Beruflich Dokumente

Kultur Dokumente

Apqp

Hochgeladen von

gtrevi_o0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

35 Ansichten2 SeitenAPQP is a framework of procedures and techniques used to develop products in industry. It is quite similar to the concept of Design for Six Sigma (DFSS) It is a defined process for a product development system for GM, fm, chrysler.

Originalbeschreibung:

Originaltitel

apqp.txt

Copyright

© © All Rights Reserved

Verfügbare Formate

TXT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAPQP is a framework of procedures and techniques used to develop products in industry. It is quite similar to the concept of Design for Six Sigma (DFSS) It is a defined process for a product development system for GM, fm, chrysler.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als TXT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

35 Ansichten2 SeitenApqp

Hochgeladen von

gtrevi_oAPQP is a framework of procedures and techniques used to develop products in industry. It is quite similar to the concept of Design for Six Sigma (DFSS) It is a defined process for a product development system for GM, fm, chrysler.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als TXT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Advanced product quality planning

From Wikipedia, the free encyclopedia

This article needs additional citations for verification. Please help improve th

is article by adding citations to reliable sources. Unsourced material may be ch

allenged and removed. (October 2012)

Advanced product quality planning (or APQP) is a framework of procedures and tec

hniques used to develop products in industry, particularly the automotive indust

ry. It is quite similar to the concept of Design for Six Sigma (DFSS).

It is a defined process for a product development system for General Motors, For

d, Chrysler and their suppliers. According to the Automotive Industry Action Gro

up (AIAG), the purpose of APQP is "to produce a product quality plan which will

support development of a product or service that will satisfy the customer." The

process is described in the AIAG manual, www.aiag.org or 248-358-3003.

Contents [hide]

1 History

2 Main content of APQP

3 See also

4 References

5 External links

History[edit]

Advanced product quality planning is a process developed in the late 1980s by a

commission of experts gathered from the 'Big Three' US automobile manufacturers:

Ford, GM and Chrysler. This commission invested five years to analyze the then-

current automotive development and production status in the US, Europe and espec

ially in Japan. At the time, the success of the Japanese automotive companies wa

s starting to be remarkable in the US market.

APQP is utilized today by these three companies and some affiliates. Tier 1 supp

liers are typically required to follow APQP procedures and techniques and are al

so typically required to be audited and registered to ISO/TS 16949. This methodo

logy is now being used in other manufacturing sectors as well.

The basis for the make-up of a process control plan is included in the APQP manu

al.[1] The APQP process is defined in the AIAG's APQP manual, which is part of a

series of interrelated documents that the AIAG controls and publishes. These ma

nuals include:

The failure mode and effects analysis (FMEA) manual

The statistical process control (SPC) manual

The measurement systems analysis (MSA) manual

The production part approval process (PPAP) manual

The Automotive Industry Action Group (AIAG) is a non-profit association of autom

otive companies founded in 1982.

Main content of APQP[edit]

APQP serves as a guide in the development process and also a standard way to sha

re results between suppliers and automotive companies. APQP specifies three phas

es: Development, Industrialization and Product Launch. Through these phases 23 m

ain topics will be monitored. These 23 topics will be all completed before the p

roduction is started. They cover such aspects as: design robustness, design test

ing and specification compliance, production process design, quality inspection

standards, process capability, production capacity, product packaging, product t

esting and operator training plan, among other items.

APQP focuses on:

Up-front quality planning

Determining if customers are satisfied by evaluating the output and supporting c

ontinual improvement

APQP consists of five phases:

Plan and Define Program

Product Design and Development Verification

Process Design and Development Verification

Product and Process Validation and Production Feedback

Launch, Assessment & Corrective Action

There are five major activities:

Planning

Product Design and Development

Process Design and Development

Product and Process Validation

Production

The APQP process has seven major elements:

Understanding the needs of the customer

Proactive feedback and corrective action

Designing within the process capabilities

Analyzing and mitigating failure modes

Verification and validation

Design reviews

Control special / critical characteristics.

Das könnte Ihnen auch gefallen

- Sheet Metal CATIA PDFDokument398 SeitenSheet Metal CATIA PDFdottorgt5845Noch keine Bewertungen

- WCE2013 pp664-669Dokument6 SeitenWCE2013 pp664-669gtrevi_oNoch keine Bewertungen

- PpapDokument4 SeitenPpapgtrevi_oNoch keine Bewertungen

- R&RDokument2 SeitenR&Rgtrevi_oNoch keine Bewertungen

- AliasDokument1 SeiteAliasgtrevi_oNoch keine Bewertungen

- Libros AdmonDokument1 SeiteLibros Admongtrevi_oNoch keine Bewertungen

- LearningStudioTools PDFDokument406 SeitenLearningStudioTools PDFgtrevi_oNoch keine Bewertungen

- Parametric Model With NX 6 PDFDokument36 SeitenParametric Model With NX 6 PDFmecanicametalNoch keine Bewertungen

- NX6 Chapter3Dokument42 SeitenNX6 Chapter3gtrevi_oNoch keine Bewertungen

- PhotoView 360 Tutorial 2011Dokument8 SeitenPhotoView 360 Tutorial 2011Rajesh VenkateshNoch keine Bewertungen

- Table of Contents NX 6 EvelDokument10 SeitenTable of Contents NX 6 Evelgtrevi_oNoch keine Bewertungen

- NX6Dokument20 SeitenNX6Sreehari ViswanathanNoch keine Bewertungen

- c02 NX 6Dokument54 Seitenc02 NX 6BJ Kiran KumarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Exam 2Dokument12 SeitenExam 2abdullah.saadpppppNoch keine Bewertungen

- Faculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVDokument7 SeitenFaculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVhasmikaNoch keine Bewertungen

- Robust Control Design of An Induction MotorDokument5 SeitenRobust Control Design of An Induction MotorranaateeqNoch keine Bewertungen

- Air Standard Cycle (Carnot, Otto, Diesel, Dual)Dokument62 SeitenAir Standard Cycle (Carnot, Otto, Diesel, Dual)Anurag JayasNoch keine Bewertungen

- Echo Cancellation in Audio Signal Using LMS AlgorithmDokument6 SeitenEcho Cancellation in Audio Signal Using LMS AlgorithmVa SuNoch keine Bewertungen

- CS605 Final Term Comprehensive Notes by Muhammad SaeedDokument30 SeitenCS605 Final Term Comprehensive Notes by Muhammad SaeedShahid Omer ToorNoch keine Bewertungen

- PID Controllers: Control Engineering by Dr. L. K. WongDokument34 SeitenPID Controllers: Control Engineering by Dr. L. K. WongArulrajNoch keine Bewertungen

- Asymptotic Stability Theorem For Autonomous Systems - Mukherjee ChenDokument3 SeitenAsymptotic Stability Theorem For Autonomous Systems - Mukherjee ChencheckgtalkNoch keine Bewertungen

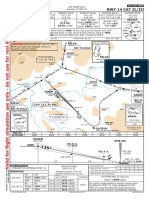

- LSZH App1 Ils14 PDFDokument1 SeiteLSZH App1 Ils14 PDFRadu Andrei MalicaNoch keine Bewertungen

- Engineering Thermodynamics E-Note 04112015 044130AMDokument189 SeitenEngineering Thermodynamics E-Note 04112015 044130AMDipesh Patel100% (3)

- Use Case Diagrams From An Event TableDokument6 SeitenUse Case Diagrams From An Event Tablehassan_m2222Noch keine Bewertungen

- Accenture Pega BPM BrochureDokument2 SeitenAccenture Pega BPM Brochuresam_roy124Noch keine Bewertungen

- Mathematica Package For Analytical and ControlDokument12 SeitenMathematica Package For Analytical and ControlHassan Ali KhanNoch keine Bewertungen

- 20 Log STD (Actual) STD (Errors)Dokument6 Seiten20 Log STD (Actual) STD (Errors)O Doutor FantasticNoch keine Bewertungen

- An Executive Level BPM GroupDokument19 SeitenAn Executive Level BPM GroupZoran ArsovskiNoch keine Bewertungen

- Requirment Elicitation Issues and Techniques For Requirement ElicitationDokument5 SeitenRequirment Elicitation Issues and Techniques For Requirement ElicitationFaizan KhanNoch keine Bewertungen

- SRS DocumentDokument11 SeitenSRS DocumentSHADOW DEVILNoch keine Bewertungen

- Basic Concepts of Thermodynamics (Animation) - YouTube - EnglishDokument4 SeitenBasic Concepts of Thermodynamics (Animation) - YouTube - EnglishtitojhezielanneNoch keine Bewertungen

- Testing ProcessDokument6 SeitenTesting ProcessKabilan Ponmudi100% (1)

- Step FOPDT LengkapDokument110 SeitenStep FOPDT LengkapRio Ananda PutraNoch keine Bewertungen

- Laws of ThermodynamicsDokument34 SeitenLaws of ThermodynamicshashimsaadfamilyNoch keine Bewertungen

- Lab Experiment 11Dokument10 SeitenLab Experiment 11Sohail Afridi100% (1)

- LAB 1-Effect of Controller GainDokument8 SeitenLAB 1-Effect of Controller GainNur FadilahNoch keine Bewertungen

- Moral Imagination and Systems Thinking: Patricia H. WerhaneDokument11 SeitenMoral Imagination and Systems Thinking: Patricia H. WerhaneRebeca CavalcantiNoch keine Bewertungen

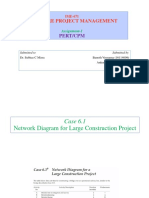

- Software Project Management: Pert/CpmDokument14 SeitenSoftware Project Management: Pert/CpmHemant SinghNoch keine Bewertungen

- Ec 6511 Digital Signal Processing Lab Manual PDFDokument88 SeitenEc 6511 Digital Signal Processing Lab Manual PDFBala913Noch keine Bewertungen

- Acc - AhuDokument3 SeitenAcc - AhuAamir ShaikhNoch keine Bewertungen

- Power Electronics and Control Techniques For Maximum Energy Harvesting in Photovoltaic Systems.Dokument1 SeitePower Electronics and Control Techniques For Maximum Energy Harvesting in Photovoltaic Systems.BLYNK STEELNoch keine Bewertungen

- Dbms Chapter 4Dokument80 SeitenDbms Chapter 4gbrhailuNoch keine Bewertungen

- Control System Teaching and Experiment Using LEGO Mindstorms NXT RobotDokument5 SeitenControl System Teaching and Experiment Using LEGO Mindstorms NXT Robotsivabharath44Noch keine Bewertungen