspection As Per SOW

Final QA/QC Document Package As Per SOW, API-653

Spot Witness

Inspector Required

Witness

As Per SOW, API-653

QA/QC# Form-

03

Acceptable Criteria ASME Sec V

Shell Appurtenances

do

Acceptable Criteria ASME Sec V

Non Conformance Report

As Per SOW, API-653,IFC

Drawing

If any NCR raised during work,it

must be closed before final

inspection

Page 3 of 6

Acceptable Criteria ASME Sec V

As Built Drawing for NDE Weld map

Refer to the repair scope & layout

Refer to the approved WPS

Refer to the approvel for WPS

Remarks

bp

Page 4 of 6

Remarks

bp

Acceptable Criteria ASME Sec V

Acceptable Criteria ASME Sec V

Acceptable Criteria ASME Sec V

Acceptable Criteria ASME Sec V

Page 5 of 6

Remarks

bp

Acceptable Criteria ASME Sec V

Acceptable Criteria ASME Sec V

If any NCR raised during work,it

must be closed before final

inspection

Page 6 of 6

Das könnte Ihnen auch gefallen

- P1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BDokument16 SeitenP1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BEILA545 QAQCNoch keine Bewertungen

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDokument2 SeitenDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNoch keine Bewertungen

- ITP C 005 (Structural Concrete)Dokument4 SeitenITP C 005 (Structural Concrete)segun ajibolaNoch keine Bewertungen

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDokument3 SeitenBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNoch keine Bewertungen

- Test Report FOR Compacted Density of Mix Aggregate Astm D-1559Dokument9 SeitenTest Report FOR Compacted Density of Mix Aggregate Astm D-1559Jovanni RodriguezNoch keine Bewertungen

- QCP & Report Rev 03Dokument30 SeitenQCP & Report Rev 03Heri FebriyantoNoch keine Bewertungen

- DBB BNCPP B M v29 0015 Revb IfaDokument6 SeitenDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990Noch keine Bewertungen

- Concrete Mix Design K175 KGDokument1 SeiteConcrete Mix Design K175 KGWiditra Fetty PurbaNoch keine Bewertungen

- A Civ Spe 000 30002 1Dokument30 SeitenA Civ Spe 000 30002 1ZaidiNoch keine Bewertungen

- Reinforcement Work Proc.Dokument5 SeitenReinforcement Work Proc.Akhilesh Kumar0% (1)

- 8474l-000-Jsd-2310-001-2-Protective CoatingDokument31 Seiten8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Project Internal Audit Procedure: SheetalkumarDokument4 SeitenProject Internal Audit Procedure: SheetalkumarTwin BullsNoch keine Bewertungen

- Gcs2 002 Gen Az7 SP 01 0 Specification For PaintingDokument31 SeitenGcs2 002 Gen Az7 SP 01 0 Specification For Paintingsondk2100% (2)

- Cico Bond Epo PDFDokument2 SeitenCico Bond Epo PDFPraveenk000Noch keine Bewertungen

- 024 Itp For Grouting Works PDFDokument8 Seiten024 Itp For Grouting Works PDFHarshvardhan PathakNoch keine Bewertungen

- Approved Itp-Dss - 28 Sep 2016Dokument4 SeitenApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNoch keine Bewertungen

- KDK Exhaust FanDokument6 SeitenKDK Exhaust FanATMANEGARA TV100% (1)

- GS-09 (Painting) PDFDokument22 SeitenGS-09 (Painting) PDFSarbendu PaulNoch keine Bewertungen

- b.6.19 - Std. Specification-Site GradingDokument5 Seitenb.6.19 - Std. Specification-Site GradingdlloitNoch keine Bewertungen

- SECTION 09960 High-Performance Coatings Rev 0Dokument48 SeitenSECTION 09960 High-Performance Coatings Rev 0rachedNoch keine Bewertungen

- Certificate of Compliance: Att: Dorat Al TameerDokument1 SeiteCertificate of Compliance: Att: Dorat Al TameerMohammad ArslanNoch keine Bewertungen

- P68 M13 Painting Documents PDFDokument708 SeitenP68 M13 Painting Documents PDFJohn TerryNoch keine Bewertungen

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDokument31 Seiten8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Lavatex 2000...Dokument2 SeitenLavatex 2000...ArifNoch keine Bewertungen

- 4) Method Statement For Steel WorkDokument5 Seiten4) Method Statement For Steel WorkMukesh PrajapatNoch keine Bewertungen

- Concrete and Asphalt Aggregate TestsDokument4 SeitenConcrete and Asphalt Aggregate Testssaber2s22ahmadNoch keine Bewertungen

- StyreneDokument2 SeitenStyreneBiju_PottayilNoch keine Bewertungen

- Itp Bored Pile Rev 1Dokument10 SeitenItp Bored Pile Rev 1Pandar HasibuhanNoch keine Bewertungen

- MS For Fabrication of Above-Ground Storage TankDokument8 SeitenMS For Fabrication of Above-Ground Storage Tankdadz mingiNoch keine Bewertungen

- MSDS Bostik 2402 PDFDokument6 SeitenMSDS Bostik 2402 PDFJunior Gabriel Cusi HuillcaNoch keine Bewertungen

- Cover Electrical & Tellemunication - RevisiDokument12 SeitenCover Electrical & Tellemunication - RevisiGhazi LuthfiNoch keine Bewertungen

- Project Title - ID: Activity NameDokument5 SeitenProject Title - ID: Activity NameRiaz MohammedNoch keine Bewertungen

- Tuffkote Protective CoatingsDokument2 SeitenTuffkote Protective CoatingsioginevraNoch keine Bewertungen

- SOW Fabrikasi C-335-01 - 19.116.1Dokument1 SeiteSOW Fabrikasi C-335-01 - 19.116.1AlfanNoch keine Bewertungen

- TR Civil Build (Rev.0 2018)Dokument24 SeitenTR Civil Build (Rev.0 2018)selva.uae8207Noch keine Bewertungen

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Dokument10 SeitenMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNoch keine Bewertungen

- Method Statement of Lateral Load Test (BHEL ANPARA)Dokument11 SeitenMethod Statement of Lateral Load Test (BHEL ANPARA)sugurpraveenNoch keine Bewertungen

- Concrete Cube Test Report FormatDokument1 SeiteConcrete Cube Test Report FormatNaiyer AzamNoch keine Bewertungen

- S21-CnS Roads and DrainsDokument39 SeitenS21-CnS Roads and DrainsLukeNoch keine Bewertungen

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDokument4 SeitenDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNoch keine Bewertungen

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTADokument5 Seiten04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793Noch keine Bewertungen

- Table of Counter FormationsDokument3 SeitenTable of Counter FormationsHan Siang KuNoch keine Bewertungen

- Inspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksDokument3 SeitenInspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksjitendraNoch keine Bewertungen

- Epoxy 2pk Primer PDFDokument2 SeitenEpoxy 2pk Primer PDFarhan4888Noch keine Bewertungen

- MS HoneycombDokument3 SeitenMS Honeycombmoytabura96Noch keine Bewertungen

- Form Lampiran Penetrant TestDokument1 SeiteForm Lampiran Penetrant Testary rizki100% (1)

- Cold Tap Coating Report 2Dokument1 SeiteCold Tap Coating Report 2Jamal BakhtNoch keine Bewertungen

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Dokument13 SeitenJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNoch keine Bewertungen

- Determination of Coating Thickness by Magnetic Method in Accordance With BS EN ISO 2178: 1995Dokument6 SeitenDetermination of Coating Thickness by Magnetic Method in Accordance With BS EN ISO 2178: 1995miteshsuneriyaNoch keine Bewertungen

- REPORT - Trial Mix Material Grout (Pumpable)Dokument7 SeitenREPORT - Trial Mix Material Grout (Pumpable)Triadi Bagus GumilarNoch keine Bewertungen

- TK0l - FB-MR-000005Dokument4 SeitenTK0l - FB-MR-000005TomasPavlovicNoch keine Bewertungen

- Palatal A408-972 (E) For PultrusionDokument1 SeitePalatal A408-972 (E) For Pultrusionbourne029Noch keine Bewertungen

- Upvc Pipe For Strom Water Above Ground Elevated HighwayDokument75 SeitenUpvc Pipe For Strom Water Above Ground Elevated HighwayutkarshsabberwalNoch keine Bewertungen

- Pds Hempinol 10220 InglesDokument2 SeitenPds Hempinol 10220 IngleseternalkhutNoch keine Bewertungen

- CPVC ChecklistDokument1 SeiteCPVC Checklistchakravarthi kanugulaNoch keine Bewertungen

- Material Approval Request: North-South Commuter Railway Extension ProjectDokument2 SeitenMaterial Approval Request: North-South Commuter Railway Extension ProjectResearcherNoch keine Bewertungen

- ITP Static EquipmentDokument12 SeitenITP Static Equipmentaamirapi100% (3)

- Itp Non AsmeDokument7 SeitenItp Non AsmeAkhilesh Kumar100% (1)

- Msog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresDokument5 SeitenMsog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresMohd SaffririzalNoch keine Bewertungen

- Itp For Tank Fabrication & Installation Work1 - Rev02Dokument22 SeitenItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

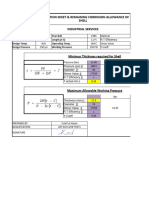

- CALCULATION SHEET For BoilerDokument6 SeitenCALCULATION SHEET For BoilerAliDadKhanNoch keine Bewertungen

- CalculationDokument6 SeitenCalculationAliDadKhanNoch keine Bewertungen

- Api 579-2 - 4.2Dokument8 SeitenApi 579-2 - 4.2AliDadKhanNoch keine Bewertungen

- Answers: Section - 2Dokument14 SeitenAnswers: Section - 2AliDadKhan100% (1)

- API 650 Course MaterialDokument36 SeitenAPI 650 Course MaterialAliDadKhanNoch keine Bewertungen

- Api 936 Refractory Question BankDokument74 SeitenApi 936 Refractory Question BankAliDadKhan100% (1)

- Section 2 API-653 Practice QuestionsDokument56 SeitenSection 2 API-653 Practice QuestionsAliDadKhan100% (4)

- VTR (Vacume Test) Qaqc07Dokument5 SeitenVTR (Vacume Test) Qaqc07AliDadKhanNoch keine Bewertungen

- API 653 Part 2Dokument93 SeitenAPI 653 Part 2AliDadKhanNoch keine Bewertungen

- India Course CATALOG 2014revDokument16 SeitenIndia Course CATALOG 2014revchristadcrNoch keine Bewertungen

- STIR (Surface Treatment Inspection) Qaqc-003Dokument1 SeiteSTIR (Surface Treatment Inspection) Qaqc-003AliDadKhanNoch keine Bewertungen

- Pipeline Construction InspecDokument48 SeitenPipeline Construction InspecAliDadKhan100% (2)

- VI (Visual Insdpection) Qaqc-04Dokument3 SeitenVI (Visual Insdpection) Qaqc-04AliDadKhanNoch keine Bewertungen

- Asia Engineers: Radiographic Inspection Report FORM No. QA/QC - 011 Rev-0Dokument1 SeiteAsia Engineers: Radiographic Inspection Report FORM No. QA/QC - 011 Rev-0AliDadKhanNoch keine Bewertungen

- Magnetic Particales Inspection: Asia EngineersDokument1 SeiteMagnetic Particales Inspection: Asia EngineersAliDadKhanNoch keine Bewertungen

- RPAS (Diemension of Bottom Plate) Qaqa-06Dokument1 SeiteRPAS (Diemension of Bottom Plate) Qaqa-06AliDadKhanNoch keine Bewertungen

- Materiale Inspection Report QAQc Form - 01 (Joint Fit Up)Dokument2 SeitenMateriale Inspection Report QAQc Form - 01 (Joint Fit Up)AliDadKhanNoch keine Bewertungen

- RPAS (Diemension of Bottom Plate) Qaqa-06-RevDokument1 SeiteRPAS (Diemension of Bottom Plate) Qaqa-06-RevAliDadKhanNoch keine Bewertungen

- ALT (Air Laeak Test) Qaqc-05Dokument1 SeiteALT (Air Laeak Test) Qaqc-05AliDadKhanNoch keine Bewertungen

- Piping Engineering CourseDokument2 SeitenPiping Engineering CourseprasannaNoch keine Bewertungen

- LesDokument4 SeitenLesAli ShanNoch keine Bewertungen

- Value Chain AnalysisDokument11 SeitenValue Chain AnalysisHardik ShahNoch keine Bewertungen

- Higueras Castillo2020Dokument16 SeitenHigueras Castillo2020Duryodhan vithal PendamNoch keine Bewertungen

- A Project Report On Analysis of Financial Statement at Kirloskar Project Report Mba FinanceDokument86 SeitenA Project Report On Analysis of Financial Statement at Kirloskar Project Report Mba FinanceAmar Singh KushwahNoch keine Bewertungen

- Tracking Antenna Spec SheetDokument2 SeitenTracking Antenna Spec SheetLouis NjorogeNoch keine Bewertungen

- Eaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsDokument24 SeitenEaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsGeorge BuitragoNoch keine Bewertungen

- InterfazPlatino-Version 1 41Dokument91 SeitenInterfazPlatino-Version 1 41sadoly7224Noch keine Bewertungen

- SGRAO Aircraft Operator Requirements V3.1Dokument287 SeitenSGRAO Aircraft Operator Requirements V3.1smr767Noch keine Bewertungen

- Avengers 004 - Stan Lee, Jack KirbyDokument36 SeitenAvengers 004 - Stan Lee, Jack Kirbybmwscribd100% (1)

- 06 Cancel Form Java 169125Dokument7 Seiten06 Cancel Form Java 169125george dascaluNoch keine Bewertungen

- Airblue: Flying On Wings of Web: Ust Institute of Management SciencesDokument12 SeitenAirblue: Flying On Wings of Web: Ust Institute of Management Sciencesnika420Noch keine Bewertungen

- Dr. Tadisina Kishen Kumar ReddyDokument2 SeitenDr. Tadisina Kishen Kumar ReddyReeta DuttaNoch keine Bewertungen

- Resume SEO Marketing Analyst Web Development Professional Michael CampolattanoDokument3 SeitenResume SEO Marketing Analyst Web Development Professional Michael CampolattanoMichael CampolattanoNoch keine Bewertungen

- SAP Enhancement Package 4 For SAP ERP 6.0 - Technical FAQDokument23 SeitenSAP Enhancement Package 4 For SAP ERP 6.0 - Technical FAQAngel LamasNoch keine Bewertungen

- Enterprise Data PlanningDokument24 SeitenEnterprise Data PlanningsjmpakNoch keine Bewertungen

- Tvs Project ReportDokument38 SeitenTvs Project ReportAnkit Dubey100% (1)

- PVC Pipes & Fittings ManufacturerDokument5 SeitenPVC Pipes & Fittings ManufacturershandgroupNoch keine Bewertungen

- Ict SystemsDokument12 SeitenIct SystemsHaa'Meem Mohiyuddin100% (1)

- (检验室)计算机化系统验证核心文件(中英文对照)Dokument18 Seiten(检验室)计算机化系统验证核心文件(中英文对照)JasonNoch keine Bewertungen

- World Audio Level Reference PDFDokument1 SeiteWorld Audio Level Reference PDFHector Herrera ChavezNoch keine Bewertungen

- 5620 SAM Part Number ListingDokument109 Seiten5620 SAM Part Number ListingSa VahidiNoch keine Bewertungen

- Rosenberg CatalogueDokument24 SeitenRosenberg CatalogueFu AunNoch keine Bewertungen

- Question Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Dokument2 SeitenQuestion Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Madhankumar .JNoch keine Bewertungen

- System Analysis and DesignDokument24 SeitenSystem Analysis and DesignKundan KumarNoch keine Bewertungen

- Review On Edg PDFDokument8 SeitenReview On Edg PDFBibekanand PadhiNoch keine Bewertungen

- Intro To Lean ManufacturingDokument46 SeitenIntro To Lean ManufacturingSharonz Muthuveeran100% (3)

- Charles BovillDokument2 SeitenCharles BovillGallg BaronNoch keine Bewertungen

- Report For Action: Date: April 16, 2019 To: City Council From: City Manager Wards: AllDokument20 SeitenReport For Action: Date: April 16, 2019 To: City Council From: City Manager Wards: AllToronto StarNoch keine Bewertungen

- Cardan Case Study1Dokument2 SeitenCardan Case Study1JJNoch keine Bewertungen