Beruflich Dokumente

Kultur Dokumente

Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following Forms

Hochgeladen von

Malkeet SinghOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following Forms

Hochgeladen von

Malkeet SinghCopyright:

Verfügbare Formate

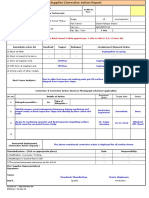

Date: 3/26/2003

REPORT SUMMARY

Page 1 of 5

Non-proprietary and non-confidential information.

Document Created 3/26/2003 Generated By ReliaSofts Xfmea Software http://www.ReliaSoft.com

In addition to this summary, this report includes the following forms:

1 RATING CRITERIA AND CLASSIFICATIONS

2 PROJECT PROPERTIES AND ANALYSIS PROPERTIES SUMMARY

3 FMEA SPREADSHEET REPORT

4 RECOMMENDED ACTIONS (Summary Report)

Xfmea Report Sample Machinery FMEA

This report was generated with ReliaSofts Xfmea software in Microsoft Word. Similar reports can also be

generated in Microsoft Excel. You can easily replace the Xfmea logo graphic with your own company logo.

Within Word and Excel, reports can be edited/annotated, if necessary, and generated in PDF and/or HTML

format for easy distribution.

This report includes:

A summary of the rating criteria (Severity Scale, Occurrence Scale, Detection Scale) and classifications that

were used in the analysis.

A summary of the project and analysis properties that were defined for the analysis.

The Machinery FMEA (MFMEA) spreadsheet report in the SAE J1739 reporting format.

A summary list of the recommended actions identified during the analysis.

The report is based on the sample analysis provided in the SAE J1739 guidelines, on page 45.

Date: 3/26/2003

RATING CRITERIA AND CLASSIFICATIONS

Page 2 of 5

Non-proprietary and non-confidential information.

Document Created 3/26/2003 Generated By ReliaSofts Xfmea Software http://www.ReliaSoft.com

RPN Calculation Method: Cause RPN = Severity x Occurrence x Detection Mode RPN = Sum of Cause RPNs Item RPN = Sum of Mode RPNS plus Sub Item RPNs

Severity Rating Scale Occurrence Rating Scale

# Description Criteria # Description Criteria

1 None

Process parameter variability within specification limits. Adjustment or

other process controls can be done during normal maintenance.

1 Failure occurs every 5 years

1 failure in 25,000 hours OR R(t) < 98%: MTBF is 50 times

greater than the user's required time.

2 Very Minor

Process parameter variability not within specification limits. Adjustment or

other process controls need to be taken during production. No downtime

and no production of defective parts

2 Failure occurs every 2 years

1 failure in 10,000 hours OR R(t) < 95%: MTBF is 20 times

greater than the user's required time.

3 Minor Downtime of up to 10 min but no production of defective parts. 3 Failure occurs every year

1 failure in 5,000 hours OR R(t) < 90%: MTBF is 10 times

greater than the user's required time.

4 Very Low Downtime of b/w 10 and 30 min but no production of defective parts. 4 Failure occurs every 6 months

1 failure in 2,500 hours OR R(t) < 85%: MTBF is 6 times greater

than the user's required time.

5 Low

Downtime of between 30 min and 1 hr or the production of defective parts

for up to 1 hr.

5 Failure occurs every 3 months

1 failure in 1,000 hours OR R(t) < 78%: MTBF is 4 times greater

than the user's required time.

6 Moderate

Downtime of between 1 and 4 hrs or the production of defective parts for

between 1 and 2 hrs.

6 Failure occurs every month

1 failure in 350 hours OR R(t) < 60%: MTBF is 2 times greater

than the user's required time.

7 High

Downtime of between 4 and 8 hrs or the production of defective parts for

between 2 and 4 hrs.

7 Failure occurs every week

1 failure in 80 hours OR R(t) < 37%: MTBF is equal to the user's

required time.

8 Very High

Downtime of more than 8 hrs or the production of defective parts for more

than 4 hrs.

8 Failure occurs every day

1 failure in 24 hours OR R(t) < 20%: MTBF is about 60% of the

user's required time.

9 Hazardous - With Warning

High severity ranking -- Affects operator, plan or maintenance personnel,

safety, and/or affects non-compliance with govt. regulations w/ warning.

9 Failure occurs every shift

1 failure in 8 hours OR R(t) < 5%: MTBF is about 30% of the

user's required time.

10 Hazardous - Without Warning

Very high severity ranking -- Affects operator, plan or maintenance

personnel, safety, and/or affects non-compliance with govt. regulations

w/o warning.

10 Failure occurs every hour

1 failure in 1 hour OR R(t) < 1%: MTBF is about 10% of the

user's required time.

Detection Rating Scale Classification Options

# Description Criteria Abbreviation Description

1 Very High

Design controls almost certainly detect a potential cause and subsequent

failure mode, machinery control not required.

C Critical

2 Very High KI Key Intermediate

3 High

Design controls may detect a potential cause & subsequent failure mode.

Machinery controls will prevent an imminent failure & isolate the cause.

KLd Key Leading

4 High KLg Key Lagging

5 Medium

Design controls may detect a potential cause and subsequent failure

mode. Machinery controls will provide an indicator of imminent failure.

S Significant

6 Medium

7 Low

Design or Machinery controls do not prevent the failure from occurring.

Machinery controls will isolate the cause and subsequent failure mode

after the failure has occurred.

8 Low

9 Very Low

10 Very Low

Design or Machinery controls cannot detect a potential cause and

subsequent failure, or there are no design or machinery controls.

Date: 3/26/2003

PROJECT PROPERTIES AND ANALYSIS PROPERTIES

Page 3 of 5

Non-proprietary and non-confidential information.

Document Created 3/26/2003 Generated By ReliaSofts Xfmea Software http://www.ReliaSoft.com

Project Properties

Project Name Based on Profile

Machinery FMEA J1739 MFMEA

Project Description

This sample project was prepared based on the Machinery FMEA (MFMEA) on page 45 of the SAE J1739 guidelines.

Remarks

Analysis Properties

ITEM 2 - Vacuum Pump

FMEA Number Prepared By Key Date FMEA Date (Orig.) FMEA Date (Rev.) Primary Approval Approval Date

MF112 John Doe 5/2/2003 2/2/2003 4/15/2003

Product Model Year(s)/Program(s) Mission

199X/AllStar

Design Responsibility Release Date Core Team Others Affected

Freebrakes (supplier) Mike Brake, John Doe, Jim Dominion (supplier)

Machinery/System 1 - Brake System Evac & Fill FMEA Number MF112

Subsystem

POTENTIAL

FAILURE MODE AND EFFECTS ANALYSIS

Vacuum Pump

Page 4 of 5

Component Design Responsibility Freebrakes (supplier) Prepared By John Doe

Model Year(s)/Program(s) 199X/AllStar Key Date 5/2/2003 FMEA Date (Orig.) 2/2/2003 (Rev) 4/15/2003

Core Team Mike Brake, John Doe, Jim Dominion (supplier)

Non-proprietary and non-confidential information.

Document Created 3/26/2003 Generated By ReliaSofts Xfmea Software http://www.ReliaSoft.com

Action Results

Subsystem

Function Req'ts

Potential Failure Mode

Potential Effect(s) of

Failure

S

e

v

C

l

a

s

s

Potential

Cause(s)/Mechanism(s) of

Failure

O

c

c

u

r

Current

Design/Machinery

Controls

D

e

t

e

c

R

P

N

Recommended Action(s)

Responsibility &

Target Completion Date

Actions Taken

S

e

v

O

c

c

D

e

t

R

P

N

2 - Vacuum Pump

Investigate longer life

cables, hoses and

jumpers. (Reduces

occurrence)

Jim Manufacturing, Mike

Cable, Supplier

- 3/28/2003

Selected cables and

hoses with longer life

than originally specified.

Investigate use of abrasion

resistant protective

covering for cables and

hoses. (Reduces

occurrence)

Joe Dressing Supplier

- 3/10/2003

Abrasion resistant

sleeves to be used at

points that are subject to

high wear and tear.

Split cabling for water

hoses/cables to minimize

length of replacement.

(Reduces

downtime/effects severity)

Joe Dressing Supplier

- 3/10/2003

Completed.

VACUUM PUMP: Provides

vacuum to evacuate brake

system. Achieve X

millimeters in Y seconds at

the furthest wheel from the

vacuum source.

Partial or complete loss of

air, water, and power supply

to the weld gun.

Moderate downtime in

replacing the dressing.

Downtime varies from 10-

30 minutes for replacement.

4 Flexing, rubbing of cables,

jumpers and hoses with

each other during welding.

6 Robot dressing

practices.

Recommended

jumper and cable

lengths. Preventive

maintenance. Water

Savers Machinery

Controls stop the

process.

- Prevention

5 120

Utilize infrared

thermography to predict

robot dressing failure.

(Improves detection)

Joe Dressing Assembly

Plant 123

- 3/12/2003

Infrared Thermography

incorporated into

predictive maintenance

plans.

3 4 4 48

Date: 3/26/2003

RECOMMENDED ACTIONS

(Summary Report)

Page 5 of 5

Non-proprietary and non-confidential information.

Document Created 3/26/2003 Generated By ReliaSofts Xfmea Software http://www.ReliaSoft.com

# Recommended Action(s)

Target

Completion Date

Responsibility Actions Taken Subsystem

Potential

Cause(s)/Mechanism(s) of

Failure

Priority

5 Investigate longer life cables, hoses and jumpers.

(Reduces occurrence)

3/28/2003 Jim Manufacturing, Mike

Cable, Supplier

Selected cables and hoses with longer life

than originally specified.

Vacuum Pump Flexing, rubbing of cables,

jumpers and hoses with each

other during welding.

6 Investigate use of abrasion resistant protective

covering for cables and hoses. (Reduces occurrence)

3/10/2003 Joe Dressing Supplier Abrasion resistant sleeves to be used at

points that are subject to high wear and

tear.

Vacuum Pump Flexing, rubbing of cables,

jumpers and hoses with each

other during welding.

7 Split cabling for water hoses/cables to minimize length

of replacement. (Reduces downtime/effects severity)

3/10/2003 Joe Dressing Supplier Completed. Vacuum Pump Flexing, rubbing of cables,

jumpers and hoses with each

other during welding.

8 Utilize infrared thermography to predict robot dressing

failure. (Improves detection)

3/12/2003 Joe Dressing Assembly Plant

123

Infrared Thermography incorporated into

predictive maintenance plans.

Vacuum Pump Flexing, rubbing of cables,

jumpers and hoses with each

other during welding.

Das könnte Ihnen auch gefallen

- Agile Essentials You Always Wanted To Know: Self Learning ManagementVon EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementNoch keine Bewertungen

- FMEA Applications Machinery FMEA: Continued On Next PageDokument10 SeitenFMEA Applications Machinery FMEA: Continued On Next Pagenelson.rodriguezm6142100% (1)

- Warm-Up - Day 2: Place Self Others Team Purpose AgendaDokument85 SeitenWarm-Up - Day 2: Place Self Others Team Purpose AgendaSanjeev SharmaNoch keine Bewertungen

- Potential Failure Mode and Effects Analysis (Risk FMEA)Dokument3 SeitenPotential Failure Mode and Effects Analysis (Risk FMEA)André Sento Sé Barreto100% (1)

- Magna Global Quality Standard: MQS 14 - Avoidance of Wrong DeliveriesDokument4 SeitenMagna Global Quality Standard: MQS 14 - Avoidance of Wrong DeliveriesGonzalo MazaNoch keine Bewertungen

- Odette ETI9Dokument23 SeitenOdette ETI9Helton MotaNoch keine Bewertungen

- 5S Cross ZoneDokument5 Seiten5S Cross ZoneAnilkumarNoch keine Bewertungen

- Yamazumi Chart 1.0Dokument1 SeiteYamazumi Chart 1.0Jesus Antonio Esquivel HernandezNoch keine Bewertungen

- 3025 44Dokument6 Seiten3025 44rambinodNoch keine Bewertungen

- Checksheet Error ProofingDokument4 SeitenChecksheet Error ProofingEzhilarasan DhoniNoch keine Bewertungen

- Design of Experiments (DOE) TutorialDokument4 SeitenDesign of Experiments (DOE) Tutorialmpedraza-1Noch keine Bewertungen

- PFMEA Ranking Table Rating Criteria Action GuidelineDokument10 SeitenPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoNoch keine Bewertungen

- Lean Six Sigma ToolkitDokument63 SeitenLean Six Sigma ToolkitLOLIMNoch keine Bewertungen

- GBE-KPO-2-027-00 Zero DefectDokument69 SeitenGBE-KPO-2-027-00 Zero DefectEduardo MaganaNoch keine Bewertungen

- Lean Thi Nki NG: Single Minute Exchange of Dies: Literature ReviewDokument11 SeitenLean Thi Nki NG: Single Minute Exchange of Dies: Literature ReviewBhanuj VermaNoch keine Bewertungen

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDokument7 SeitenSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNoch keine Bewertungen

- Layered Process Audit Checklist (LPA)Dokument5 SeitenLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONoch keine Bewertungen

- APQPStatus Reporting GuidelinesDokument19 SeitenAPQPStatus Reporting GuidelinesskluxNoch keine Bewertungen

- Calibration CertificateDokument3 SeitenCalibration CertificateMARIBETH AGUBANoch keine Bewertungen

- Annex A - Evaluation Checklist - 3a EditionDokument10 SeitenAnnex A - Evaluation Checklist - 3a EditionEliane CostaNoch keine Bewertungen

- Promblem Solving Combined March 2017 AnelleDokument25 SeitenPromblem Solving Combined March 2017 AnelleSravan DasariNoch keine Bewertungen

- MMOG - LE Foreword and Intro, V3 2009 PDFDokument26 SeitenMMOG - LE Foreword and Intro, V3 2009 PDFwrr190Noch keine Bewertungen

- Plantilla R&R Variables-ANOVA Julio2013Dokument4 SeitenPlantilla R&R Variables-ANOVA Julio2013Carlos Jose Sibaja CardozoNoch keine Bewertungen

- Smed Forms For Lean ProjectsDokument11 SeitenSmed Forms For Lean ProjectscivanusNoch keine Bewertungen

- 8d's y 5 Por Que de NissanDokument8 Seiten8d's y 5 Por Que de NissanSergio RuizNoch keine Bewertungen

- Lean Product Development - Redefining The Indian AutomotiveDokument13 SeitenLean Product Development - Redefining The Indian AutomotiveTaynan SilvaNoch keine Bewertungen

- Quality Training ModulesDokument1 SeiteQuality Training ModulesMani Rathinam RajamaniNoch keine Bewertungen

- 1.CORPORATE QUALITY MANAGEMENT SYSTEM (CQMS) Overvie PDFDokument85 Seiten1.CORPORATE QUALITY MANAGEMENT SYSTEM (CQMS) Overvie PDFJose Cepeda100% (1)

- A3 Single Point Lesson 8 X 11Dokument1 SeiteA3 Single Point Lesson 8 X 11sbtharanNoch keine Bewertungen

- Hatsumono DUCTODokument11 SeitenHatsumono DUCTOSerchecko JaureguiNoch keine Bewertungen

- F M E A (FMEA) P 4 - C C: Ailure Ode and Ffects Nalysis ART Haracteristic LassificationDokument12 SeitenF M E A (FMEA) P 4 - C C: Ailure Ode and Ffects Nalysis ART Haracteristic LassificationGonzalo MazaNoch keine Bewertungen

- 01 - Layered Process Audit Example B 2011Dokument7 Seiten01 - Layered Process Audit Example B 2011RN XaverNoch keine Bewertungen

- Variation and DefectsDokument16 SeitenVariation and DefectssushmaxNoch keine Bewertungen

- Home Inspection ChecklistDokument4 SeitenHome Inspection Checklistpradip barasiyaNoch keine Bewertungen

- HOTEL CONNISSEUR Python Project (With Code)Dokument42 SeitenHOTEL CONNISSEUR Python Project (With Code)Scary PeepsNoch keine Bewertungen

- IC Lean Project Management 5S Checklist For Offices TemplateDokument1 SeiteIC Lean Project Management 5S Checklist For Offices TemplateJosé Carlos Gamero LeónNoch keine Bewertungen

- Defect Matrix AutosavedDokument23 SeitenDefect Matrix AutosavedVikas KashyapNoch keine Bewertungen

- Aerospace Lean Manufacturing MetricsDokument2 SeitenAerospace Lean Manufacturing MetricsMani Rathinam RajamaniNoch keine Bewertungen

- GM 1927-87 Special Nonconforming Material AuditDokument6 SeitenGM 1927-87 Special Nonconforming Material AuditMichael HicksNoch keine Bewertungen

- ICAS Initial-Capacity-Assessment-Sheet 2010-12-09Dokument15 SeitenICAS Initial-Capacity-Assessment-Sheet 2010-12-09Fitzi ShadyNoch keine Bewertungen

- Advantech IPC-610-H - DS (022020) - NEW20200505185841 - DSDokument2 SeitenAdvantech IPC-610-H - DS (022020) - NEW20200505185841 - DSMuhammad Rizki SetiawanNoch keine Bewertungen

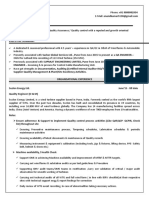

- Anand Kumar ResumeDokument3 SeitenAnand Kumar ResumeArun ShishodiaNoch keine Bewertungen

- MFMEA Workshop Class Overhead 04Dokument43 SeitenMFMEA Workshop Class Overhead 04Carlos Lourenço100% (2)

- Welcome - Day 1 2012: Failure Mode and Effects AnalysisDokument63 SeitenWelcome - Day 1 2012: Failure Mode and Effects AnalysisKaya Eralp AsanNoch keine Bewertungen

- VAL-SV - E-0170-P TD WSM 450 Wave Solder Machine Rev 1 Gabriel 2 Dec 2016 (1) - Edy4decDokument19 SeitenVAL-SV - E-0170-P TD WSM 450 Wave Solder Machine Rev 1 Gabriel 2 Dec 2016 (1) - Edy4decarumNoch keine Bewertungen

- Jishu Hozen Audit Sheet: Step 1: Initial Cleaning Department: Area: Circle Name: Circle LeaderDokument7 SeitenJishu Hozen Audit Sheet: Step 1: Initial Cleaning Department: Area: Circle Name: Circle LeaderharshavardhanNoch keine Bewertungen

- Design Review Based On Failure Mode 1-Day Workshop by TetrahedronDokument2 SeitenDesign Review Based On Failure Mode 1-Day Workshop by TetrahedrontetrahedronNoch keine Bewertungen

- Leaf 7 Alain Pri OulDokument10 SeitenLeaf 7 Alain Pri OulSunny DayNoch keine Bewertungen

- 5s Radar Chart 2012Dokument2 Seiten5s Radar Chart 2012akbars.thasimaNoch keine Bewertungen

- LP LA N: Control PlanDokument26 SeitenLP LA N: Control PlanSyed ShabbirNoch keine Bewertungen

- Dmaic Roadmap PDFDokument1 SeiteDmaic Roadmap PDFKristof MCNoch keine Bewertungen

- Statistical Process Control Chart PDFDokument2 SeitenStatistical Process Control Chart PDFparam540Noch keine Bewertungen

- 6S - 5S - Evaluation and Implementation Tool - LeanDokument8 Seiten6S - 5S - Evaluation and Implementation Tool - LeanShekhar RaviNoch keine Bewertungen

- SOD Machinery FMEADokument3 SeitenSOD Machinery FMEAUmashankar Gautam100% (1)

- Setup & Inprocess Inspection Report CaseDokument19 SeitenSetup & Inprocess Inspection Report CaseMURALIDHRANoch keine Bewertungen

- Familywise MatrixDokument22 SeitenFamilywise MatrixVikas KashyapNoch keine Bewertungen

- 5 GRR Calculation Presentation TemplateDokument5 Seiten5 GRR Calculation Presentation TemplatePradeep ShindeNoch keine Bewertungen

- E06a Triggers ENGDokument58 SeitenE06a Triggers ENGMirkoVivianiNoch keine Bewertungen

- Robot Safety Check SheetDokument1 SeiteRobot Safety Check SheetkurniaNoch keine Bewertungen

- MTPDokument10 SeitenMTPmurilocabriniNoch keine Bewertungen

- CPPDSM4008A Manual Part 2 v15.1 December 2014Dokument112 SeitenCPPDSM4008A Manual Part 2 v15.1 December 2014Malkeet SinghNoch keine Bewertungen

- CPPDSM4008A Manual Part 1 v16.1 December 2014Dokument154 SeitenCPPDSM4008A Manual Part 1 v16.1 December 2014Malkeet Singh0% (2)

- 1502 AssignmentDokument3 Seiten1502 AssignmentMalkeet SinghNoch keine Bewertungen

- Feasibility Study ReportDokument14 SeitenFeasibility Study ReportMalkeet Singh100% (1)

- 126Dokument9 Seiten126ieom2012Noch keine Bewertungen

- ALL Vegetabl ES (31nbvhjbj KBMN, M N, MDokument9 SeitenALL Vegetabl ES (31nbvhjbj KBMN, M N, MMalkeet SinghNoch keine Bewertungen

- Situation Analysis: Dim Sum and Co. Is A Company With Chinese Cuisine. Dim Sums Are Very PopularDokument3 SeitenSituation Analysis: Dim Sum and Co. Is A Company With Chinese Cuisine. Dim Sums Are Very PopularMalkeet SinghNoch keine Bewertungen

- Product QualityDokument17 SeitenProduct QualityMalkeet SinghNoch keine Bewertungen

- ALL Vegetabl ES (31nbvhjbj KBMN, M N, MDokument9 SeitenALL Vegetabl ES (31nbvhjbj KBMN, M N, MMalkeet SinghNoch keine Bewertungen

- Abdul Kasham Mohammed Acknowledgement Form 44e74 MoretonbayfoodDokument1 SeiteAbdul Kasham Mohammed Acknowledgement Form 44e74 MoretonbayfoodMalkeet SinghNoch keine Bewertungen

- Oriental Merchant Pty LTDDokument2 SeitenOriental Merchant Pty LTDMalkeet SinghNoch keine Bewertungen

- Complete Access: Closing Balance $510.00 CR Enquiries 13 2221 (24 Hours A Day, 7 Days A Week)Dokument2 SeitenComplete Access: Closing Balance $510.00 CR Enquiries 13 2221 (24 Hours A Day, 7 Days A Week)Malkeet SinghNoch keine Bewertungen

- Creep Damage Evaluation 9 - 12 CR SteelsDokument22 SeitenCreep Damage Evaluation 9 - 12 CR SteelsDilip Gajanan Namjoshi100% (1)

- Progress of Writing A Paper PDFDokument17 SeitenProgress of Writing A Paper PDFElefteria KoseoglouNoch keine Bewertungen

- AMR Assignment Pilgrim Bank: Indian Institute of Management RaipurDokument20 SeitenAMR Assignment Pilgrim Bank: Indian Institute of Management Raipursiddhants3108Noch keine Bewertungen

- Chomsky A Minimalist Program For Linguistic TheoryDokument61 SeitenChomsky A Minimalist Program For Linguistic TheoryAlex De Britto RodriguesNoch keine Bewertungen

- Data Exploration in RDokument6 SeitenData Exploration in RCeekhNoch keine Bewertungen

- The Effect of Soil and Cable Backfill Thermal ConductivityDokument6 SeitenThe Effect of Soil and Cable Backfill Thermal ConductivitymiguelpaltinoNoch keine Bewertungen

- Lab2 Leveling Manual-3703Dokument5 SeitenLab2 Leveling Manual-3703AbdallaNoch keine Bewertungen

- Steiger 1990Dokument9 SeitenSteiger 1990AlexNoch keine Bewertungen

- Practical Research 2 Q2 Module 3 1Dokument14 SeitenPractical Research 2 Q2 Module 3 1Rosita Antiquina ElopreNoch keine Bewertungen

- Fba Functional Behavior Assessment Template 1 - 3Dokument4 SeitenFba Functional Behavior Assessment Template 1 - 3api-338037250Noch keine Bewertungen

- 6502 - Assignment 2Dokument10 Seiten6502 - Assignment 2aamirshehzad1383010Noch keine Bewertungen

- Competency MappingDokument26 SeitenCompetency Mappingmridulakhanna83% (12)

- The Lived Experiences of Women With Different Somatotypes On Public Transportation: A Phenomenological StudyDokument101 SeitenThe Lived Experiences of Women With Different Somatotypes On Public Transportation: A Phenomenological StudyCaitlyn CombateNoch keine Bewertungen

- Social Tenure Domain Model - A Tool For PRO-POOR Land Management in TanzaniaDokument5 SeitenSocial Tenure Domain Model - A Tool For PRO-POOR Land Management in TanzaniaInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Eapp Imrad FormatDokument14 SeitenEapp Imrad FormatMarc Alquin CantoNoch keine Bewertungen

- Ootd Preferences Simple Contra Trendy and The Level of Self-Confidence of Grade 12 Students in MiinhsDokument43 SeitenOotd Preferences Simple Contra Trendy and The Level of Self-Confidence of Grade 12 Students in MiinhsChristian RamosNoch keine Bewertungen

- A Systematic Review of Human Resource Management Systems and Their MeasurementDokument40 SeitenA Systematic Review of Human Resource Management Systems and Their MeasurementAfifah FidaNoch keine Bewertungen

- Confidence Intervals For Proportions Take Home TestDokument5 SeitenConfidence Intervals For Proportions Take Home Test1012219Noch keine Bewertungen

- Action Verbs For Strategic PlanningDokument1 SeiteAction Verbs For Strategic PlanningRex RevelarNoch keine Bewertungen

- Class Programme: Approval of ManufacturersDokument19 SeitenClass Programme: Approval of ManufacturersShih-Bou WangNoch keine Bewertungen

- Mutliple Regression-McqsDokument10 SeitenMutliple Regression-McqsSaadatNoch keine Bewertungen

- An Analysis of Job Market Expectations of Students of Economics-A Case Study On Stamford University BangladeshDokument2 SeitenAn Analysis of Job Market Expectations of Students of Economics-A Case Study On Stamford University BangladeshAzharul IslamNoch keine Bewertungen

- III. Expiremental and Non-ExpirementalDokument38 SeitenIII. Expiremental and Non-ExpirementalSabrina Frances Dela VegaNoch keine Bewertungen

- Adoption of Renewable Energy Technologies in Rural Tigray, EthiopiaDokument6 SeitenAdoption of Renewable Energy Technologies in Rural Tigray, EthiopiaTafesse GezahegnNoch keine Bewertungen

- GMP 11 Calibration Intervals 20180131Dokument9 SeitenGMP 11 Calibration Intervals 20180131acanis1016Noch keine Bewertungen

- QualDokument39 SeitenQualaigerim kazhigaliyevaNoch keine Bewertungen

- 3rd PTDokument3 Seiten3rd PTKimberley TadeoNoch keine Bewertungen

- Amul ProjectDokument63 SeitenAmul ProjectsnehaldoddamaniNoch keine Bewertungen

- Contoh QuestionnaireDokument63 SeitenContoh QuestionnaireNadFauziNoch keine Bewertungen

- Assessment GlossaryDokument2 SeitenAssessment Glossaryapi-551389172Noch keine Bewertungen